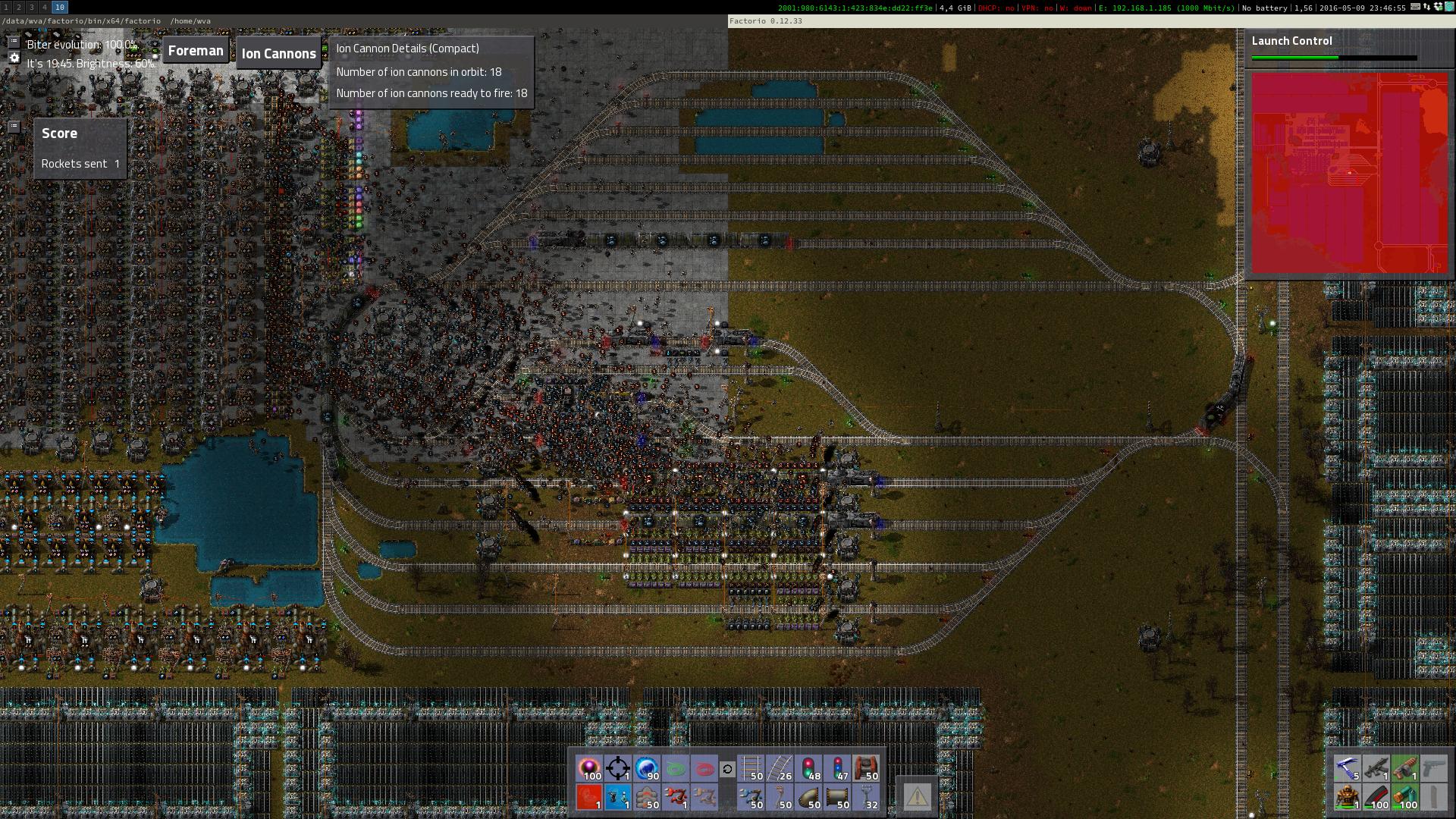

map

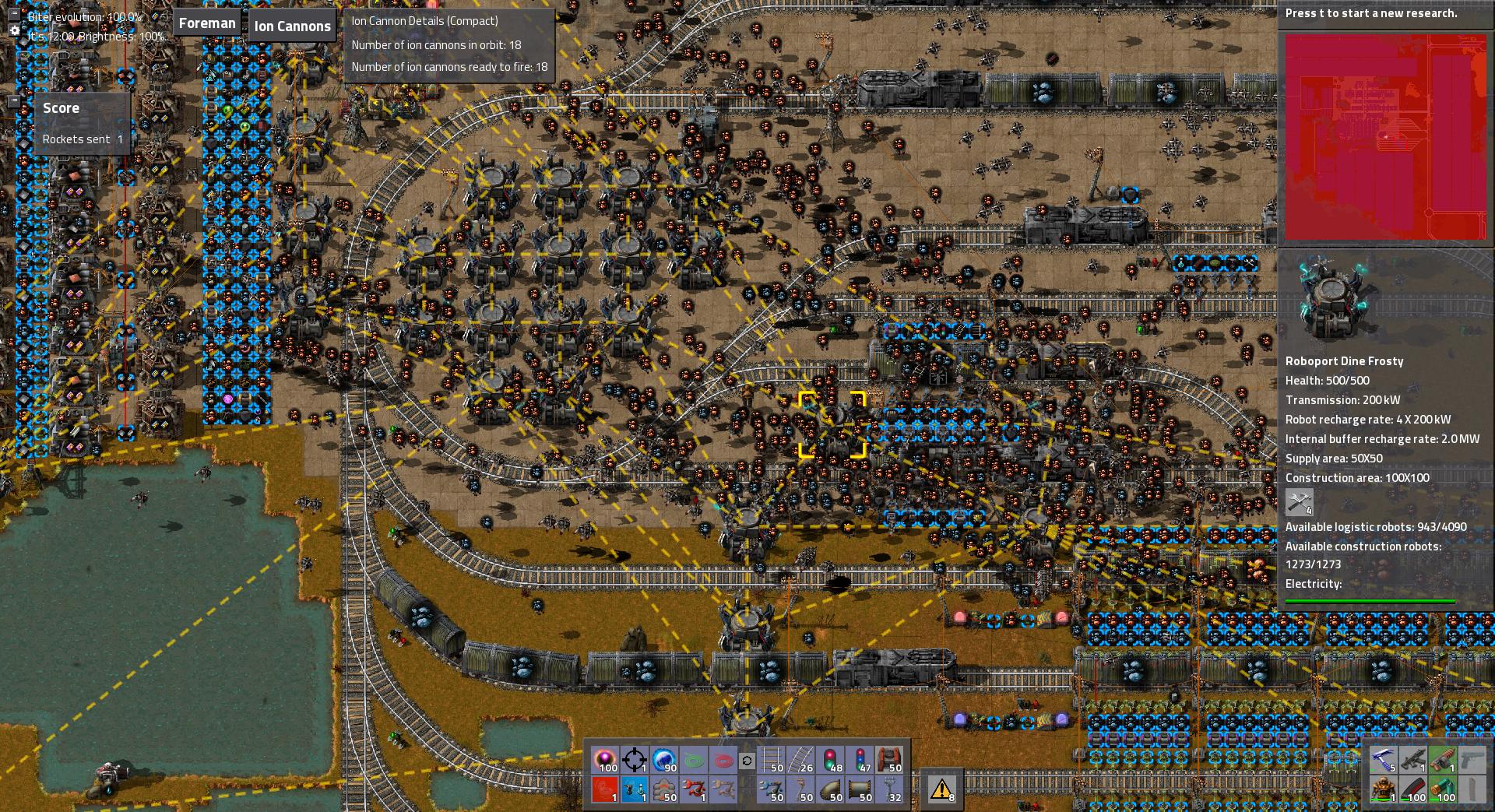

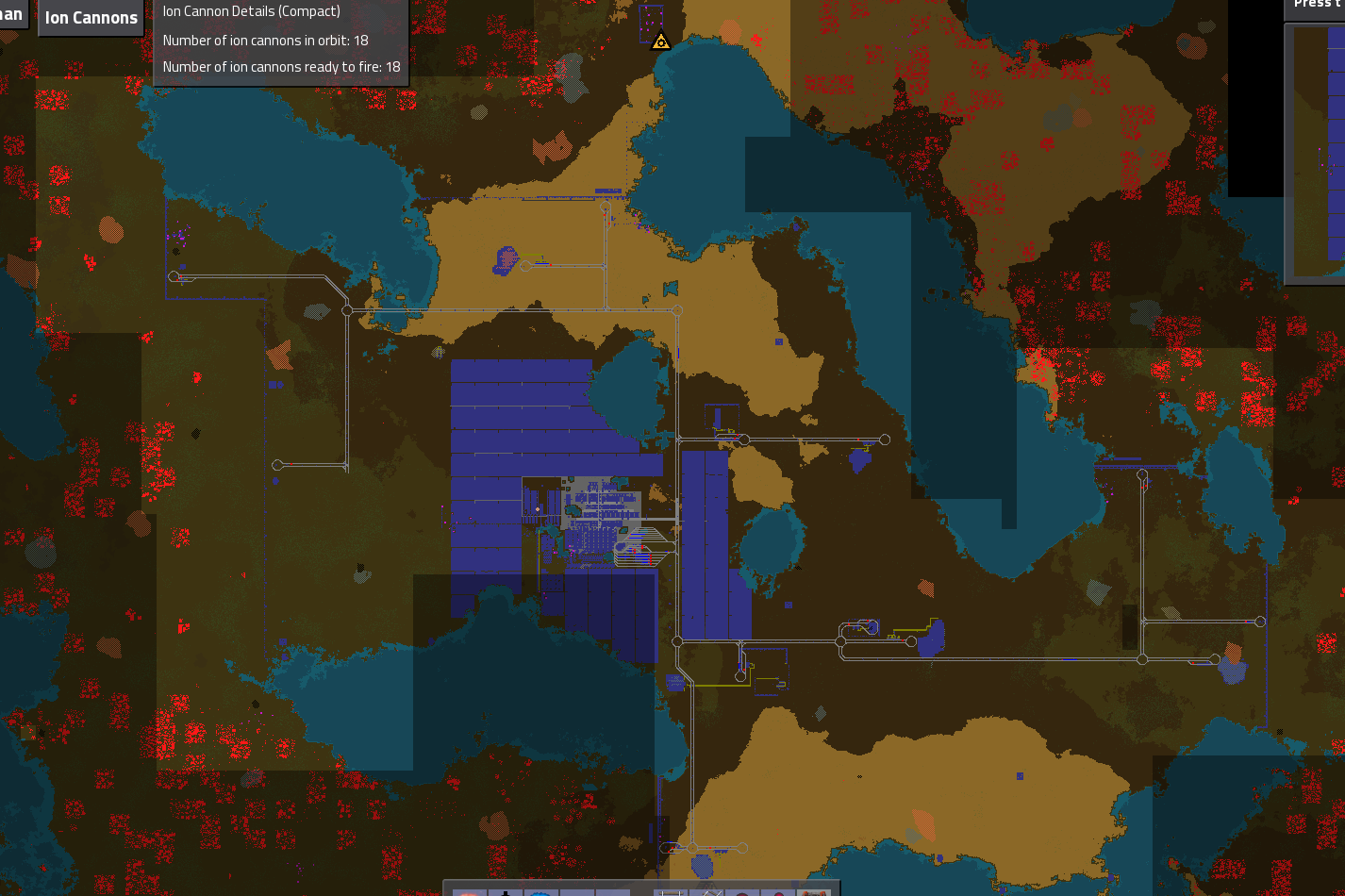

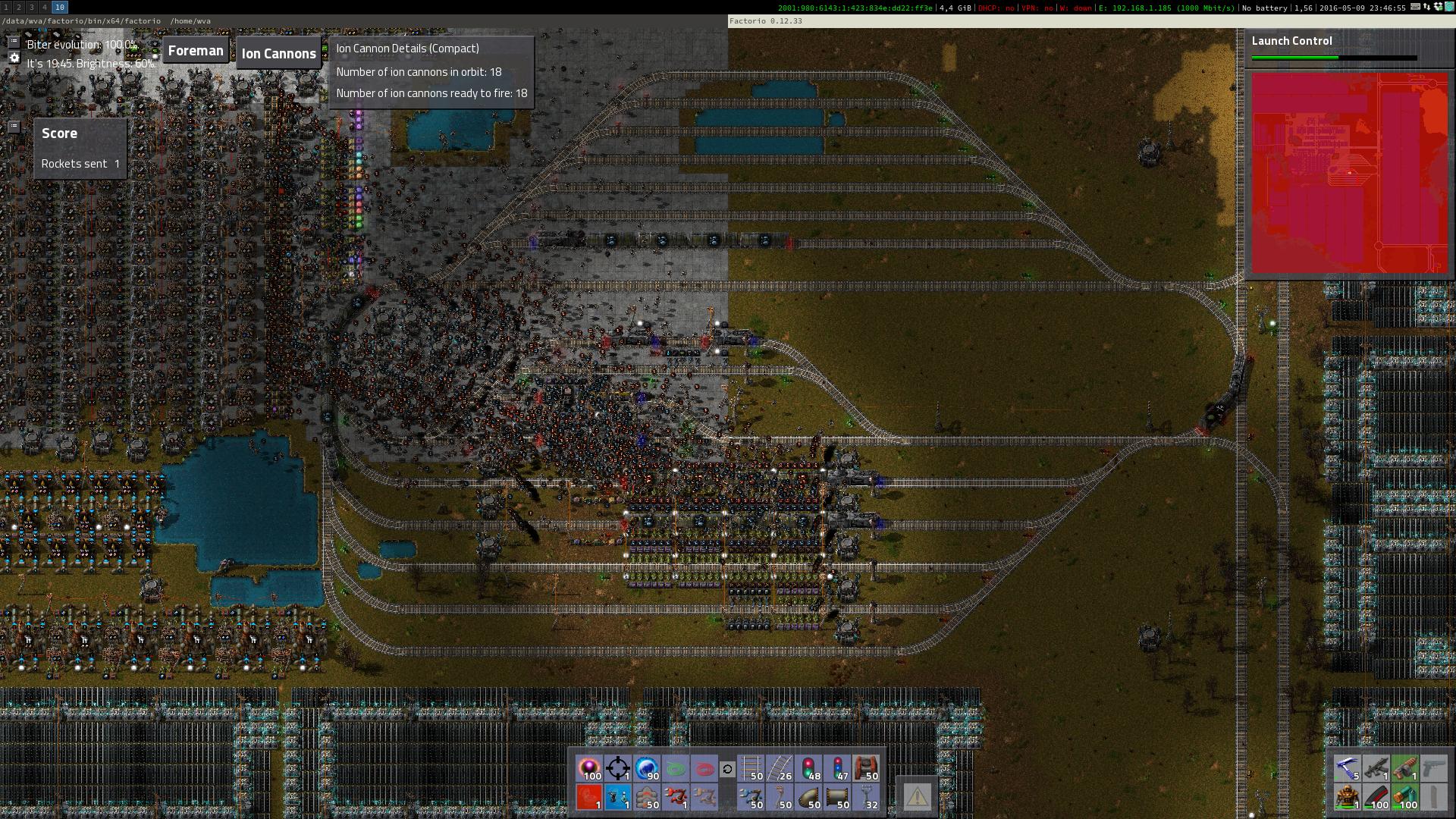

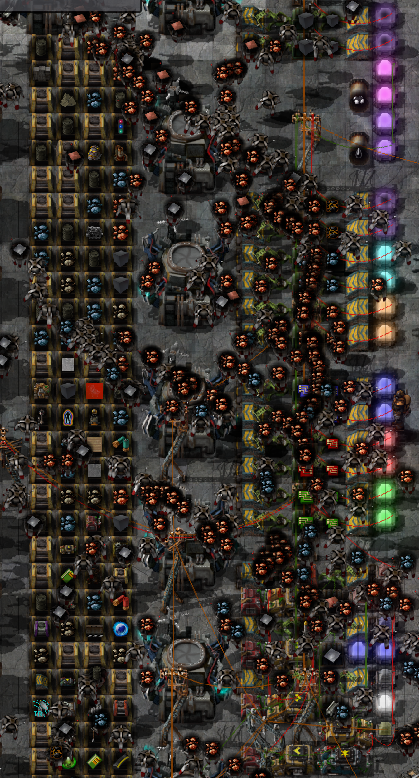

