I like building my heat exchangers in blocks of 16 since your first two reactors feed 16 exchangers, and after that every pair of reactors feeds another 32 exchangers (source: https://www.reddit.com/r/factorio/comme ... ar_ratios/)

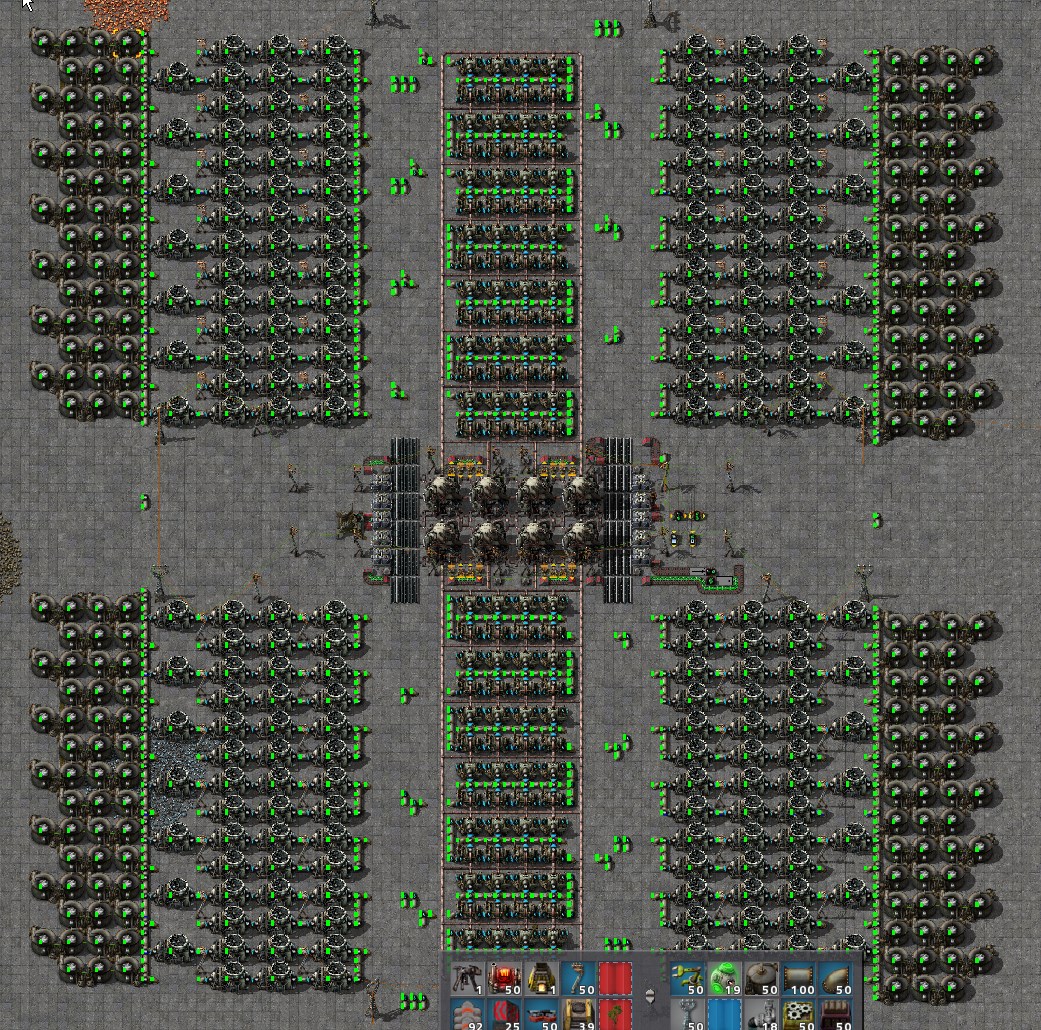

My naive design was to have a column of heat exchangers followed by two columns of turbines and a column of storage tanks. This worked wonders, but now have such large blocks near the reactor will make it difficult to stay within the limit of the heat pipe.

From what I can see, 16 exchangers under full load can be serviced up till 65 heat pipes distance. Since the column itself takes 16*3=48 pipes, this gives you only 17 pipes to connect to the reactor. If you have a 4x2 design which needs 7x16 exchangers there is no way it will fit all within 17 tiles of the reactor (right?)

