Some aspects of the implementation might seem kind-of wierd but there are reasons for most of the design choices I made. For now I won't elaborate too much, for fear of tldr problems. I'd be happy to consider any ideas or answer any questions.

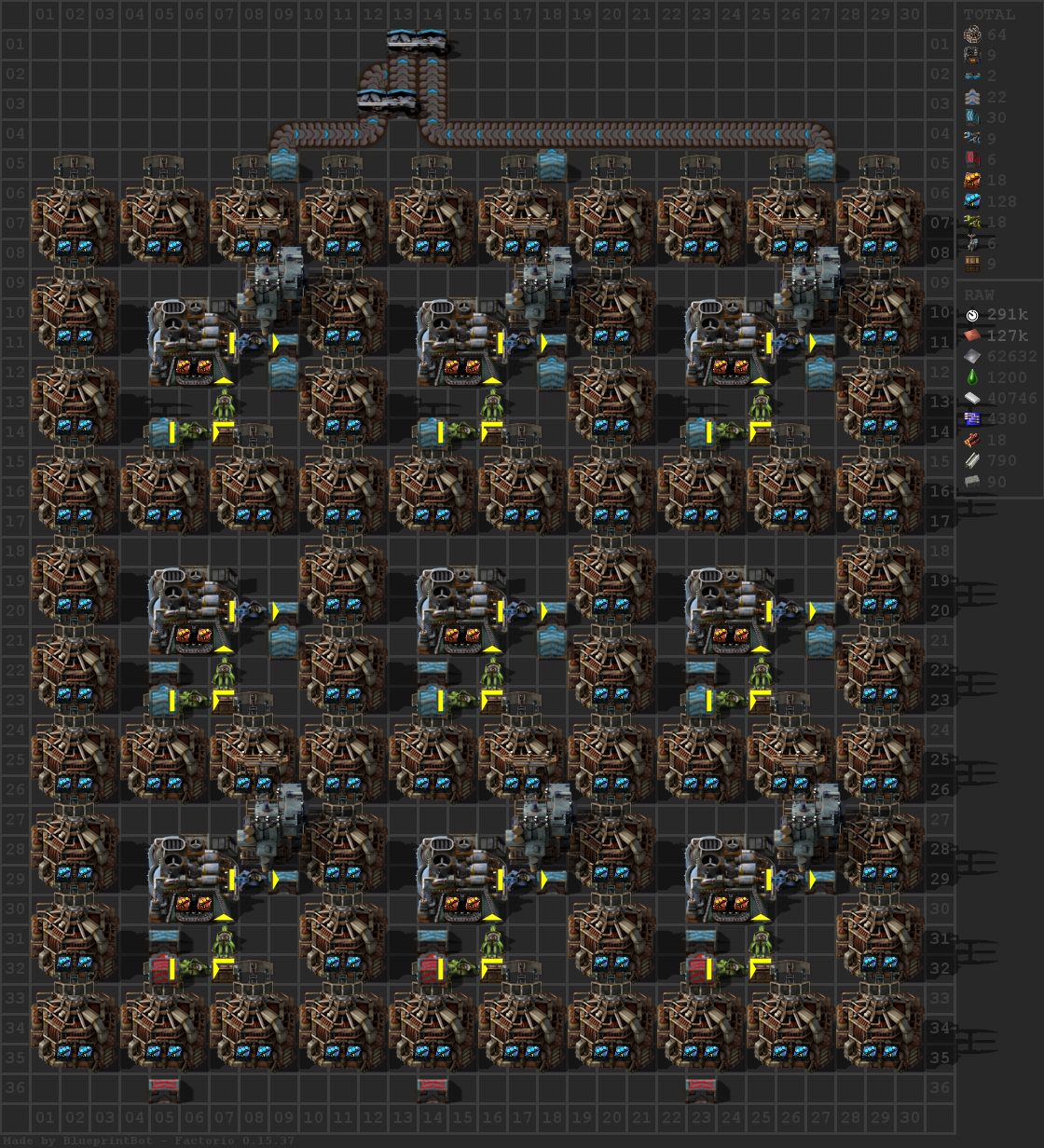

One thing worth mentioning is the decision to feed the bottom row separately from the top two rows, which share the same belt (but not lanes) for input and output. If we tried to put the ore for all three smelters on one belt-lane, we create a maths problem. If we want each column of smelters to produce 1/3 of a belt of output this will require 2/3 of a belt of input. Obviously (but not obviously enough that I failed to discover this the hard way) only one belt-lane cannot provide this. Productivity modules almost-but-not-quite rescue us from this problem -- each column would require 8/15 belts of input, just 1/30 more than one lane can hold. But the result is less than satisfying. We could solve the problem by sharing input and output lanes; but even if we get rid of or replace the productivity modules, inevitably, a bit of raw stone slips through. I did manage to produce some designs which solved this using belt circuit conditions, but that kind of violated the no-circuits constraint I was trying to work within, and resulted in a big ugly mess. The three splitters and reliance on backpressure seemed like a lesser concession. Earlier designs used a second layer of 1->3 splitters and routed ore to each smelter individually which worked fine but seemed like overkill; this seems to work just as well and is presumably much more UPS-efficient.