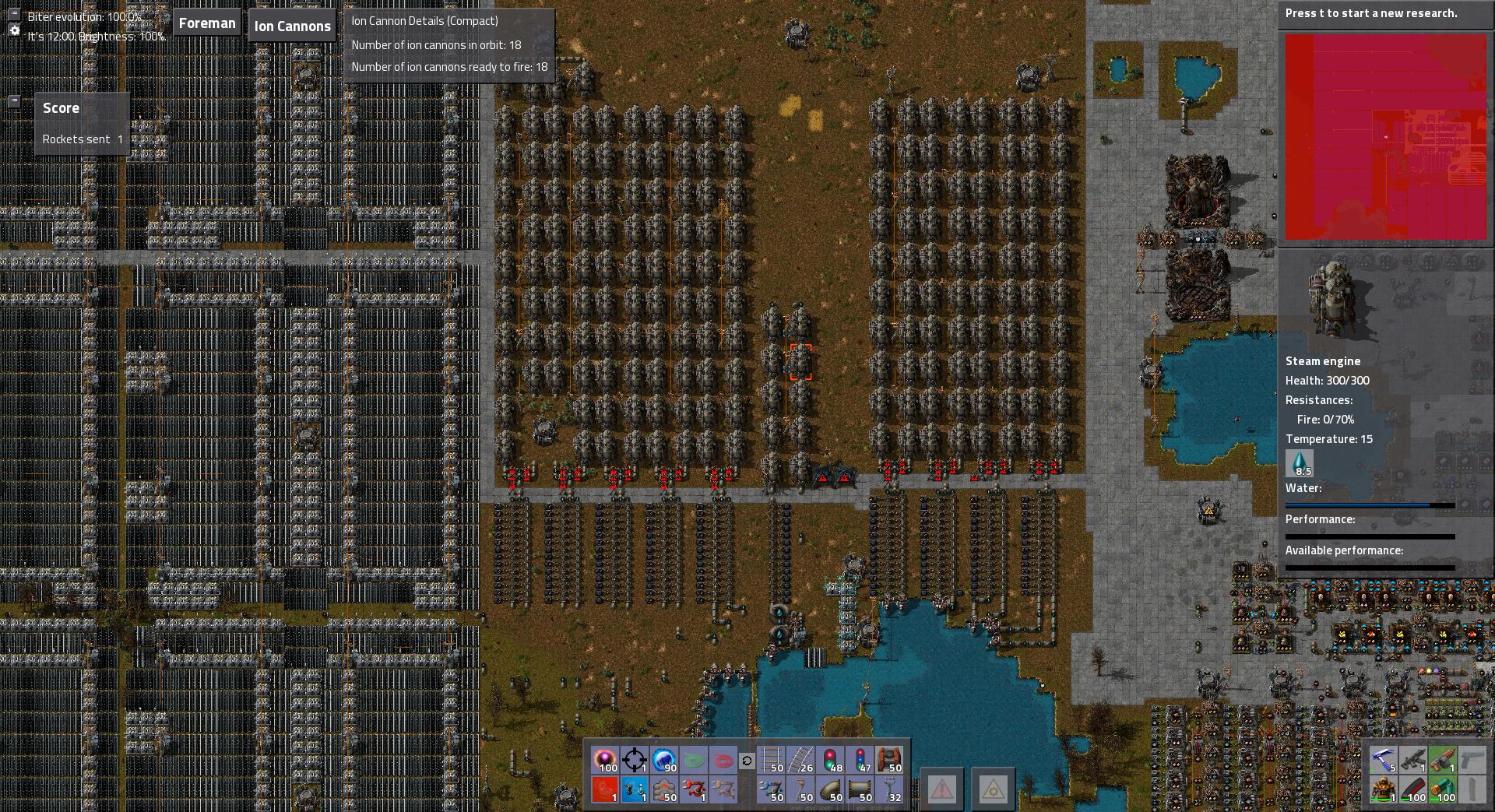

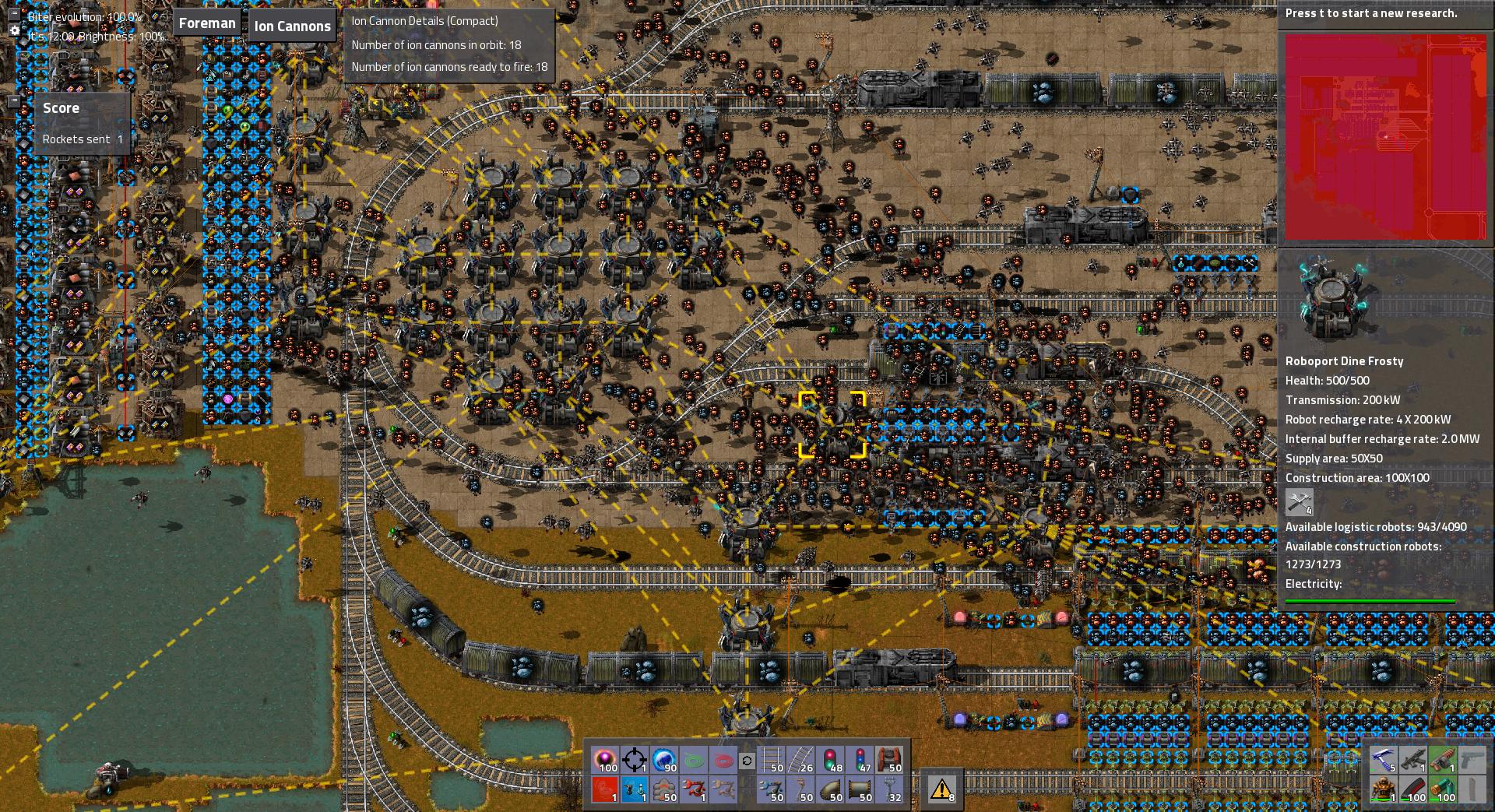

I play with RSO, very rich resources (except coal) and very rich biters. I ended up walling off part of the map (using some of the big lakes) to concentrate defenses on a "great wall" rather than arm individual outposts, making it much easier to set up mining outposts and add more solar panels:

