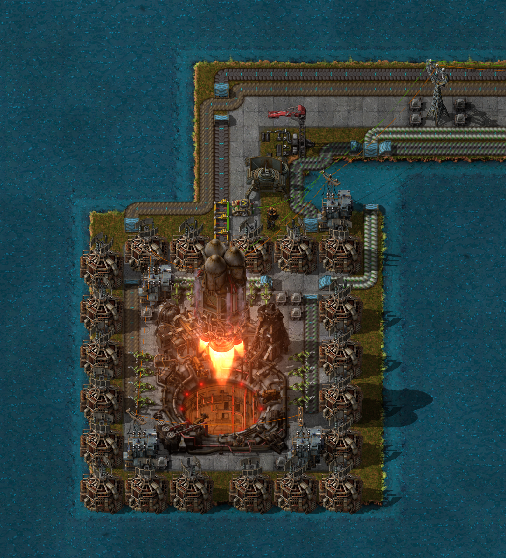

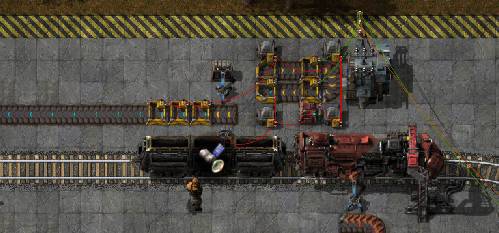

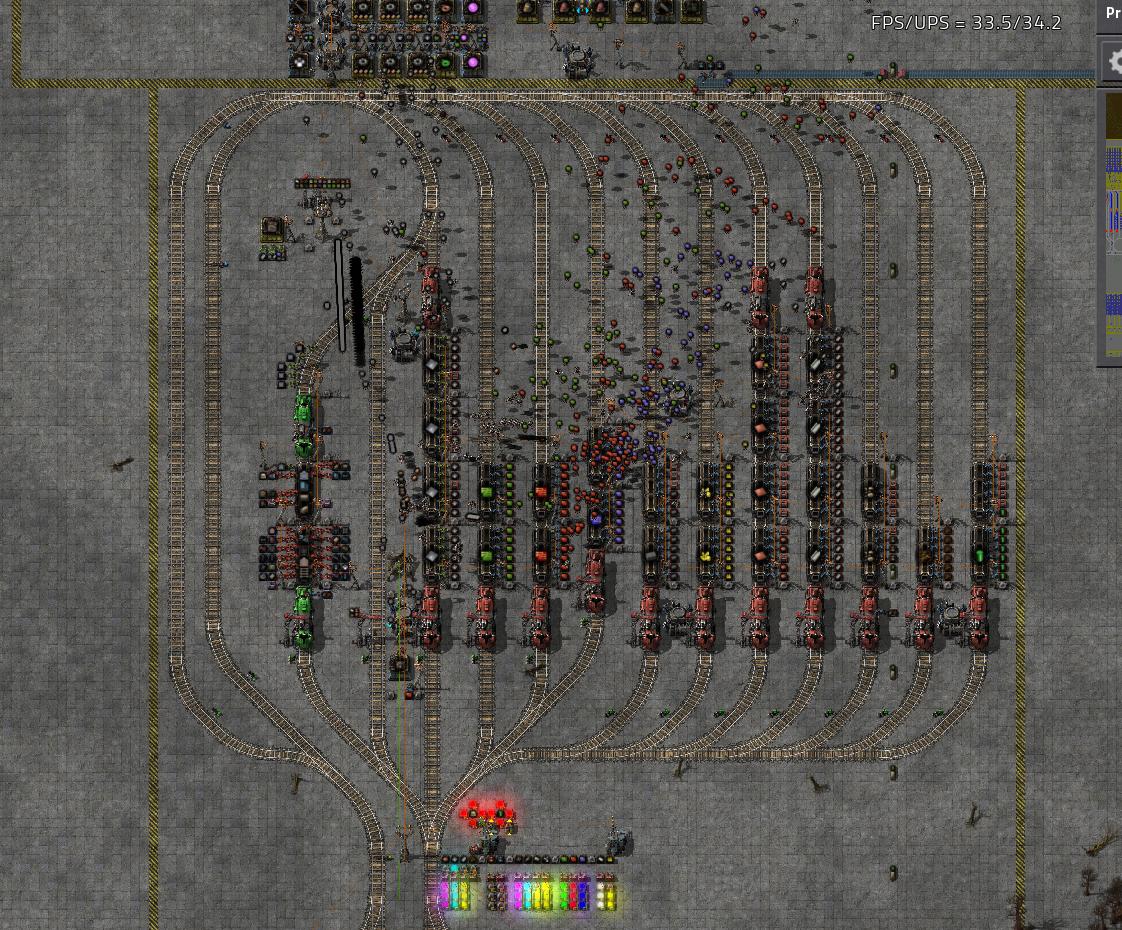

(This is my only silo, with 4xprod and max speed beacons it manages to launch almost 1 rocket per minute. The production is pretty fast, it's the launch animation that's the problem...

Below is an overview of the various parts with links to the designs, feel free to ask for any particulars!

Setup

I wanted to try out the 'train-bus' concept, i.e. not have a main bus but use trains for all medium-range hauling. The game is mostly vanilla, with three major exceptions:

1) nucular power (cause solar is boring and coal is annoying)

2) endless ores and I actually replaced all patches with circular patches so I could use a blueprint for the mines.

3) no biters, used nucular plutonium->purple for science and AlienArtifacts for modular armor

All production is done with prod3 modules and speed beacons. No bots are used except in the 'store' that produces belts, plants, etc.

The goal was to have slight overcapacity everywhere, and use backpressure (propagated via trains set to wait until empty) to regulate production. Plants are switched off to save power based either on buffer contents or on output backing up.

1) nucular power (cause solar is boring and coal is annoying)

2) endless ores and I actually replaced all patches with circular patches so I could use a blueprint for the mines.

3) no biters, used nucular plutonium->purple for science and AlienArtifacts for modular armor

All production is done with prod3 modules and speed beacons. No bots are used except in the 'store' that produces belts, plants, etc.

The goal was to have slight overcapacity everywhere, and use backpressure (propagated via trains set to wait until empty) to regulate production. Plants are switched off to save power based either on buffer contents or on output backing up.

