It's important to remember that this game is not mainly about building rocket defense. Sure, it's the official end of game, but most of us probably have their own ideas of how to play and what to do.

So if you're not trying to achieve perfect efficiency, putting everything on a belt might be a nice idea if you thinks it's fun.

I watched a LP where the LPer was annoyed with things queueing up on belts. So he came up with a very special solution. There was a single red circular belt that transports everything. To try and prevent deadlocks, he would add smart inserters so only items that are currently required somewhere else would be put on that belt. Guess what, it was slow as hell compared to most setups, but it was fun to watch and probably fun to build (and fix the cabling and inserter conditions).

See this vid: https://www.youtube.com/watch?v=ZM8kn_ITQlU

Why having everything on a belt is a bad idea

Re: Why having everything on a belt is a bad idea

ssilk wrote:I also shaked the head about putting copper cables on the belt.

The lack in throughput for green circuits could be already seen in the last video...

But well. I think he tries to think in categories of newbies: They like this "all on a belt"-idea. I see that a lot, they really like it.

And it makes really sense to have such a central bus for copper, iron, circuits and maybe some more...

It's eventually our "duty" in the forum (and wiki and more) to always put a finger on this and say: "Well, nice and clear, but useless..." ... like in this thread....

Belting copper cables isn't always a bad decision. Done properly, you can bulk-produce all of your wire supply (with room for expansion) very early in the circuit chain since nothing needs copper bars. At a very low tech level you can pretty much produce all the copper wires you will need with a very short feed line, and can save space elsewhere in a chip-centric factory. The consequence comes in having to use multiple/fast inserters.

The cost is more power (ultimately trivial) for the extra inserters, and the gain is expandability and design simplicity as well as all wire factories are able to contribute to all demand simultaneously instead of waiting for independent copper resource feeds to filter through snaked belts and splitter chains.

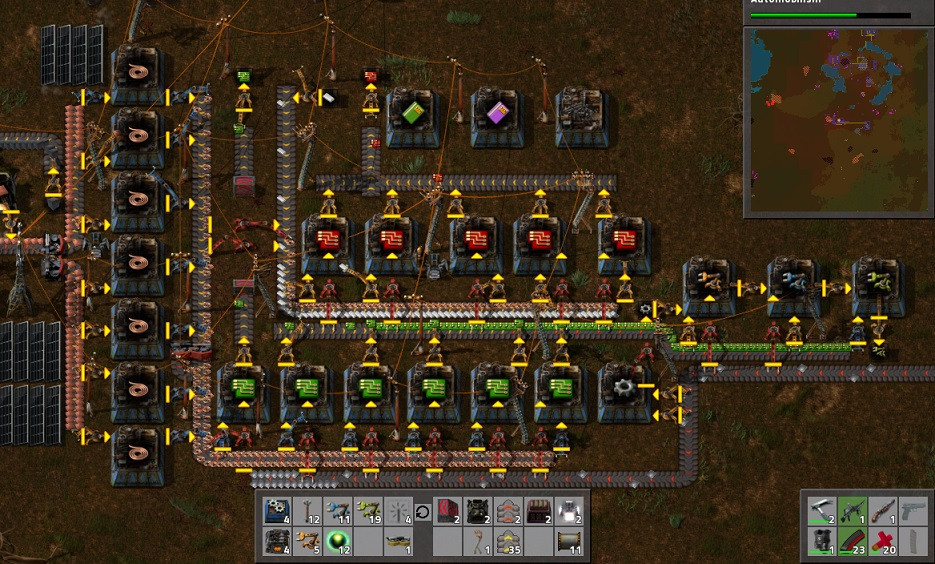

Below is a sample of an in-development chip plant away from the main base w/ belted copper wire. It uses local copper/iron supplies (completely separate from my main base) hence the reduced iron inputs, before anyone harasses about the iron flow. It runs fine for my needs, and I planned on expanding it for Processors as well. The price paid in electric power makes up for simplicity and not needing bots for anything other than the eventual train station.

Re: Why having everything on a belt is a bad idea

Red belt lines & splitters != very early, or just early, gameplay.

-

LordFedora

- Filter Inserter

- Posts: 310

- Joined: Fri Nov 07, 2014 3:46 am

- Contact:

Re: Why having everything on a belt is a bad idea

red belts are earlier then red circuts, you can get them as soon as you set up green science

Re: Why having everything on a belt is a bad idea

This guy gets it. Belt hell, while not the most efficient, can be fun.Blackence wrote:It's important to remember that this game is not mainly about building rocket defense. Sure, it's the official end of game, but most of us probably have their own ideas of how to play and what to do.

So if you're not trying to achieve perfect efficiency, putting everything on a belt might be a nice idea if you thinks it's fun.

I watched a LP where the LPer was annoyed with things queueing up on belts. So he came up with a very special solution. There was a single red circular belt that transports everything. To try and prevent deadlocks, he would add smart inserters so only items that are currently required somewhere else would be put on that belt. Guess what, it was slow as hell compared to most setups, but it was fun to watch and probably fun to build (and fix the cabling and inserter conditions).

