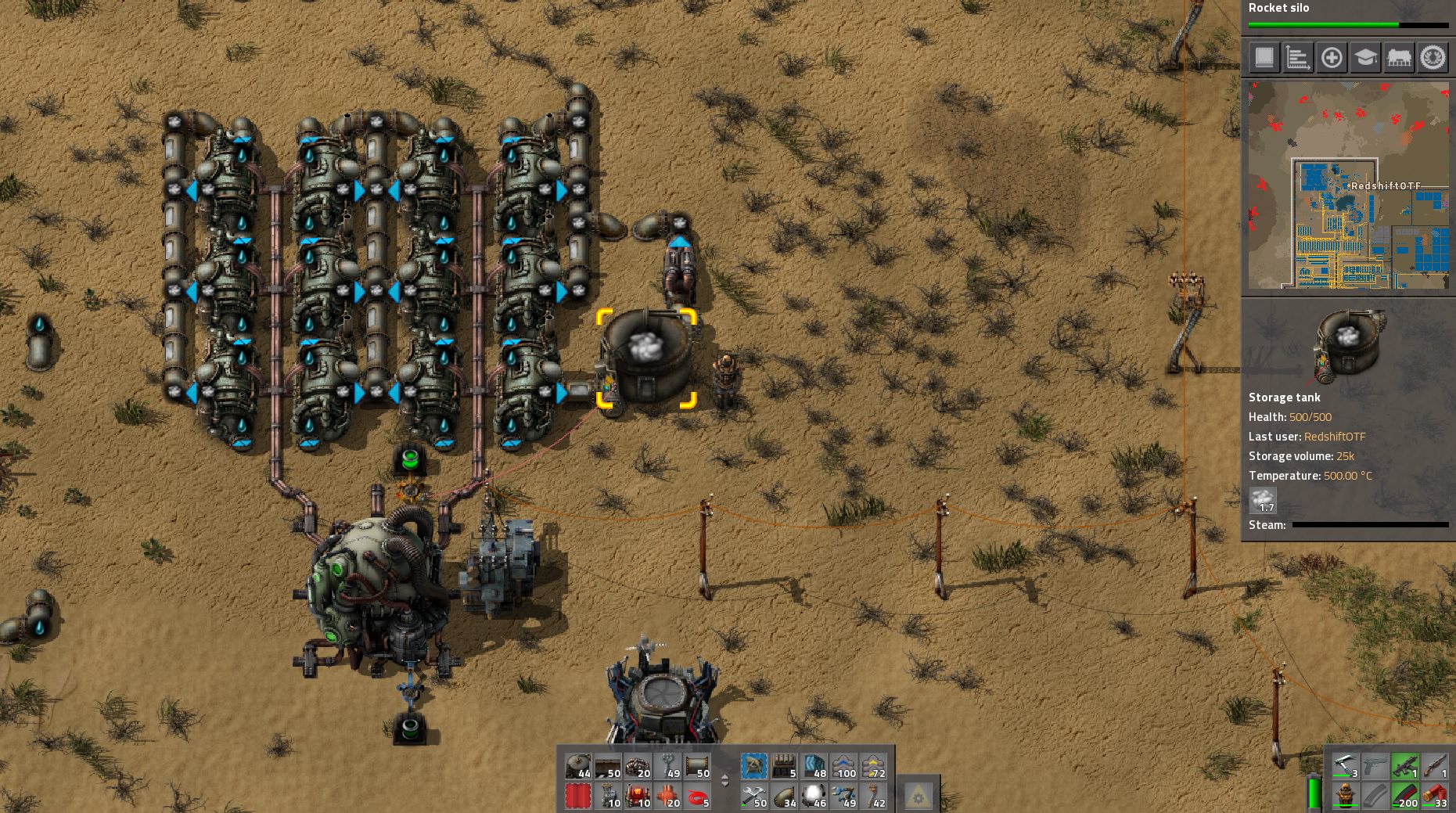

Basically you connect 1 tank to 1 of the Heat Exchangers in your power plant, add a pump to the output and then connect that to the rest of your steam. When the Heat Exchanger is running the tank will hover around 450 steam, (for a 2x2 setup. This value depends on how much steam your station is currently using), as the pump is not fast enough to completely drain the tank but as soon as the Heat Exchanger cuts out the steam level will fall to almost nothing really fast. Connect the tank to your fuel inserters using red wire and set them to run when the steam level is less than 1 for example. As soon as the fuel is inserted the steam level will jump straight back up again, quick enough that the inserters only have time to place one fuel cell into the reactor. You can use a level greater than 1 if your plant is running at full capacity and you can't afford the 15 seconds down time, (if you have reserves of steam it won't be a problem), just bear in mind that a value greater than 10 increases the chance that the inserters add more than 1 fuel cell. A setting of <1 is pretty good if the plant isn't running at full capacity and isn't full of steam.

