If you guys manage to get a true and accurate procedural rating system to work, give IBM or Google a call, I'm sure they'd be interested in your creation of A.I.

Let's see your clever builds

Re: Let's see your clever builds

With a selection of pre-determined layouts, making that rating into a conformity index, rather than a cleverness one.

If you guys manage to get a true and accurate procedural rating system to work, give IBM or Google a call, I'm sure they'd be interested in your creation of A.I.

If you guys manage to get a true and accurate procedural rating system to work, give IBM or Google a call, I'm sure they'd be interested in your creation of A.I.

Re: Let's see your clever builds

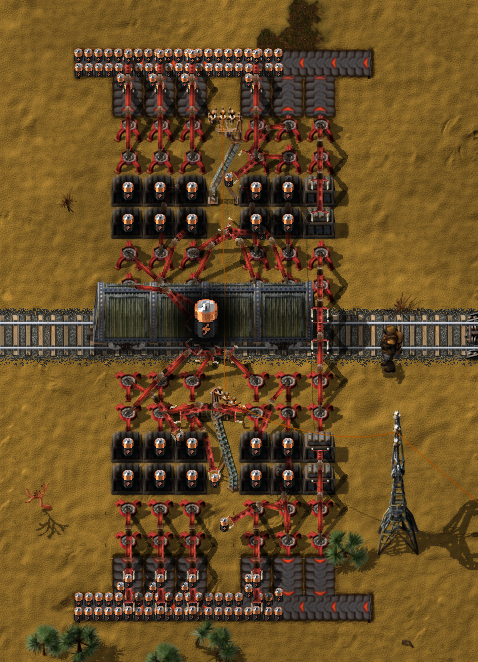

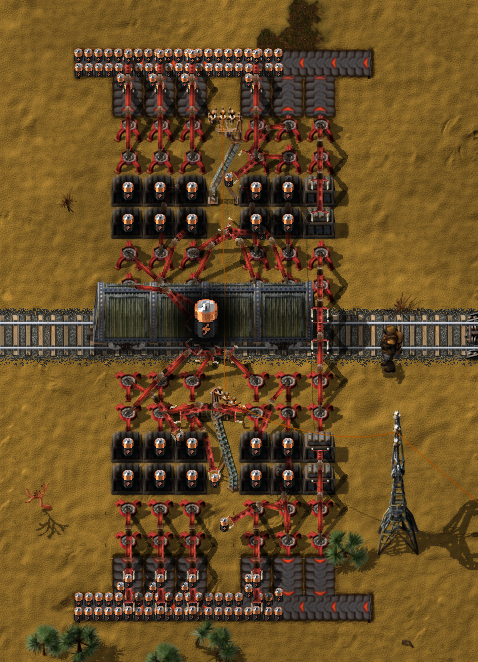

In an attempt to bring things back on topic:

