Based on the recent discussion here (viewtopic.php?f=5&t=47757), XKnight's great posts here (viewtopic.php?f=18&t=19851) and my earlier simple control design (viewtopic.php?f=208&t=47687) and the nuclear ratios at (https://www.reddit.com/r/factorio/comme ... ar_ratios/) I think I figured out a good set of components for a power plant design again that is .15.11 safe and downscales automatically for reduced loads.

The idea:

Since heat pipes should now be kept short but steam pipes can be arbitrarily long with pumps, I've separated the turbines from the exchangers to keep the exchangers close to the core. So, we we will setup a reactor with n cores feeding into m banks of 8 exchangers, which produce steam that is lead to m banks of 14 turbines+7 storage tanks. The number 8 is chosen (a) because reactor ratios are all in increments of 16/32 for pairs of cores; and (b) because of fluid mechanics: 8 exchangers convert 825 water into the same amount of steam, and a single pipe can transport that over >200 pipe distances without extra pumps. If needed, a pump can be inserted every 125 tiles to maintain enough flow.

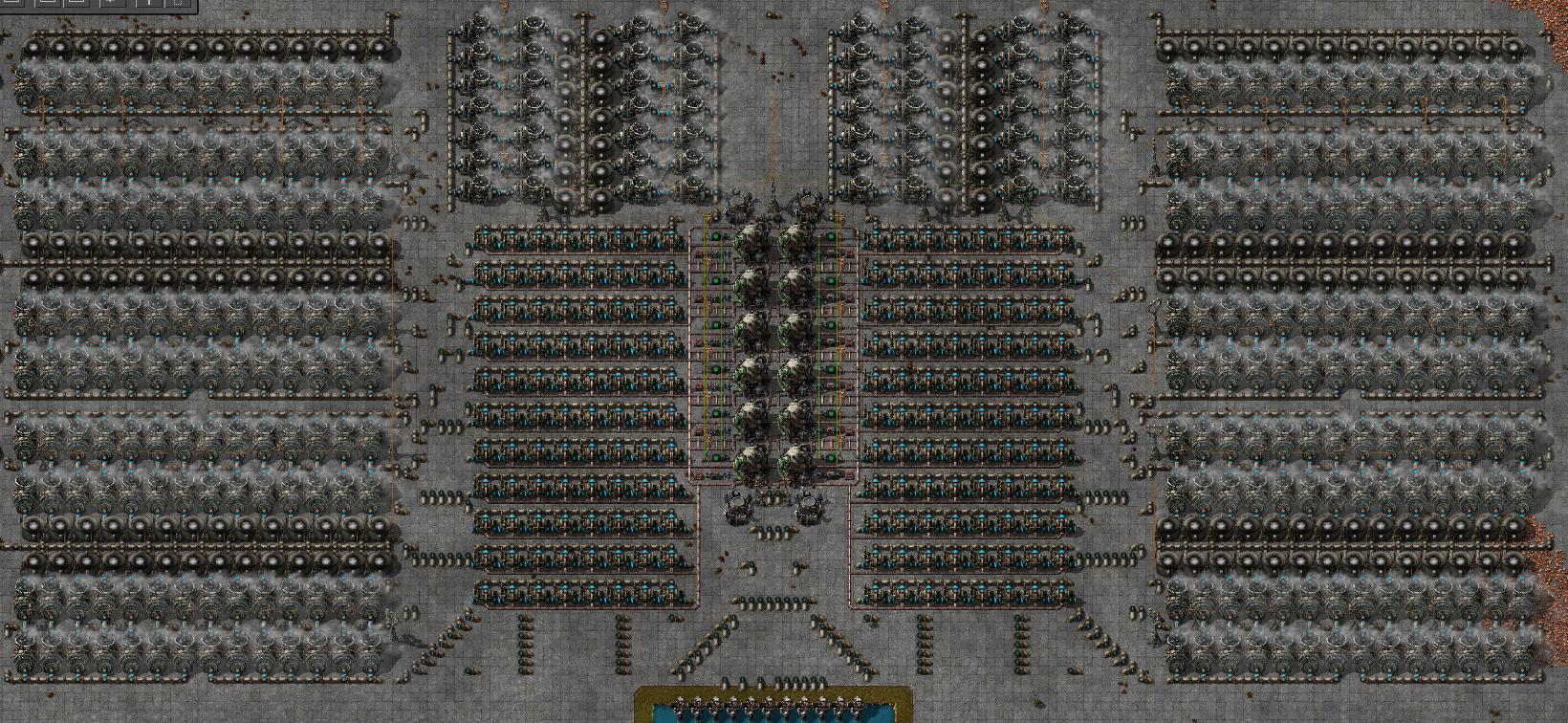

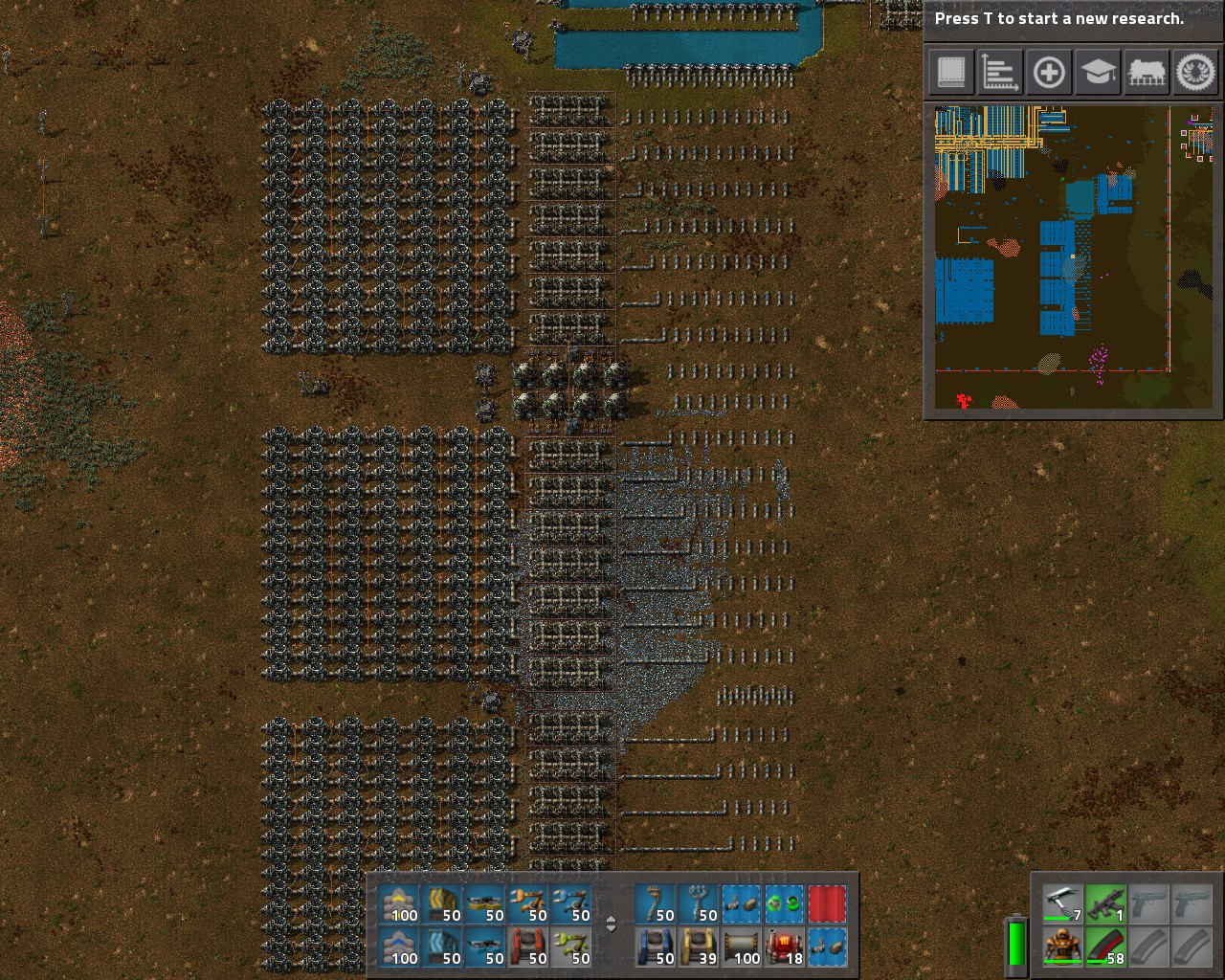

Overview screenshot

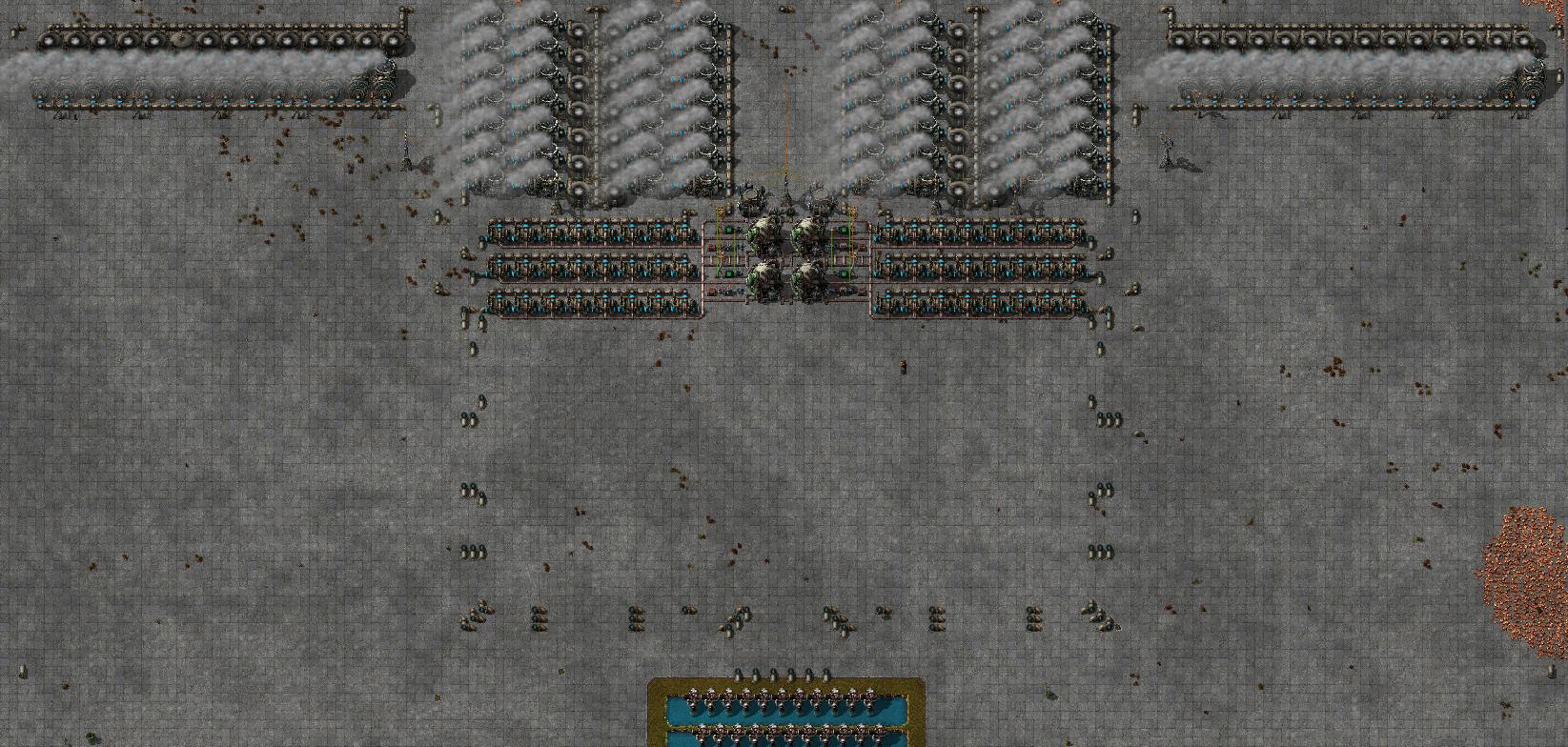

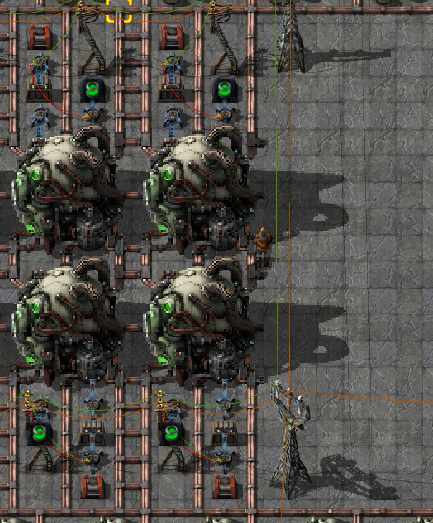

Components:1: Core and control

Control is achieved by monitoring steam in one of the storage tanks, probably best take one far away from the core, and only insert new fuel if (a) there is no current fuel in the reactor [measured by depleted fuel in the memory chest] and (b) steam < X:

