**************************************************

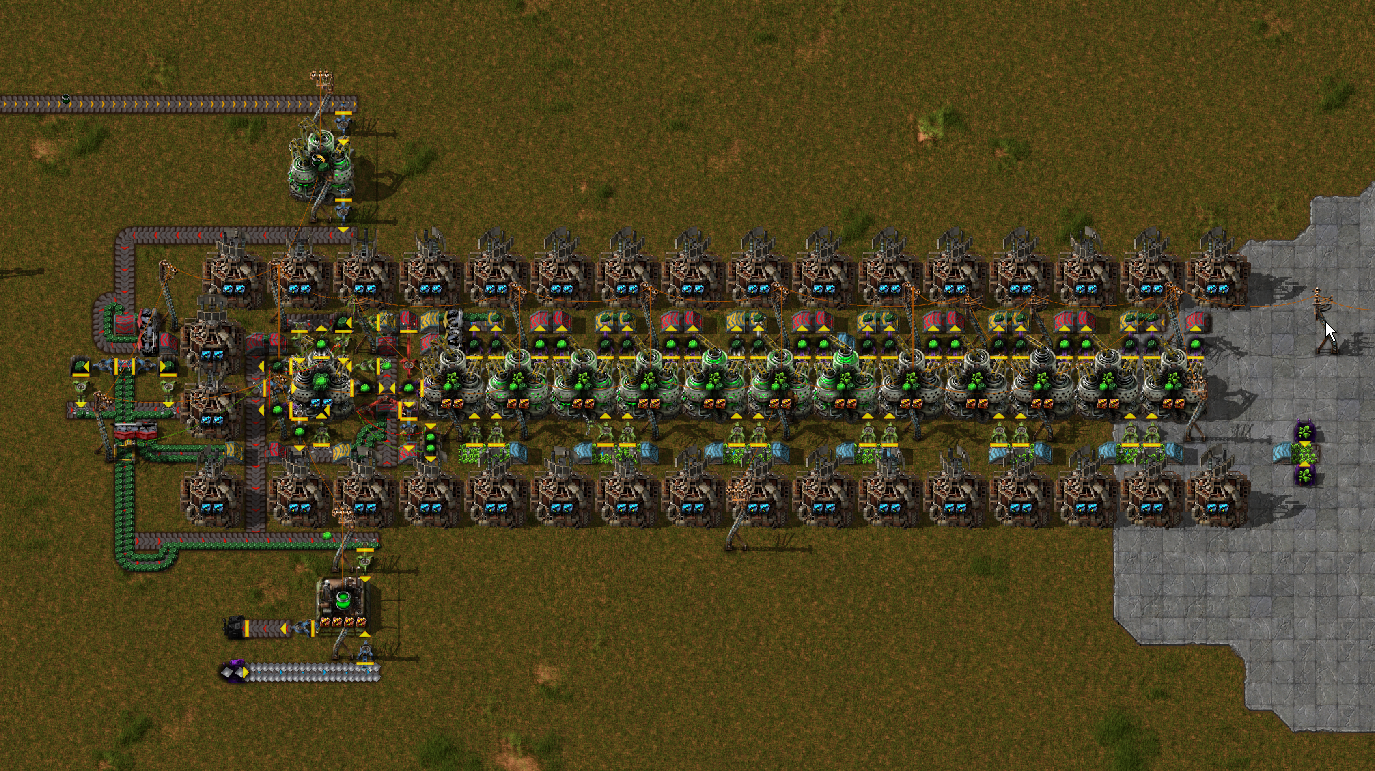

Just like everyone else, been straining my brain, trying to figure out a sleek way of keeping the Kovarex process moving, without tying up too much U235 in the process. My latest attempt seems promising, and has been shooting 100% so far in testing. The only real drawbacks are: 1)

The basic premise is this: if you can empty out over half the centrifuges' output in one go, you've got a guaranteed one-time event that you can use for triggering something else. Such as another inserter set to stack size 1. Since each production cycle creates 41 U235, we need to remove at least 21 of them at once. Three stack inserters with a stack of 7+ will do nicely...

And this is basically it. A triple stack inserter unload direct into the next Centrifuge. The lone filter inserter (with stack size forced to one) is set to pull out a single U235 when the three stack inserters are holding their maximum payload (stack size x 3). At the end of the line, simply unload onto a belt that leads back to the start of the line. Also, make sure you're running filtered versions of the inserters and stack inserters, or things foul up right quick.

This pattern can be extended pretty much indefinetely. Current testing is scoring 100% consistency with stack sizes as high as 12, and right down to 7. Since there's only 2 tiles of stuff on each size, feel free to speed beacon the hell out of it.

Blueprints are below. Be aware that, depending on your stack size research level, you'll need to set the constant in EACH filter inserter to be equal to (stack size x 3) - 1.