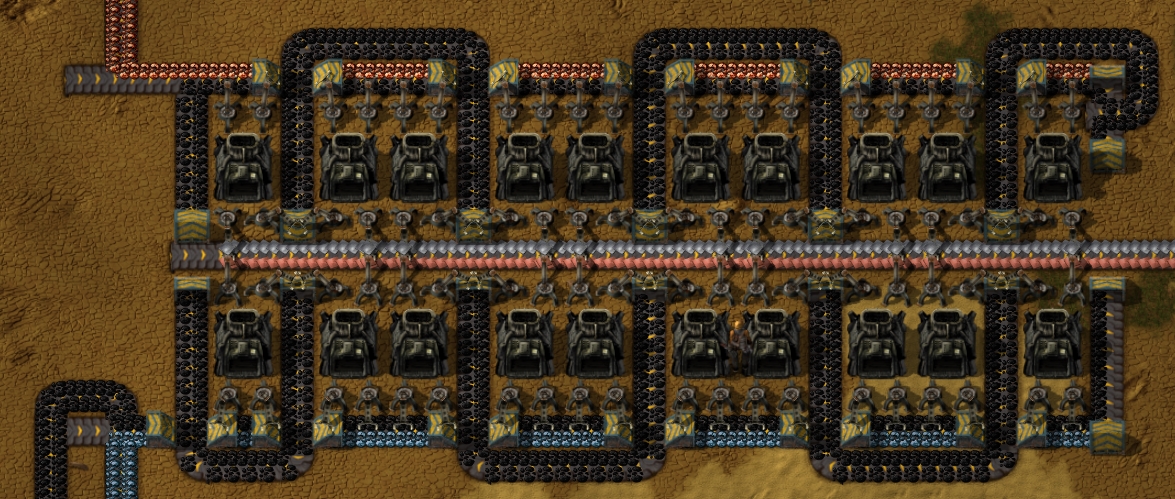

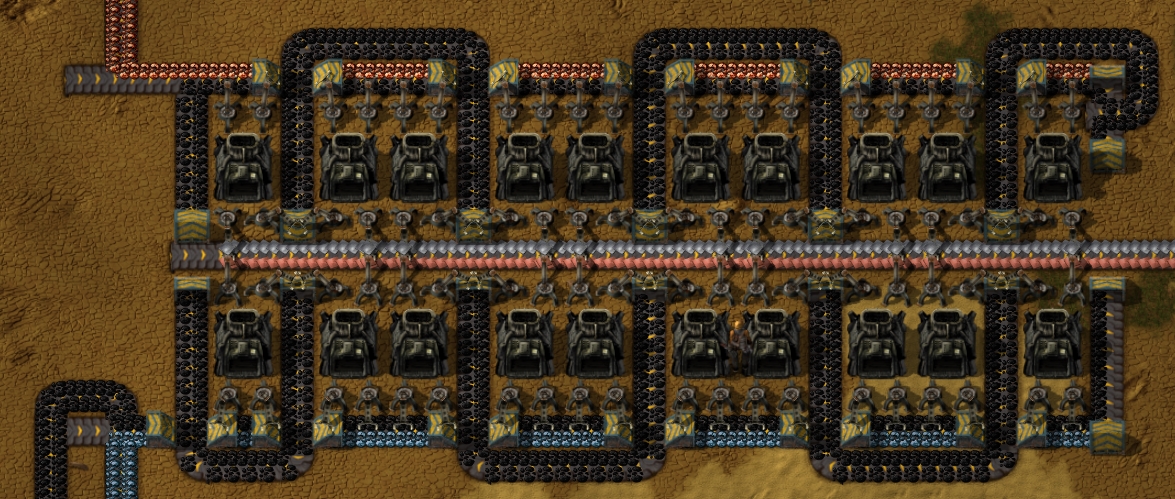

I built a testing rig to see if there was a faster way to load/unload a train. There is. Two rows of long-handed inserters are a little bit faster than fast inserters. Side advantage: double buffer storage from the 2 rows of chests required to make it work.

I built a testing rig to see if there was a faster way to load/unload a train. There is. Two rows of long-handed inserters are a little bit faster than fast inserters. Side advantage: double buffer storage from the 2 rows of chests required to make it work.

Re: Let's see your clever builds

Holy Moly!

They really can move stuff around. I especially like the fact it's easily possible to have them fill both sides of the belt:

They really can move stuff around. I especially like the fact it's easily possible to have them fill both sides of the belt:

Re: Let's see your clever builds

You beat me to showing a test stop in action. The disadvantage to this build is the 48 inserters it takes to make it work. I think I figured out the fastest way to do a train stop in vanilla.

Re: Let's see your clever builds

Good point. Hmmm. You need to measure the throughput of the system, too. And, well, that cannot be automated.hoho wrote:How would you differentiate between random mess of belts, splitters and inserters from something that actually does something?

Cool suggestion: Eatable MOUSE-pointers.

Have you used the Advanced Search today?

Need help, question? FAQ - Wiki - Forum help

I still like small signatures...

Have you used the Advanced Search today?

Need help, question? FAQ - Wiki - Forum help

I still like small signatures...

Re: Let's see your clever builds

Smelting without electricity

Re: Let's see your clever builds

What's up with the snaking coal line?Neotix wrote:Smelting without electricity

Re: Let's see your clever builds

He uses them to keep the Burner Inserters on the output side filled with fuel. It's working but it looks really awkward.mike_smit wrote:What's up with the snaking coal line?

I question myself what's up with all the guys trying to do everything without electric power all of a sudden.

Last edited by MeduSalem on Mon Feb 16, 2015 10:00 pm, edited 1 time in total.

Re: Let's see your clever builds

To keep the burner inserters working on copper and iron

Re: Let's see your clever builds

why not like this? seems to me a more future proof design

EDIT*************

here is the full screenshot with attachment to main bus

EDIT*************

here is the full screenshot with attachment to main bus

Re: Let's see your clever builds

How do you keep the main engines turned off? With the pumps? If I understand correctly, whenever you have enough energy in your accumulators, the burner inserter doesn't get fuel so the pumps don't let any water go through. Is that correct?MadZuri wrote:I can't find the original thread, but here seems like a good place for itBootstrap adaptive power supply, it activates before you have a power failure. This is because of the way accumulators work when they are connected to multiple power networks. It maintains 0 charge, and eats enough power from the main grid to power the inserters and light. Right before your main accumulator bank is completely discharged, the dummy one here can't charge fast enough to run the inserters and the burner inserter can grab the fuel. It is a boot strap because it powers the later steam engines by powering the pumps. Without the accumulator, it works just like any other adaptive steam engine setup. Enjoy.