Overview

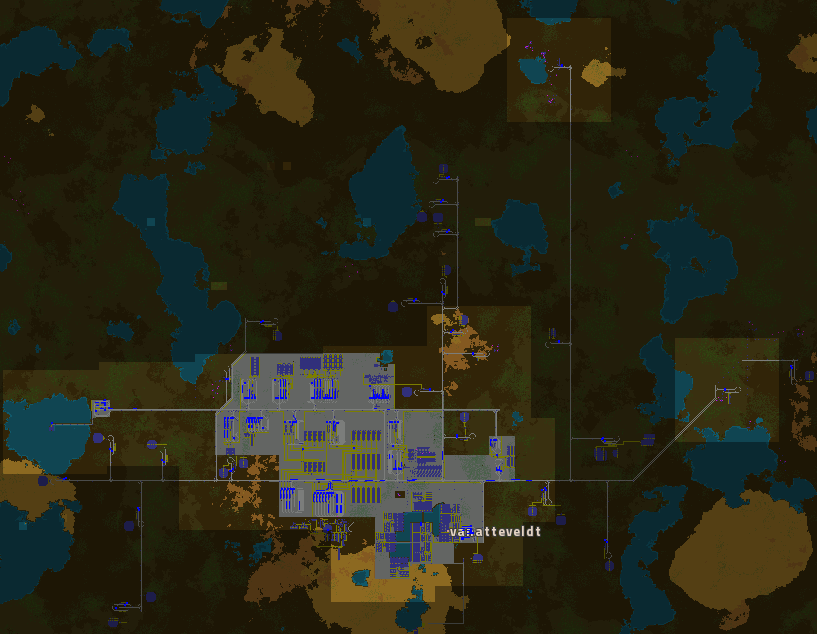

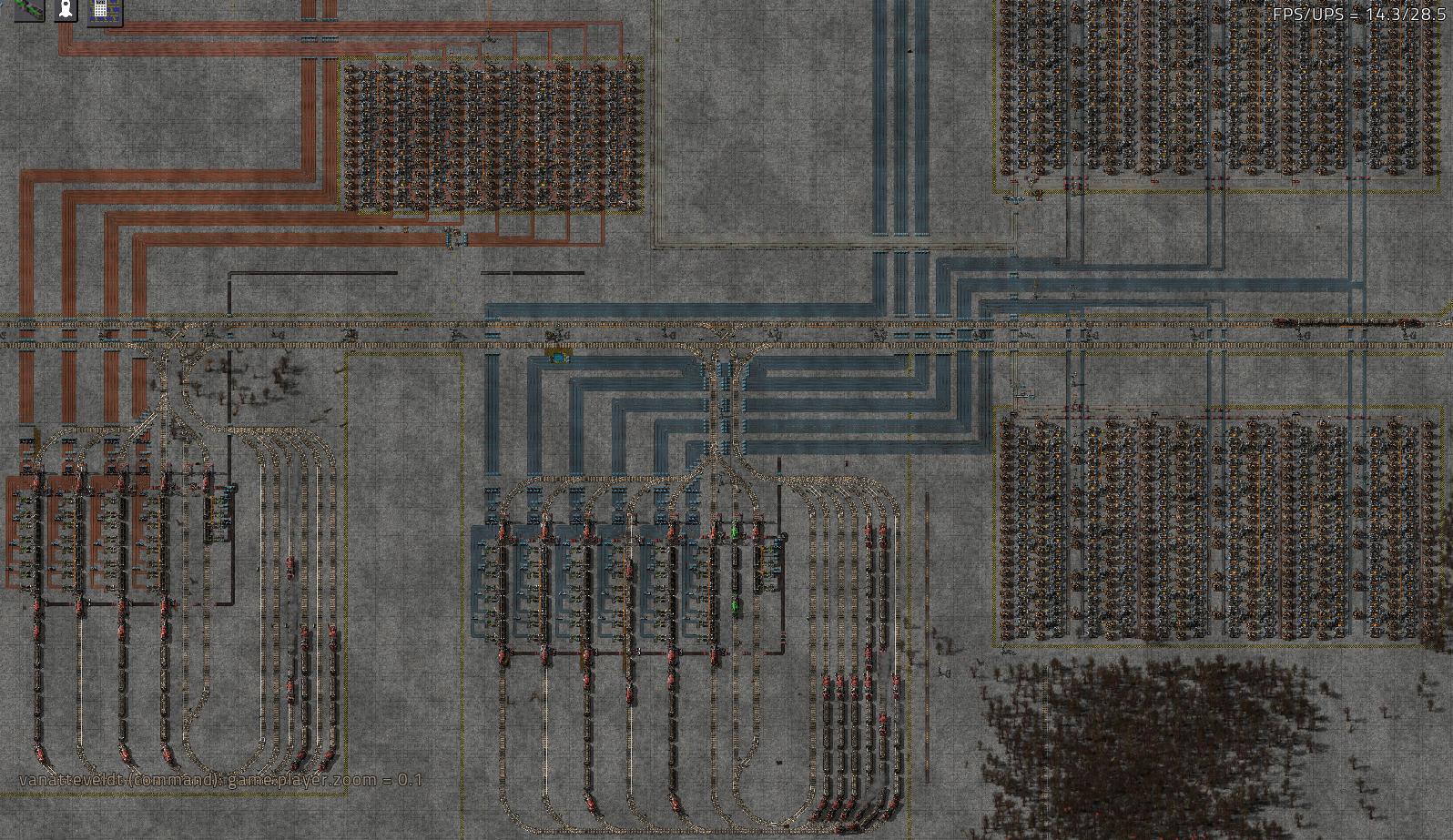

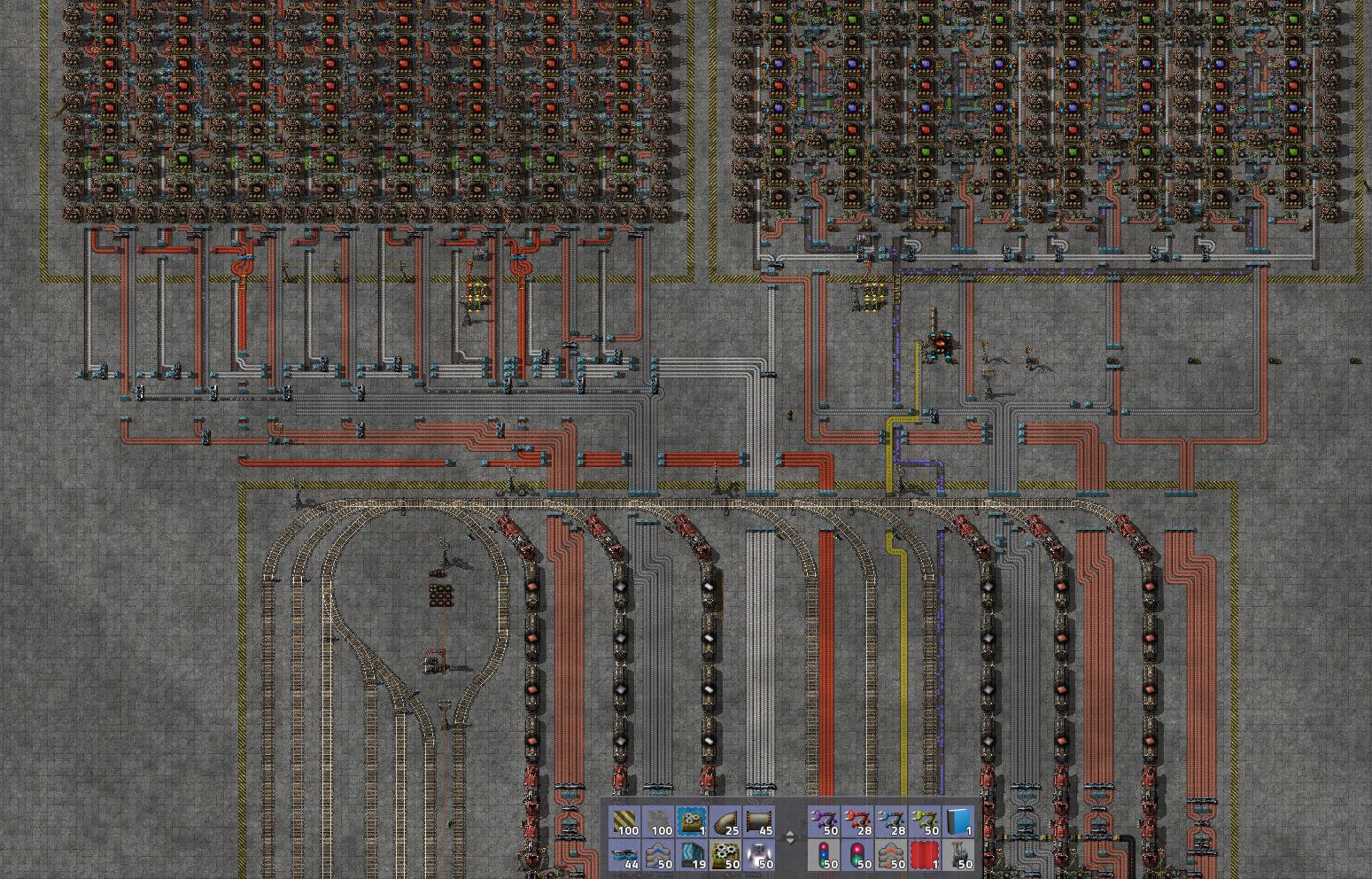

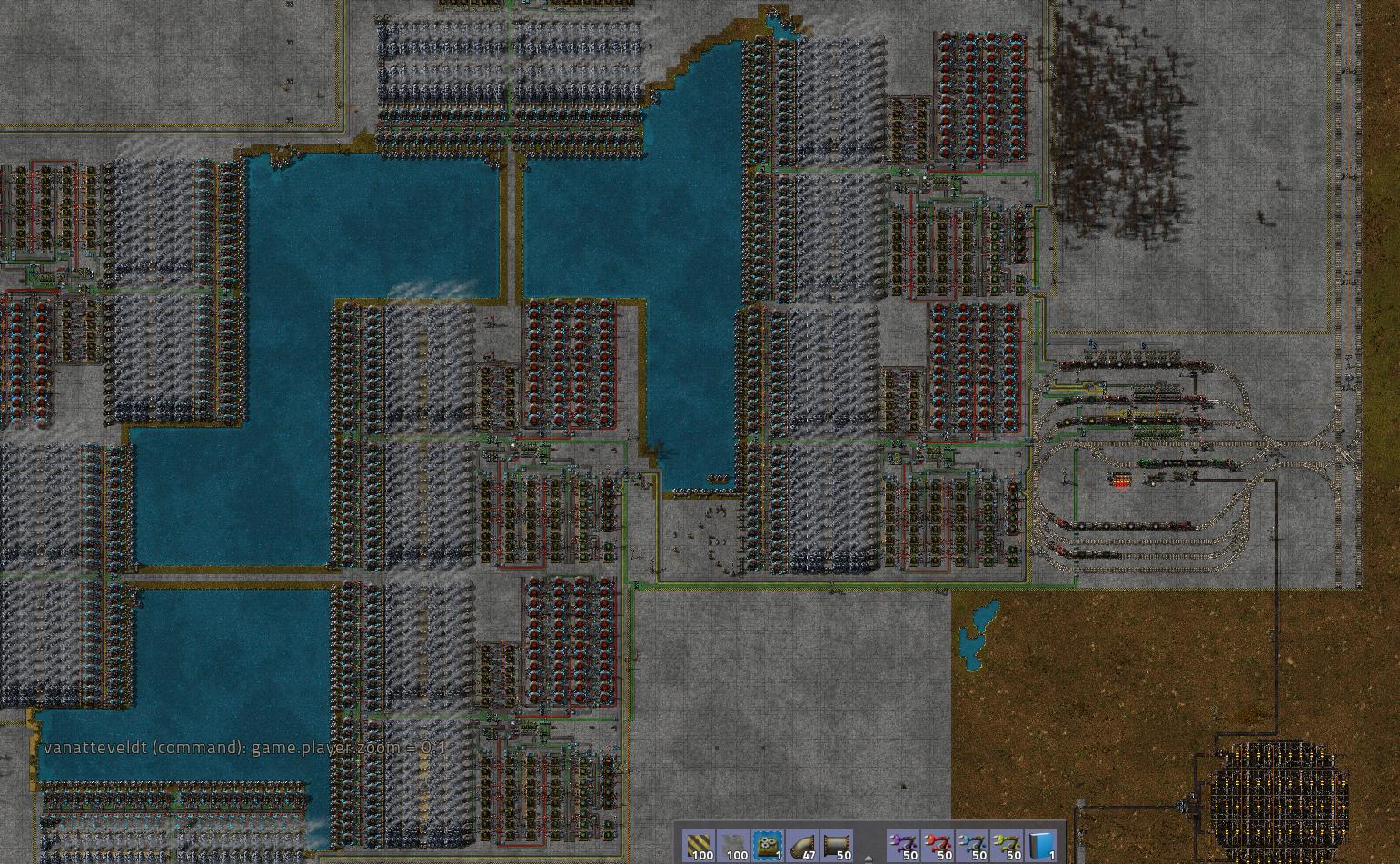

Base overview:

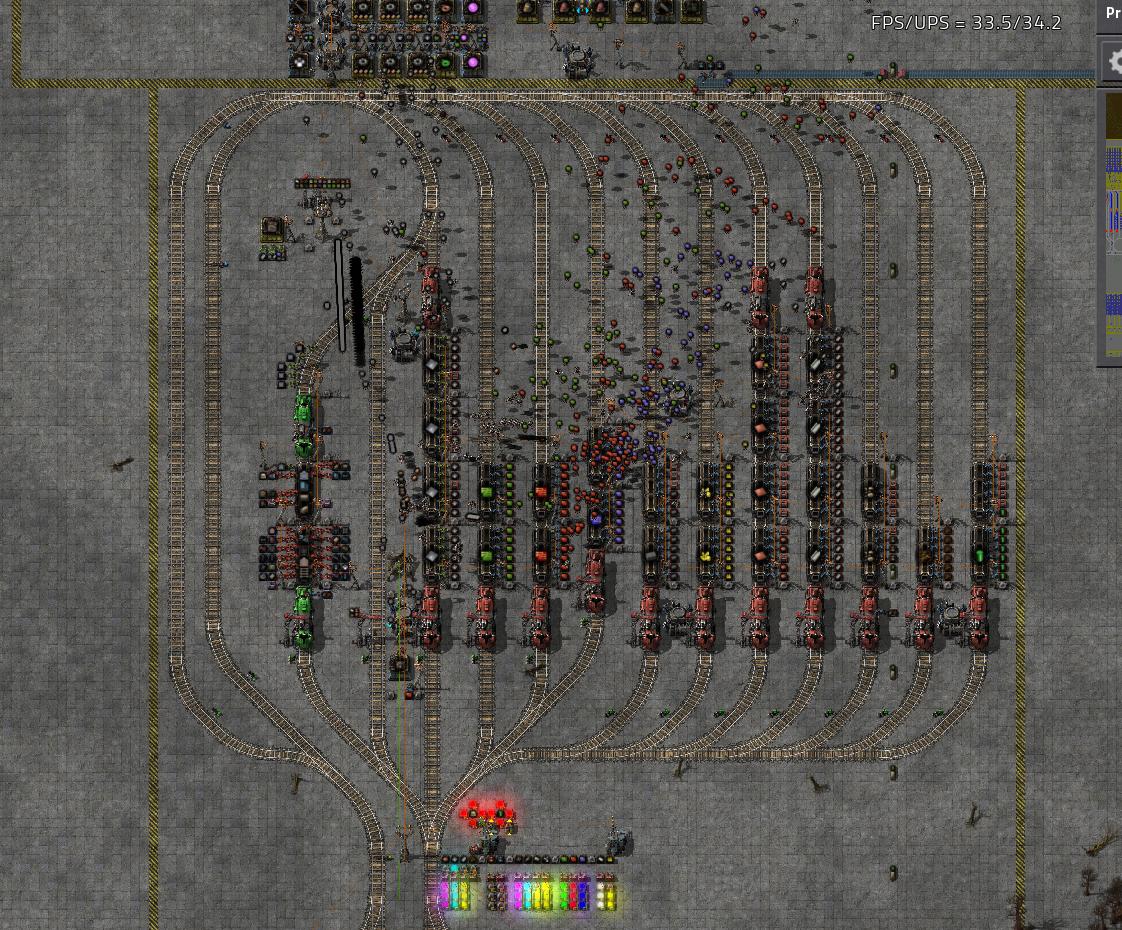

I use two main parllel east-west main train (trunk) lines: bottom is for raw resources (ore+oil) only, and top is for all produced goods. The bottom trunk link has branches to the ore patches, the top one is just a single straight line.

All stations have a loop and have waiting bays before the loop and stops after the loop. All stations also have a passenger station and most stations have a fuel supply. Where possible, each stop has a dedicated waiting bay just before the stop so there is always a train waiting right behind the unloading train.

All trains are LCCCL with both locs facing forward (same as LLCCCC but makes it easier to upgrade and combine LCC and LCCCCL on the same network). The general idea beind the track layout is described here: viewtopic.php?f=194&t=30357

Outposts:

I use two main parllel east-west main train (trunk) lines: bottom is for raw resources (ore+oil) only, and top is for all produced goods. The bottom trunk link has branches to the ore patches, the top one is just a single straight line.

All stations have a loop and have waiting bays before the loop and stops after the loop. All stations also have a passenger station and most stations have a fuel supply. Where possible, each stop has a dedicated waiting bay just before the stop so there is always a train waiting right behind the unloading train.

