- input: plates, plastic and circuits

- belts-only

- every assembler gets max productivity modules

- as many beacons as reasonable are used

- try to be close to perfect ratios and use direct insertion where possible

- tileable designs ('racks') that share beacons where possible

Rocket Control Units (RCU)

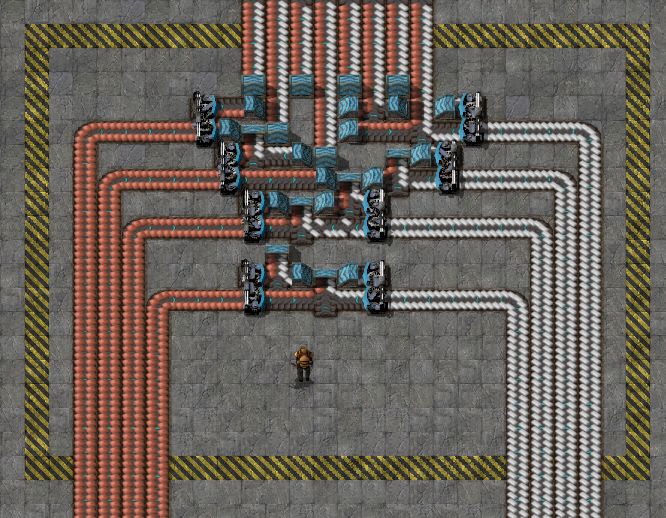

Each RCU requires 1 blue circuit and 1 speed module, which in turn requires 5 red + 5 green. Speed modules are produced twice as fast as RCU, and don't take prod modules, so the ratio is even more skewed. Rather than trying to use one sp1 assembler per 2.x RCU assemblers, I decided to speed boost the sp1 assemblers less and do 1:1 underneath the beacon row:

The ratio is still off, as the sp1 assemblers have speed 3.75 while the RCU assemblers have 5.5, but I'm not too worried about 'wasting' sp1 assemblers as they don't have modules.

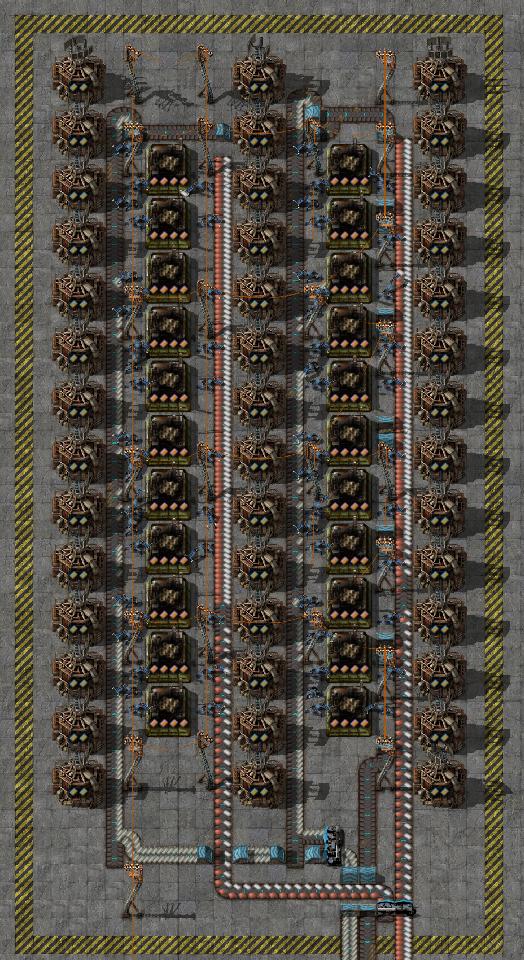

Each RCU assembler consumes 2*5.5=11 blue per minute and 55 red and green to produce 2*5.5*1.4=15.4 RCU per minute. So, a full belt each of red and green (2400/min) is consumed by 43.6 assemblers (22 rows) and will produce 672 RCU per minute. Note that if this is enough, you can also combine the red and green belts into one belt, but as I needed more I have two full belts.

