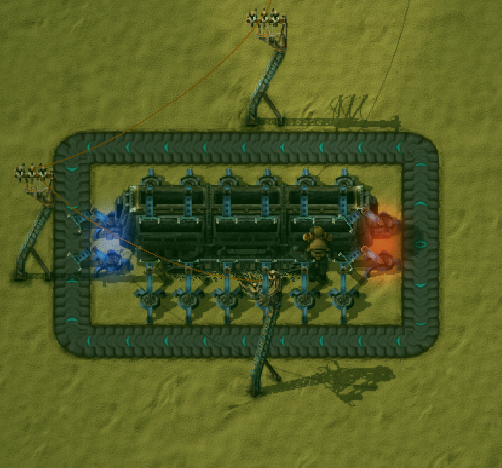

And the first item i put in always got taken out through the 4th from top left, until I put something else in. Then everything started cycling through the 1st from top left, even after emptying everything and starting over. In short, I have no idea what is going on or if it's even deterministic (which it should be, right?)

Furthermore, what happens when a factory that needs some item has several inserters which can supply it? Which one does? Do they take turns? Does anybody already know???