base overview

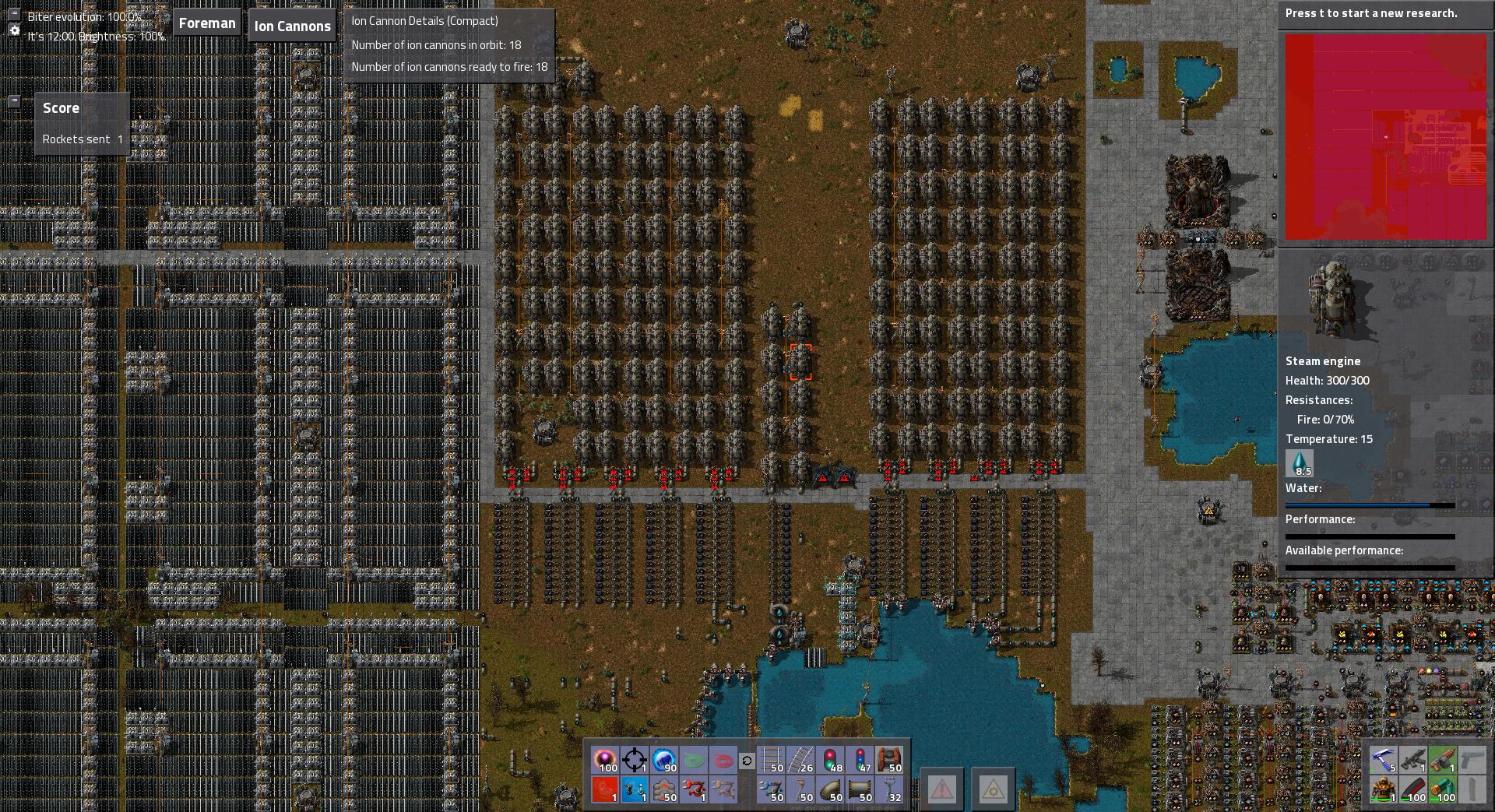

This is a overview picture of the main part of the factory. Bottom left are smelters (with refinery below it), bottom right is rail station, top is manufacturing, and top left is edge of backup power plant

This is a overview picture of the main part of the factory. Bottom left are smelters (with refinery below it), bottom right is rail station, top is manufacturing, and top left is edge of backup power plant

