I've asked similar questions before, and they've been asked. But I really don't get it. For example, in the past, situations such as austerity were mentioned regarding the problem I will talk about... But there is a much more obvious "extraordinary" here in my opinion.

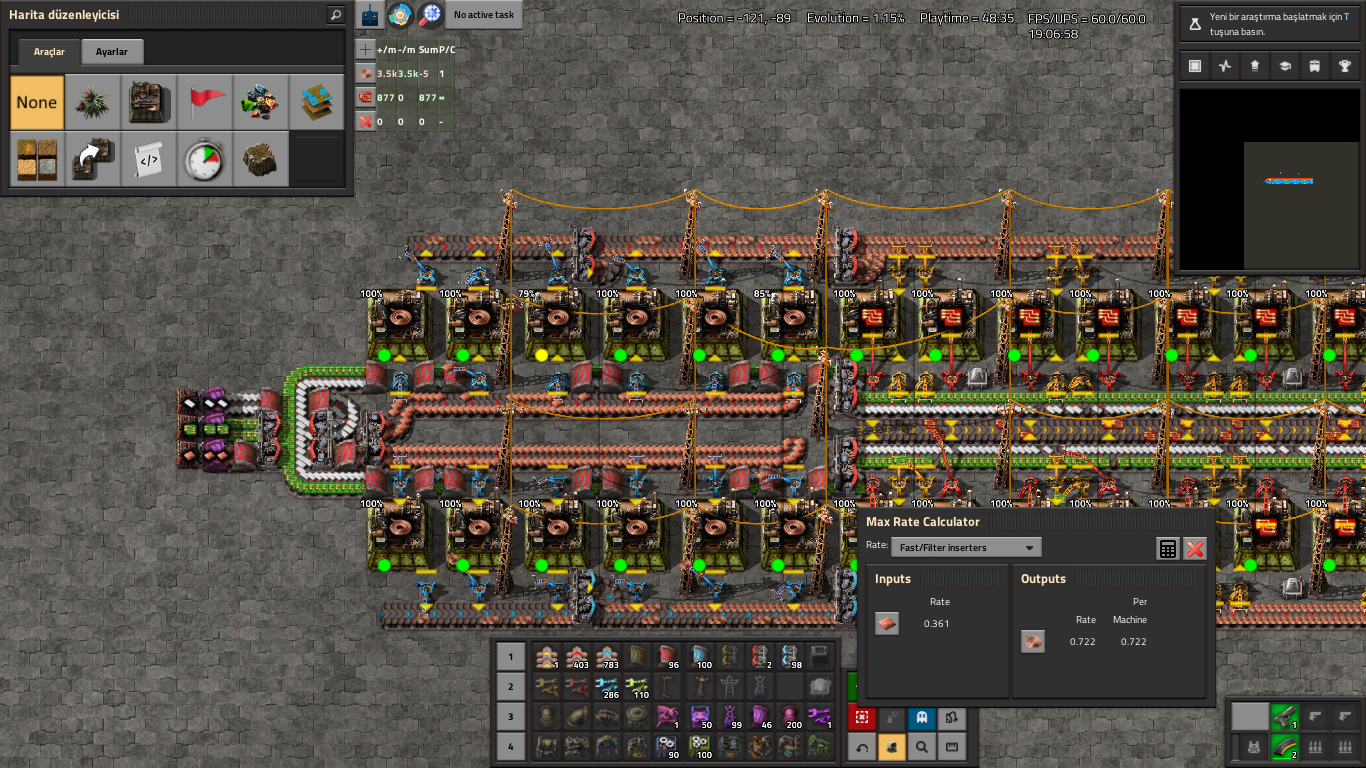

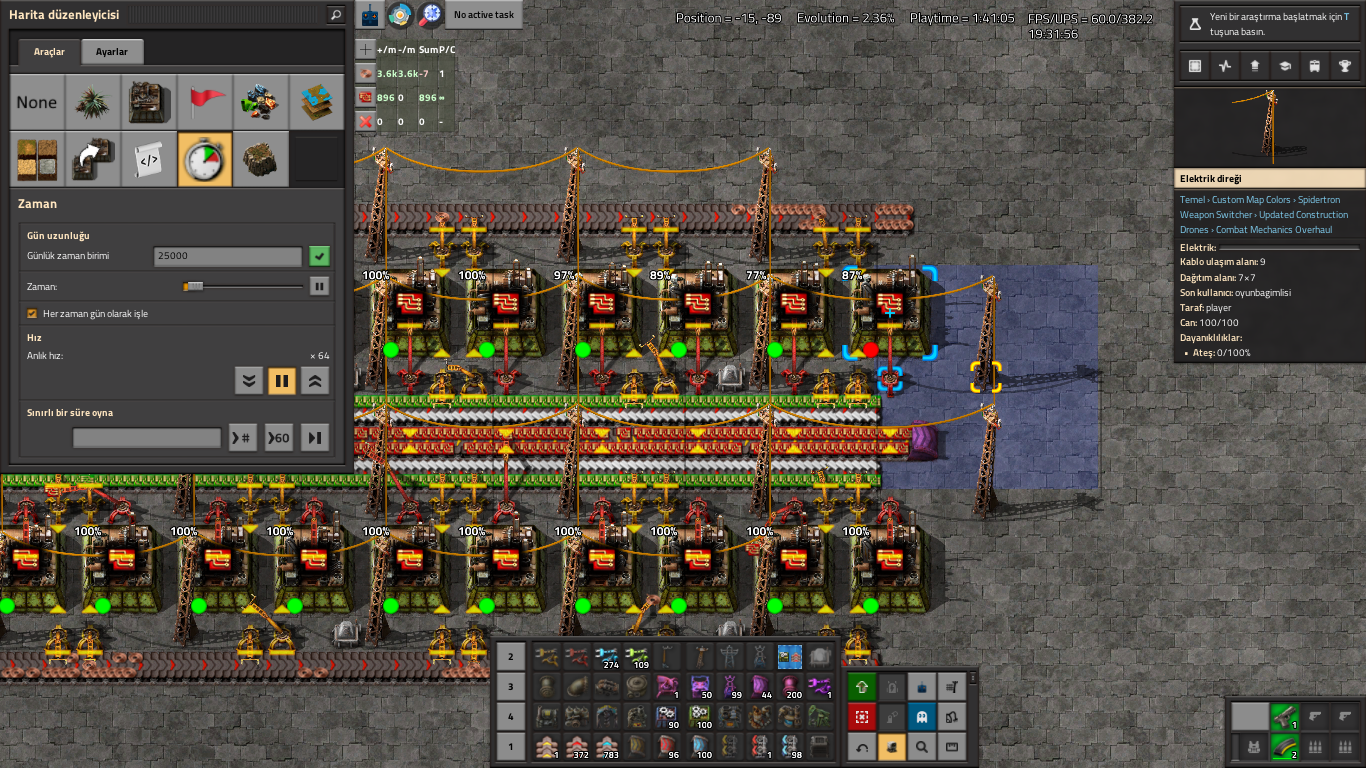

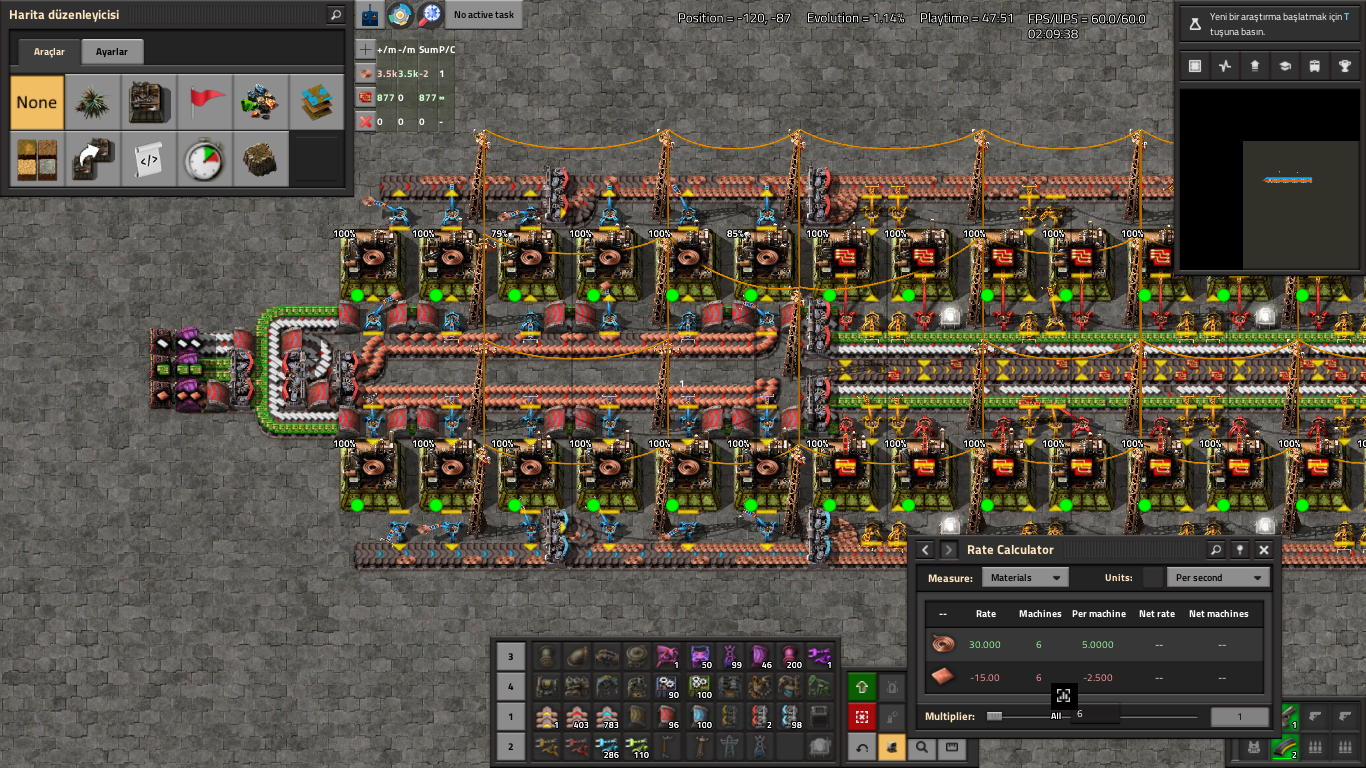

*The output of 6 (mk3) copper mounts is 30 i/s (1 full red stripe)