(see viewtopic.php?f=208&t=47687 for combinator settings)

blueprint

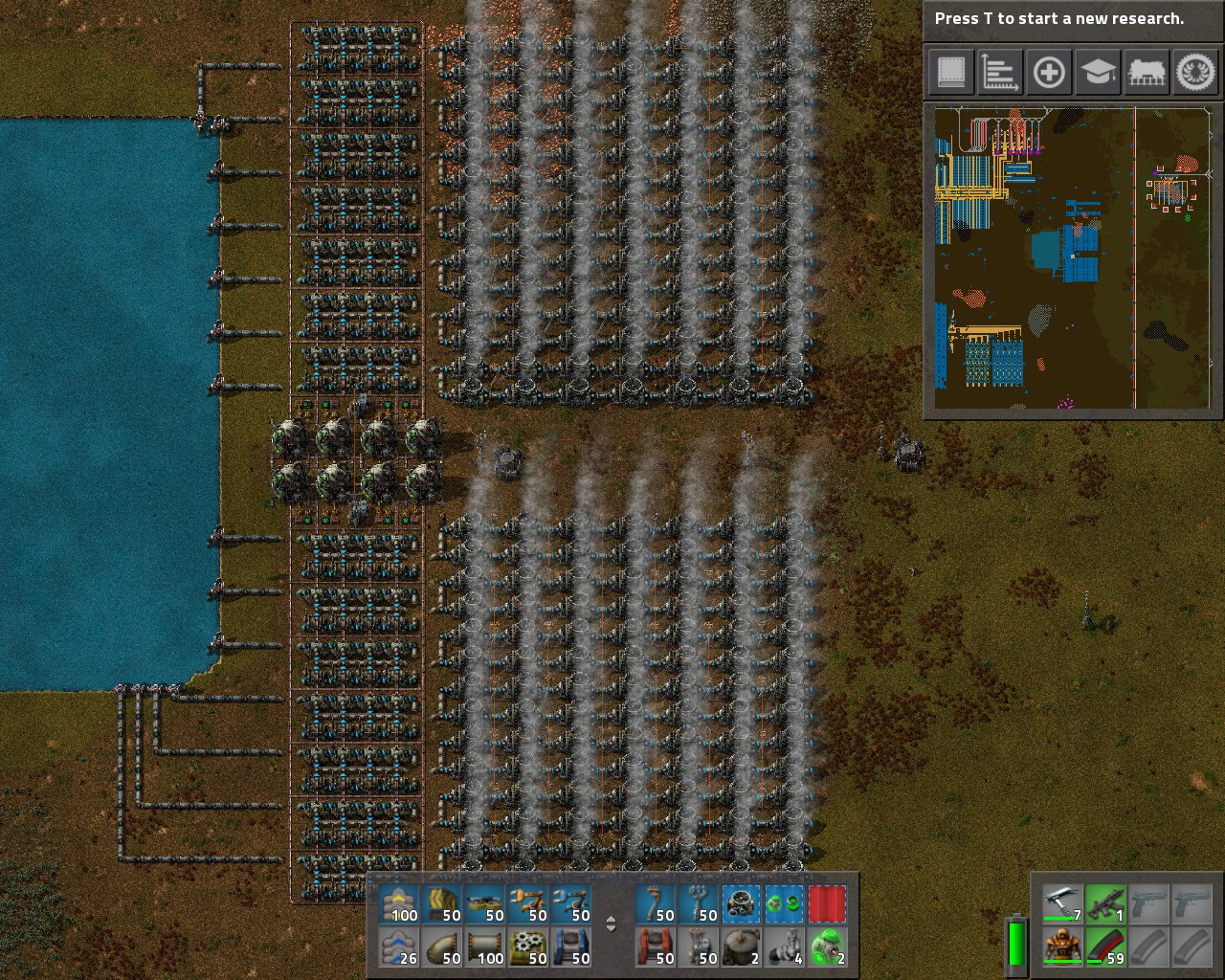

2. Heat banks

The blueprint contains 2x8 heat banks connected to heat pipe at one end and to water and steam pipes at the other.

