1. Works correctly and efficiently with or without productivity modules in the centrifuge, i.e., can detect an extra U-235 that appears every few cycles.

2. Tolerant of input materials getting cut off, i.e., will start back up again properly when they return.

3. Tolerant of output belts getting backed up, i.e., will promptly stop and then start up again when allowed.

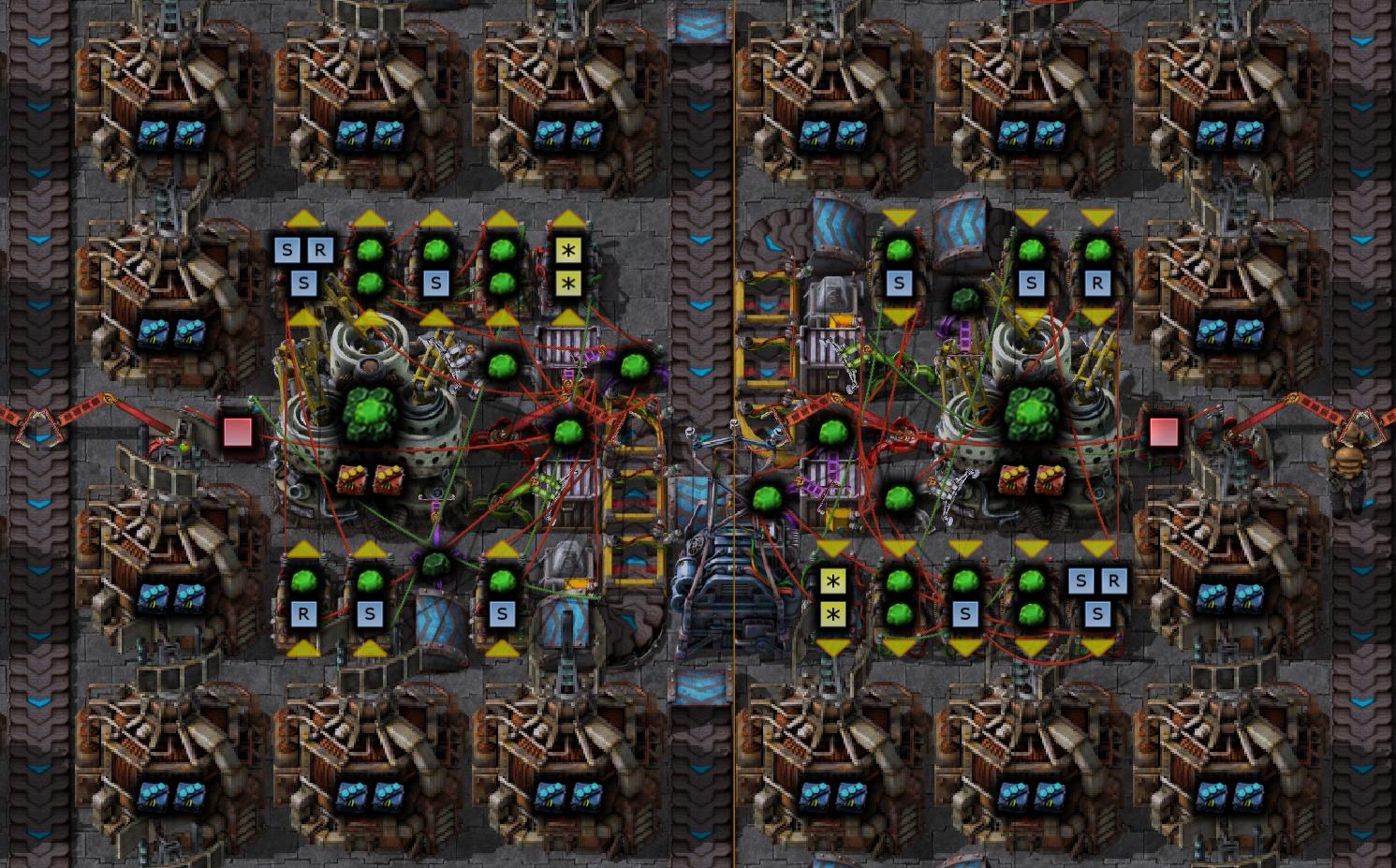

4. Easy to start up -- place 40 U-235 in the chest closest to the bottom of the centrifuge in the below image (not in the centrifuge) and just let the U-238 come in on input belt.

5. No input materials will ever accumulate in the centrifuge or in the chests, i.e., it will only ever take in the input that it needs, and will expel any output that it doesn't need to the output belts. If excessive U-238 gets put into the centrifuge then it will be given priority over the ones on the input belt.

6. No bots needed.

The reason for all the combinators is mainly due to item (1) above, i.e., getting all of the desirable properties to hold both with or without productivity modules in the centrifuge. The combinators involved create the following:

1. One RS latch

2. One counter that goes up to 41 and then resets to zero. This counter always knows how many U-235 are input into the centrifuge.

3. A few extra combinators that translate inputs from the boxes/inserters into signals into the latch and counter.

Here is an image/blueprint with two of them side-by-side; together they form a tile-able unit.

Will be curious to get feedback on this and to know if there is a simpler setup that has the same properties, in partcular supporting prod modules in the centrifuge without malfunctioning or destabilizing.

Edit

--------

Let me clarify how to start it up: let U-238 come in on the input belts, and then place 40 U-235 in the lower chest (for the centrifuge on the right) and in the upper chest (for the centrifuge on the left). It is important that the U-235 initially go into the correct chest so that the counters start up properly.