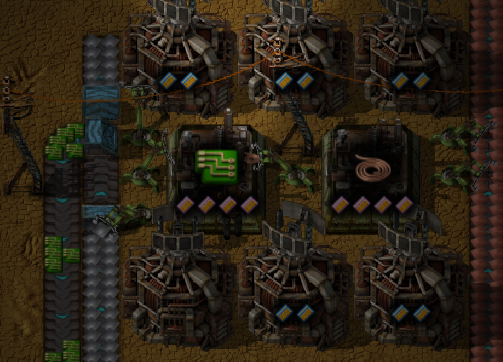

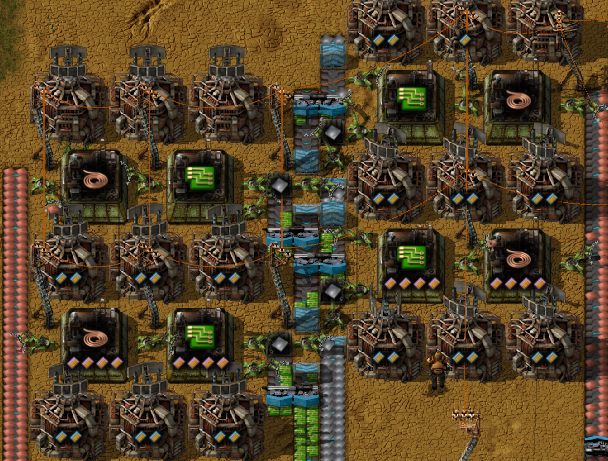

Since with prod3 modules cable:circuit is about 1:1, the setup is simple:

Every plant has 4 productivity modules and 6 beacons for speed 4.25 (+240%) and productivity 1.4.

This should produce 11 circuits/s using 9.5 copper and 7.9 iron, with 23.8 cables/s as intermediate (see below). From a simple test setup, a stack inserter can move 26.5 items/s between containers (so the cable is fine with a single inserter), 12.5 items/s from container to belt, and 11 items/s from belt to container (probably slowed by the jittering in picking up items from a moving belt). So, in theory a single stack inserter should be enough for all input and output.

What I see, however, is that circuit production is occasionally stalled by lack of iron, while the cable production runs fine. This is strange, as iron requirements are lower than copper requirements (since the circuit plant runs a bit below max).

So, what I think is the problem is that the iron inserter only starts inserting when the iron input buffer < 2, and before the inserter gathers the 12 iron and puts them in the assembler, it runs out of iron. What I don't understand, however, is why the copper input doesn't stall in the same fashion (the screenshot shows two inserters from the copper belt, but it runs fine with a single inserter as well). Does the output buffer come into the calculation at any point?

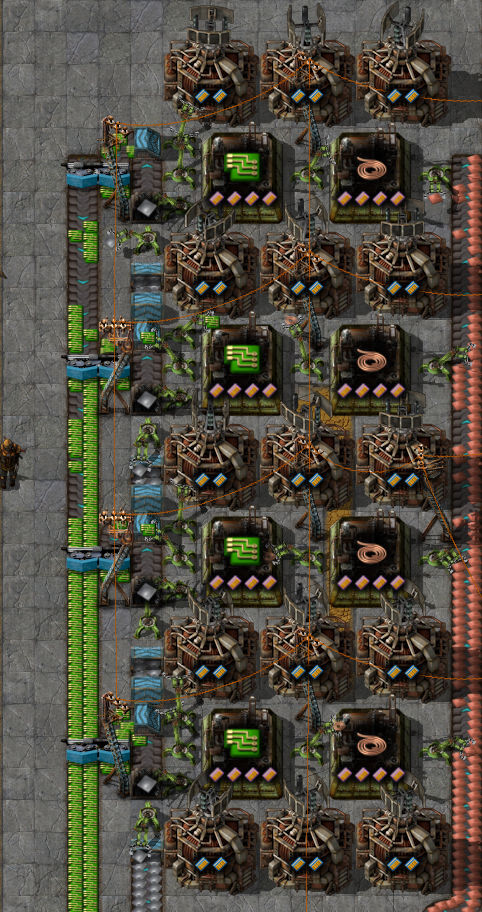

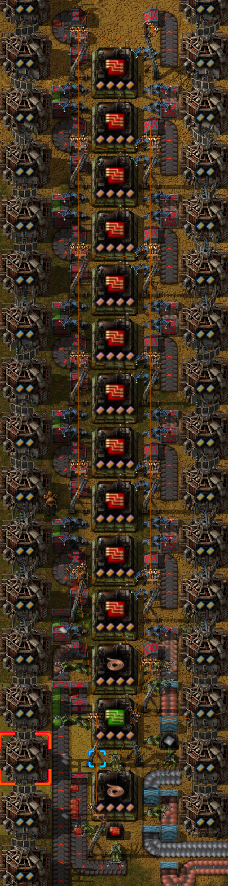

A workaround is to put a chest between the iron belt and the assembler. This allows the stack inserter to work more quickly as it no longer needs to gather material, and the assemblers seem to work more or less full time:

So, my questions are:

1) Why can't a stack inserter keep up with iron input for the circuit production?

2) Is there a better way to deal with this than the buffer chest? (two stack inserters from a belt doesn't seem to help)

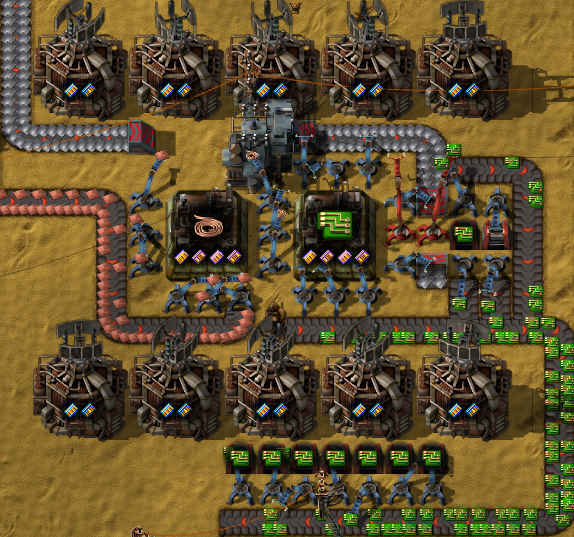

3) What is *your* design for end-game circuit production without bots?

4) Are there any "scientifically valid" numbers on stack inserter speed from/to belts/containers?

(never mind the chest consuming the red circuits, that's just the test setup)

(never mind the chest consuming the red circuits, that's just the test setup)