*Required density for 3 assembly machines / 3 inserters is 15 i/s

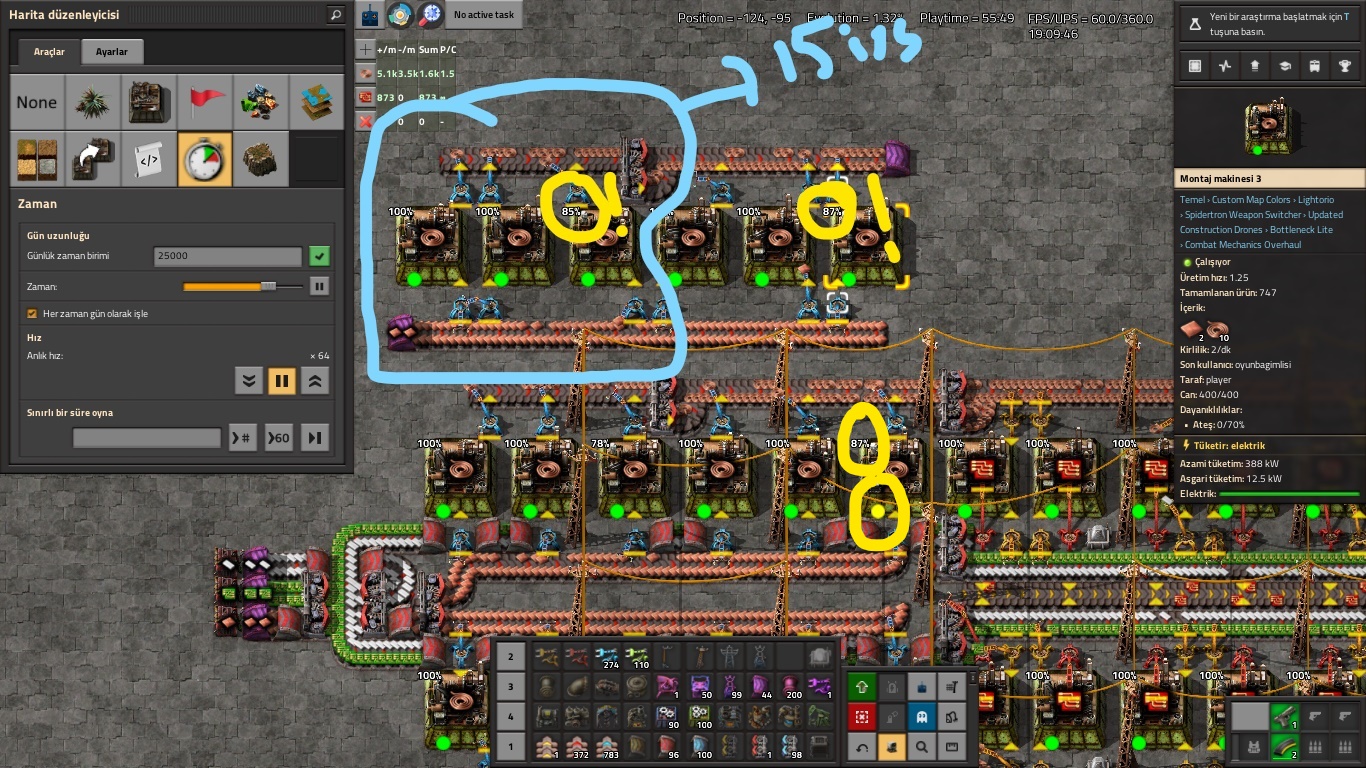

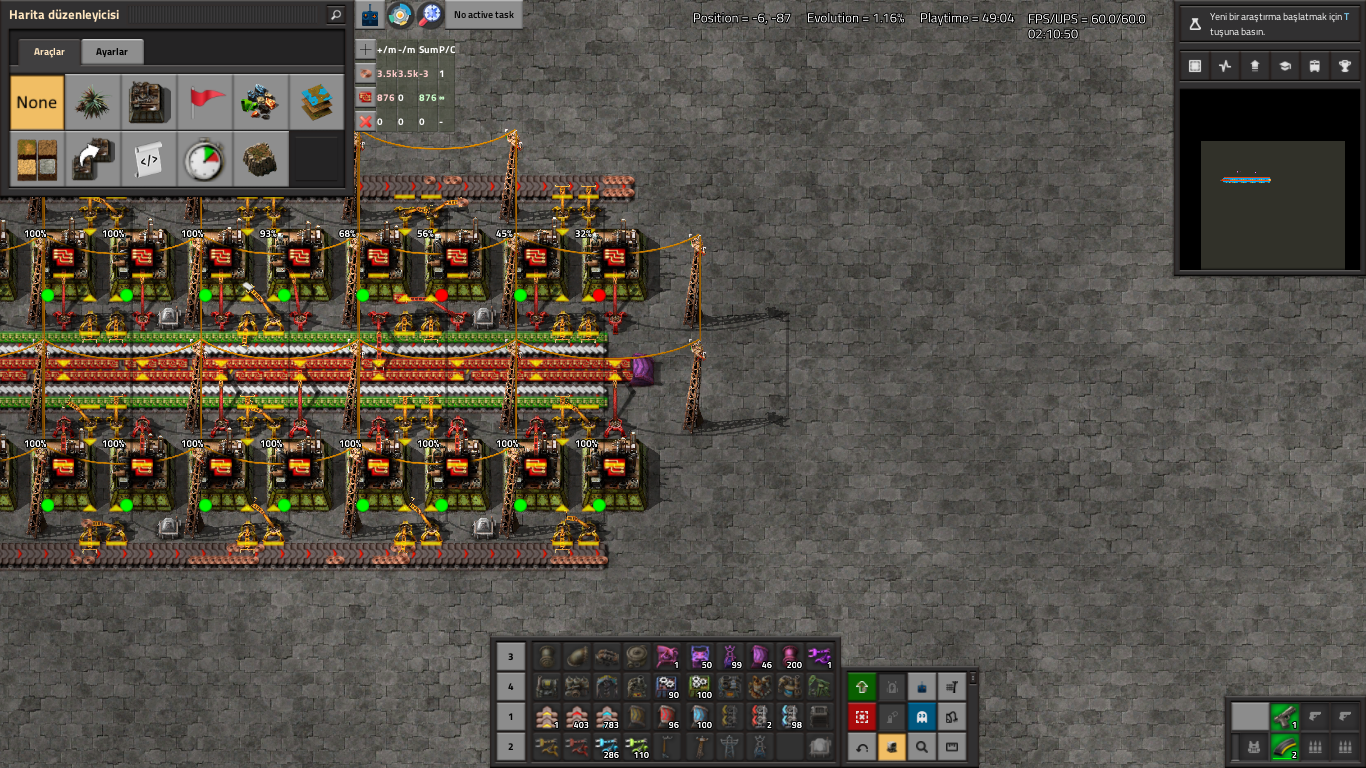

=(far side of red belt only) (Inserters leave far side.) (15i/s)

The splitter after the 3rd machine is set to drop first on the proximal side of the belt. (50% (15i on the near side-15i on the far side) as the next 3 machines will exit to the far side