I know for a fact that each 10 engines require 13 or 14 boilers (depending on the travel distance), is there a trick to only use 1 bootstrap steam engine for like 40 steam engines (4 water input sources)?

Edit: Found https://forums.factorio.com/forum/vie ... f=5&t=6066, that could probably work right?

Re: Let's see your clever builds

Yes, I keep the main engines turned off by removing power from the pumps. And yes, the inserters prevent the burner inserter from getting fuel. If they lose power, the bootstrap steam engine powers up and allows water to flow to the main engine system. Each cluster of 9 engines needs a bootstrap engine. I've since improved that design, but I didn't think anyone was interested in it. I swapped to a power sensor, and intentionally mixed fuel line feeding the bootstrap engines. It is blueprint tileable, but you gotta remember to remove the cables in the middle. My other design, just south of this one, uses 2 bootstrap engines to power the pumps for 70 steam engines. I like to play around with this sort of thing. I hope this helps.Talguy wrote: How do you keep the main engines turned off? With the pumps? If I understand correctly, whenever you have enough energy in your accumulators, the burner inserter doesn't get fuel so the pumps don't let any water go through. Is that correct?

I know for a fact that each 10 engines require 13 or 14 boilers (depending on the travel distance), is there a trick to only use 1 bootstrap steam engine for like 40 steam engines (4 water input sources)?

Edit: Found https://forums.factorio.com/forum/vie ... f=5&t=6066, that could probably work right?

Re: Let's see your clever builds

Thanks for the answer!

I'm seriously going to experiment with this! Also, if you could export the blueprint, that would be awesome

Anyone viewing this topic is, I guessMadZuri wrote:[...] but I didn't think anyone was interested in it.[...]

That helps! I love how the first one looks(red inserter trick),and like the way the boilers are set in the second.[...]uses 2 bootstrap engines to power the pumps for 70 steam engines..

Can you explain why you have mixed fuel?[...] intentionally mixed fuel line feeding the bootstrap engines.

I'm seriously going to experiment with this! Also, if you could export the blueprint, that would be awesome

Re: Let's see your clever builds

Mixed fuel for the staggered burn times, each line is powered for a different length of time. It helps with my wildly varying power demands. I'll do better than blueprint export, I'll email you the save file, send me a PM with your preferred address.Talguy wrote: Can you explain why you have mixed fuel?

I'm seriously going to experiment with this! Also, if you could export the blueprint, that would be awesome

(edit) I can't seem to get the Foreman mod to work, so no easy BP export...