All trains are LCCCL with both locs facing forward (same as LLCCCC but makes it easier to upgrade and combine LCC and LCCCCL on the same network). The general idea beind the track layout is described here: viewtopic.php?f=194&t=30357

Outposts:

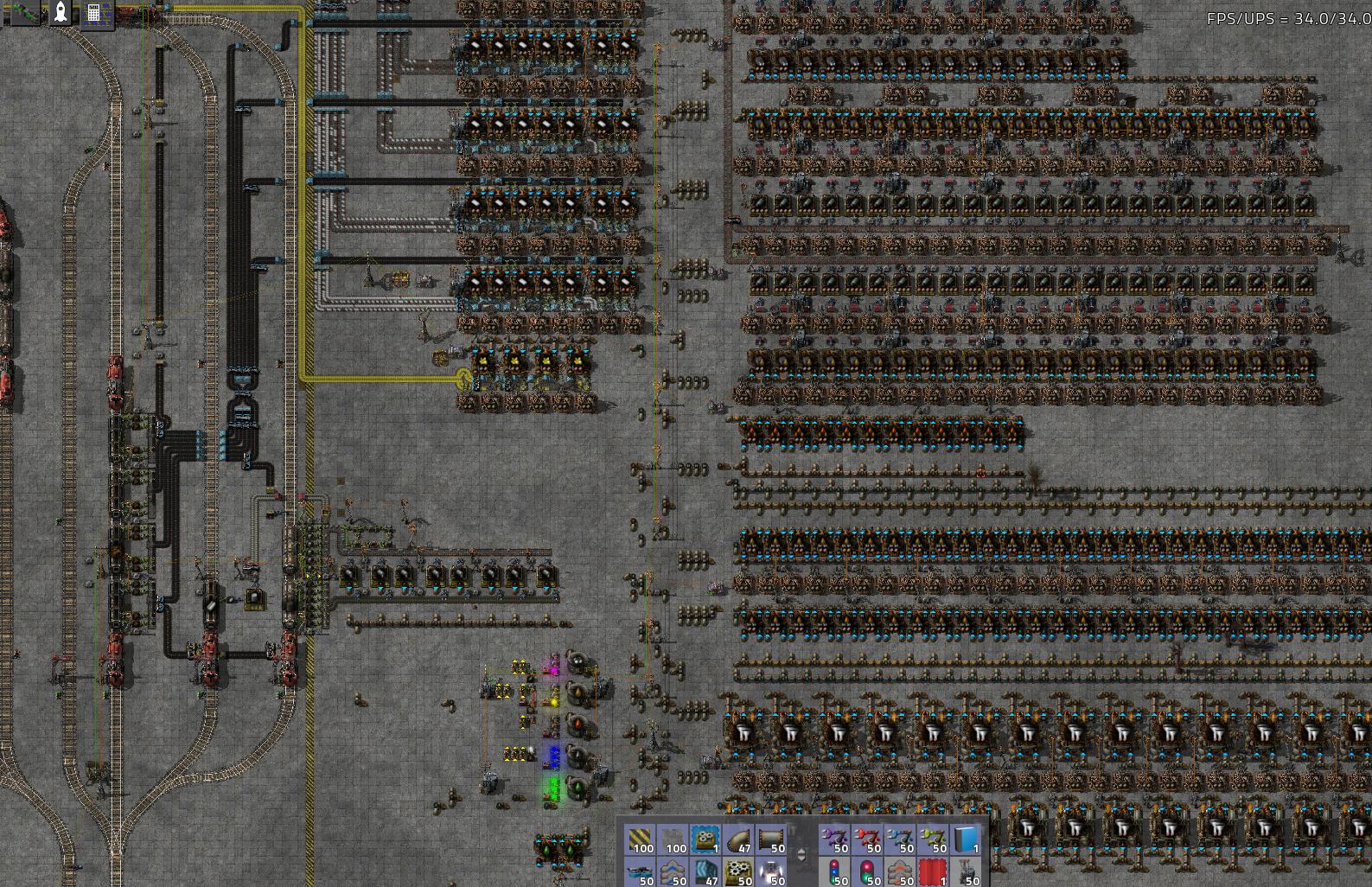

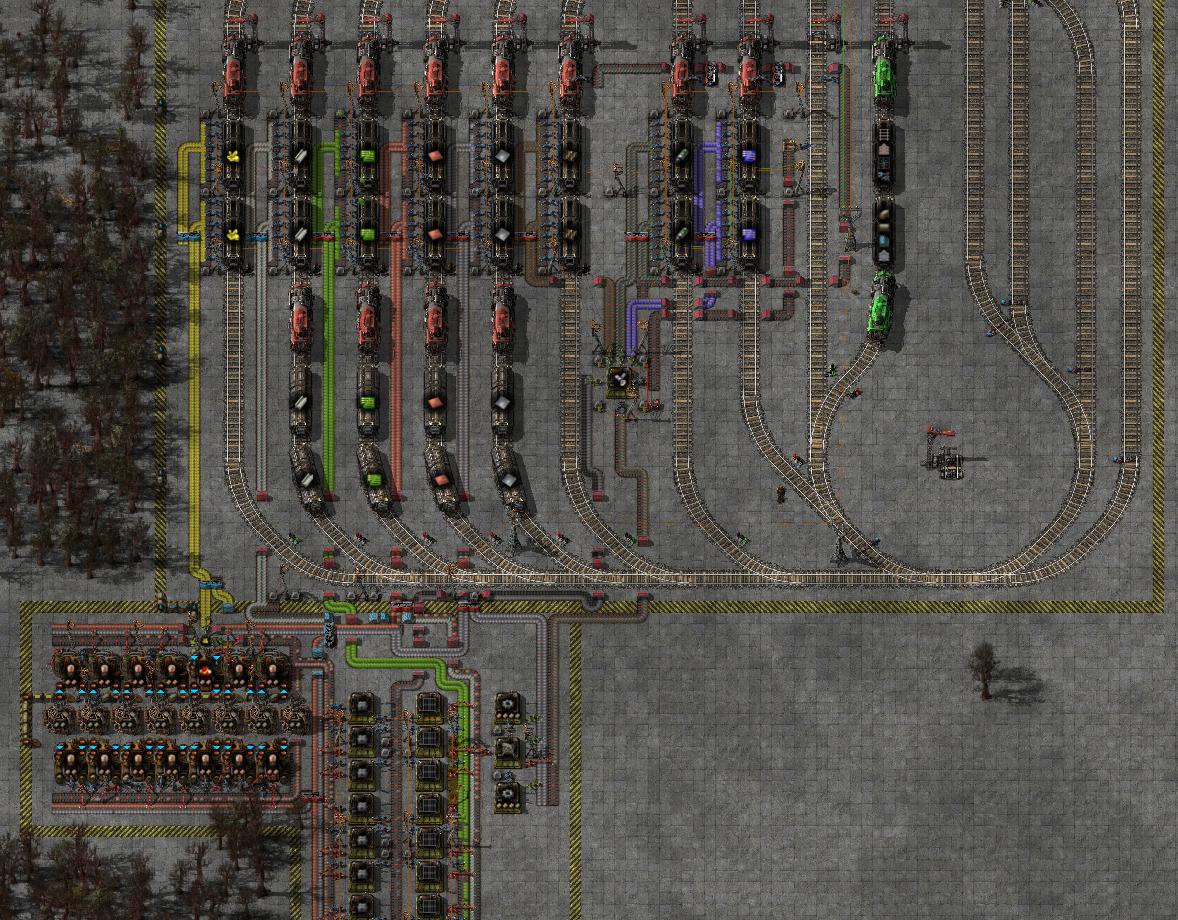

Smelting

The smelters and refinery have two stations: an unloading station (for ore) and a loading station). I combines steel and iron plates, using 6x4 express belts of ore (each unloading from one stop) to produce 3x4 belts of iron plate and around 3 belts of steel. Copper uses 4x4 belts or ore to make 4x4 belts of steel.

Smelting design: viewtopic.php?f=202&t=33375

As you can see, the station actually has two loops, to separate the ore waiting bays from the passenger+fuel stops. This allows the ore waiting bays to have two trains per bay.

Smelting is controlled with a little belt-loop that switches the power on and off below/above a certain threshold for the train loading buffer contents.

