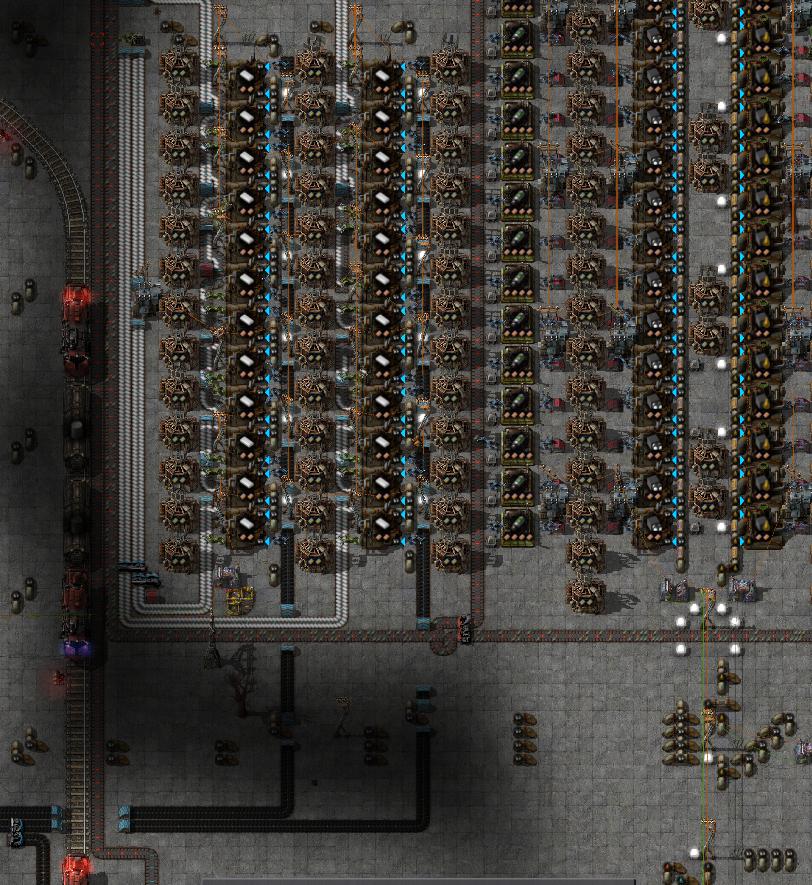

This is my current setup that seems to have solved the problem:

But I feel like I don't really know what I'm doing, so maybe this is massive overkill, and maybe this is just plain stupid design.

Practical questions:

1) Is the 90/s value for 14-224 pipes still correct?

2) Is it OK to connect pipes? For example, in the bottom right of the screenshot I reconnect all 4 pipes to branch to the solid fuel processing (which is activated only if PG is too high) and then branch them off again:

Does that lower/alter total throughput? Does that depend on whether fuel processing is switched off, i.e. whether PG is diverted north?

3) Does connecting pipes like above balance the fluids? I.e., if PG is diverted north, does it come equally from all 4 pipes, or only/mainly from the top one?

4) Suppose I reconnect two of the pipes just before they go into the plastics rack. Does that give more flow in the connected part? If half of it is consumed within 14 pipes, is the max for the remainder of the rack still 90/s?

(and is there a "flow meter" mod somewhere? They should really allow wires to connect to pipes like they do to belts...)