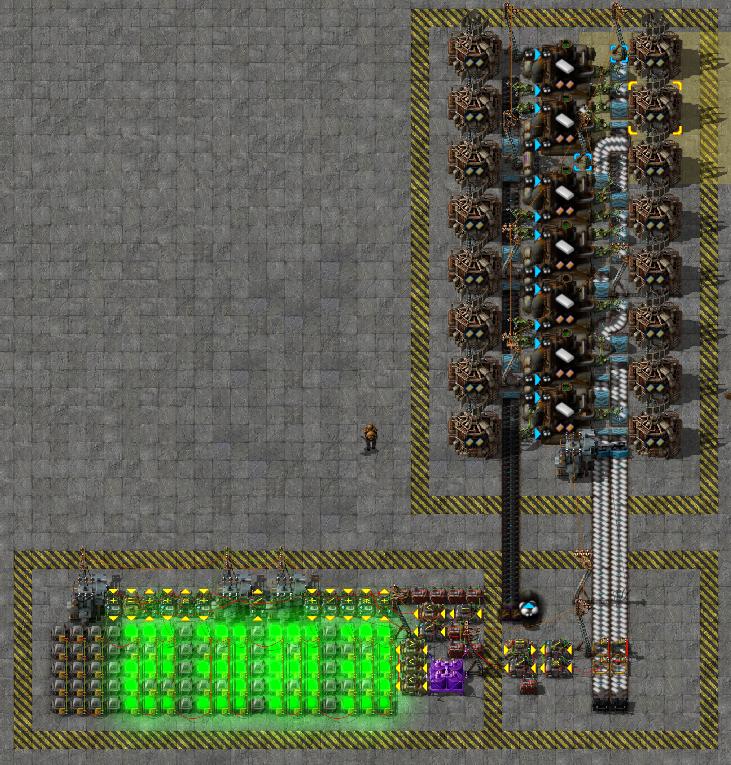

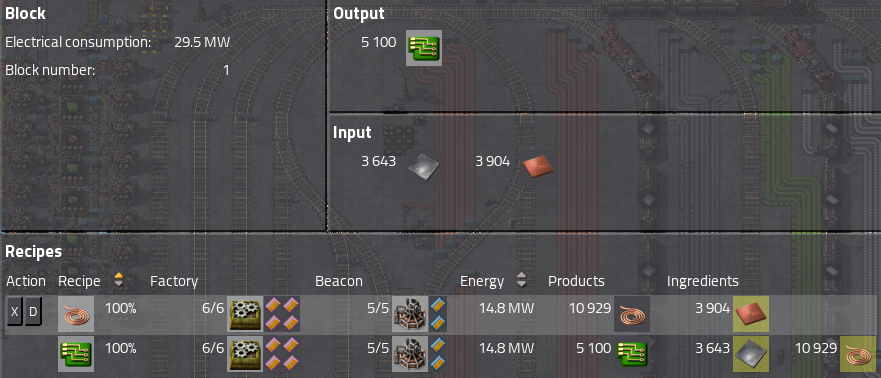

My general goal is to use productivity everywhere and boost with as many speed beacons as possible shared by as many assemblers as possible, which often means a linear layout without gaps between assemblers 'sandwiched' between rows of beacons, allowing the beacon rows to be shared between racks (such as in my design below).

This means a plastic plant gets 2 prod3 modules and 8 sp3 beacons, for a total speed of 5.874, producing 2*5.875*1.2=14.1 plastic/s. This also means that 3 plants can fill a blue belt, but adds a challenge for a good design, since it outputs too much for a single stack inserter to put on a belt, meaning you need to place two inserters per plant. Since you also have coal and PG input, that gives very little room to spare.