Note that the layout is a bit strange because I first had the train station N of the track and the smelters E of the train station, but I ran out of space for both smelting and unloading, so I moved the train station to S of the track but kept the smelters where they were. I guess it would be prettier if I moved both iron and copper smelting west so they're immediately north of their stations...

Smelting design: viewtopic.php?f=202&t=33375

As you can see, the station actually has two loops, to separate the ore waiting bays from the passenger+fuel stops. This allows the ore waiting bays to have two trains per bay.

Smelting is controlled with a little belt-loop that switches the power on and off below/above a certain threshold for the train loading buffer contents.

Note that the layout is a bit strange because I first had the train station N of the track and the smelters E of the train station, but I ran out of space for both smelting and unloading, so I moved the train station to S of the track but kept the smelters where they were. I guess it would be prettier if I moved both iron and copper smelting west so they're immediately north of their stations...

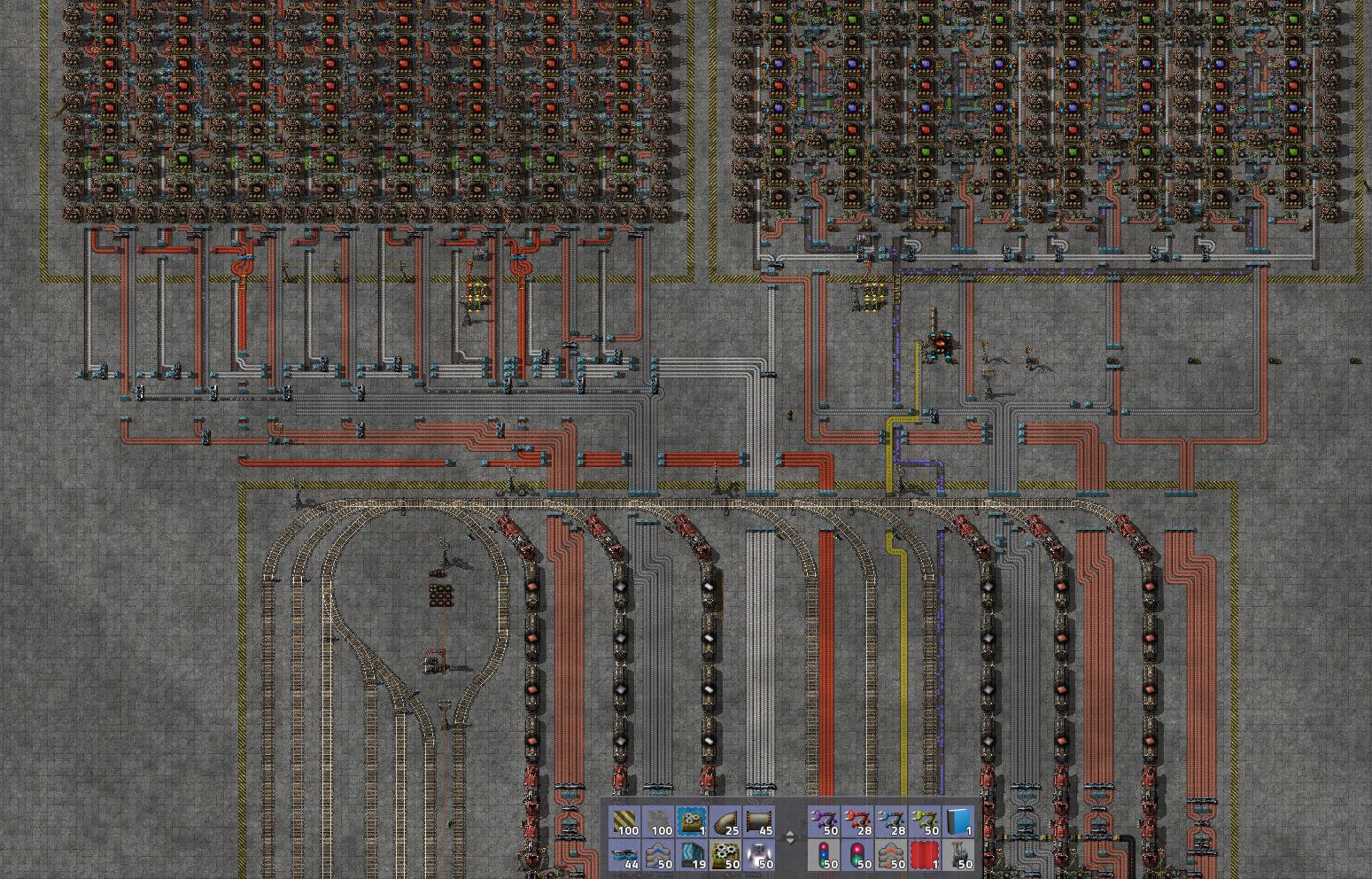

Refinery

The refinery also has two separate stations, one for unloading crude oil and one for loading refined goods (plastic, sulfur, rocket fuel). Lubricant is piped to the 'store' for belts and engines.

The tanks at the bottom are mostly for measurement, lights indicate storage level and combinators+lights to the left decide and show which processes are activated (cracking, fuel production) although light->PG cracking is mostly avoided as most light gets converted to rocket fuel, if caclulations are right it should even have a bit of PG oversupply, so some PG will be turned to rocket fuel.

Designs:

- Refinry: viewtopic.php?f=8&t=35800

- Plastic plant: viewtopic.php?f=8&t=38390#p230124

The tanks at the bottom are mostly for measurement, lights indicate storage level and combinators+lights to the left decide and show which processes are activated (cracking, fuel production) although light->PG cracking is mostly avoided as most light gets converted to rocket fuel, if caclulations are right it should even have a bit of PG oversupply, so some PG will be turned to rocket fuel.

Designs:

