Probably. I've not tried it again yet.iamwyza wrote:@bobingabout

Did 0.15.12 fix the electric boilers?

bobrevamp has been removing that since 0.12.Recon777 wrote:Bob, did you remove the recipe for Sulfur from Petroleum Gas?

I was just setting up my battery factory and noticed my blueprint is invalid.

Already done in my latest WIP.British_Petroleum wrote:Bob can you add bottling for ammonia?

Ammonia and nitric oxide bottles, Hydrazine, dinitrogen tetroxide and hydrogen peroxide barrels. Also added Nitrogen Dioxide bottles to revamp too, even though bobplates already does that.

I also noticed that I've based all the new recipes around the number 10 in the new system, yet all the existing ones in bobplates are based around 20, so I've adjusted numbers all over the place. Pretty much all numbers in the new rocket fuel tree were doubled, so you'll need more electrolysers and nitrogen chemical plants, but the rest of the chain will be about the same.

The main reason why I did this is when you compare the old nitrogen dioxide production to the new stuff, say, for making nitric acid. In the old system you needed 1 nitrogen dioxide plant to feed 1 nitric acid plant. The new system would have no only required 2 nitrogen dioxide plants instead of 1, but also 2 ammonia plants, and 2 nitric oxide plants... do by doubling everything in this stage, it reduces the new factories required from 6 to 3.

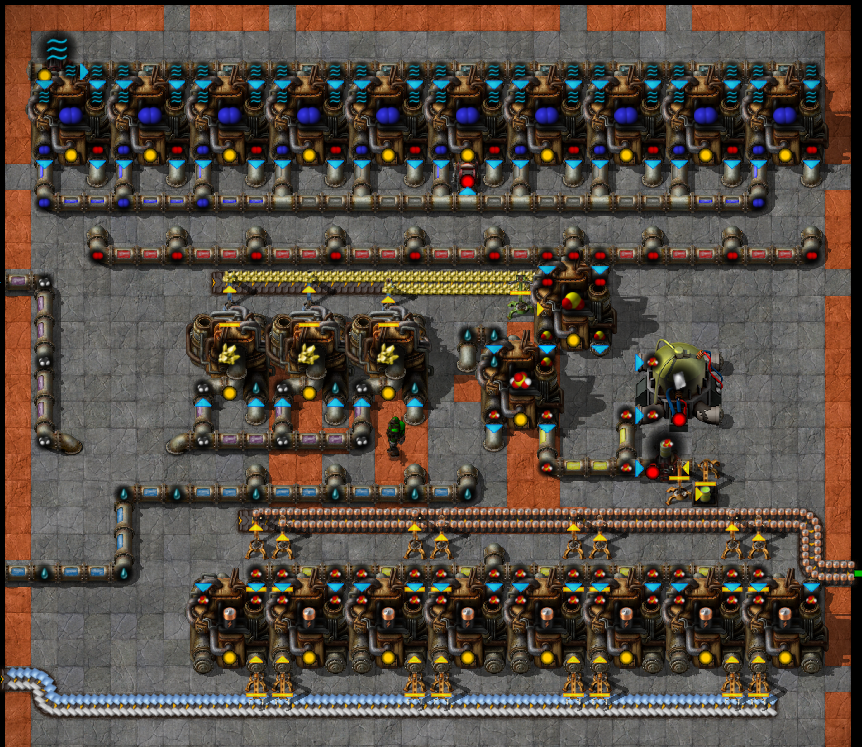

I also worked out these numbers.

3 rocket fuel plants requires: 2 hydrazine and 1 dinitrogen tetroxide plants, 3 ammonia plants, 1 hydrogen peroxide plant, 1 nitrogen dioxide, 1 nitric oxide plant. This part remains unchanged, but now you need 4.4 Electrolysers for Hydrogen, 4.4 Electrolysers for Oxygen and 1.5 chemical plants for Nitrogen (The oxygen from the nitrogen plants is excess), previous numbers were exactly half of this. these numbers were calculated for MK4 all around because the MK3 electrolyser and MK4 chemical plant both have a crafting speed of 3.5. you will need more electrolysers for lower tiers because an electrolysers MK1 has a speed of 0.8, where a chemical plant has a speed of 1.25 (or 1.5? I forget) so you would need 7 electrolysers at this stage.