Re: Let's see your clever builds

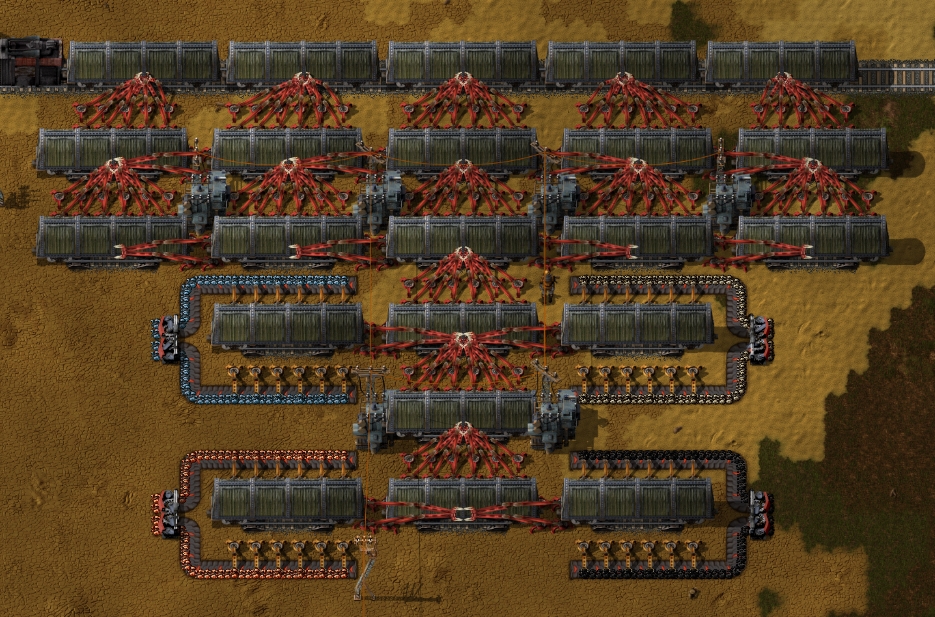

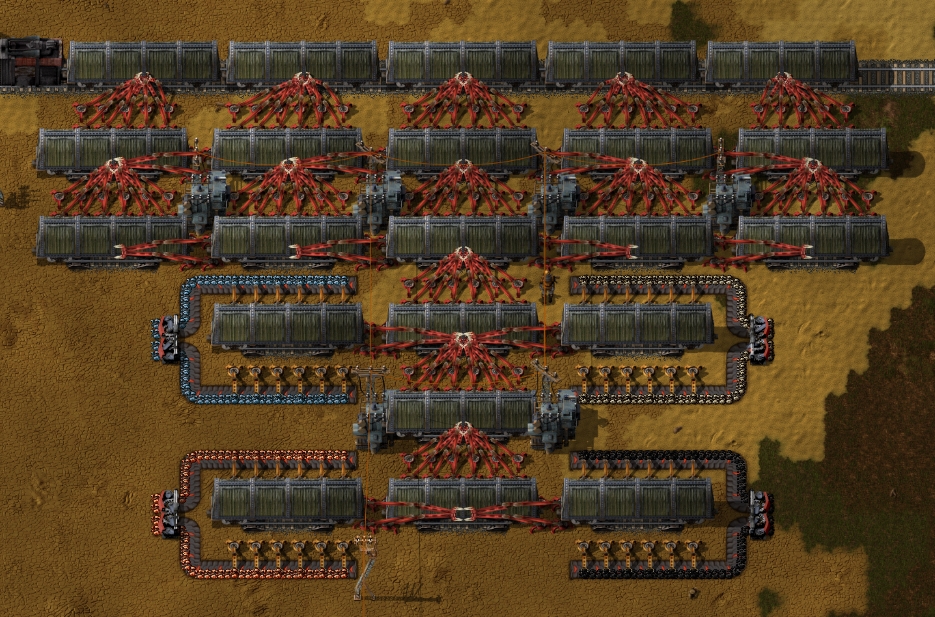

Wagon Sorter

Train can transport any kind of items (unsorted). Each wagon in sorter have set filters to receive only specific kind of items. For example first row have set to receive Iron Ore, Copper Ore, Coal and Stone. Second row is only for faster unload and transport Iron Ore and Copper Ore. Only wagon in the middle of the second row have all four resource. Next items are transported down and spitted on the left and right. In that way sorter never stuck because it will take only that items which have free space in sorter, and the rest will stay in train.

It's important to set filters with proper priority. On screen Iron Ore have the highest priority and Stone the lowest.

In first step Iron Ore and Stone are sorted so to the next step transportet are only Copper Ore and Coal. Of course with proper priority.

We can build sorter on both side to double sorting speed.

Train can transport any kind of items (unsorted). Each wagon in sorter have set filters to receive only specific kind of items. For example first row have set to receive Iron Ore, Copper Ore, Coal and Stone. Second row is only for faster unload and transport Iron Ore and Copper Ore. Only wagon in the middle of the second row have all four resource. Next items are transported down and spitted on the left and right. In that way sorter never stuck because it will take only that items which have free space in sorter, and the rest will stay in train.

It's important to set filters with proper priority. On screen Iron Ore have the highest priority and Stone the lowest.

In first step Iron Ore and Stone are sorted so to the next step transportet are only Copper Ore and Coal. Of course with proper priority.

We can build sorter on both side to double sorting speed.

Re: Let's see your clever builds

Blueprint string works just fine, it exports all your blueprints.MadZuri wrote:(edit) I can't seem to get the Foreman mod to work, so no easy BP export...

Re: Let's see your clever builds

Well now that's an unusual setup.Neotix wrote:Wagon Sorter

Would come in handy if you don't have smart inserters available until long after trains are running, though I'm not sure that's a particularly valid stipulation.

Definitely functional, but I wonder if there's a problem with the lack of speed from having four inserters on the front/back of each wagon (as opposed to the twelve on the sides, which should be able to keep up with any reasonable throughput requirements).

I suppose it wouldn't be much harder to extend the layout in such a way as to overcome/avoid that being a bottleneck. Something like making it three times as high and therefore having three times as many inserters feeding from the front and backs of the cars, particularly for the output wagons.

A very unusual setup, but quite interesting.

Re: Let's see your clever builds

Sorter with belts and smart inserters have that problem that it can be easily overflowed and stuck. We have to control incoming items to be sure that not wanted items are not unload from the train. In previous gameplays I was able to achieve that by controlling load in mine stations but it become pain in the ass when factory become quite large. I think that wagon sorter can be solution to that problem. Of course my setup is only prototype and it can be improved to increase speed. I'm thinking about combine it with that layouts: Mass production with ZERO belts and robots  .

.

-

DoctorWho?

- Long Handed Inserter

- Posts: 80

- Joined: Sat Jan 10, 2015 3:42 am

- Contact:

Re: Let's see your clever builds

Why did everyone leave? THIS WAS A COOL POST!!!!

And now it has died. It's so sad!

And now it has died. It's so sad!