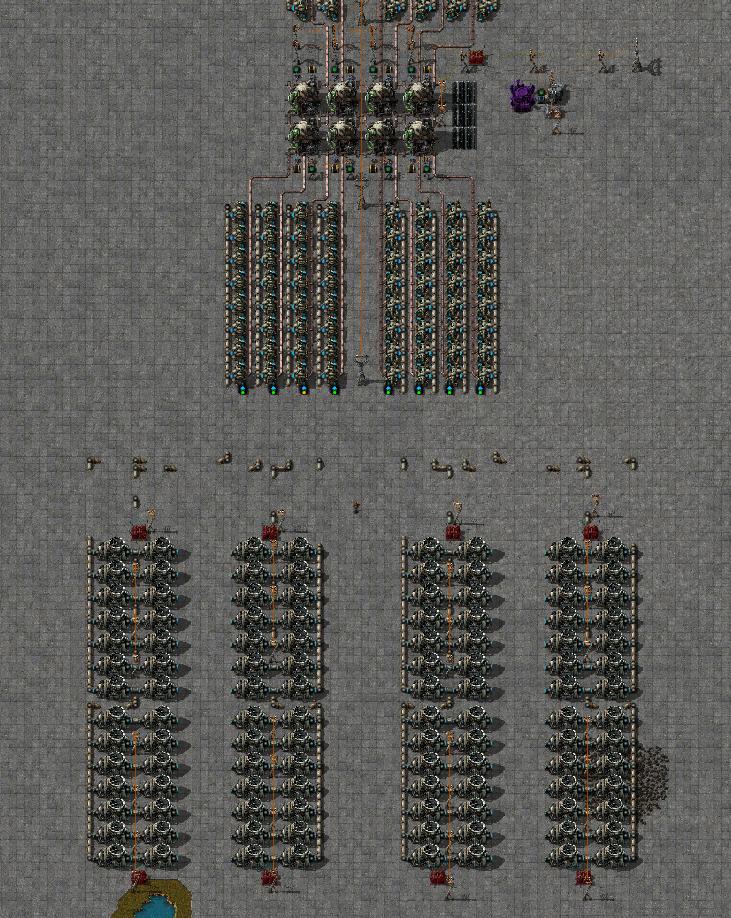

The solution is probably to separate heat exchangers from turbines. Apparently an exchanger produces about 103 steam/s (https://www.reddit.com/r/factorio/comme ... s/dgv04zb/). If .14 lore is still correct, a pipe can transport 900/s over longish distances and 1200/s over shortish distances (<14 tiles, where UG pipes count as 2 tiles?). So, the steam from 16 exchangers can be safely transported over long distances by 2 pipes.

