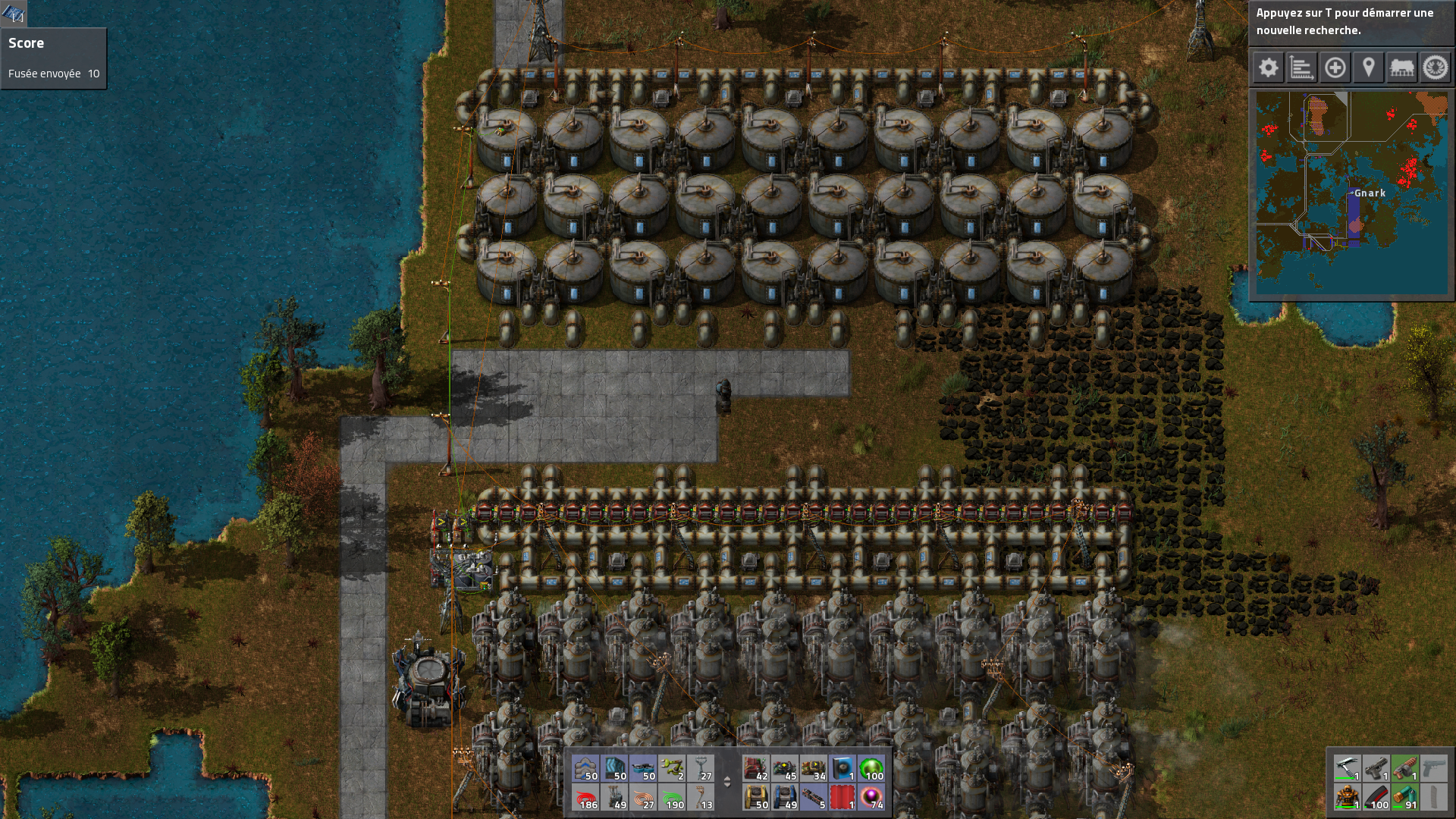

It's 6 pumps on 6 tiles vertically. It increases the width, not the shore length. The vertical distance is the same, 6 tiles. The pumps do take the same amount of space, but not vertically since they are stacked horizontally. You can't use that space much more effectivly without also landfilling lots of water to place the steam engines, so it is essentially free extra water that would otherwise go unused.Patric20878 wrote:I looked at that picture already. Where is there anything about 200% pumps and 1 tile per pump? If you think artificial shore length doesn't count as shore length, you're totally missing the idea. Every pump is still taking the normal space.

It's my idea, so I'm not missing it. The idea is to get as much power and water per shore length possible. The shore length is the vertical distance, so the extra landfill strips do not count, because they do not increase the vertical distance.