See this vid: https://www.youtube.com/watch?v=ZM8kn_ITQlU

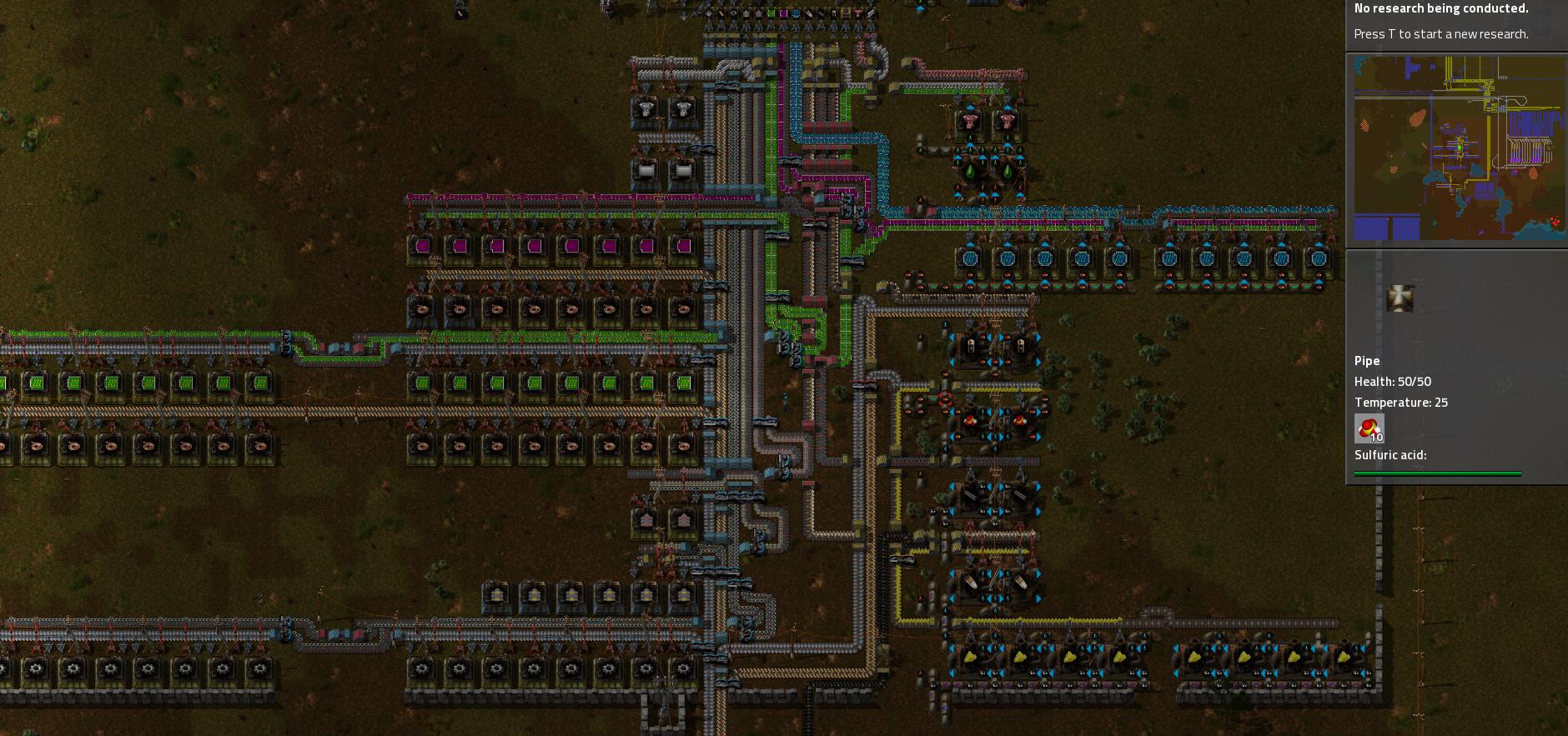

This is our current multiplayer belt monstrosity. http://i.imgur.com/afyduoh.png

Also, chem is a mess

Re: Why having everything on a belt is a bad idea

Belts excel during two stages of gameplay:

- early on while factory is small and logistic bots aren't researched

- extreme late game, when material throughput overwhelms roboports.

- Y-axis adds new products to the main line.

- X-axis expansion increases production of lagging products.

- If done correctly it is possible to produce blue belts at maximum capacity of 10+ products and deliver them to their final destination. (Roboports cannot handle more than 3-4 blue belts at maximum capacity)

http://i.imgur.com/umDLBGV.jpg

Currently i am designing a new one with liquid-dependent production using one side, and general production on the other, and beacons everywhere.

In normal speed designs (no productivity modules) I never put copper wires on the belt as it usually requires 2 fast inserters for 1 circuit factory. However if the factories are slow enough that one inserter keeps up with the speed it is certanly possible to put wires on the belt (or two belts to keep up with the demand )

)

- early on while factory is small and logistic bots aren't researched

- extreme late game, when material throughput overwhelms roboports.

My general design

Above is my usual way of constructing long-term factories:- Y-axis adds new products to the main line.

- X-axis expansion increases production of lagging products.

