I want to know how the input and output fluid resources of a recipe are distributed to the available fluid boxes of the corresponding entity. What logic is used or is it somewhere hardcoded?

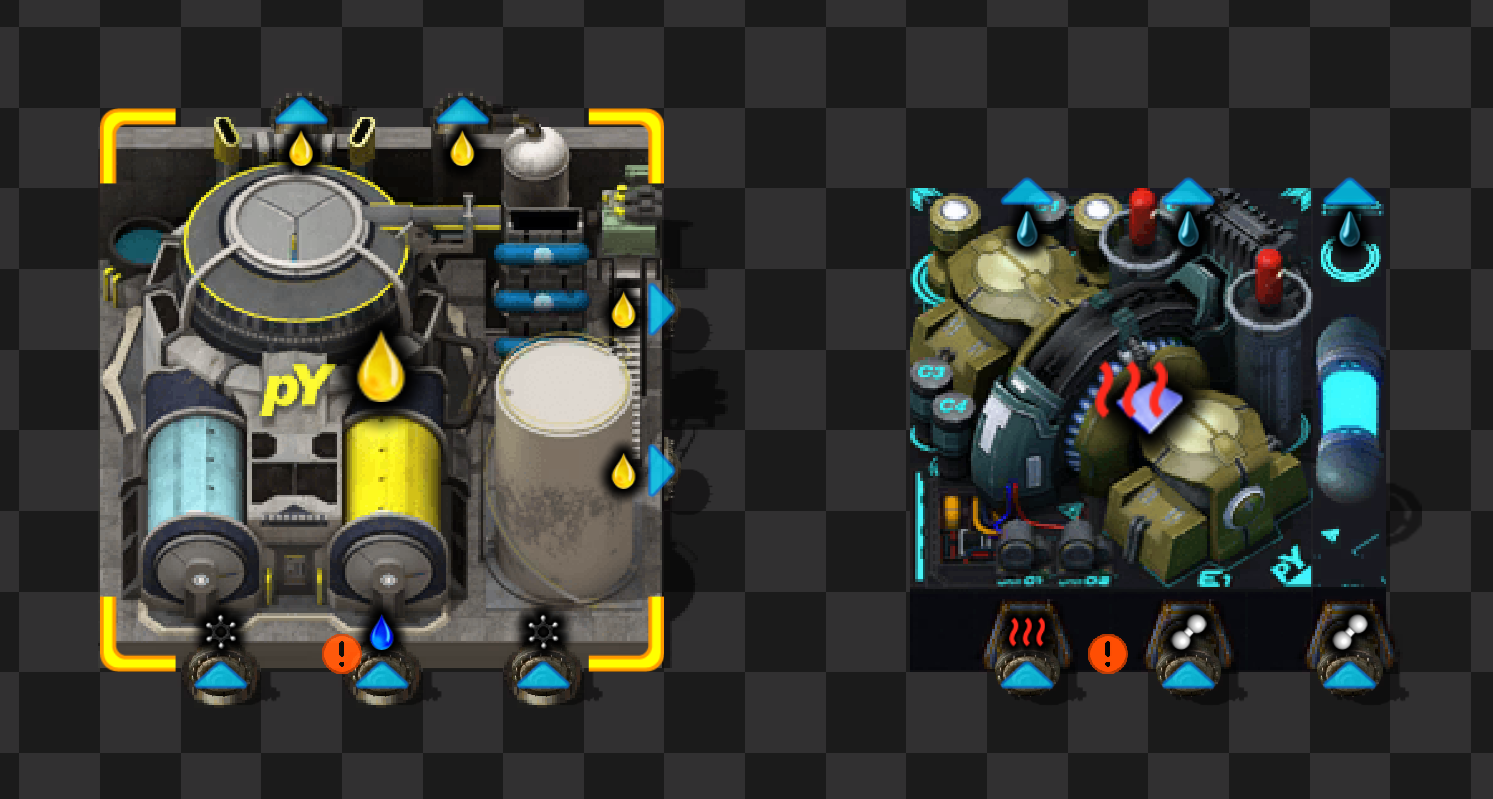

Look at the example below: both recipes require 2 different fluids as ingredients but for the assembler on the left the fluid connections are always assigned "ABA" while the assembler on the right has them always assigned as "ABB".

Thanks in advance!