- Can switch between nuclear fuel and chemical fuel, automatically

- Uses turbines for both low energy and high energy steam

- Can be configured to prefer nuclear or chemical fuel. Default: Prefer chemical (since oil is an inexhaustable resource).

- Will dynamically switch based on power plant load. Must be able to rapidly ramp up power production. Should not be the cause of brownouts or blackouts (barring fuel starvation)

- Should not waste nuclear fuel. Reactors should be offline if there is sufficient energy in the system.

Well, that's quite the laundry list, isn't it? Let's tackle the demands one by one.

- Switch between nuclear and chemical fuel, automatically.

This can be handled by a few pumps and the circuit network.

- Use turbines for both steam types.

Again, easy enough to do. The combined steam outputs of the chemical boilers and the heat exchangers gets dumped directly into the turbines. 165dgr steam and 500dgr steam can freely mix.

- Configure to prefer nuclear or chemical fuel.

Combinators can determine this. Since nuclear satisfies the full load of the plant, an override to turn off the chemical boilers entirely is all that is needed. Preferring chemical is more complex, so should be the default.

- Should not waste nuclear fuel. Reactors should be offline if there is sufficient energy in the system.

If a steam buffer is used for the heat exchangers, blocking reactor feeding once the buffer is at or near capacity handles this. Any excess energy is stored as heat on the reactor, heatpipes and heatexchangers.

In my previous design I had a 200 second timer to determine if the reactors were ready for new fuel. Now that the spent fuel cell is ejected -after- burning through it, that event on a latch is a much simpler way to handle things.

- Will dynamically switch based on power plant load. Must be able to rapidly ramp up power production. Should not be the cause of brownouts or blackouts (barring fuel starvation)

Here's where the trouble starts. Main issue is that I can't measure the current load on the power grid. I can only measure that there is a shortage by way of Accumulator charge dropping below 100. But using Accumulators to compensate for 4MW per turbine means you need a ton of those. Also, if the turbines are loaded with 165dgr steam, even switching the supply means it takes a few seconds before they ramp up to 500 dgr. The energy shortage is short term, but it is there.

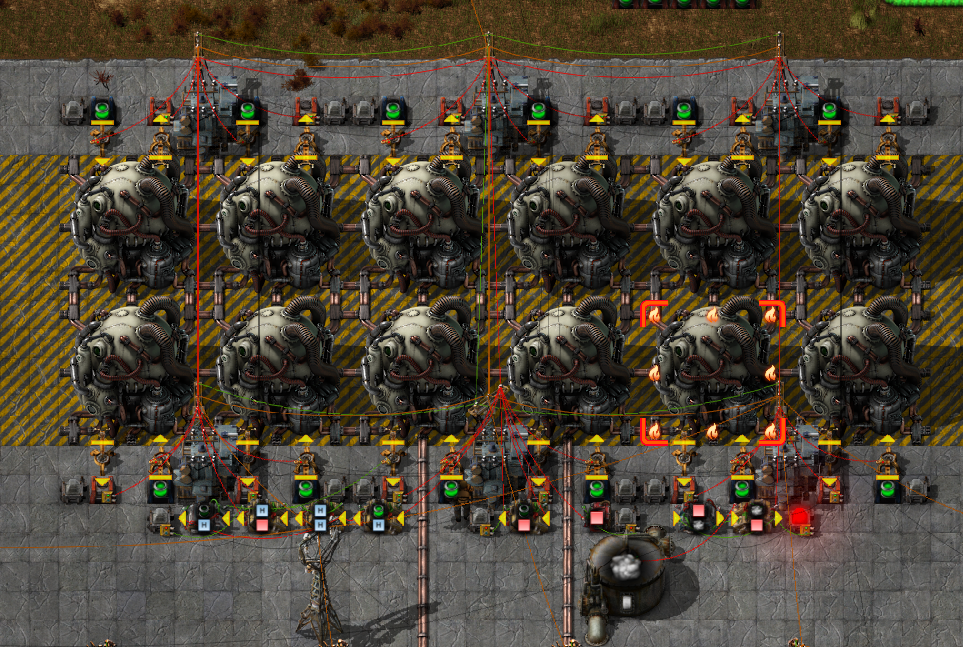

The reactor cluster:

Pretty simple design, an expandable row that frankly, is tileable to infinity, but after building 12 reactors I found that the heat capacity of the reactors, heatpipes and heat exchangers was at it's limit. My plant draws about 500MW, so 12 reactors is definately way more then it needs - but the neighbour bonus makes adding on additional reactors a good idea, since it reduces nuclear fuel consumption.

The reactor control grid checks for several conditions before inserting fuel:

- High energy steam buffer being at capacity. Means there's still energy waiting to be converted to steam in the reactors, so no fuel consumption is needed.

- Manual reactor toggle. In case you want to adjust some things and don't want to waste fuel.

- Fuel presence latch. This is set at fuel being inserted, and cleared by the spent fuel cell being ejected from the reactor.

- Spent fuel cell buffer overflow. If the spent fuel cells aren't being cleared there's a problem and fuel shouldn't be put in the reactors.

If any of these require the reactors to not take fuel, they throw a Red signal on the red circuit, the fuel inserters on the reactors deactivate on that.

