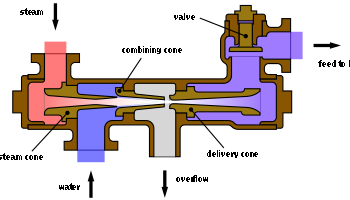

This picture shows pretty much the steam engine I'm talking about: https://en.wikipedia.org/wiki/File:Rank ... layout.png.

The way I imagine a pipe, when you have a pressure differential between two points in it, there water flows there and

pumps create pressure differential around themselves (lower pressure in front of the pump, higher pressure after the pump).

Now, the part I don't understand is what a boiler does. When the water is heated up, I think that it should increase pressure, but i also imagine a boiler as some sort of a fancy pipe, with no direction different from the other. So how can it increase pressure on the hot end without causing it to reverse the flow?

This is not directly related to Factorio, although some day I'd like to change the current pipes to be more realistic.