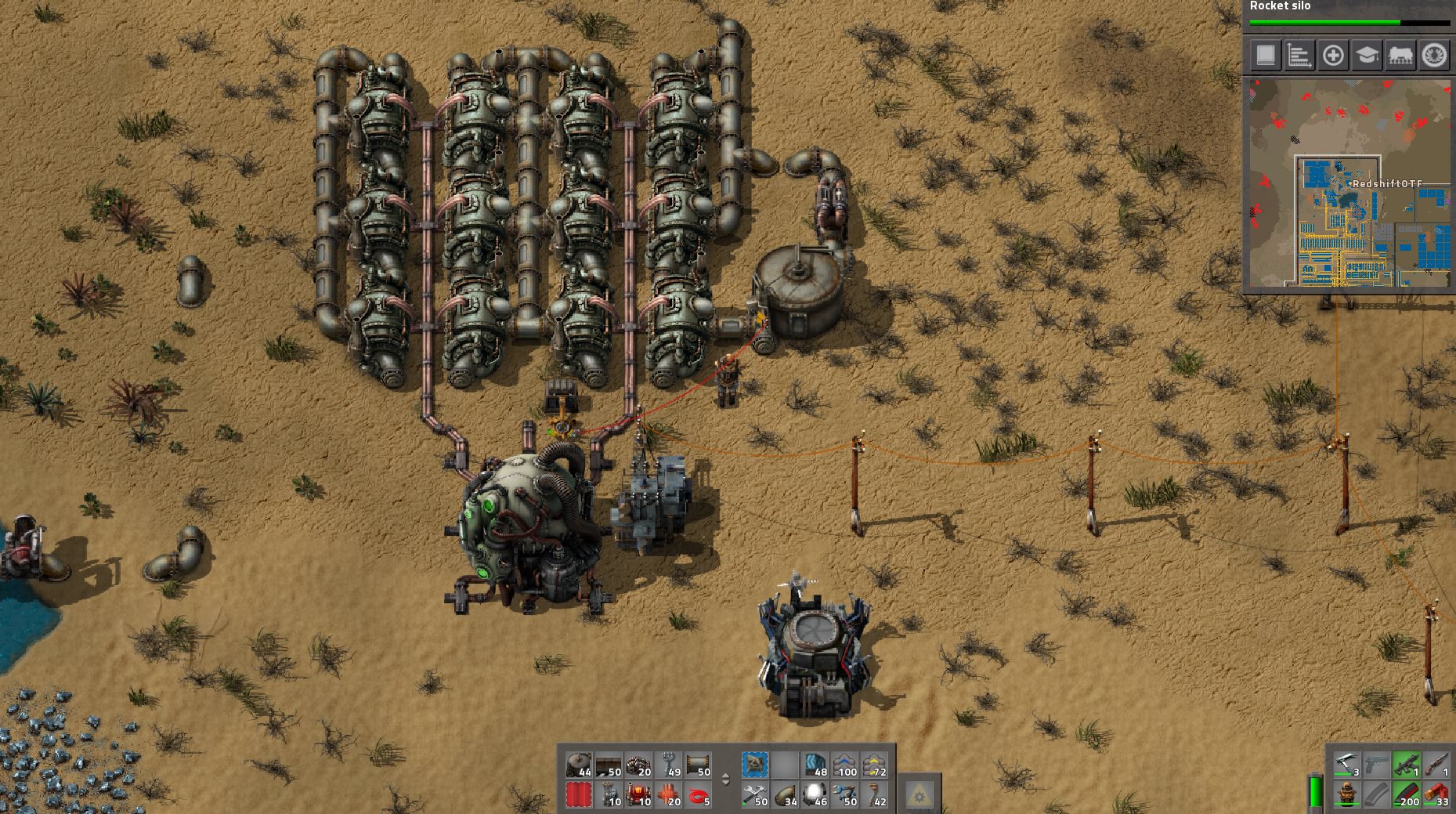

Here's a couple of screenshots of the setup.

