But how many different techniques can overcome this problem? 1? 2?

I know 5 of them for now, let's discuss a bit about them.

As a reminder, the reactor turns the fuel item into heat which is stored into reactors and heatpipes.

The heat is turned into steam in the heat exchanger, that steam is stored into pipes and turbines but they can also be stored in tanks.

The steam turbines are then making electricity from that steam.

Also I assumed everyone already knew this but:

The fuel cells must be inserted at the same time if you have multiple reactors so you maximise the neighbor bonus.

The cells also must be inserted one by one to allow for these automation systems.

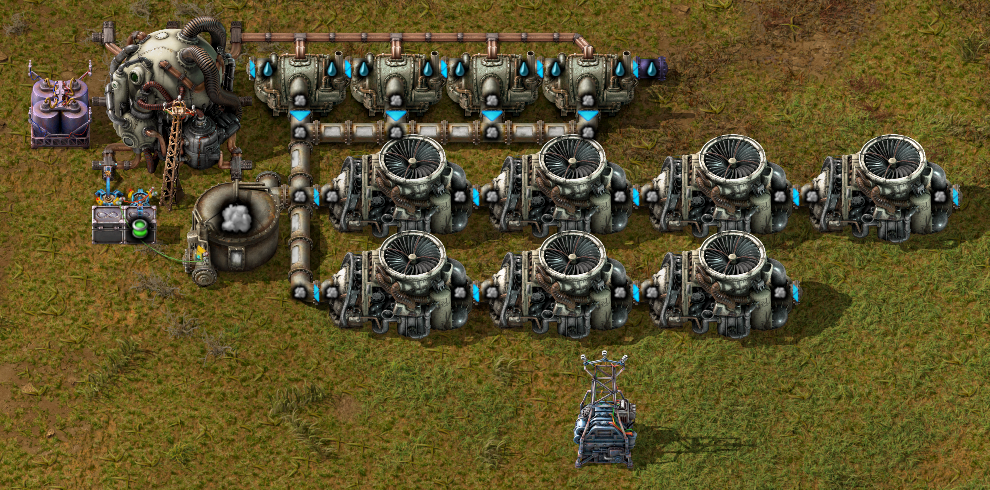

1. Steam Level

This is currently the most popular, you just store some steam in storage tanks and add cells when the steam level is too low.There are two main things to consider in this setup:

- the minimum amount of steam that can be used to continue producing power between the moment the cell is inserted in the reactor and the moment the steam level stops falling (this value can be found by looking at how much steam dips under an arbitrary threshold value with the power plant running at 100%)

- the maximum amount of steam that the reactor will produce with a single cell (this value can be found by looking how much steam is rising above the threshold value with the power plant running at 0%)

This setup is quite easy to understand and thus works well for small power plants (1 to 4 reactors) its downside being that it requires a lot of storage tanks.

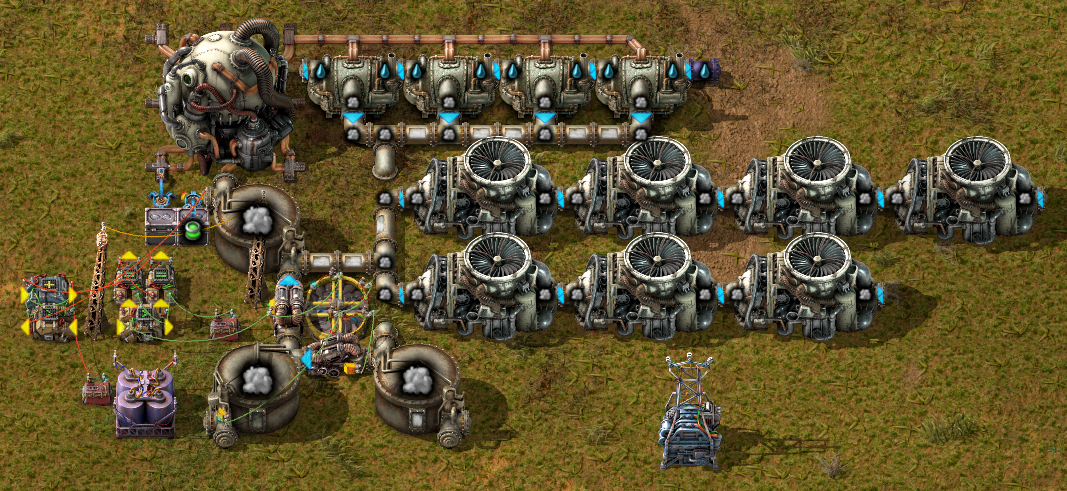

2. Steam Production

To be clear I'm talking here about detecting if steam is produced or not, as a boolean.In order to do that, you take the furthest heat exchanger, and plug it to a pump, then a tank then another pump before going into the rest of the system.

The first pump is only here to prevent the tank from being filled too much, so the automation stays nice and reactive.

The second pump is setup so it never empties too much.

Now if the tank is low (second pump is disabled) that means the heat exchanger is cold, so a new cell must be inserted.

This automation is a bit hard to setup, but it has the advantage of requiring only one tank for the whole power plant.

So it's really nice for power plants with a fixed amount of reactors.

3. Steam Flow

In theory, when you put a fuel cell in a reactor, it will produce a very accurate amount of steam (without reactor bonuses it's around 82474 steam per fuel cell).Well, in practice this is also the case.

And a way to measure the amount of steam produced is to fill a tank completely, then emptying before filling it again, thus making exact steps of 25400 fluid (a pump holds 400 units on its output).