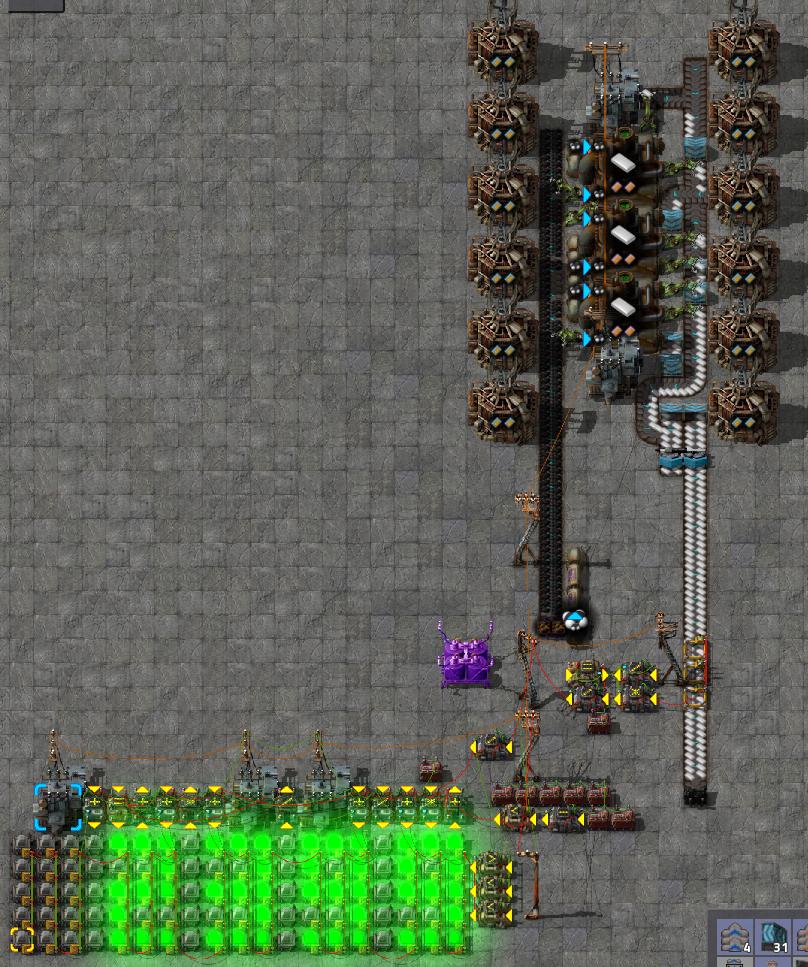

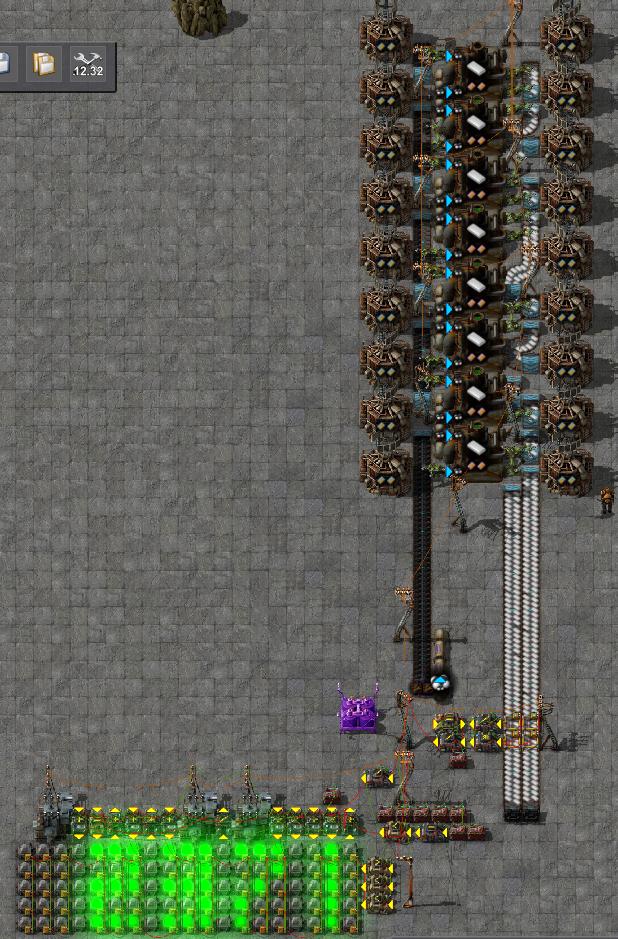

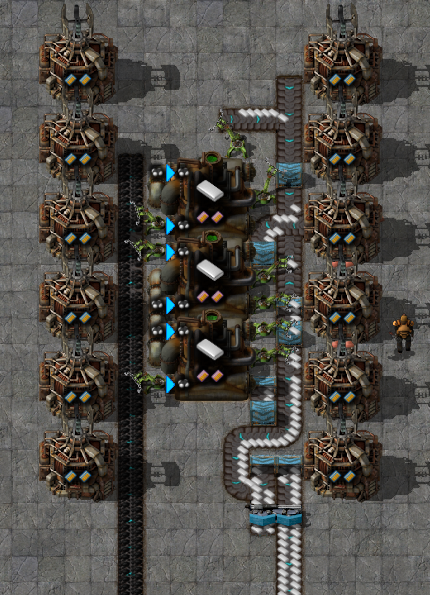

This is my current solution:

It outputs between 2.3 and 2.4k/min, so close to saturating the blue belt.

But I don't like how much space it takes above and below the plants. Especially the space above means that you cannot easily place a mirrored rack above this one, which would have been nice since there is plenty of coal and PG. Also, it doesn't quite produce 2.4k/min, which of course annoys my inner OCD. Finally, the design is more a result of tinkering than of deep thought, so I would think that something better is possible.

So, the challenge is to produce 2.4k/min on a single blue belt with the rack setup displayed above, minimizing room needed primarily "above" the rack and secondarily below the rack. 500 bonus points if it has space for an extra belt coming down (the plastic output of the 'mirorred' plant), but I don't think that's possible (?)

NM, found siggyboy's contraption for measuring average throughput (viewtopic.php?f=8&t=29679&start=0#p190249) and combined it with xelephant's counter (viewtopic.php?f=193&t=19825&start=40#p193337. If the counter is correct my production is fine at 2390+ plastic/min.