blueprint

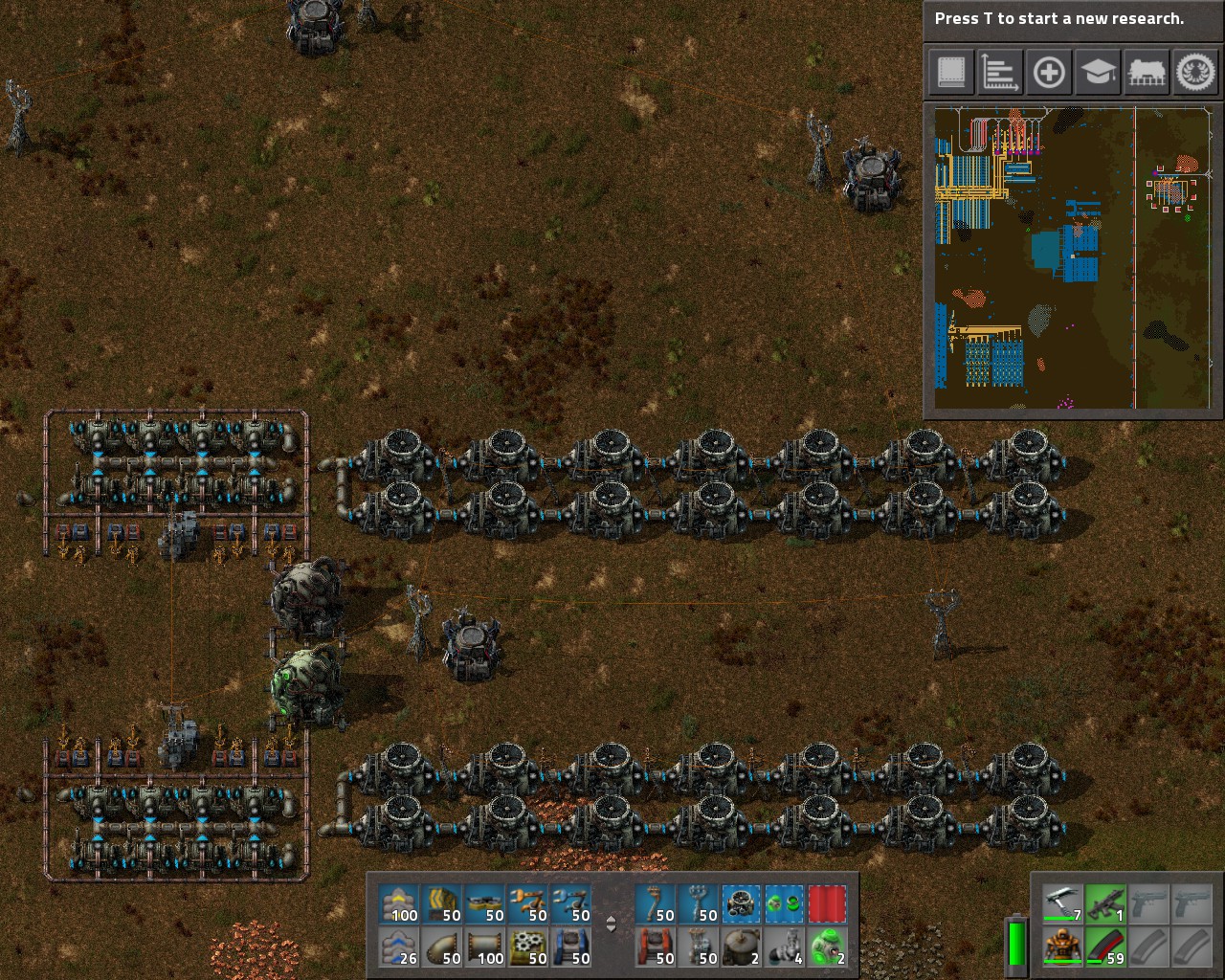

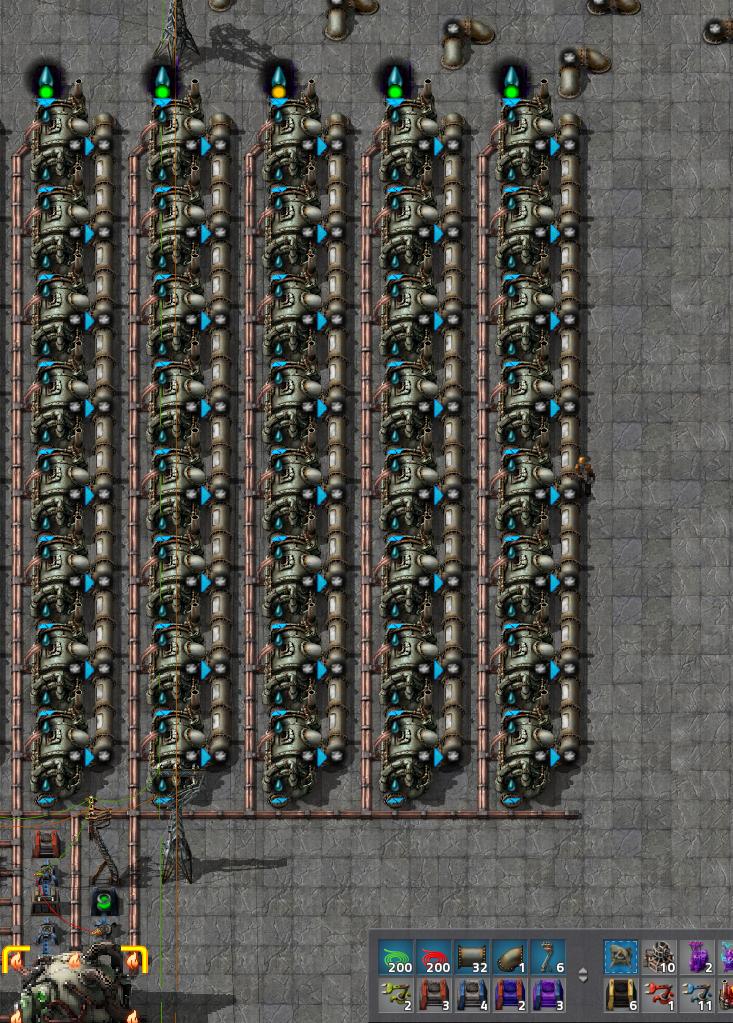

3. TurbinesTurbines are placed in blocks of 14. I place two blocks in a row with the steam pipe for the second block braided between the turbines:

By placing the blocks back to back I can connect the tanks with a steam pipe to feed to a liquification plant if needed.

blueprint for 2x14 turbines

blueprint for 4x14 turbines

Instructions: 1) Place the components: place the reactor cores and the exchangers close to each other. The turbines can be as far as you want, you need to at least leave enough space for plumbing. I would say 2 UG pipes length.

2) Connect the heat exchangers to (1) offshore pumps (1 pump per 8 exchangers) and (2) the turbines. You can use up to 251 pipe segments between offshore pump and exchangers and between exchangers and turbines, so you have plenty of space. If necessary, place pumps just before/after the exchangers and just before the turbines, and every 125 pipe segments as needed.

3) Connect the green wire from a steam tank to the core. It's probably best to use one of the further steam tanks, but it might not matter that much.

4) Make sure all fuel requester chests have plenty of fuel, and feed a single fuel in each reactor manually to start the process.

Expandability

Everything is modular so you can start with a 2 core / 16 exchanger reactor and add cores as needed. There's a limit because of the heat pipes, but I've expanded to a 2x8 core 2.4 GW reactor without a problem, and at some point it is probably more feasible to build another reactor as the plumbing will get pretty horrible.

Observations on use

The 2x8 plant could provide the theoretical max of 2.4GW without problem over long time spans. It might need some time to heat up, though, and if you draw full power immediately I think it sometimes doesn't get to high enough core temperatures to give full yield (?) With a lower load (I tested with 1.2 GW) it will automatically switch off if there is enough steam and switch back again if steam is low.

Note: 1 tank per 2 turbines should be enough to capture the energy in a reactor cycle, but since there also is quite a bit of energy stored in the temperature of the cores, heat pipes, and exchangers, the system will produce steam for a pretty long time after cores shut down. With a 1.2 GW load it fluctuated between 0k and 24k steam in a single tank without brownout, but I think that with a higher load it might be wiser to connect more tanks and set the lower steam level higher.