- Refinry: viewtopic.php?f=8&t=35800

- Plastic plant: viewtopic.php?f=8&t=38390#p230124

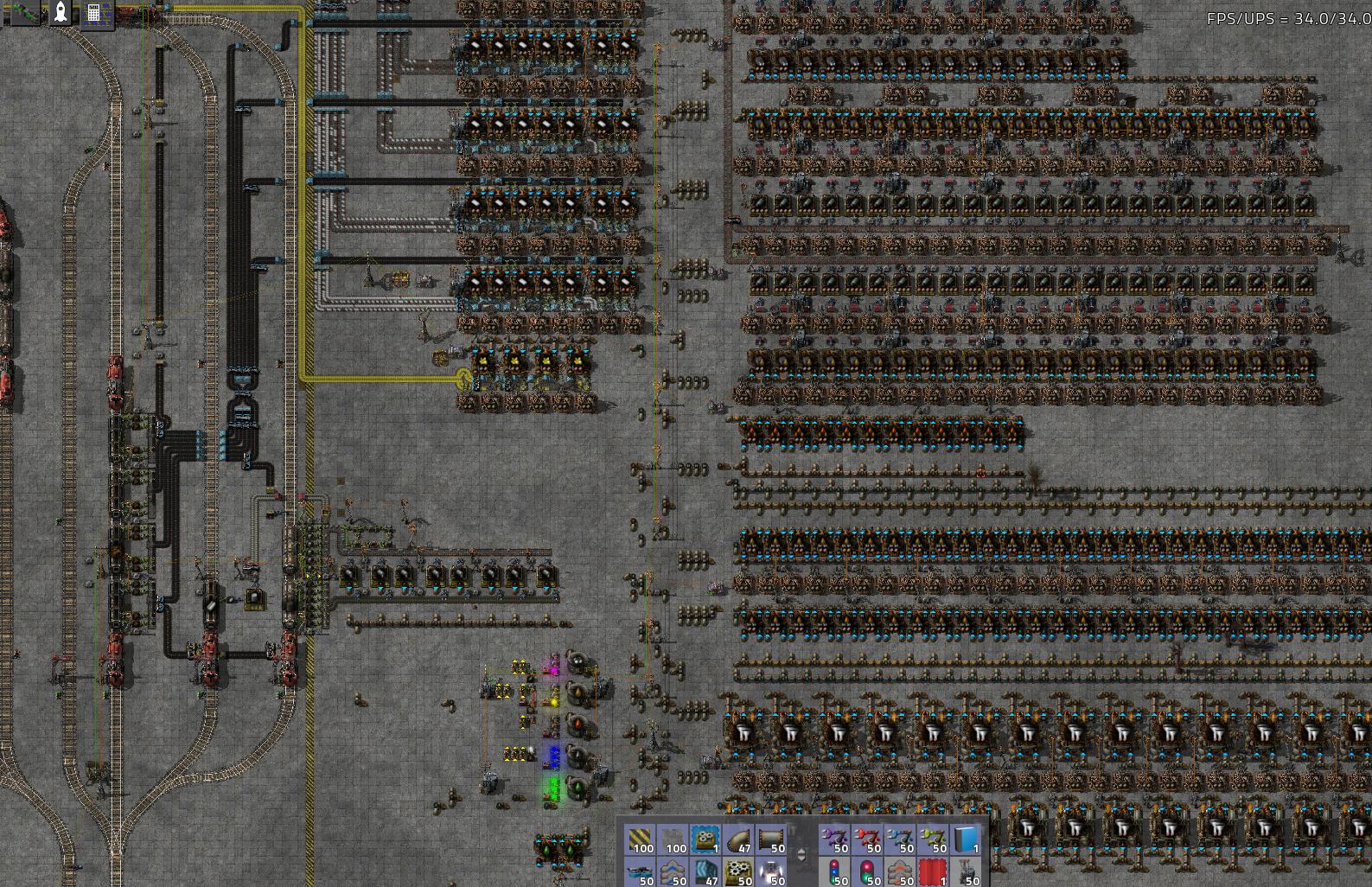

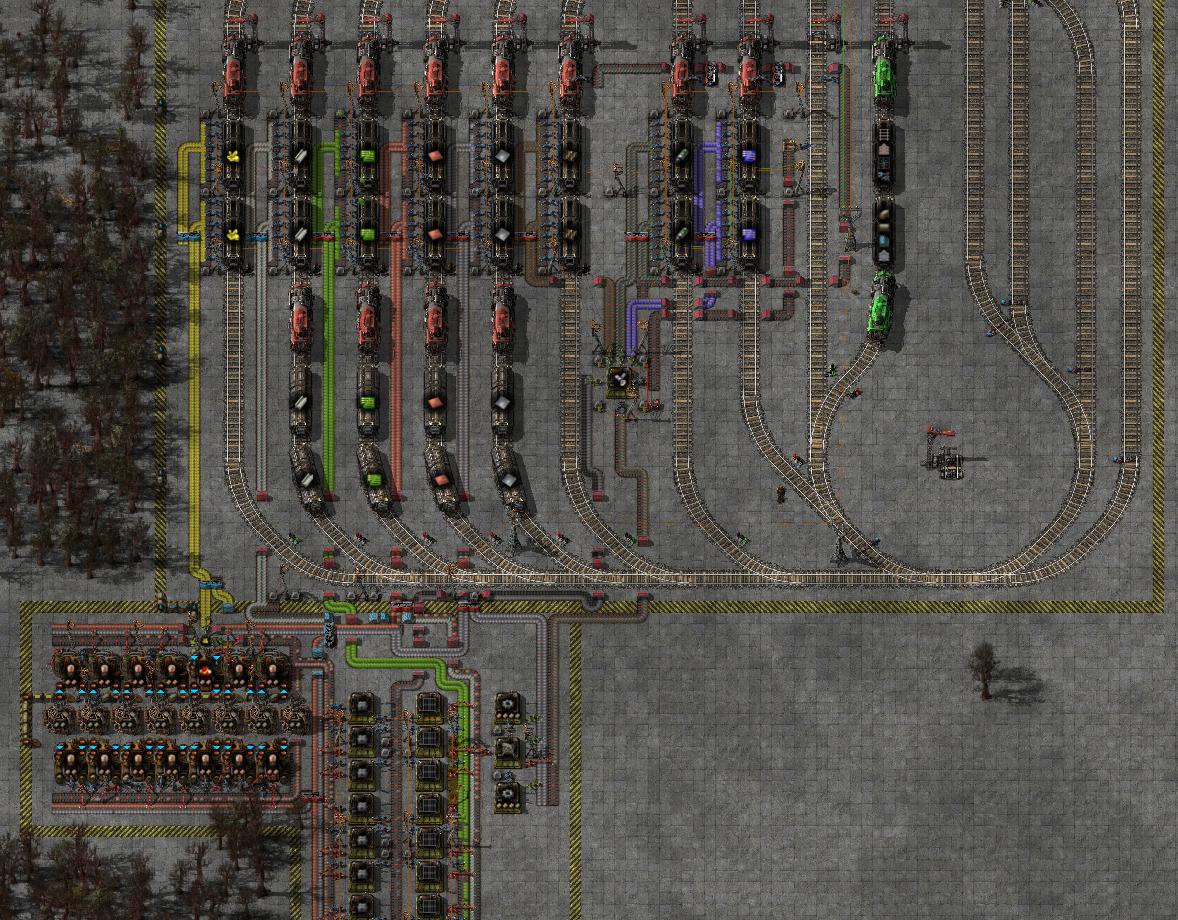

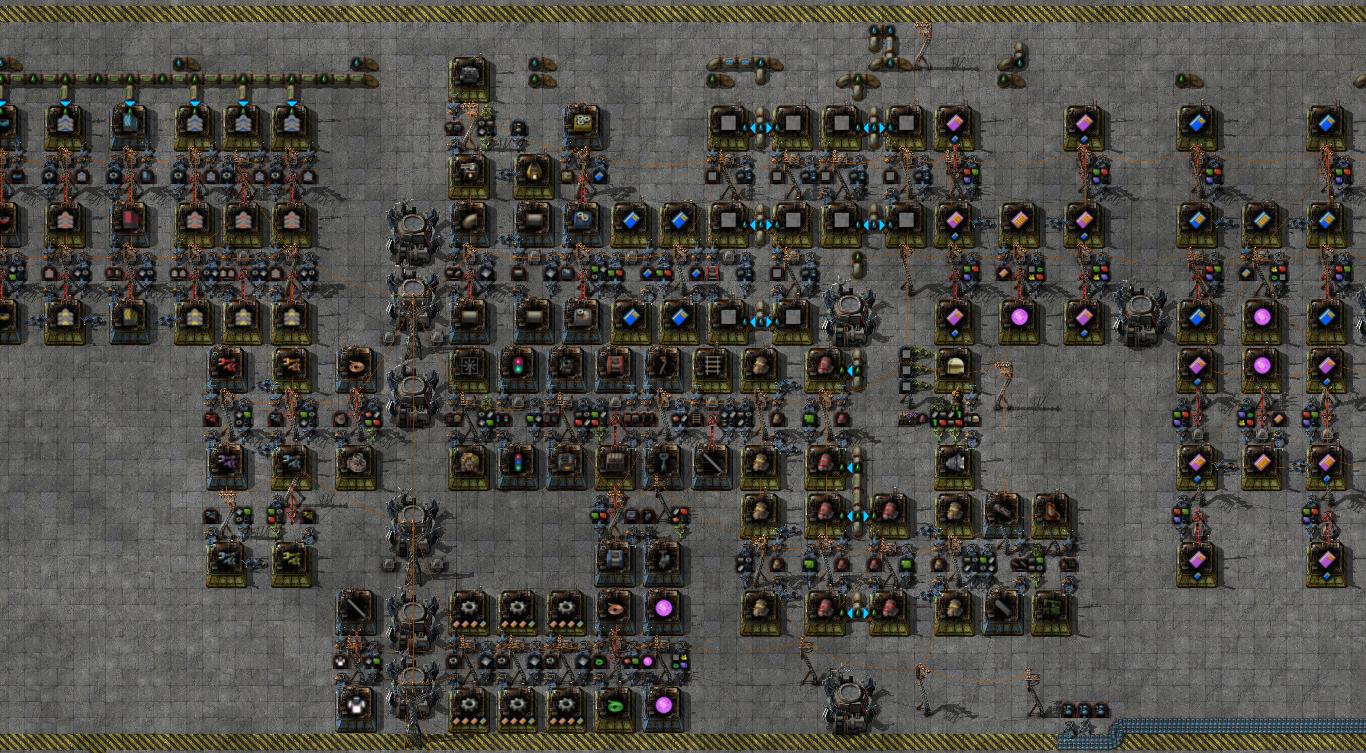

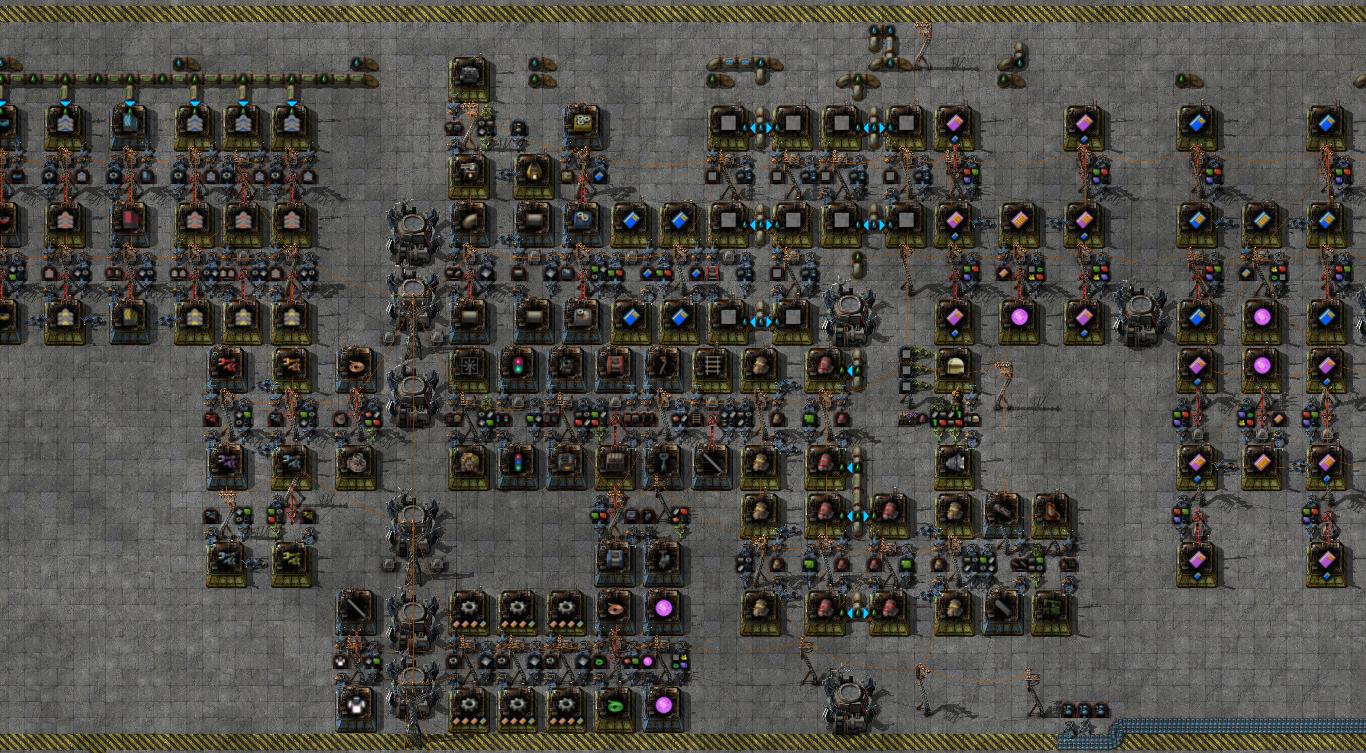

Production

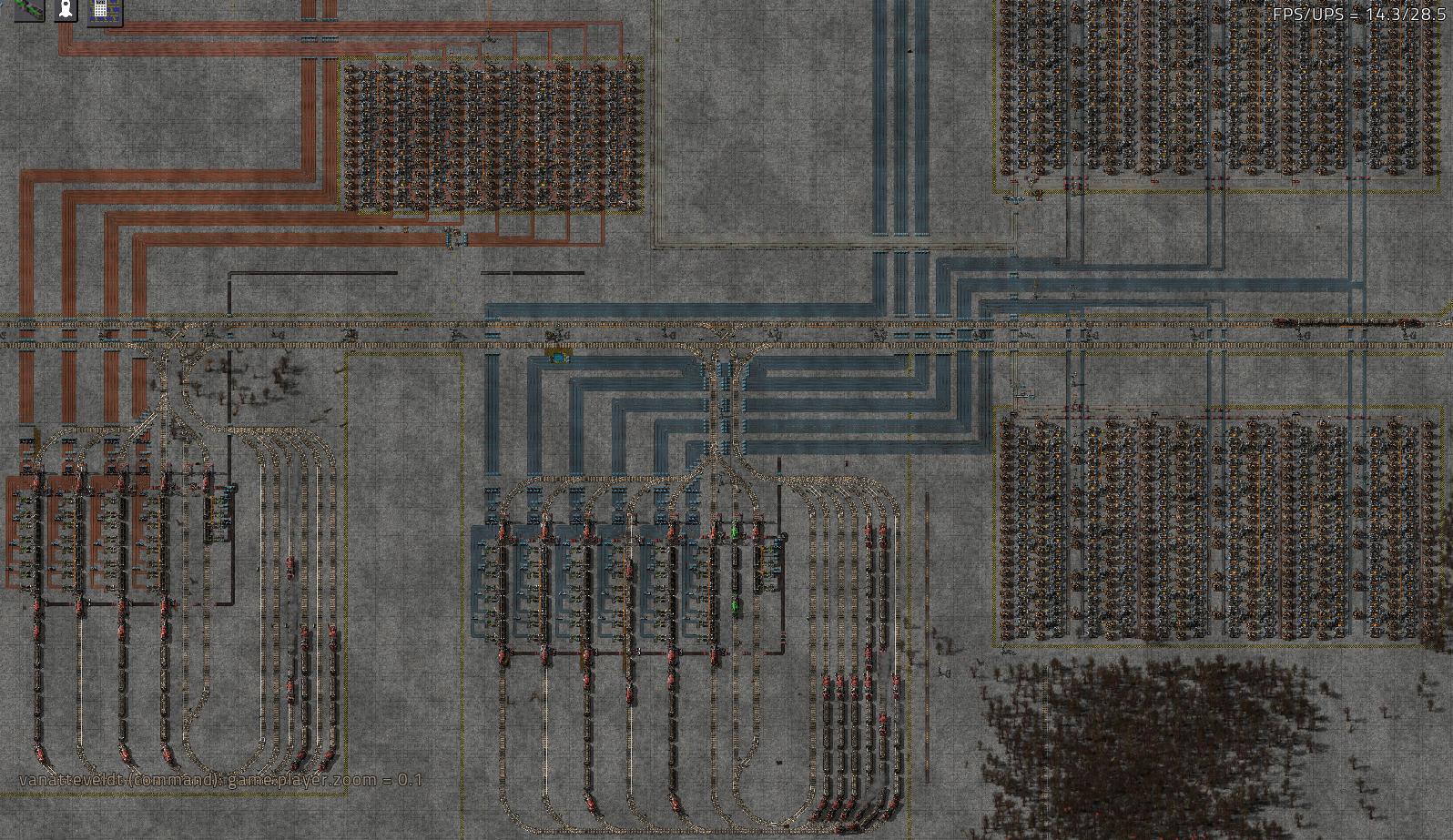

All other production is located in separate plants per product (except red and blue circuits, this was a mistake). They have a station on the 'goods' trunk with both loading and unloading.

For illustration, this is the red+blue circuit plant. All other plants have the same basic design: loading+unloading station, belt area, production plant.

Designs:

- green circuit: viewtopic.php?f=202&t=33355#p210326

- red (+green) circuits: viewtopic.php?f=8&t=37859

- blue (+green+red) circuits: viewtopic.php?f=8&t=37858

- rocket control and low density: viewtopic.php?f=202&t=38301

For illustration, this is the red+blue circuit plant. All other plants have the same basic design: loading+unloading station, belt area, production plant.