Logic for turning things on and off... I have 3 pumps (acting as on off valves) 1 to feed air into the nitrogen plant on a nitrogen <= oxygen switch. 1 to feed pure water into the electrolysers on a hydrogen <= oxygen switch, and 1 to vent oxygen on a oxygen > 80% of a tank switch. You may need a few cycles to let gas enter the system before this becomes reliable.

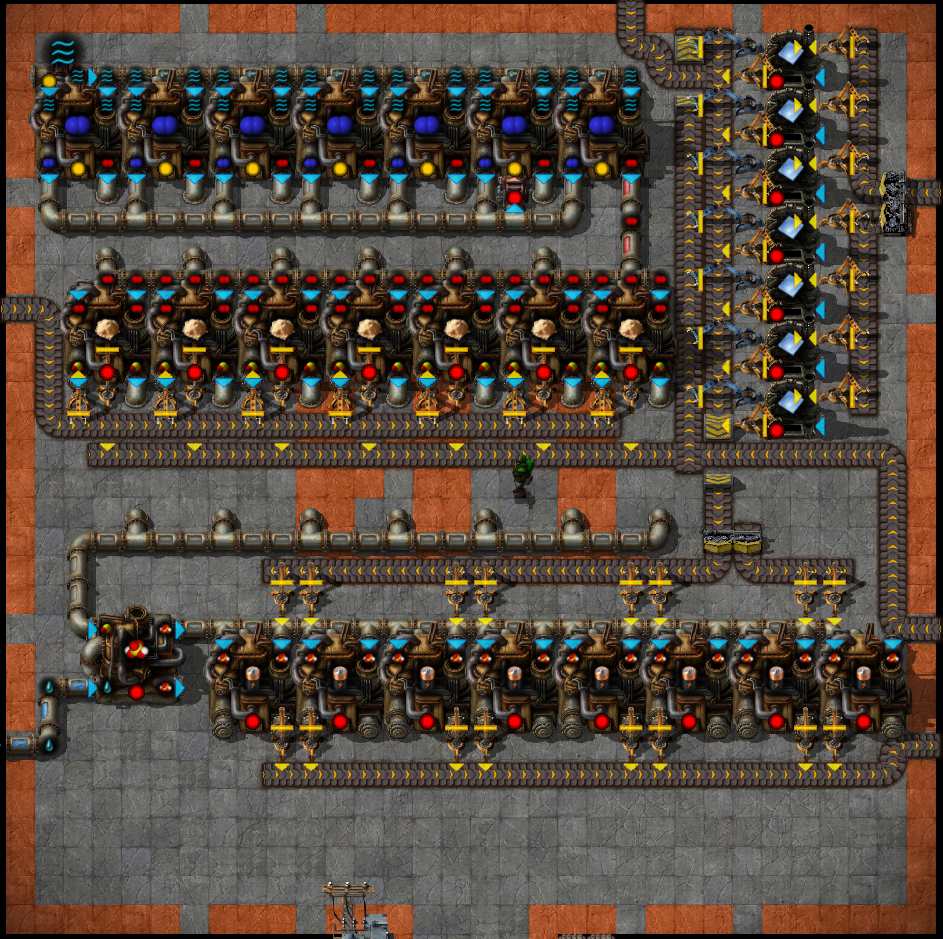

when activated, since you actually produce more oxygen than needed, the oxygen will slowly fill to 80% and then vent. presuming you're producing more hydrogen and nitrogen than needed (since you need 4.4 electrolysers, you have 0.6 more than needed if you build 5 etc.) these tanks will slowly fill up until they reach this 80% too, and since oxygen is venting, but the other two gasses aren't, the machines will switch off.

Of course, you could do something with the oxygen other than vent it, such as bottle it, but then the system isn't independent anymore, and a chest full of oxygen bottles would mean the oxygen tank gets full, so you can't produce more hydrogen and nitrogen and would clog the system.

Speaking of barrelling the new gasses, and venting... I should add a venting recipe for Nitric oxide and Ammonia. (Though, since you're making them both on purpose, and they're a single product, not a byproduct, why the hell would you want to.)