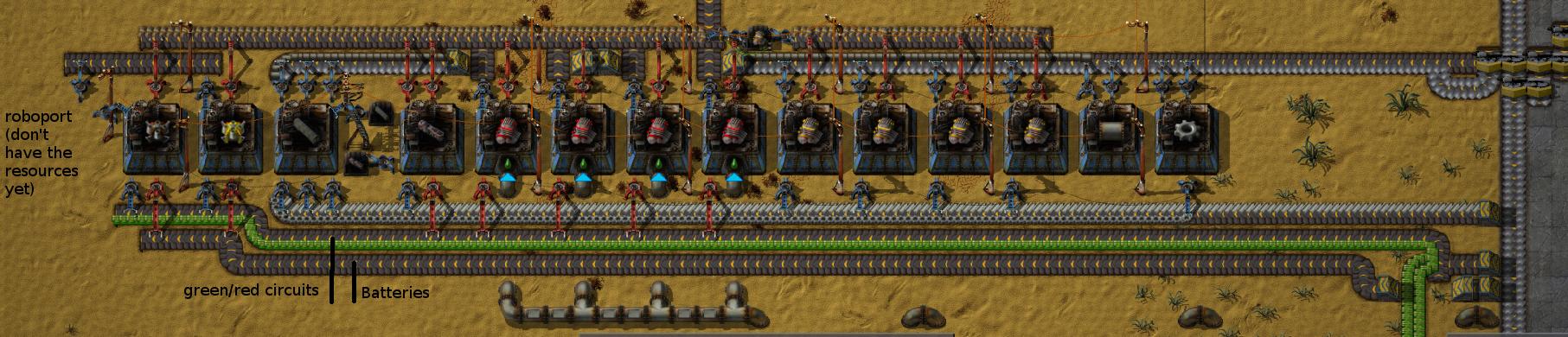

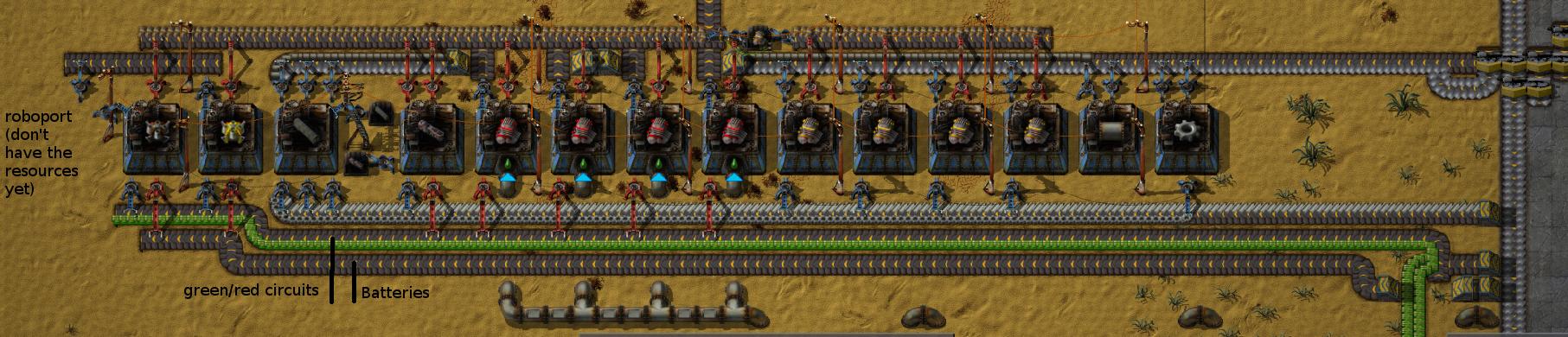

I tried to make my own setup and it looks like this:

I'm not really happy with it so I wanted to see some of your setups.

update: I forgot to add robot frame production

Thanks to everyone for the cool setups and explanations

thanks for the answer, can you maybe post a screenshot of your setup?SyncViews wrote:Well an engine takes 20 seconds, an electric engine needs 1 engine and also takes 20 seconds, and a robot frame needs one electric engine and is again 20 seconds.

Which means if you use all the same assemblers and modules, you can just have 3 assemblers in a line with a single inserter between, no belts (engine -> electric -> frame) and repeat the desired number of times.

When feeding frames to the logistic and construction bot assemblers, I personally recently put all the frames onto one belt, then had a splitter just before the bot assemblers to ensure an even share when both are in demand. The bot assemblers then feed directly into separate passive provider chests (limited to say 400 units).

Standalone engines and electric engines are in far less demand, I just put an extra pair of assemblers in that dont feed to a frame assembler, but instead fill a chest upto 50 units.

yes, I also just saw I forgot the robot frame productionOptera wrote:That screenshot is missing assemblers for robot frames.

Generally the 1-1-1 works fine. I tend to prefer 2-2-1 so i have spare engines.

that looks very cool! maybe I'm gonna try something like thisOptera wrote:That screenshot is missing assemblers for robot frames.

Generally the 1-1-1 works fine. I tend to prefer 2-2-1 so i have spare engines and can use prod modules for the engines. It needs some manual feeding with batteries and red circuits until the first bots are done though.