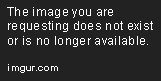

I thought about doing that too with my build... I just can't do it currently because there's no room behind the turbines... There's a rail track in the way and I can't move it. xDAeternus wrote:[Edit2] Realized too late that having the heatpipe where it is isn't convenient. Made a slight modification by adding 2 more tanks to the end of the turbines, crossconnecting them with underground pipes. That frees up room between the turbines all the way to the heat exchanger - I run the heat pipes that way, which brings the input for the heat pipes behind the turbines (where you usually want your reactors). That allows you to basically put a row of reactors at the far side of the turbines. Since reactors themselves also act as heat pipes internally, it's not needed to run heatpipes to the reactors furthest away from the turbines - they'll handle that internally.

That said the reactors will only transfer as much as 10GW internally, afterwards you'd need a heatpipe for each additional GW.

I'm still thinking about what is the best locations to place the reactors at. Perpendicular behind the Turbines? Parallel to the exchangers/Steam Turbines? Something else?

The problem is definitely that the underground pipes are just 1 tile to short to cover the distance of 2 reactors.

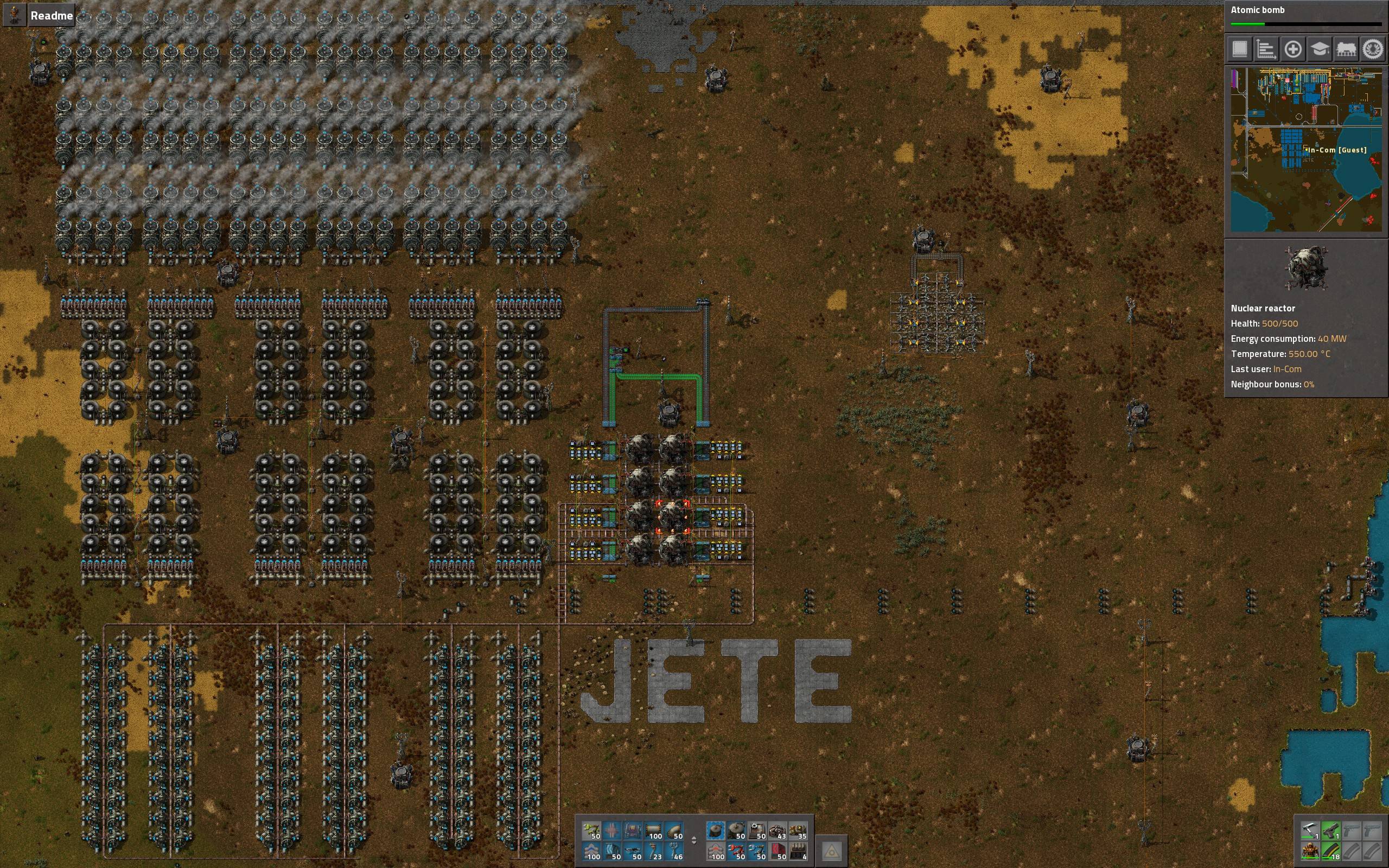

I also thought about changing the ratio to 1 Offshore Pumps : 20 Boilers : 8 Heat Exchangers : 20 Steam Turbines... per row. It would be an extremely long build but it would make the most out of a shore line. The problem is that each 2 additional Reactors add another 320MW... and that's where the 0.5 : 4 : 10 build becomes extremeley wide at the shoreline extremely fast. And if you don't use the shore it becomes a tedious underground pipe mess of routing that many offshore pumps somewhere else inland.