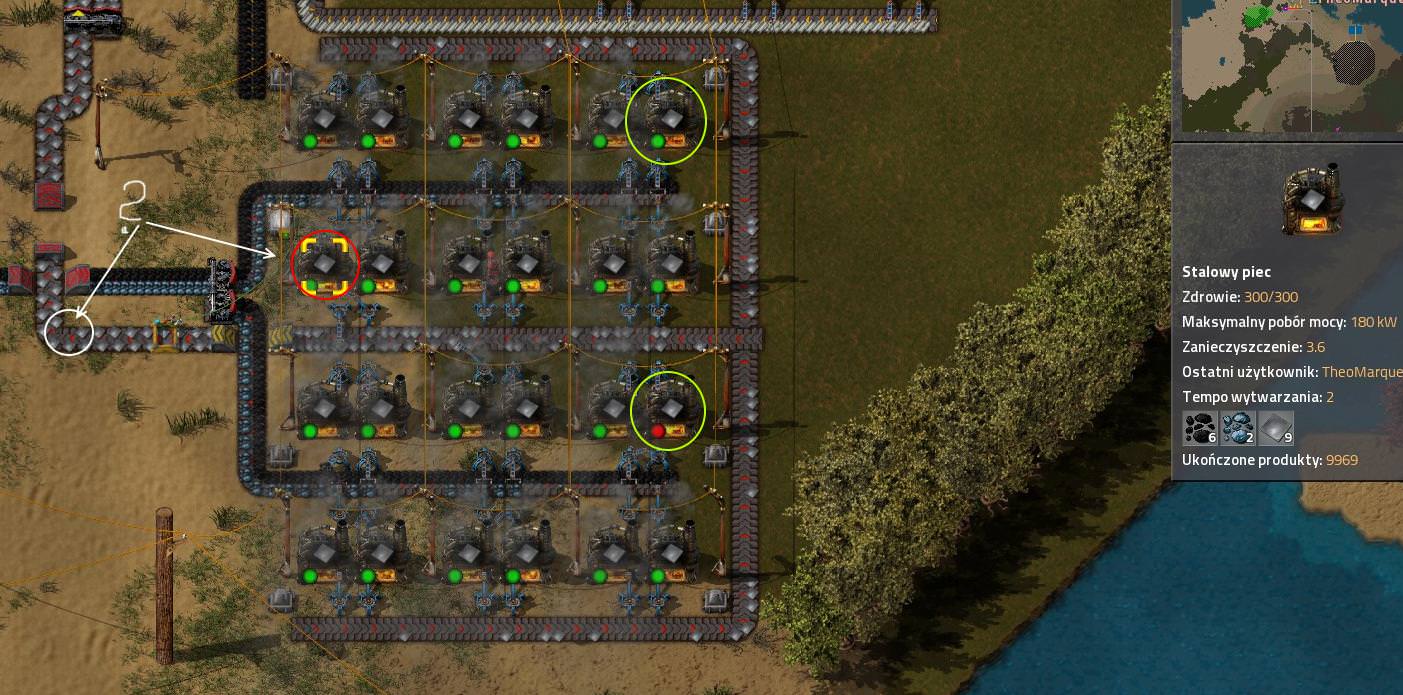

I build iron works using steel furnaces. Idea for this deign is simply, max flow. Iron ore input is yellow belt (compressend to half red belt), output is the same, yellow belt (undergorund).

But... Ise something strange. Furnaces selected lime circle sometimes run out of iron ore. Is ok, because efficency of this setup is 11,66 furnace per yellow belt. But problem is with furnace selected by red circle. This furnace storage iron plates because inserter can't put it on belt. Belt was choked by yellow underground belt but is not matter where I set yellow belt choke, it will be overfilled later. But ofter choke I saw tiny holes. I think that splitter directing iron ore to steel furnaces not split ores by 50/50 but 50,5/49,5.

There is a bug or this layout is bad?