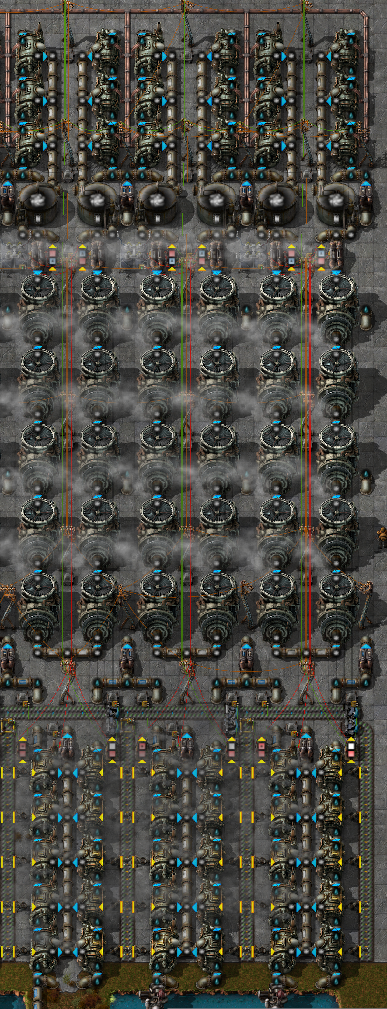

The turbine array:

Pain in the neck now that water and steam aren't the same anymore...

First try: Putting the heat exchangers behind the chemical boilers in a single line, then feeding all that into the turbines.

This means you can't have a steam buffer between the turbines and the boilers/heat exchangers. The switch from low energy to high energy steam to feed the turbines must be very fast. Interconnected steam buffers behind the turbines allow some buffering for them. However, since the energy value of the steam itself can't be measured, the level of steam in the tanks is not useful for determine power plant load directly. If the turbines are stressed while consuming 165dgr steam, they won't produce enough power. The difference needs to be caught by another system while the switch is made. The Accumulator is ideal for this, but it needs to be able to handle the difference in output between the turbine at low energy steam, and the turbine at normal power. This difference is 4MW. Per turbine, you therefor need: 4/0.3 = 13.3 accumulators. One is part of the switching mechanic, so 13 more need to be added -per turbine-. This means a park of 130 accumulators to catch a sudden load difference for every 10 turbines. I don't like that.

Also, with a steam buffer that is shared between low and high energy steam, production ramp-ups seem to go rather sluggishly. All in all, this isn't working the way I want.

Second try: 10 turbines sandwiched between heat exchangers above, and boilers below near the water. Water is always on for both boilers and heat exchangers. Heat exchangers dump into a buffer tank, from which a pump rapidly forces steam into the turbines. From the other side, the boilers dump, via a switching pump, into the turbines too. Since the amount of steam in the system is far lower, the plant switches much quicker. It still limits the plant's ability to switch based on load instantly however. Only accumulator use shows that there is a power shortage. But if the accumulators are being tapped there is already a power shortage, which means you need sufficient accumulators to handle the difference. Which is 13 per turbine again, but only if your power plant load varies extremely (no load - max load switching). If the process is gradual, far fewer accumulators can catch the brief shortages. But the time-to-switch can't be bridged other then by accumulators. Not even separating out the chemical boilers in a standalone plant with steam engines will solve that, as a load spike beyond what the chemical plant can handle would still need to be caught somewhere. Only having the turbines already supplied with 500dgr steam continuously would solve the sudden max load issue, but that would, at present, mean a nuclear-only plant, with a separate chemical plant as primary, which means you've got a bunch of turbines just sitting there doing nothing...

Third try (Screenied): Refined the system from the second try. Added a bunch of Accumulators somewhere else on the main grid so that battery capacity is not an issue. Circuit network switches between chemical and nuclear on conditions. Red signal is made active to deactivate the chemical boilers on the following conditions:

- No chemical fuel available (checks belt inventory): Nuclear power only.

- "White" signal on the green plant-wide circuit network. Signifies that the system shouldn't use chemical fuel and nuclear is preferred.

- Accumulator level falls below 75%. Means the plant is overloaded and needs to switch to higher energy steam. This level is set high since it takes a few seconds for the turbines to get rid of the low energy steam, so the switch should be as early as possible. The accumulators are on a latch, and chemical is switched back on once they reach 95%

Overall conclusion: Without the ability to upgrade low energy to higher energy steam, hybrid plants are still possible, but carry significant drawbacks. A simple, tile-able design seems a thing of the past, unless you back it up with a big blob of batteries somewhere (which I eventually decided to just do). Even then, the system switches between chemical -or- nuclear, instead of having the option to combine them, and the chemical part has only roughly a third of the power producing capacity that the turbines offer at maximum. If power requirements are high, chemical will barely be used. If you prefer instead to make full use of chemical power and use nuclear only when chemical doesn't cope, I recommend a separate chemical power plant with slightly more steam engines then the boilers can service, and a small steam buffer. Once the steam buffer isn't at 95% or above, fire up the nuclear plant. But you'll have a nuclear plant on hot standby that way, most of the time, which is also not efficient...

Share your thoughts. How would you design a hybrid power supply?