I finally made something responsible for producing Bioflux that meets my requirements

Rules

- Fastest process for highly spoilable ingredients: All Yumako mash and Jelly must exist for the shortest time possible before consumption. This means they must be transferred directly from biolab to biolab by green inserters. Each biolab should hold no more than the necessary amount of Yumako mash or Jelly needed for subsequent production.

- Resilience to bottlenecks: The system must not break if the Bioflux output becomes jammed or if there is a temporary shortage of Yumako or Jellynut. In such cases, the system should be capable of restarting using the spoilage generated within it.

- No spoilage in normal operations: During regular operation, with sufficient Yumako, Jellynut, and no output jams, nothing should spoil—including nutrients.

- Do not break ratios that much: You need 2.5 Yumako processing and 1 Jelly processing per 3 Bioflux processing. It is something nice to have but not entirely neccesary and should not by put higher in priorities above previous points.

Yumako mesh processing creates a reasonable ammount of nutrients to feed other biolabs. But keep in mind its ingredient (yumako mesh) has short spoilage time.

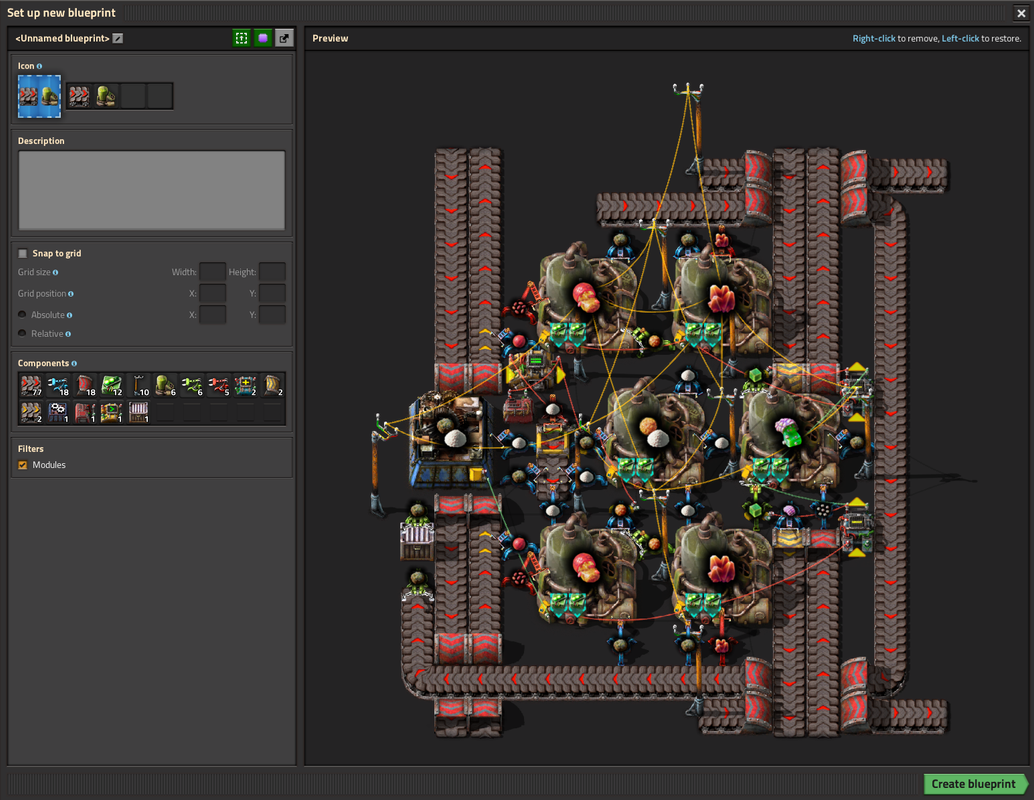

Blueprint

Small note: You might find it confusing why the picture shows only spoilage output from the nutrient processing to the belt on the left. That’s not the case. There is a controlled inserter with filters in place to ensure that no more than one nutrient is on the belt at a time.

Theory behind

Our aim is to create science packs with the highest possible freshness. The freshness of science packs is influenced by their sub-ingredients. In the production chain, almost all ingredients have a spoilage time of one hour or more, except for two: Jelly and Yumako mash. For example, 1 second of spoilage on Yumako mash results in the same spoilage impact as 20 seconds on Yumako. This creates a strong incentive to minimize the time Yumako mash and Jelly spend in the system. Let me explain the first trick.

In the picture above, Yumako processing is conditional and operates only if the bioflux processing system has no more than the amount required for the current production cycle and the next one (2 * 15 = 30). Without a system like this, Yumako mash can accumulate, leading to an increased spoilage rate. This issue could be addressed by maintaining a perfect ratio of 5 Yumako mash to 6 bioflux production cycles. However, achieving this precise ratio is a logistical challenge and likely not feasible without negatively impacting processing speed.

It might be surprising, but this simple trick using just one wire within the Yumako mash processing system can achieve the same effect as upgrading your Yumako fruit transport from yellow belts to trains.

Now, let’s talk about nutrients. There is a lot to cover on this topic alone. As you may know, there are three different recipes for producing nutrients

Each of these recipes has its own efficient way to be utilized.

Processing spoilage should not be your primary source of nutrients, as the ratio is highly inefficient. However, it is ideal for kickstarting your factory when recovering from an unexpected accident. Note: Among all these recipes, spoilage processing can be performed in a standard assembly machine, which does not require any additional nutrients to function. This makes spoilage processing even more suitable for resolving accidental scenarios.

Yumako mash processing generates a reasonable amount of nutrients to supply other biolabs. However, keep in mind that its main ingredient, Yumako mash, has a short spoilage time.

Bioflux processing generates a large amount of nutrients in a very short time, making it an excellent candidate for recipes that explicitly require nutrients. However, if it is used to supply only a few regular biolabs, there could be an issue where a significant amount of nutrients is produced at once, potentially leading to excessive spoilage.

Now let me explain another trick that helps reduce nutrient spoilage.

Once again, this setup uses just one wire and condition in the biolab (and reading its content). The wire connects any pole to the biolab, ensuring that the biolab sends a signal to itself. This trick prevents the production of additional nutrients when the previous batch is still inside the biolab. Without this setup, nutrients could accumulate excessively, leading to an unnecessarily high rate of spoilage.

Speaking of nutrients in general, it is also recommended to reduce biolab consumption to the minimum limit (20%). This can be achieved using one of these common module choices.