Designs:

- green circuit: viewtopic.php?f=202&t=33355#p210326

- red (+green) circuits: viewtopic.php?f=8&t=37859

- blue (+green+red) circuits: viewtopic.php?f=8&t=37858

- rocket control and low density: viewtopic.php?f=202&t=38301

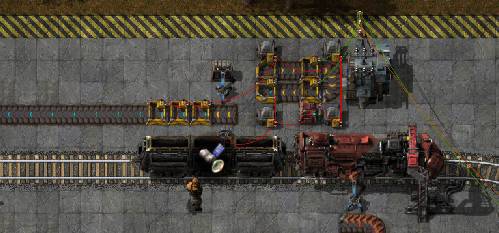

Sattelite production and supply management

This is the sattelite plant, which produces the batteries->accus and solar panels needed for 1 sattelite per minute:

Since backpressure takes a lot of time with sattelites (especially given the long belt from the launch site station to the launch site), sattelite supply is managed by combinators: the output inserter on the sattelite plants is deactivated if there are 3 sattelites waiting to be picked up by the train.

At the unloading station, there is a loop just above the sattelite unloading station to manage supply to the launch site:

The green wire connects this loop to the launch site, where it is connected to the sattelite buffer chest and to the belts just before it (which emit S when a sattelite is detected on the belt).

When supply is low the SE belt is activated, passing the token sattelite to the measurement belt on the SW corner, which activates the inserter. As soon as the sattelite is on the belt, the NW corner belt is activated, and the inserter stops. This puts 2 sattelites on the belt down to the launch site. The NE belt blocks the token from going further until the sattelite has reached the launch site. The two yellow belts give the inserter at the launch site time to place the sattelite into storage, blocking the SE belt again if supplies are now sufficient. The train only leaves when it is empty, and the sattelite plant deactivates when it has enough sattelites in its output buffer, creating a backpressure without needing to fill the whole belt to the launch site with sattelites...

Since backpressure takes a lot of time with sattelites (especially given the long belt from the launch site station to the launch site), sattelite supply is managed by combinators: the output inserter on the sattelite plants is deactivated if there are 3 sattelites waiting to be picked up by the train.

At the unloading station, there is a loop just above the sattelite unloading station to manage supply to the launch site:

The green wire connects this loop to the launch site, where it is connected to the sattelite buffer chest and to the belts just before it (which emit S when a sattelite is detected on the belt).

When supply is low the SE belt is activated, passing the token sattelite to the measurement belt on the SW corner, which activates the inserter. As soon as the sattelite is on the belt, the NW corner belt is activated, and the inserter stops. This puts 2 sattelites on the belt down to the launch site. The NE belt blocks the token from going further until the sattelite has reached the launch site. The two yellow belts give the inserter at the launch site time to place the sattelite into storage, blocking the SE belt again if supplies are now sufficient. The train only leaves when it is empty, and the sattelite plant deactivates when it has enough sattelites in its output buffer, creating a backpressure without needing to fill the whole belt to the launch site with sattelites...

Store

As said above, I have a logibots-based 'store' that produces everything I need to build outposts and plants. It has a stop that automatically loads my passenger train, so if I am building something I can grab stuff send it to store and back, and it comes back with fresh supplies. There are indicator lights that show overall buffer levels, only the ore buffers are disconnected.

Power

Power is entirely nucular, there is a little wood stove in the store to burn off excess wood and there is an emergency coal plant to restart the nuclear plant if needed. Total power is 2.8 GW from 8 490MW plants around a big lake now called 'glowing lake' (which was landfilled to create straight edges). Eacht plant has all enrichment/reprocessing facilities and an internal fuel buffer (design: viewtopic.php?f=93&t=21676&start=100#p229100)

6 plants consume one express belt of iron and less than one mixed belt of uranium+sulfur (so essentially it's burning iron more than uranium...)

The plants close to the station output excess fuel which is shipped to the 'store' to build new reactors.

6 plants consume one express belt of iron and less than one mixed belt of uranium+sulfur (so essentially it's burning iron more than uranium...)

The plants close to the station output excess fuel which is shipped to the 'store' to build new reactors.

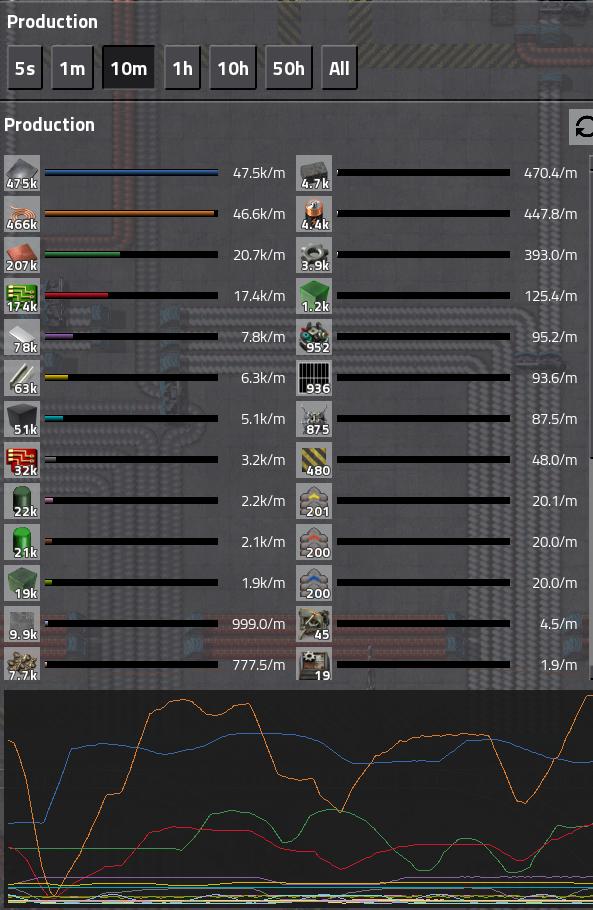

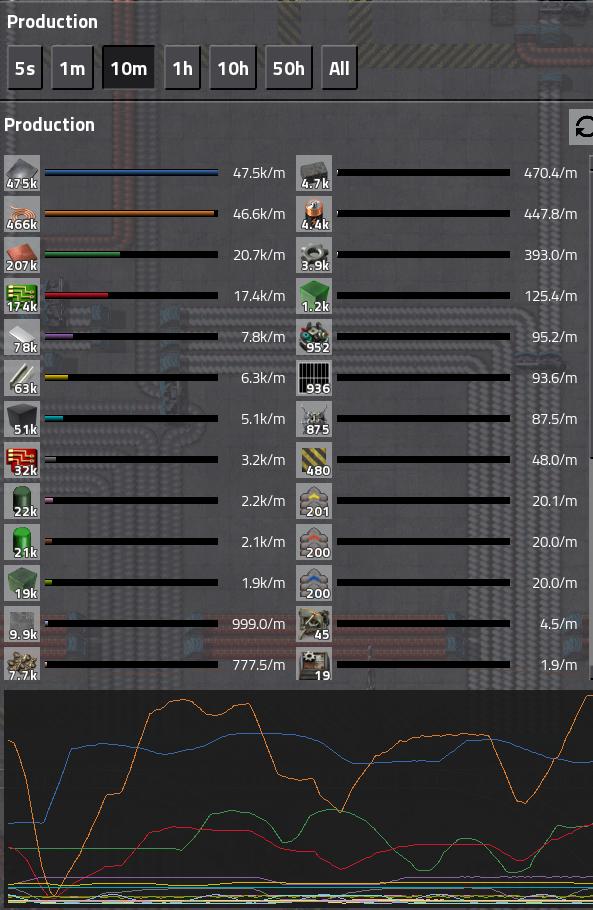

Statistics

I used Helmod to plan the base. 1 rocket per minute requires 715 of each rocket part per minute and a sattelite (=100 LDS+50fuel). This in turn requires 5.1k green, 3.5k red, and 815 blue circuits per minute. In total, it needs 27k copper plates, 18k iron, 6k steel, 3k plastic and 1k sulfur (mainly for sattelite batteries).

(edit: screenshot corrected, see below)

(P)roduction screen:

(edit: screenshot corrected, see below)

(P)roduction screen:

_

_