Note that due to floating point rounding it might be between 25400 and 25399 but only if the flowrate is less than 60 fluid per second, and it's still insanely accurate so that's fine.

You can also fill a tank while you empty another, making the throughput much higher and constant.

This automation is very complex but is tileable and require much less tanks than the steam level automation.

So it works well for 2xN setups.

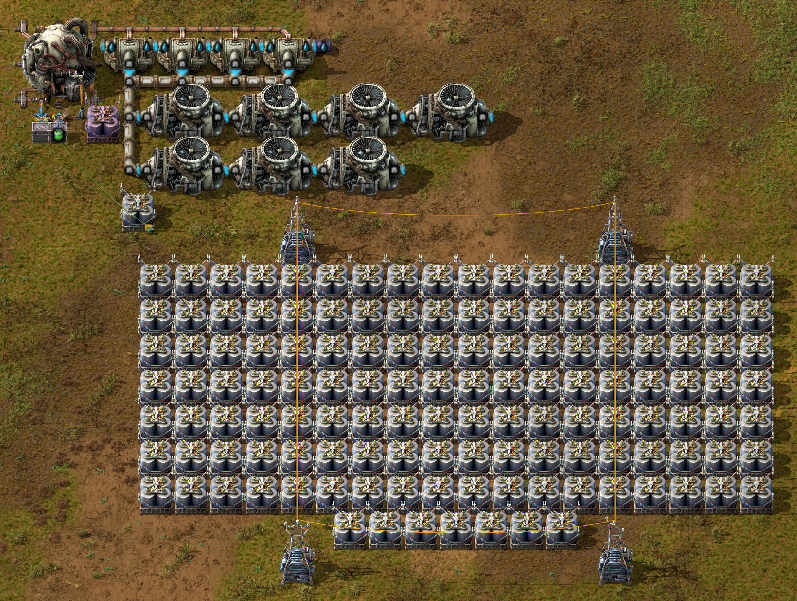

4. Honorable Mention: Accumulator Level Monitoring

Aka the most impractical solution of all.It technically works, just like steam level automation except you measure electric charge level.

How bad it is? Well you need more than 500 accumulators per reactor on a 2xN setup (the bottleneck being power throughput and not power capacity).

So yeah, don't use this.

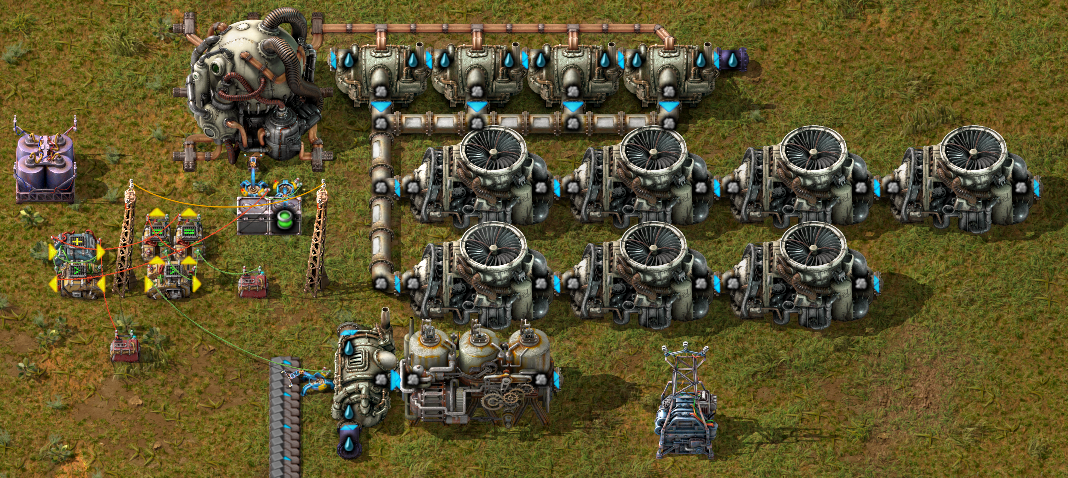

5. Side Channel Power Production Monitoring

That's actually my favourite, what lies behind that bit of a cryptic name is actually quite simple.If you have a steam turbine or a steam engine on the same power grid as others, they will all be used equally the same (in percentage).

So if on your power grid you have many steam turbine and a single steam engine, you can get how much steam has been produced (like the 3rd automation, steam flow) by simply counting how many fuel items has been inserted in the burner making steam for that steam engine.

You got it, the downsides are the need for an external ressource (although a single depleted oil well is enough to make all the solid fuel you need) and you can't add any other steam turbine or steam engine without fucking the system up (which is ok if your factory is well planned).

Not tested but adding solar panels or accumulators should not interfere at all.

On another hand, it requires no storage tank, it doesn't take too much space and is very suitable for 2xN setups.

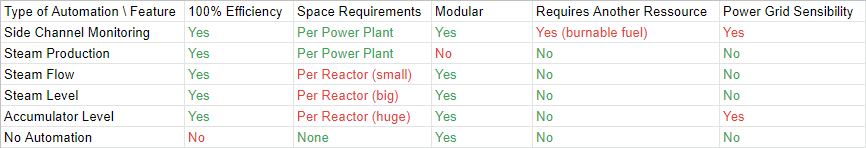

TL;DR

Here's a quick summary of all these kind of automation:

I was only planning to discuss about these but I can provide blueprints, saves and detailed setup tutorials if you want so.

The factory must grow.