blueprint for 8 rows

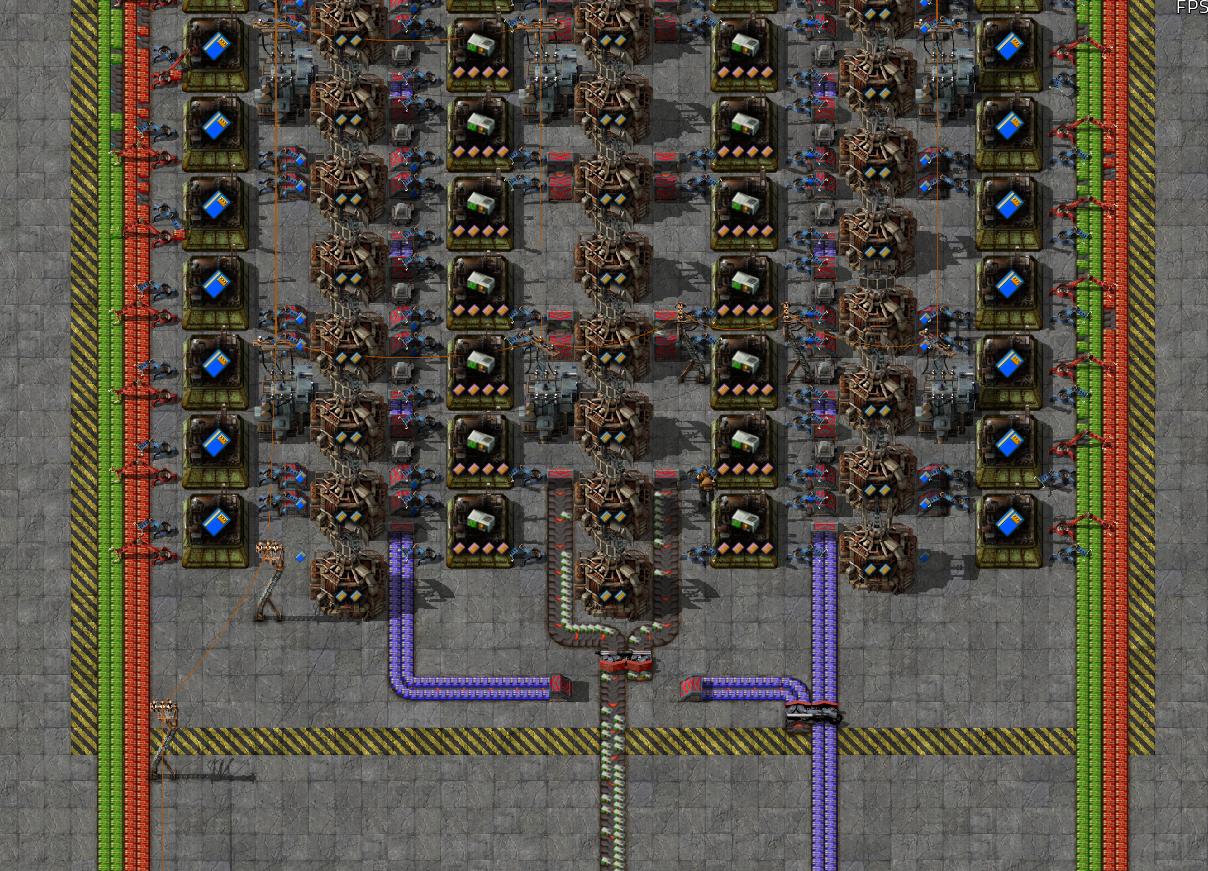

Low-Density StructureLDS consume three raw resources only, so it is easiest to just have racks with two belts, and use one lane for output to be sorted at the end of the rack:

(The LDS are looped through the inserters and output at the bottom)

Each LDS runs at 5.5 speed, using 5*5.5/30=0.916 copper/plastic and 1.83 steel.

So, a blue lane of steel can feed 10.9 assemblers. This setup has 2x11 assemblers, consuming a full belt of steel and a lane each of copper and plastic to produce 335 LDS per minute.

blueprint

As a "bonus", this is my blueprint for heavy-duty combining of 4x2 belts into 8 mixed belts:mixer