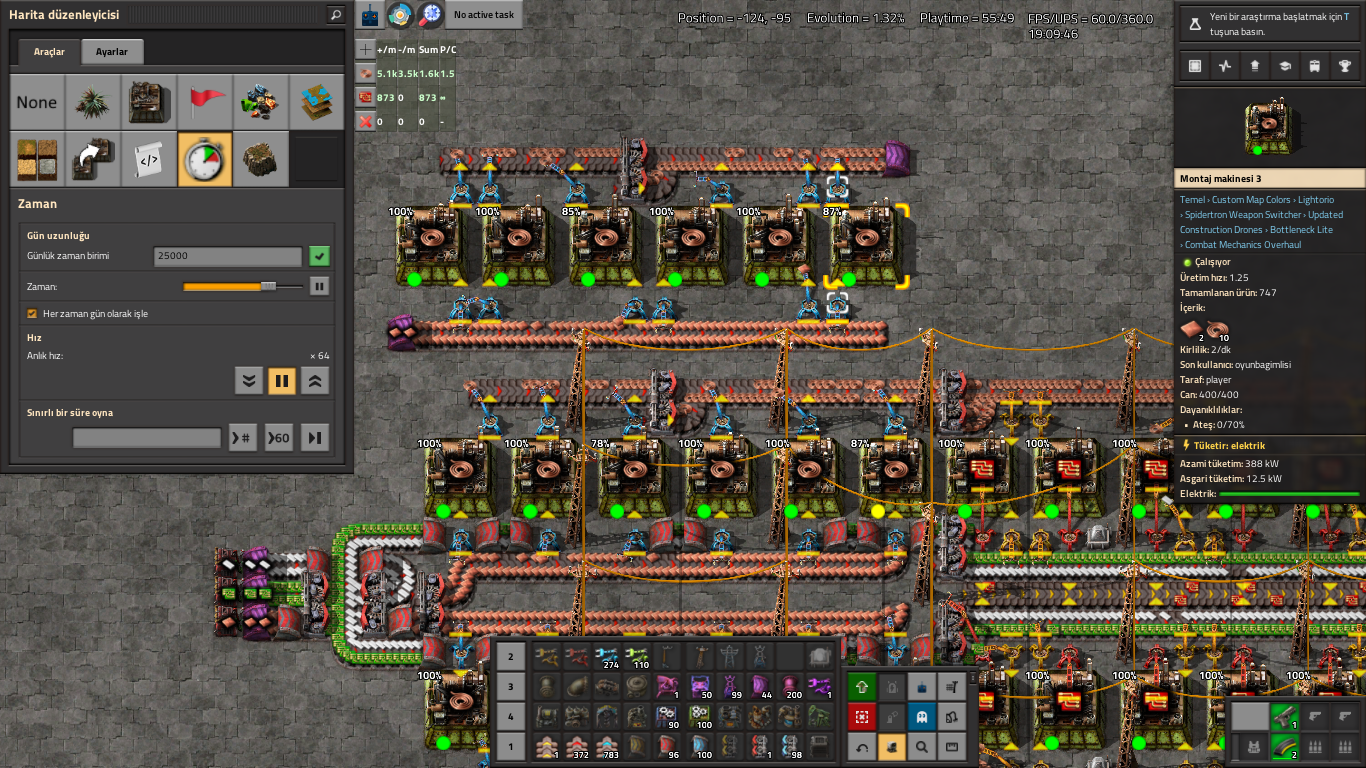

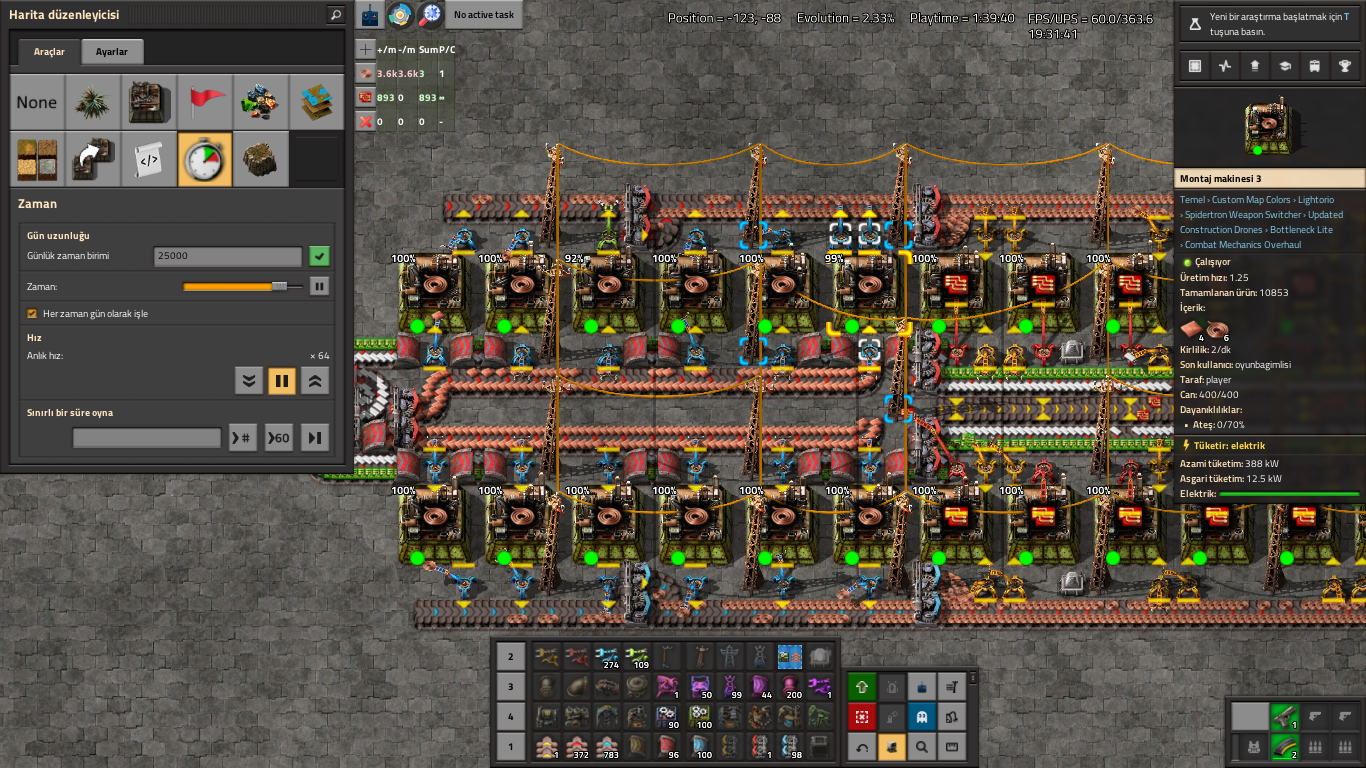

But the red belt is not enough. Machines are bottlenecked. As a solution, they always told me to upgrade. Yes, the Blue belt (raising the inserter if needed, etc.) does work. But I really don't understand why our knowledge in theory doesn't work out in practice.