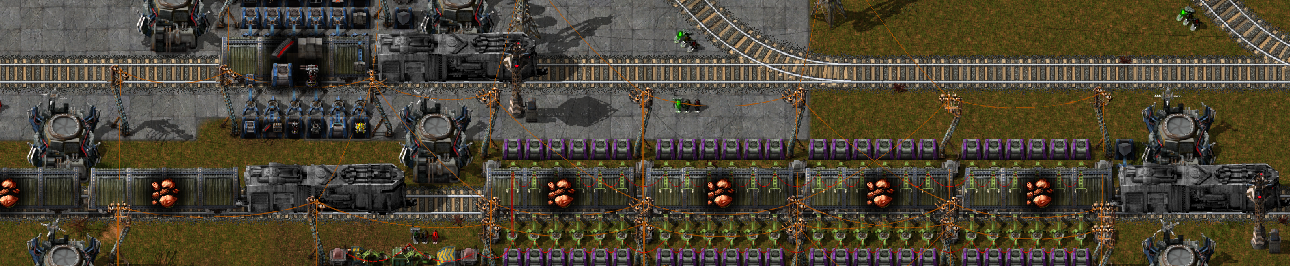

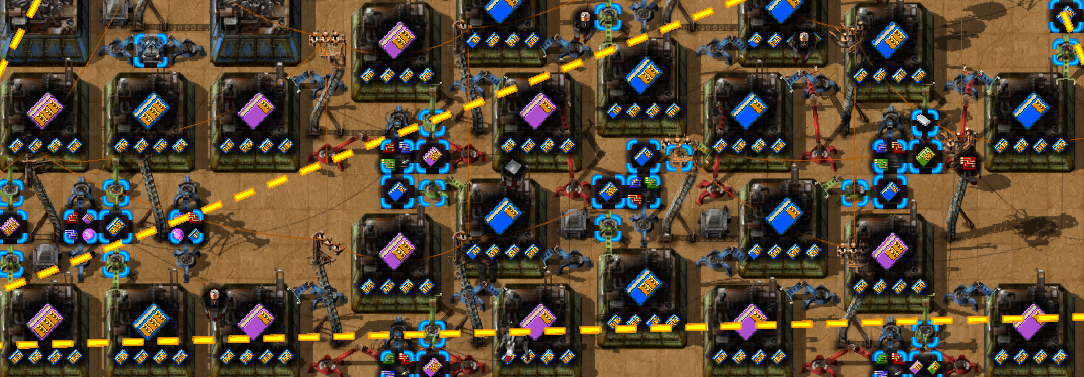

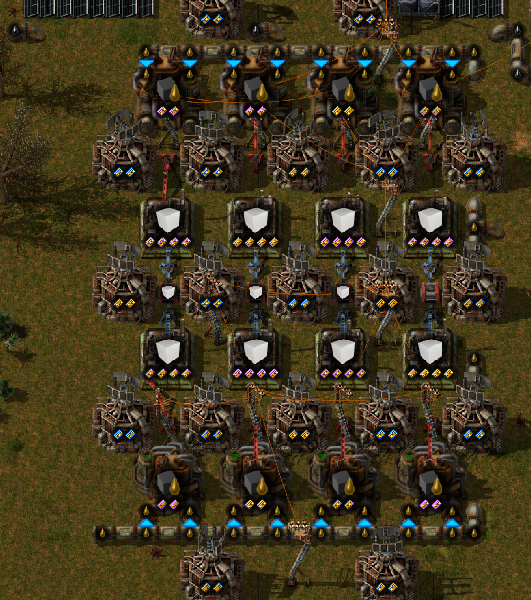

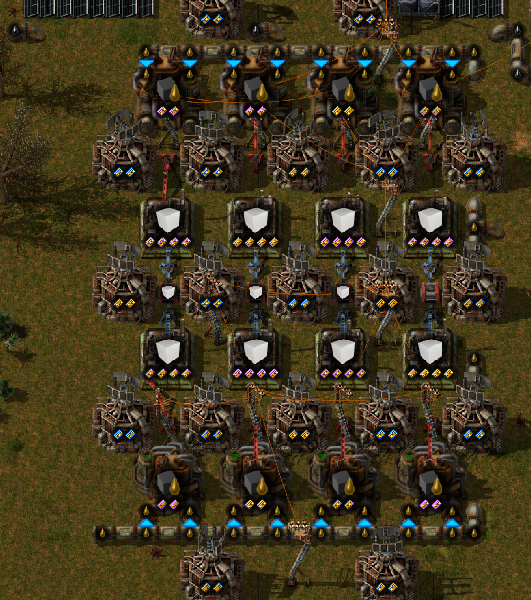

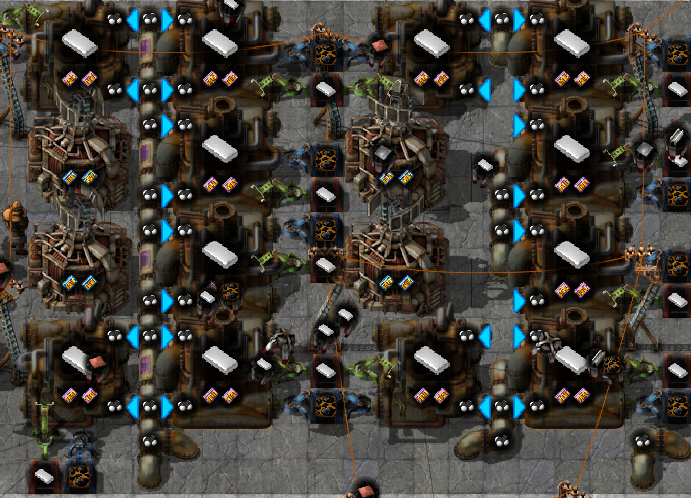

unloading

At the top are a set of waiting bays, which all lead to a single track going down. There is a single unloading station for each ore type, with unloading from both sides into active provider chests. Behind each station is a single waiting bay so the next train can proceed with minimal delay.

A smart chest setup controls the stock level:

The smart inserter loads a single ore into the chest if stock is low (currently <40k), and the other inserter unloads the ore if stock is high (>45k), and the underground belt brings it back to the first inserter. The smart chest is connected to all inserters (and the indicator lights), so trains are only unloaded if stock is low. Since all trains are set to wait until full, this makes sure that trains only run when they are needed and the storage area is not clogged up with 200k copper ore.

(I used a logistic condition on the inserters before (ie unload a train if ore < X), but that means you need to change all inserters if you want to adjust stock levels, while this setup gives a single point of control)

You can also see one of the specialized train stations at the top. I use a "base builder" train for setting up military bases (walls, guns, etc), and a FARL with mining supplies for setting up new outposts. There is also a supply train that provides ammo, repair kits, and replacement guns to the walls.

At the top are a set of waiting bays, which all lead to a single track going down. There is a single unloading station for each ore type, with unloading from both sides into active provider chests. Behind each station is a single waiting bay so the next train can proceed with minimal delay.

A smart chest setup controls the stock level:

The smart inserter loads a single ore into the chest if stock is low (currently <40k), and the other inserter unloads the ore if stock is high (>45k), and the underground belt brings it back to the first inserter. The smart chest is connected to all inserters (and the indicator lights), so trains are only unloaded if stock is low. Since all trains are set to wait until full, this makes sure that trains only run when they are needed and the storage area is not clogged up with 200k copper ore.

(I used a logistic condition on the inserters before (ie unload a train if ore < X), but that means you need to change all inserters if you want to adjust stock levels, while this setup gives a single point of control)

You can also see one of the specialized train stations at the top. I use a "base builder" train for setting up military bases (walls, guns, etc), and a FARL with mining supplies for setting up new outposts. There is also a supply train that provides ammo, repair kits, and replacement guns to the walls.

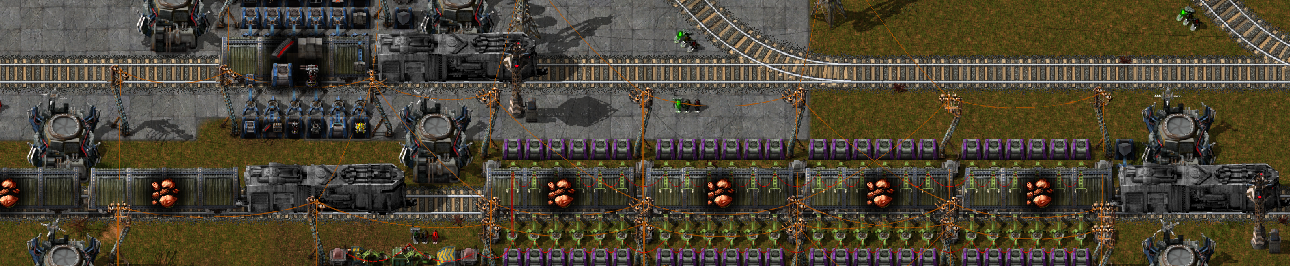

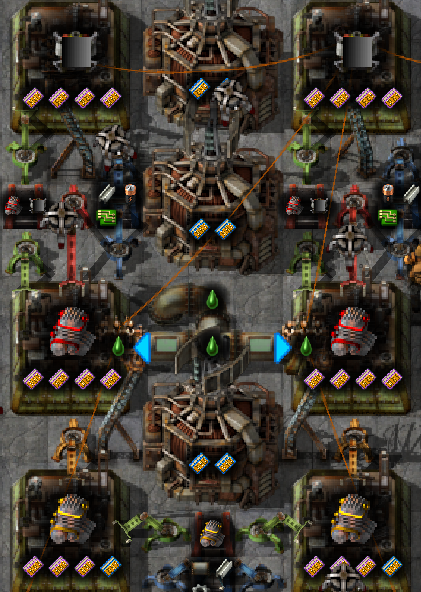

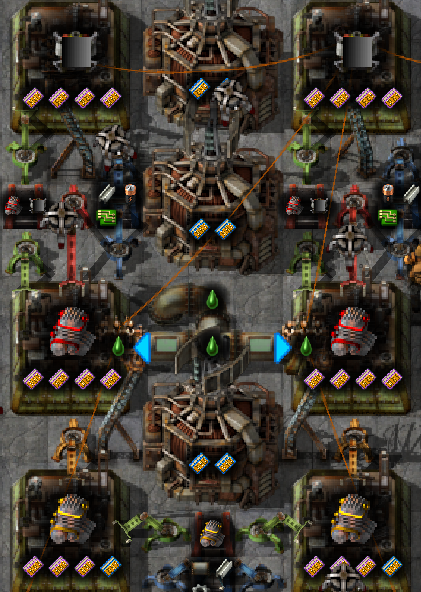

smelting

In total there are >135 "smart" smelters, each with 2 prod3 modules and interleaved with beacons with speed3 modules, for +20% productivity and 9.4 crafting speed for the ones in the middle. All smelters are fed with all 3 ores, controlled by a single control panel as discussed in this thread: viewtopic.php?f=8&t=24938

In total there are >135 "smart" smelters, each with 2 prod3 modules and interleaved with beacons with speed3 modules, for +20% productivity and 9.4 crafting speed for the ones in the middle. All smelters are fed with all 3 ores, controlled by a single control panel as discussed in this thread: viewtopic.php?f=8&t=24938

