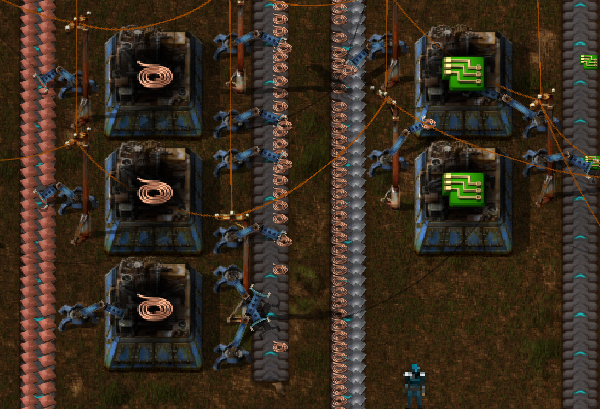

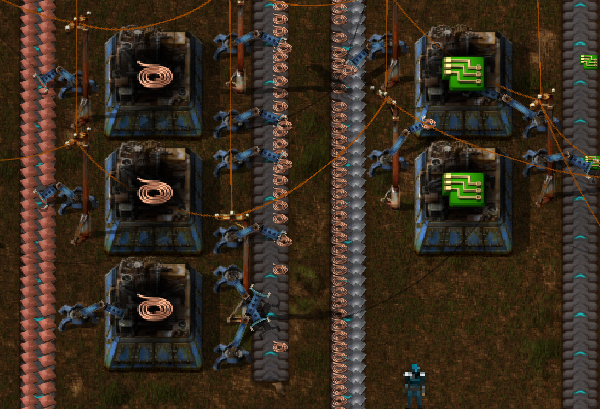

This produces ES at the speed of 96 items/minute:

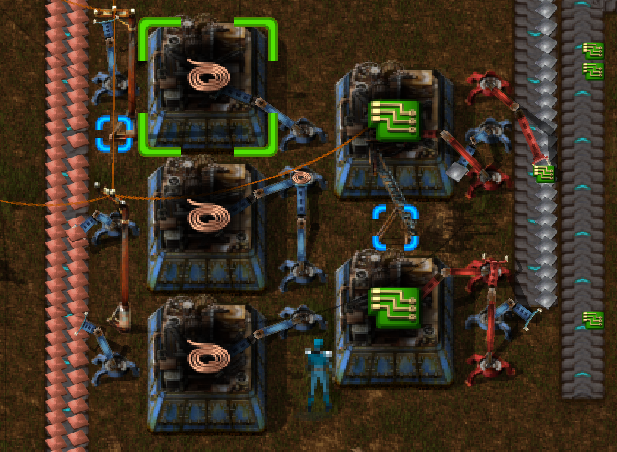

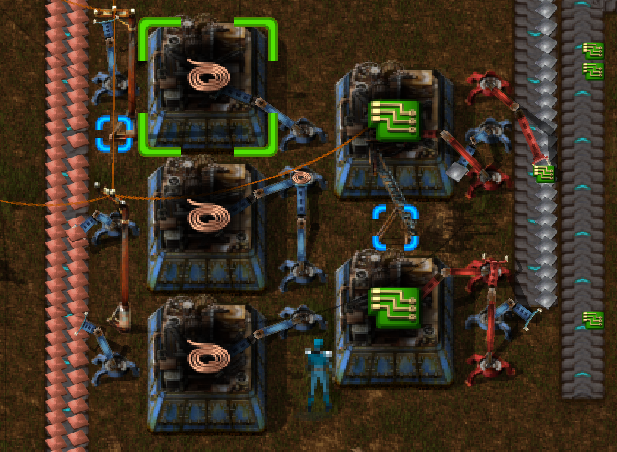

And this produces ES at the speed of 264 items/minute:

Number of inserters is the same, except in later case 4 are red instead of blue, and it takes less space

Well, you can speed up the first case to the same speed as the second by putting 3 blue inserters in front of AMs that are making ESs.ssilk wrote:It's very often discussed here, that copper wires on belts is a bad idea.

Generally yes. However, this is usually not a problem if you are using multiple inserters. If you use 3 inserters, you can, generally, move all the needs at once. Upgrade to fast/express belts and fast inserters, and things should chug along nicely. If you do it this way, you will potentially need to double-bandwith the wires for larger circuit layouts.ssilk wrote:It's very often discussed here, that copper wires on belts is a bad idea.

This looks like a great design, I'll go with this, thanks! If anyone has any other efficient layouts please poatPenrif wrote:Indeed, iron input can become a bottleneck. Easily resolved by inputing the iron from the sides:

Nevermind the stray normal inserter. Pretend it's blue.

I am haivng trouble visualizing what you are describing, but i agree that iron plate isnt the botteneck in in the OPs second pic, the bottleneck would be the long-handed inserters being too slow, correct?n9103 wrote:Personally, if I were doing a bot layout I would still have the iron on a belt, but I would have the assemblers on the copper side spaced one apart from each other with the circuits being taken out towards the copper side, (into a chest of course), with the iron on the opposite side. (Much closer to being the 2nd pic in OP, than the one Penrif posted.)

Otherwise, I usually aim for something like shown in the OP's last pic.

But in either case, the 2nd pic doesn't have iron as the bottleneck. It may have a problem with inserting copper with only one blue inserter, and it may have a problem with extracting the circuits if the AMs get module'd, but otherwise it's fine.

silman wrote:I am haivng trouble visualizing what you are describing, but i agree that iron plate isnt the botteneck in in the OPs second pic, the bottleneck would be the long-handed inserters being too slow, correct?

So what is the "best" electronic circuit design that is easily expandable and efficient?

As far as those long handed inserters go, how well do you think it would work if you replaced them with fast inserters and used underground belts to free up the path in front of them?n9103 wrote:I'm between games, so these are only mockups.

No modules.With logisticsWithout2nd red inserter removing is a must to keep up with Mk2 AMs.

If you're using speed modules, then this wouldn't keep up.

But if you're using speed modules on general circuit production, your factory needs an overhaul.

Given that this machine uses a 2:3 ratio of iron plates to copper plates, I would assume that, since one fast inserter per assembler is all that is needed for iron plates the same would be true of copper as well.Crud. I meant to test if that 2nd blue inserter for copper was required to keep up or not.

Anyways, there's what I was talking about.