- If done correctly it is possible to produce blue belts at maximum capacity of 10+ products and deliver them to their final destination. (Roboports cannot handle more than 3-4 blue belts at maximum capacity)

http://i.imgur.com/umDLBGV.jpg

Currently i am designing a new one with liquid-dependent production using one side, and general production on the other, and beacons everywhere.

In normal speed designs (no productivity modules) I never put copper wires on the belt as it usually requires 2 fast inserters for 1 circuit factory. However if the factories are slow enough that one inserter keeps up with the speed it is certanly possible to put wires on the belt (or two belts to keep up with the demand

Re: Why having everything on a belt is a bad idea

That's a nice design and all (no seriously, it really is a nice build, I do like itZourin wrote: Belting copper cables isn't always a bad decision. Done properly, you can bulk-produce all of your wire supply (with room for expansion) very early in the circuit chain since nothing needs copper bars. At a very low tech level you can pretty much produce all the copper wires you will need with a very short feed line, and can save space elsewhere in a chip-centric factory. The consequence comes in having to use multiple/fast inserters.

At a low tech level, you want to maximize everything you've got.

I would argue that you don't gain expandability through belting copper cable. I would say that you gain yourself a giant headacheZourin wrote:The cost is more power (ultimately trivial) for the extra inserters, and the gain is expandability

This is probably a philosophical difference, however a copper plate shortage is (in my opinion) easier to deal with than a throughput problem relating to copper cable. Upping your copper plate production is just a matter of, upping your smelting or increasing the belt speed. A throughput problem may require a complete redesign of the system if you exceed the limits of expandability for the build.Zourin wrote: as well as all wire factories are able to contribute to all demand simultaneously instead of waiting for independent copper resource feeds to filter through snaked belts and splitter chains.

There is nothing stopping you or anyone from putting cables on a belt. In fact, I do it in a specific case (when assembling red circuits without logistics bots). But when you scale up and start to create some really beastly factories, you'll see that to get the maximum out of each component, cables on a belt is a really, really big headache

^ Well summarized. I just editted the second one a littleGarm wrote:Belts excel during two stages of gameplay:

- early on while factory is small and logistic bots aren't researched

- late game, when you need some big throughput numbers

Re: Why having everything on a belt is a bad idea

I think this is exact the point: throughput for copper wires must be double as big than the input.-root wrote:This is probably a philosophical difference, however a copper plate shortage is (in my opinion) easier to deal with than a throughput problem relating to copper cable. Upping your copper plate production is just a matter of, upping your smelting or increasing the belt speed. A throughput problem may require a complete redesign of the system if you exceed the limits of expandability for the build.Zourin wrote: as well as all wire factories are able to contribute to all demand simultaneously instead of waiting for independent copper resource feeds to filter through snaked belts and splitter chains.

There is nothing stopping you or anyone from putting cables on a belt. In fact, I do it in a specific case (when assembling red circuits without logistics bots). But when you scale up and start to create some really beastly factories, you'll see that to get the maximum out of each component, cables on a belt is a really, really big headache

It means, you need two belts of copper wire, when you input one line of copper. There is really no way around it. And this need for two belts (better: double throughput) is in my eyes the main point against it.

Relationship between throughput and bottleneck

I want to explain it a bit.

The throughput of any belt transport cannot be higher than the smallest bottleneck. A bottleneck can be easily seen, when you use belts (btw. this is one reason to use belts): the items are completely compressed and after some point they are running free; there is some kind of stop and go and when they pass a point they don't stop; you can see "collision waves" running through the belt backwards (look at this using debug mode, see wiki) and after after a point, there are no visible anymore; in other words there is some jam on the belts and suddenly the jam is resolved. That is the physical area/point of the bottleneck!

Again:

* before bottleneck: items run stop and go, visible collision waves, full compression

* inside bottleneck: items run fluid, but fully compressed

* after bottleneck: there is visible space between items, nearly no collisions visible

So a bottleneck can be long. And this is the case here: the bottleneck for copper wire is as long, as the belts for them. You won't notice any problem on the copper wire belts, but you will see, that the copper will jam before the copper wire assemblies, cause the outgoing inserters won't be able to put the wires on the belts, and you'll notice, that after the copper wire belts the items (green circuits) run free.

You might think, there is no problem. But that hits the definition of a bottleneck.

Cool suggestion: Eatable MOUSE-pointers.

Have you used the Advanced Search today?

Need help, question? FAQ - Wiki - Forum help

I still like small signatures...

Have you used the Advanced Search today?

Need help, question? FAQ - Wiki - Forum help

I still like small signatures...

Re: Why having everything on a belt is a bad idea

There's no link to another forum topic there! Something must have befallen the Ssilkbot!

Re: Why having everything on a belt is a bad idea

That factory won't go "large scale' in much of the many ways as most people around here would even consider 'small scale'. I don't focus on production throughput, favoring instead a slow-and-steady assurance that things are being built at a 'good enough' pace. I won't have to worry about 'maxing out' the feed lines.

Saves me a lot of stress to help deal with my blue-pack meltdown.

Saves me a lot of stress to help deal with my blue-pack meltdown.