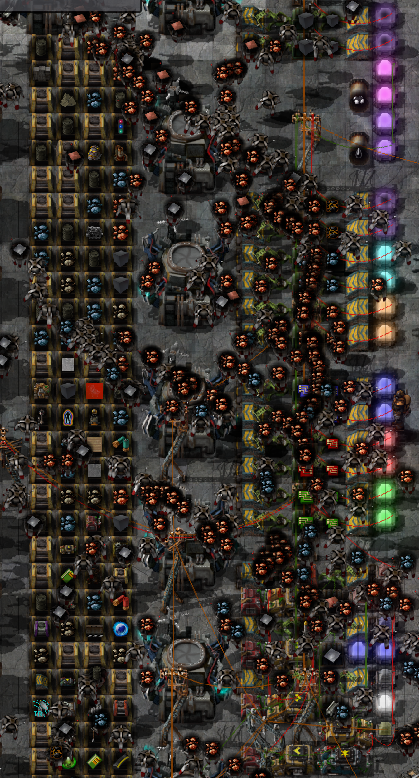

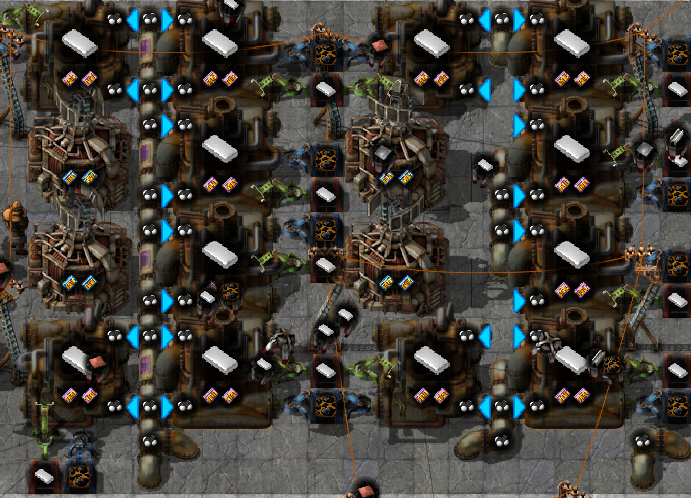

control panel

This is the control panel and storage area between the smelters and the station. The bottom right cell is the control panel for the smelters (viewtopic.php?f=8&t=24938), using the circuit network to read stock in the smelter output chests, select the lowest stock using combinators, and putting a dummy signal on the logistics network to control the smelters. Stock is controlled by a single combinator, now set to 10k for each plate type.

The other sets of lights are stock levels for circuits, ores, and fluids/fuel. Except for the fluids (which are on the circuit network from the storage tanks), all lights are controlled by the same inserter setup discussed above in the station.

This is the control panel and storage area between the smelters and the station. The bottom right cell is the control panel for the smelters (viewtopic.php?f=8&t=24938), using the circuit network to read stock in the smelter output chests, select the lowest stock using combinators, and putting a dummy signal on the logistics network to control the smelters. Stock is controlled by a single combinator, now set to 10k for each plate type.

The other sets of lights are stock levels for circuits, ores, and fluids/fuel. Except for the fluids (which are on the circuit network from the storage tanks), all lights are controlled by the same inserter setup discussed above in the station.

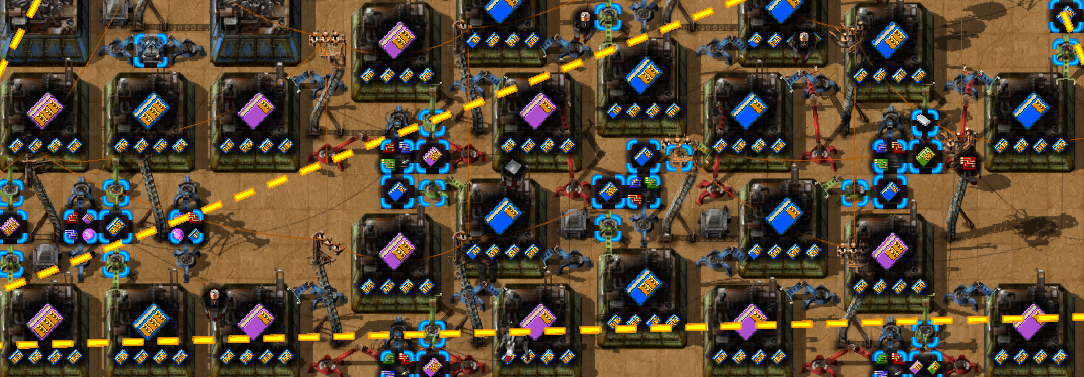

manufacturing

Overview:

Manufacturing is organized into (mostly) repeatable racks for the modules (bottom right) and rocket parts (top right), generalized manufacturing (right) and specific setups for fluid-based manufacturing, modules, science, and military (left).

Green circuits. The regular 3:2 setup becomes almost perfectly 1:1 when factoring in productivity modules. I staggered the circuits plants so the currently selected one still benefits from an extra speed beacon, although that means that not all circuit plants are perfectly balanced. The productivity modules mean you get 1.3 circuits per copper plate instead of the regular 0.67.

Red circuits. The caple plant is not utilized fully as it could supply more than 8 red plants, but I couldn't find an elegant way to add more red plants while still adding the beacons, and as each plant benefits from 3 beacons output is still higher than 8 plants without the beacons (.665 circuit per cycle compared to .28, showing how important the beacons are for offsetting the producivity speed penalty).

Blue circuits, nothing very special going on.

Manufacturing is organized into (mostly) repeatable racks for the modules (bottom right) and rocket parts (top right), generalized manufacturing (right) and specific setups for fluid-based manufacturing, modules, science, and military (left).

Green circuits. The regular 3:2 setup becomes almost perfectly 1:1 when factoring in productivity modules. I staggered the circuits plants so the currently selected one still benefits from an extra speed beacon, although that means that not all circuit plants are perfectly balanced. The productivity modules mean you get 1.3 circuits per copper plate instead of the regular 0.67.

Red circuits. The caple plant is not utilized fully as it could supply more than 8 red plants, but I couldn't find an elegant way to add more red plants while still adding the beacons, and as each plant benefits from 3 beacons output is still higher than 8 plants without the beacons (.665 circuit per cycle compared to .28, showing how important the beacons are for offsetting the producivity speed penalty).

Blue circuits, nothing very special going on.

general manufacturing

Most of the general manufacturing is quite boring, with two facing assemblies fed from a requester chest and outputting to a provider controled by logistic conditions to make sure all basic goods are always at decent level.

Modules using direct insertion from the 2 first-tier plants to one second-tier plant, but in retrospect this is just unnecessary complexity as the bots could have just taken care of this.

Bot manufacturing. I think the amounts balance out given the modules with some extra capacity in the engine production to supply pumps and trains, but I didn't think about it for very long. It runs continuously because you can never have enough bots. Right?

Modules using direct insertion from the 2 first-tier plants to one second-tier plant, but in retrospect this is just unnecessary complexity as the bots could have just taken care of this.

Bot manufacturing. I think the amounts balance out given the modules with some extra capacity in the engine production to supply pumps and trains, but I didn't think about it for very long. It runs continuously because you can never have enough bots. Right?

refinery and fluids

(sorry for the night vision)

This is the general refining, with barrel unloading to the left, feeding into oversized crude oil tanks and into the refining row, with productivity modules in the refining and speed modules in two beacons between every two refineries.

The output is stored into one tank each (to measure stock), and from there sent to either lubricants, cracking, petroleum-based manufacturing, or solid fuel -> rocket fuel.

Fluid control is done with a series of pumps based on fluid levels. Heavy oil is cracked when heavy > 1000 (to keep some stock for lube, but since I don't use belts I really don't need a lot). Light oil is cracked if light < PG, and sent to the soild fuel production if light > 500. PG is converted to solid fuel only if PG is very high and light is low, to make sure that a glut of PG doesn't stop rocket fuel production.

This is rocket fuel production, with max productivity modules and a lot of speed beacons. The extra beacons at the top and bottom balance out soild->rocket fuel production.