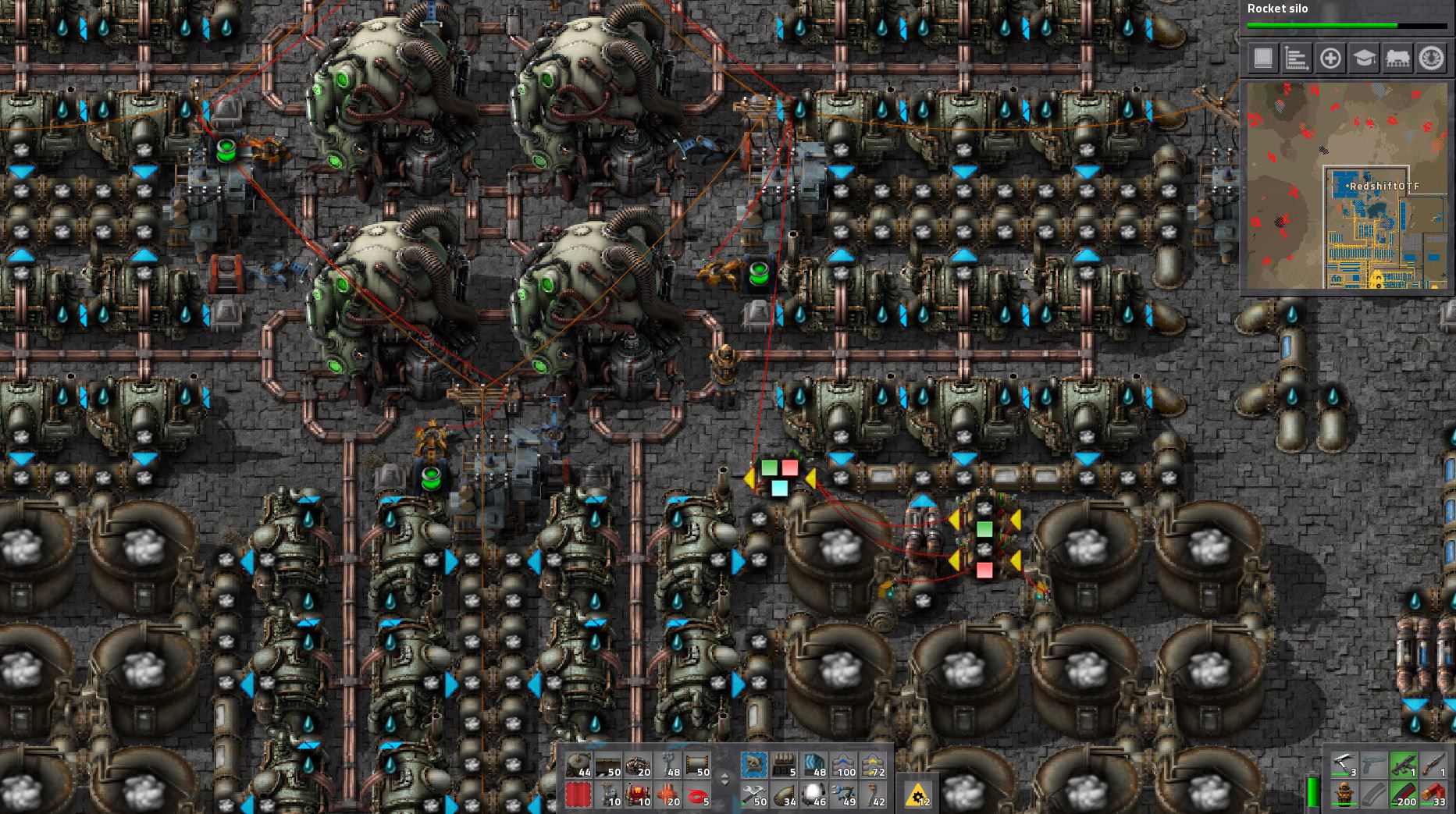

If the inserters are inputting more than 1 fuel cell it is down to the fact that you have too much stored steam in your system. To solve this you can create an AND gate where 1 input is as above and the second input monitors the steam level of your other tanks and only outputs when the stored level is say 5k, (this is better as you don't really want to activate the reactor if you have stored steam in your main tanks!).

In the above setup the green decision combinator monitors steam in the tank connected to the Heat Exchanger and pump, the red decision combinator is monitoring the stored steam in the main tanks and the red and green arithmetic combinator, set to AND, outputs blue when it receives red and green. The inserters activate when blue = 1.