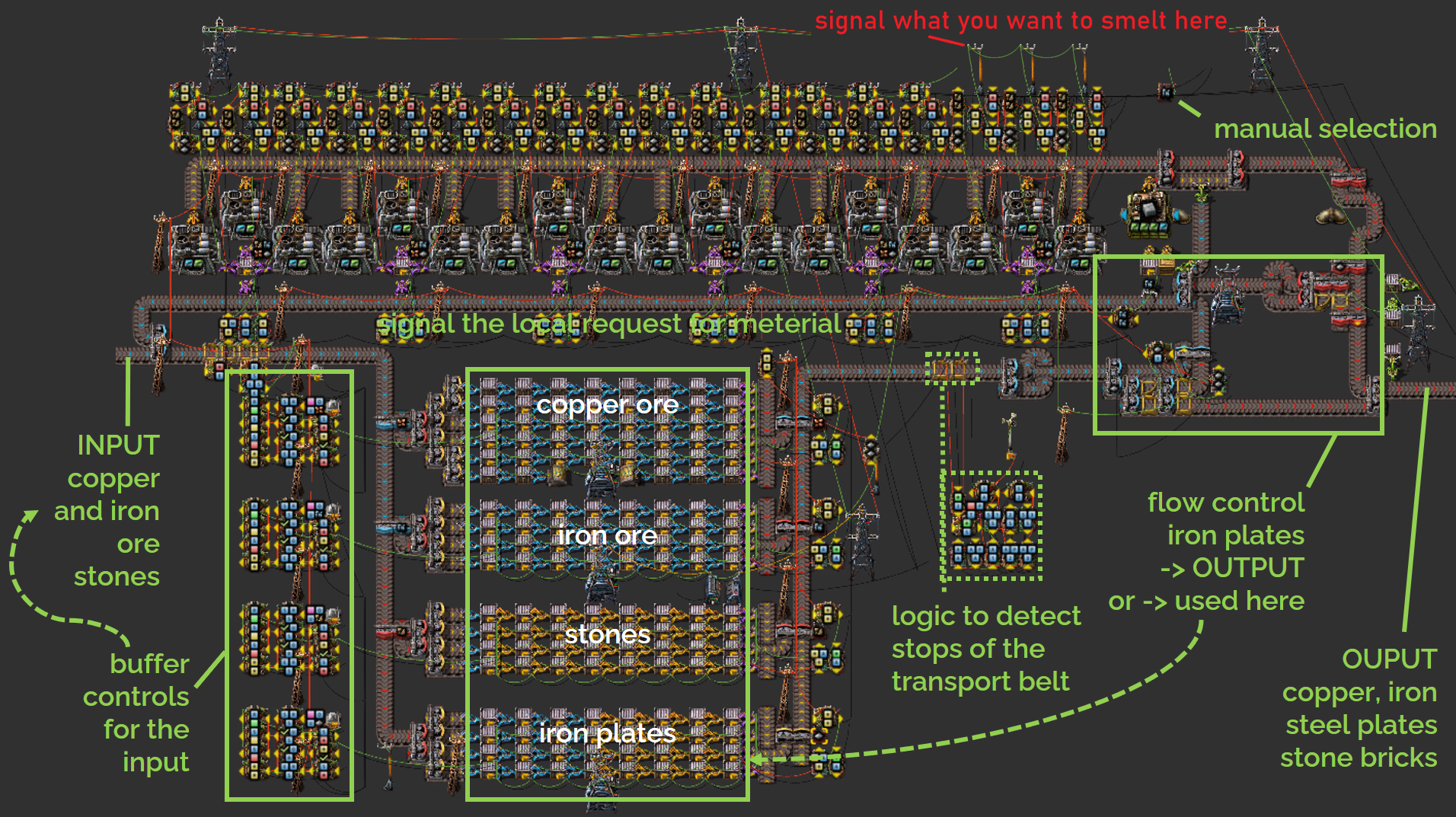

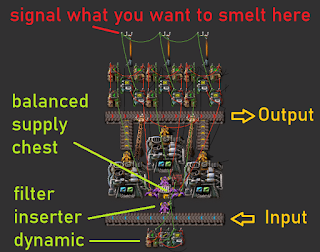

You can put as many as you want in a row. Its possible to produce different products at the same time. The production line may change products as fast as the ovens work. The only limitation is the supply chest. All raw material have to be in there. The filter inserter for the ovens are set to the desired material. The solution ist efficient.

The logistics of my factory is organised with pull control. Instead of the widespred main-bus system, which ist basically a push system. Thus i need flexible sourcing with bases Material. In my current factory I replaced >40 ovens with 18 without loss in performance.

Thanks to Fab2000 for the basic setup.