Petroleum gas is piped to the manufacturing area and controlled with a set of logistic->circuit detectors. Each output good (battery, plastic, blue module) is compared to each other good, and if it is lowest is kept in the chest, so the lowest good always has 2 in the chests (currently batteries). The rightmost detector activates when PG is high and puts 2 of each in the chest. The pipes to the various plants are controlled by pumps set to [good]>1, so if PG is high all racks produce, but if it is low only the lowest stock gets produced (to prevent e.g. all PG to go to circuit production while the factory is starved of batteries)

Crude oil is stored in barrels in the normal storage network, currently with an excess of 5k filled barrels or 50 normal oil tanks.

Finally, plastic and battery production, nothing very fancy:

(sorry for the night vision)

This is the general refining, with barrel unloading to the left, feeding into oversized crude oil tanks and into the refining row, with productivity modules in the refining and speed modules in two beacons between every two refineries.

The output is stored into one tank each (to measure stock), and from there sent to either lubricants, cracking, petroleum-based manufacturing, or solid fuel -> rocket fuel.

Fluid control is done with a series of pumps based on fluid levels. Heavy oil is cracked when heavy > 1000 (to keep some stock for lube, but since I don't use belts I really don't need a lot). Light oil is cracked if light < PG, and sent to the soild fuel production if light > 500. PG is converted to solid fuel only if PG is very high and light is low, to make sure that a glut of PG doesn't stop rocket fuel production.

This is rocket fuel production, with max productivity modules and a lot of speed beacons. The extra beacons at the top and bottom balance out soild->rocket fuel production.

Petroleum gas is piped to the manufacturing area and controlled with a set of logistic->circuit detectors. Each output good (battery, plastic, blue module) is compared to each other good, and if it is lowest is kept in the chest, so the lowest good always has 2 in the chests (currently batteries). The rightmost detector activates when PG is high and puts 2 of each in the chest. The pipes to the various plants are controlled by pumps set to [good]>1, so if PG is high all racks produce, but if it is low only the lowest stock gets produced (to prevent e.g. all PG to go to circuit production while the factory is starved of batteries)

Crude oil is stored in barrels in the normal storage network, currently with an excess of 5k filled barrels or 50 normal oil tanks.

Finally, plastic and battery production, nothing very fancy:

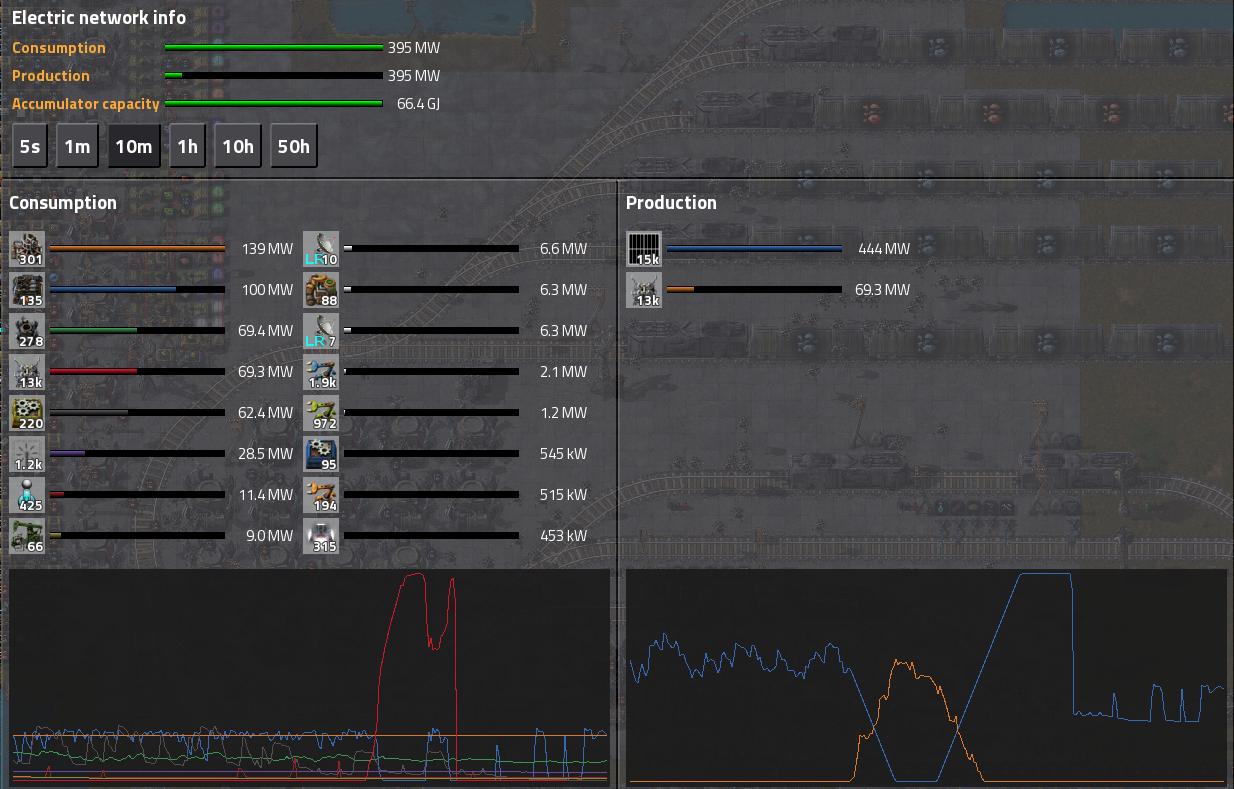

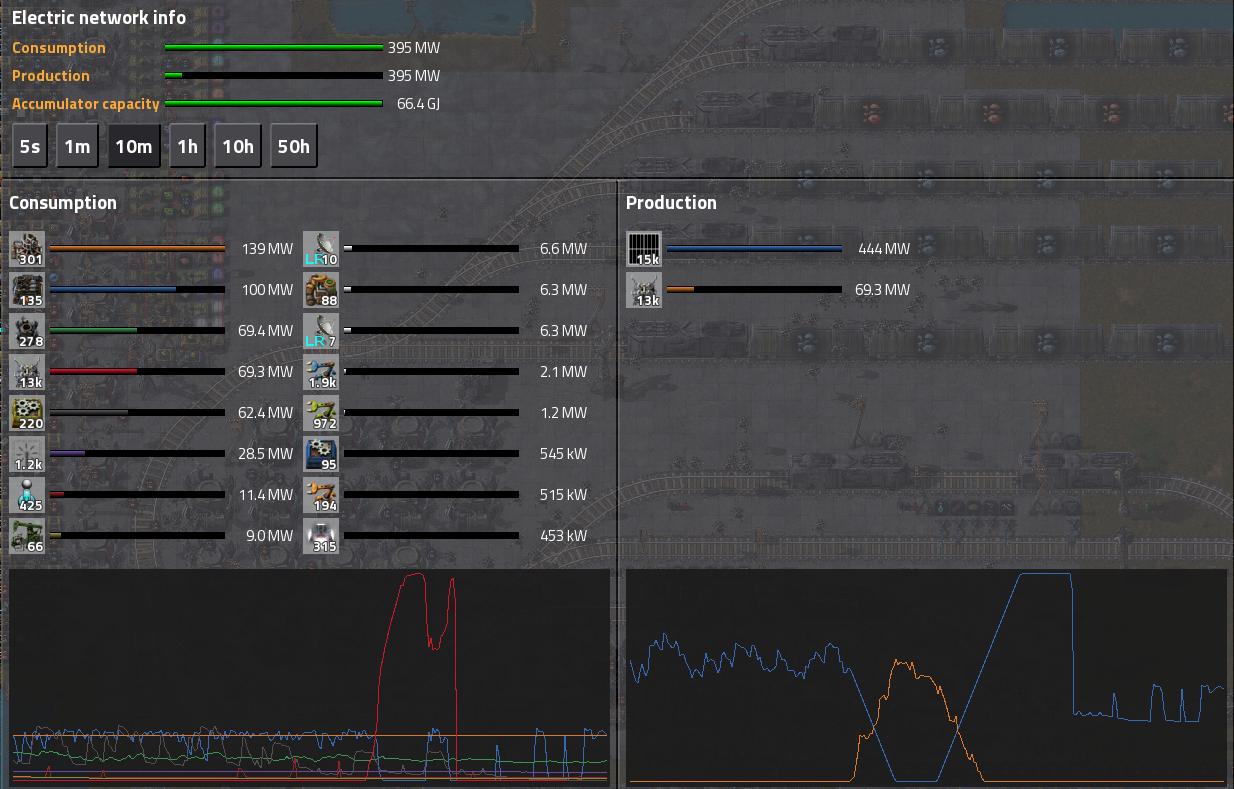

power

The base is primarily powered by solar cells. I made a blueprint centered around a roboport that is close to ideal proportions (183/158) and can be tiled leaving a single tile path between the blocks, in total I have around 80 such blocks or 15k solar cells, giving a sustained production of around 600MW (900MW peak):

The block increase in power use is by the smelters firing up, drawing an additional 100MW.