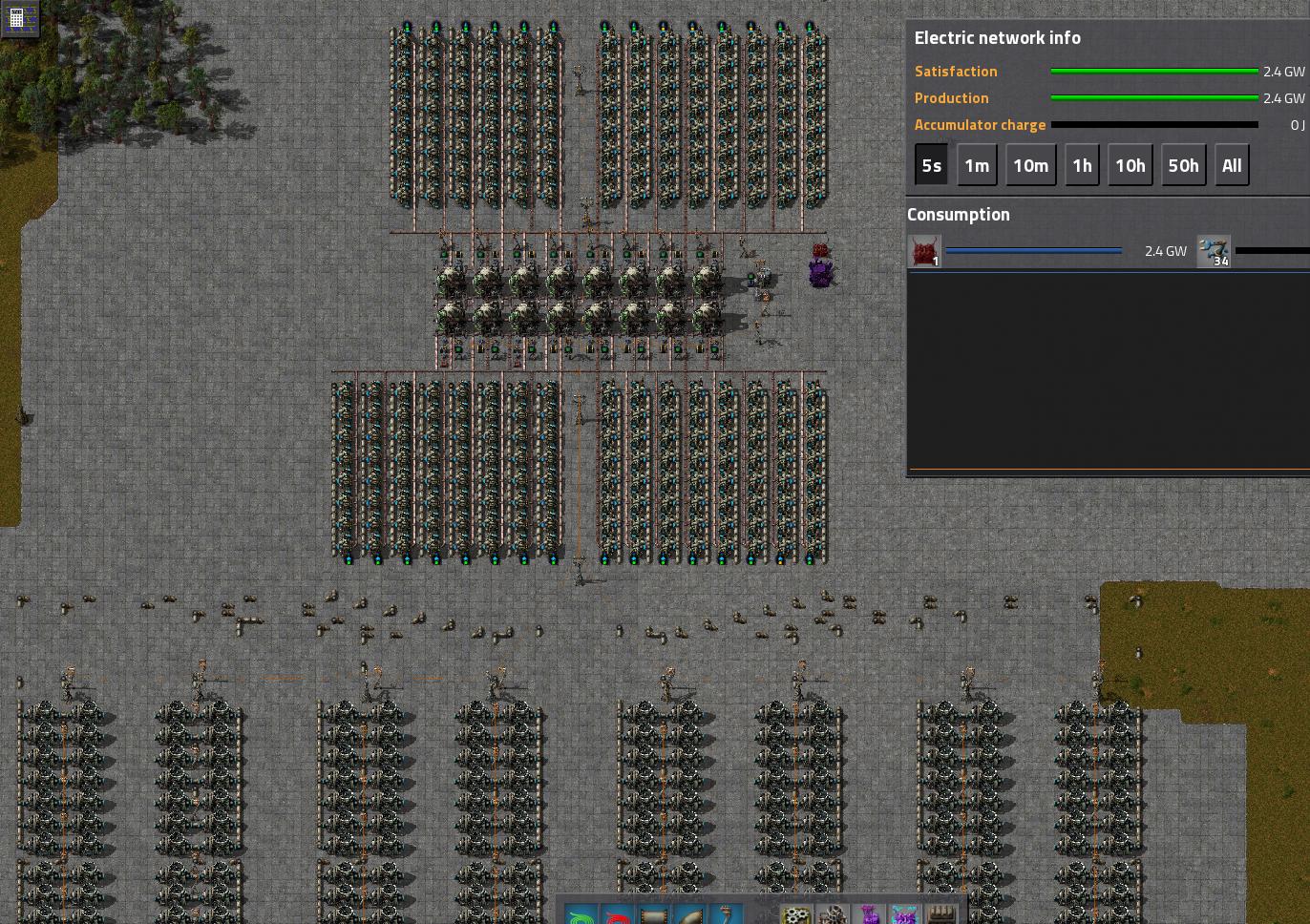

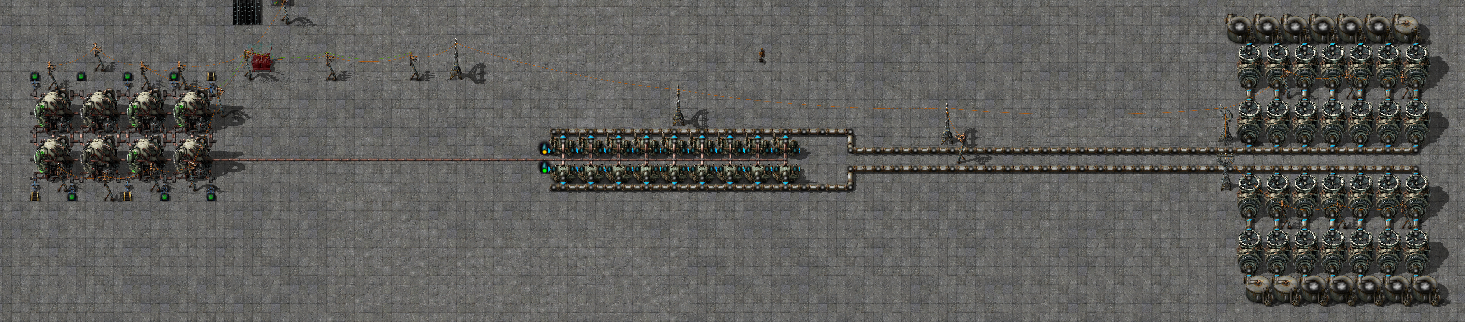

This is confirmed by the fact that this setup produces maximum expected power of 160MW:

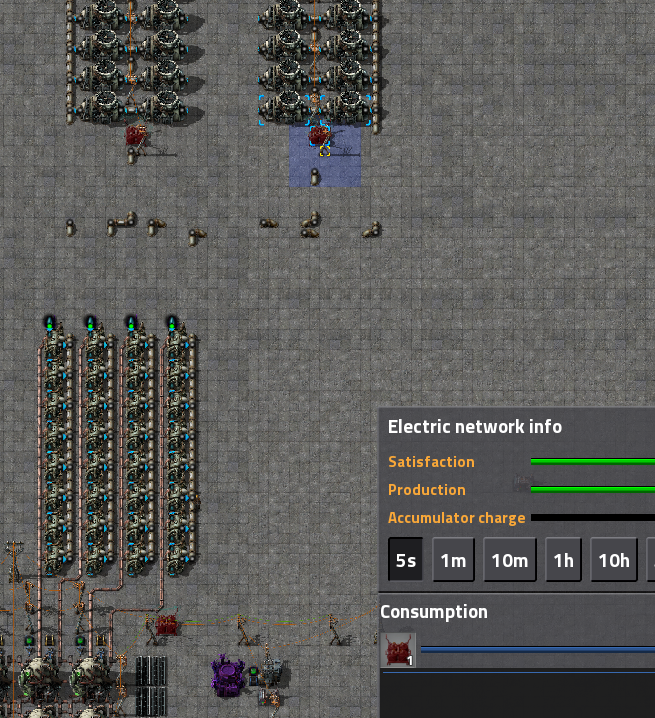

If you move the exchangers 2 tiles away from the reactor, performance drops to 140MW, apparently the 62 pipes now between reactor and furthest exchangers is about the limit.

Steam, however, we can move pretty far away, especially with the new pumps (is there a post explaining .15 liquid throughput and pumps?). Obviously you can use underground pipes to further increase allowed distance, but if the wiki is still correct you get 90/s throughput until 224 pipes, so that should be enough for most purposes.

So, I think reactor design will now have three concentric rings: reactor core >-heat pipes -> heat exchangers >- steam pipes -> turbines.

I guess that also makes it attractive to think in terms of 1 pump : 8 exchangers : 14 turbines. This puts less strain on a single heat pipe, allowing you (experimental value) 91 tiles between reactor and furthest turbine, or about 65 tiles before the start of a row of 8 turbines. Since adding a block of 2 new reactor cores requires 4x8 extra exchangers and gives more than 4 connection points for heat pipes, it seems that this should allow you to build out more or less arbitrary.