There is also a backup system with solid fuel with a capacity of just under 100MW, controlled by the system described here: viewtopic.php?f=8&t=10268.

The block increase in power use is by the smelters firing up, drawing an additional 100MW.

There is also a backup system with solid fuel with a capacity of just under 100MW, controlled by the system described here: viewtopic.php?f=8&t=10268.

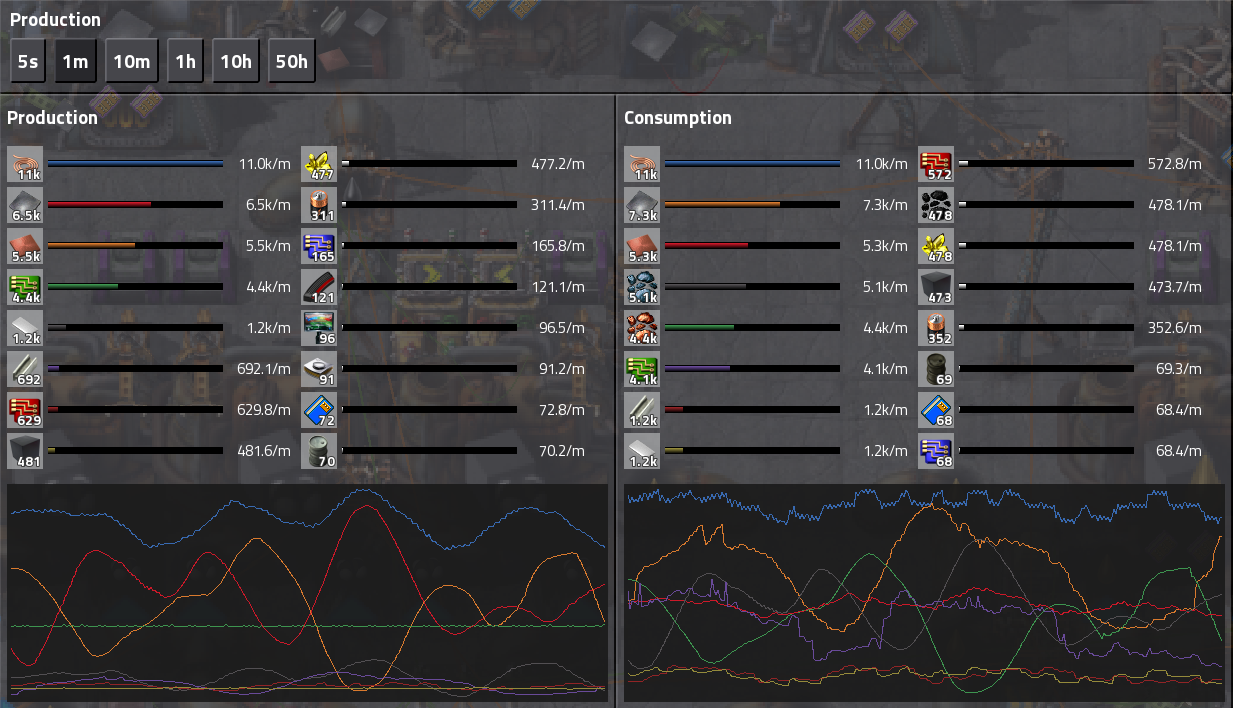

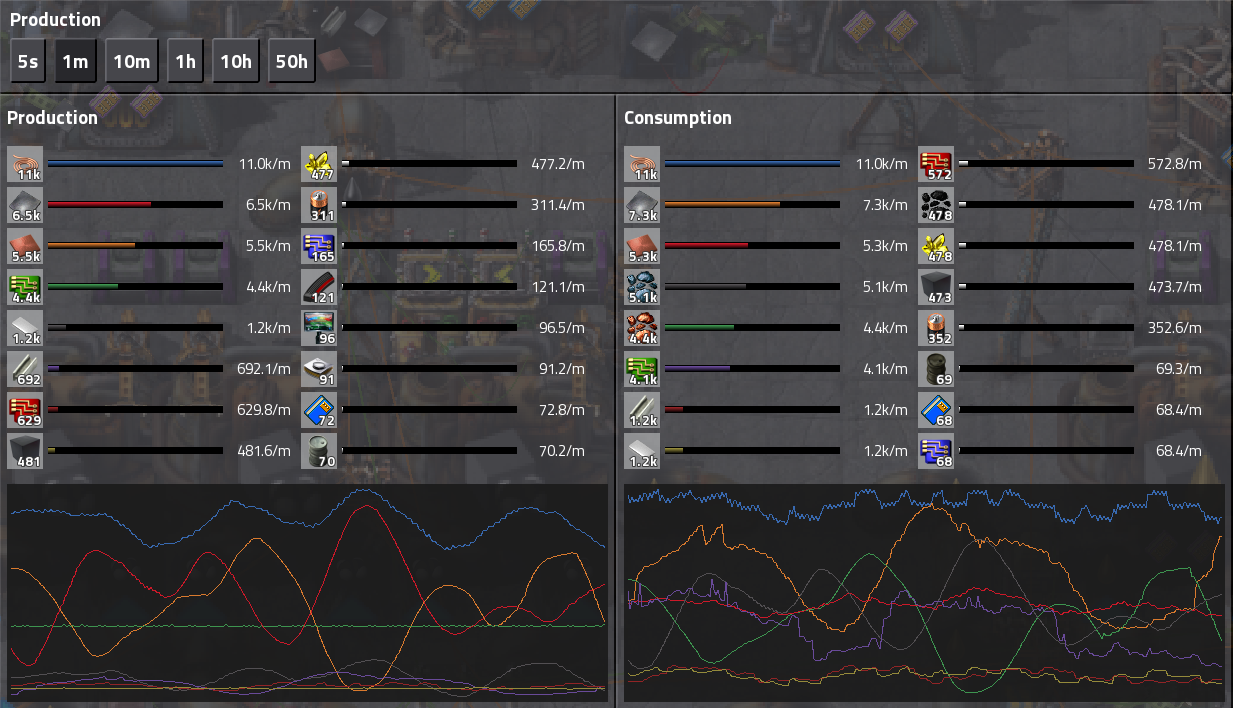

production statistics

The production neatly shows the sinoid patters produced by the smart smelting setup with e.g. The big iron peak/copper drop in the middle caused by an iron shortage. Consumption is about 10-15k ore per minute producing 4.5k green, .6k red, 165 blue and around 100 of each rocket part, but I didn't do math on where the current bottleneck is.

Logistics are driven by my fleet of 4000 bots. For the screenshot, I upped the ore stock levels causing both stations to start unloading simultaneously, showing that these bots are actually all useful for very high throughput burst transport:

The production neatly shows the sinoid patters produced by the smart smelting setup with e.g. The big iron peak/copper drop in the middle caused by an iron shortage. Consumption is about 10-15k ore per minute producing 4.5k green, .6k red, 165 blue and around 100 of each rocket part, but I didn't do math on where the current bottleneck is.

Logistics are driven by my fleet of 4000 bots. For the screenshot, I upped the ore stock levels causing both stations to start unloading simultaneously, showing that these bots are actually all useful for very high throughput burst transport: