Why big output buffer in Furnaces?

Why big output buffer in Furnaces?

The Stone Furnaces, Steel Furnaces and Electric Furnaces in Factorio stand apart from the other machines, such as Assembler Machines, Refineries and Chemical Factories, in that they have huge output buffers, able to internally store a stack of 100 metal Plate or 100 Brick, whereas the other machines can only store comparatively few items, or comparatively small amounts of fluids.

I think that should be changed.

First of all it's a control issue. I might want to set up a huge pair of rows of Furnaces but not want them to consume energy and input to build up a huge buffer. If I wanted a buffer I could set that up manually with space-limited Chests. I should have the choice of whether to have a buffer or not, instead of a size-100 buffer being forced inavoidably upon me.

Secondly, it's a balance issue. Buffers take up space. Specifically the height or the weight of a furnace setup is increased by 2 tiles or 4 tiles for a double-sided one, the extra space it takes for a Chest and the Inserter. It costs next to nothing to build or to power (the cost to move one single item with electrical power is something like 1/400 Coal), but it would take up space, making for slightly larger factories overall.

I think that should be changed.

First of all it's a control issue. I might want to set up a huge pair of rows of Furnaces but not want them to consume energy and input to build up a huge buffer. If I wanted a buffer I could set that up manually with space-limited Chests. I should have the choice of whether to have a buffer or not, instead of a size-100 buffer being forced inavoidably upon me.

Secondly, it's a balance issue. Buffers take up space. Specifically the height or the weight of a furnace setup is increased by 2 tiles or 4 tiles for a double-sided one, the extra space it takes for a Chest and the Inserter. It costs next to nothing to build or to power (the cost to move one single item with electrical power is something like 1/400 Coal), but it would take up space, making for slightly larger factories overall.

Re: Why big output buffer in Furnaces?

Because in the early game, you can setup furnaces to smelt without electricity, using burner miners and burner inserters. It would be incredibly inconvenient that they would only stack to 4 or 5 in the furnaces, meaning you would have to keep emptying them very regularly.

I for one, am happy with the current output inventory size, and do not think it is any issue that needs to be fixed

I for one, am happy with the current output inventory size, and do not think it is any issue that needs to be fixed

Re: Why big output buffer in Furnaces?

Inserters won't feed an assembler when the finished good is overstocked, AND the assembler has a stalled output inserter. Furnaces don't have this behavior for some reason. If the output can't be removed, inserters will keep feeding the smelter until the output stack is full.

Under most circumstances this is good behavior. Raw ore is pretty much useless and a furnace can empty out pretty fast when it gets used. It is a minor problem for steel smelting, as a line of steel clogged furnaces represents a huge amount of ore.

Under most circumstances this is good behavior. Raw ore is pretty much useless and a furnace can empty out pretty fast when it gets used. It is a minor problem for steel smelting, as a line of steel clogged furnaces represents a huge amount of ore.

- bobingabout

- Smart Inserter

- Posts: 7352

- Joined: Fri May 09, 2014 1:01 pm

- Contact:

Re: Why big output buffer in Furnaces?

It's not really a difference in the output buffer, in all cases the output can store one whole stack of said item.

The difference is in the construction behaviour.

In all cases, if you put the ingredients into a machine, the machine will work until either it no longer has enough ingredients to produce the item, or the output contains a full stack. If the ingredients are fluids, they'll always fill the machine, so you often find chemical plants auto-produce until the output is full too.

A furnace is a "Dumb" machine, it will take one ingredient only, and automatically choose the recipe to produce an item from the ingredient. It will just keep feeding in ingredients upto the input buffer, until the output is full. Since it is usually used as a furnace to melt metal, something you use a lot of, this is generally desired behaviour.

An assembling machine (and other machines based on the mechanics, like chemical plant and oil refinery) is a "Smart" machine, it will only take in ingredients up to what it needs to make an item if the output doesn't contain more than one of said item, waiting for the output item to be removed before continuing.

Does this help at all?

The difference is in the construction behaviour.

In all cases, if you put the ingredients into a machine, the machine will work until either it no longer has enough ingredients to produce the item, or the output contains a full stack. If the ingredients are fluids, they'll always fill the machine, so you often find chemical plants auto-produce until the output is full too.

A furnace is a "Dumb" machine, it will take one ingredient only, and automatically choose the recipe to produce an item from the ingredient. It will just keep feeding in ingredients upto the input buffer, until the output is full. Since it is usually used as a furnace to melt metal, something you use a lot of, this is generally desired behaviour.

An assembling machine (and other machines based on the mechanics, like chemical plant and oil refinery) is a "Smart" machine, it will only take in ingredients up to what it needs to make an item if the output doesn't contain more than one of said item, waiting for the output item to be removed before continuing.

Does this help at all?

Re: Why big output buffer in Furnaces?

Assemblers will automatically shut down when their output is clogged. This behavior only happens when inserters are involved- they will refuse to load in excess resources until the previous product is ejected. I think the "issue" is that furnaces don't have this behavior. Inserters will continue to fill up a furnace until the output is maxed out.

While it's usually nice to keep your smelters busy and build up a resource buffer, it is a bit inconsistent to have one system throttle its input while the other doesn't.

While it's usually nice to keep your smelters busy and build up a resource buffer, it is a bit inconsistent to have one system throttle its input while the other doesn't.

- Ranakastrasz

- Smart Inserter

- Posts: 2173

- Joined: Thu Jun 12, 2014 3:05 am

- Contact:

Re: Why big output buffer in Furnaces?

I would note that, at least in vanilla, nothing you make with a furnace can be wastefully overproduced. Assemblers can make really expensive things which you might not want, so inserters are set to only put materials in if there is room for the result. If you want a lot of stuff out, you can use inserters to remove the stuff as it is made.

Furnaces however make plates and stone brick. None of those are really the kind of thing you only want 2 of. You need dozens or hundreds for most projects, so it makes some sense for it to have the higher cap.

However, for consistency, I can agree that furnaces should have the same limitation. This might also encourage usage of burner inserters.

Furnaces however make plates and stone brick. None of those are really the kind of thing you only want 2 of. You need dozens or hundreds for most projects, so it makes some sense for it to have the higher cap.

However, for consistency, I can agree that furnaces should have the same limitation. This might also encourage usage of burner inserters.

My Mods:

Modular Armor Revamp - V16

Large Chests - V16

Agent Orange - V16

Flare - V16

Easy Refineries - V16

Modular Armor Revamp - V16

Large Chests - V16

Agent Orange - V16

Flare - V16

Easy Refineries - V16

Re: Why big output buffer in Furnaces?

I for one am happy with our max-stack furnace overlords. It makes the early game less annoying

Re: Why big output buffer in Furnaces?

This is very true.Ranakastrasz wrote:I would note that, at least in vanilla, nothing you make with a furnace can be wastefully overproduced. Assemblers can make really expensive things which you might not want, so inserters are set to only put materials in if there is room for the result. If you want a lot of stuff out, you can use inserters to remove the stuff as it is made.

Furnaces however make plates and stone brick. None of those are really the kind of thing you only want 2 of. You need dozens or hundreds for most projects, so it makes some sense for it to have the higher cap.

However, for consistency, I can agree that furnaces should have the same limitation. This might also encourage usage of burner inserters.

It's just that early in the game, I might want to avoid producing to buffer, especially for Steel. I might very well want to set up a lot of Furnaces but not wanting the excess pollution that smelting to buffer would create, whereas later in the game I'd be perfectly OK with utilizing the internal 100-size buffer that each Furnace has.

And, yes, consistency.

- Ranakastrasz

- Smart Inserter

- Posts: 2173

- Joined: Thu Jun 12, 2014 3:05 am

- Contact:

Re: Why big output buffer in Furnaces?

I do think that the game would not suffer much from applying the same 2-cycle cap on furnaces as assembling machines use, as long as it follows a few rules

If a mining drill goes directly into the furnace, then it should still go to cap. Once you get an electric drill, you need two furnaces to keep up, but that just means you go from 2 to 4 inserters, since you need an output as well.

Since you might have trouble getting enough electronic inserters early, I would suggest burner inserters. Since those are essentially unable to be recycled, a recipe change would be sane (and is long overdue in my opinion) (I haven't gotten any clear data on if burner inserters feeding boilers is more efficient than electric inserters)

Burner Inserter + Electronic Circuit = Inserter

If a mining drill goes directly into the furnace, then it should still go to cap. Once you get an electric drill, you need two furnaces to keep up, but that just means you go from 2 to 4 inserters, since you need an output as well.

Since you might have trouble getting enough electronic inserters early, I would suggest burner inserters. Since those are essentially unable to be recycled, a recipe change would be sane (and is long overdue in my opinion) (I haven't gotten any clear data on if burner inserters feeding boilers is more efficient than electric inserters)

Burner Inserter + Electronic Circuit = Inserter

My Mods:

Modular Armor Revamp - V16

Large Chests - V16

Agent Orange - V16

Flare - V16

Easy Refineries - V16

Modular Armor Revamp - V16

Large Chests - V16

Agent Orange - V16

Flare - V16

Easy Refineries - V16

Re: Why big output buffer in Furnaces?

I'd like that cap to be raised to 3 in general. Just feels neater. But it should apply to Furnaces too.Ranakastrasz wrote:I do think that the game would not suffer much from applying the same 2-cycle cap on furnaces as assembling machines use, as long as it follows a few rules

Re: Why big output buffer in Furnaces?

I think dumb furnaces should remain dumb. you put ore in, you get plates out. I also think that they should keep burning fuel permanently, not only when doing usefull smelting. how did those 5 stones i used to make the furnace learn to turn on and off the fire depending on if there's ore in the thing? Though i think if this is done there should be a smart version of the stone and steel furnaces added (that include green chips in recepie)

Electric furnaces, yes, those include a circuit, so they should be smart, and only use electricity when there's something to smelt, and only smelt as much as the output can handle (be that an output inserter, or just the stack on the output side if there isnt an inserter taking out, just like assembly machines do).

For those that dont want furnces to include buffers, just feed your furncaces with smart inserters wired to stop when the output is clogged (either smart chest on other side of furnace or wire from your storage area or logistic network)

Electric furnaces, yes, those include a circuit, so they should be smart, and only use electricity when there's something to smelt, and only smelt as much as the output can handle (be that an output inserter, or just the stack on the output side if there isnt an inserter taking out, just like assembly machines do).

For those that dont want furnces to include buffers, just feed your furncaces with smart inserters wired to stop when the output is clogged (either smart chest on other side of furnace or wire from your storage area or logistic network)

Re: Why big output buffer in Furnaces?

Why do you think this needs to be changed?

Cool suggestion: Eatable MOUSE-pointers.

Have you used the Advanced Search today?

Need help, question? FAQ - Wiki - Forum help

I still like small signatures...

Have you used the Advanced Search today?

Need help, question? FAQ - Wiki - Forum help

I still like small signatures...

Re: Why big output buffer in Furnaces?

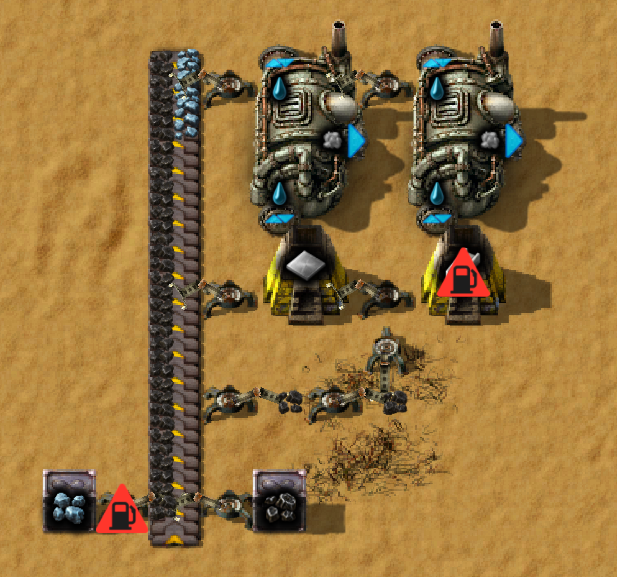

You can avoid this with a simple circuit.

Set the transport band on the output side to read hold, and connect to the input inserter, and on the inserter set requirement that the output material (steel) be less than 1.

Then the inserter will only be active if there is no steel on the output side, so when the transport band is full and not moving, nothing will be inserted so the furnace will not buffer.

Set the transport band on the output side to read hold, and connect to the input inserter, and on the inserter set requirement that the output material (steel) be less than 1.

Then the inserter will only be active if there is no steel on the output side, so when the transport band is full and not moving, nothing will be inserted so the furnace will not buffer.

- Attachments

-

- 16519171508079031761776947862646.jpg (3.61 MiB) Viewed 6961 times

-

MisterDoctor

- Long Handed Inserter

- Posts: 63

- Joined: Sat Oct 27, 2018 11:10 pm

- Contact:

Re: Why big output buffer in Furnaces?

it's very noticeable when you first make steel because at first you just want some steel, but you are committing to consuming 500 extra iron plates per furnace, which for a small basic setup with say 18 furnaces is 9000 iron. that's 9000 iron worth of steel that will basically just sit there forever unused unless you happen to run out of steel. and that 9000 becomes 18000 or more if you have more steel smelting. and in early game when maybe you're close to exhausting your first iron patch and you only have ~60k left in it, wasting 10s of thousands of iron like that does hurt a fair bit. later in the game when you have claimed some million+ patches it doesn't matter quite so much anymore.

- Stargateur

- Fast Inserter

- Posts: 179

- Joined: Sat Oct 05, 2019 6:17 am

- Contact:

Re: Why big output buffer in Furnaces?

I think electric furnace are more like an assembling machine than a basic furnace from early game. I think electric furnace should not stack forever, it's not early game so no problem with no stacking for the start of the a game. Then it's electric so "smart" and heat can be turn off and on by a button.A furnace is a "Dumb" machine, it will take one ingredient only, and automatically choose the recipe to produce an item from the ingredient. It will just keep feeding in ingredients upto the input buffer, until the output is full. Since it is usually used as a furnace to melt metal, something you use a lot of, this is generally desired behaviour.

An assembling machine (and other machines based on the mechanics, like chemical plant and oil refinery) is a "Smart" machine, it will only take in ingredients up to what it needs to make an item if the output doesn't contain more than one of said item, waiting for the output item to be removed before continuing.

Re: Why big output buffer in Furnaces?

Or connect the input and output inserters and input items when the output doesn't hold anything in it's hand.Plantagen wrote: ↑Sat May 07, 2022 9:54 am You can avoid this with a simple circuit.

Set the transport band on the output side to read hold, and connect to the input inserter, and on the inserter set requirement that the output material (steel) be less than 1.

Then the inserter will only be active if there is no steel on the output side, so when the transport band is full and not moving, nothing will be inserted so the furnace will not buffer.

Re: Why big output buffer in Furnaces?

They are still based on the furnace prototype and that has the "keep inserting ore" behavior. At the point you have electric furnaces you have circuit control so I think it's not needed. They also mostly only makes sense with beacons and having them sit idle smelting nothing wastes a lot of power. You might as well throw in a power switch and turn off the whole row of furnaces, beacons and inserters when the output belt is full. So probably not worth adding an exception to the code to make electric furnaces "smart".Stargateur wrote: ↑Wed Sep 14, 2022 3:42 amI think electric furnace are more like an assembling machine than a basic furnace from early game. I think electric furnace should not stack forever, it's not early game so no problem with no stacking for the start of the a game. Then it's electric so "smart" and heat can be turn off and on by a button.A furnace is a "Dumb" machine, it will take one ingredient only, and automatically choose the recipe to produce an item from the ingredient. It will just keep feeding in ingredients upto the input buffer, until the output is full. Since it is usually used as a furnace to melt metal, something you use a lot of, this is generally desired behaviour.

An assembling machine (and other machines based on the mechanics, like chemical plant and oil refinery) is a "Smart" machine, it will only take in ingredients up to what it needs to make an item if the output doesn't contain more than one of said item, waiting for the output item to be removed before continuing.

Note: There are mods that have furnaces based on assembler prototypes where you have to choose the recipe. So you do have to choice to change them.

- Stargateur

- Fast Inserter

- Posts: 179

- Joined: Sat Oct 05, 2019 6:17 am

- Contact:

Re: Why big output buffer in Furnaces?

And ? that a technical detail, thus I think factorio dev can't change this behavior I just read this thread and give my feedback. That would be breaking change now. Maybe for 2.0.They are still based on the furnace prototype and that has the "keep inserting ore" behavior. [...] So probably not worth adding an exception to the code to make electric furnaces "smart".

That irrelevant, not needed is relative, not everyone would like to use signal to emulate behavior of assembling machine for furnace. I could say "you have circuit control so you don't need priority output on splitter."At the point you have electric furnaces you have circuit control so I think it's not needed. [...] So probably not worth adding an exception to the code to make electric furnaces "smart".

Like ... every assembler. Anyway, you would lose this inactive time after so that doesn't change much.They also mostly only makes sense with beacons and having them sit idle smelting nothing wastes a lot of power.

I didn't find one that suit me, but feel free to link them. I think industrial revolution did that thus that a big mod, I also find one that was not up to date. (I will maybe fix it myself)There are mods that have furnaces based on assembler prototypes where you have to choose the recipe. So you do have to choice to change them.

Re: Why big output buffer in Furnaces?

The one I currently have comes from "Bob's metals >> Angels Refining >> Sea Block". As in Bob introduced the entity and Angel and Sea Block modified it. Bob adds new ores so Bob's metals might not fit into a vanilla style game. But worst case just look at the code or the mod you found and make an updated version for vanilla recipes.Stargateur wrote: ↑Wed Sep 14, 2022 1:42 pmI didn't find one that suit me, but feel free to link them. I think industrial revolution did that thus that a big mod, I also find one that was not up to date. (I will maybe fix it myself)There are mods that have furnaces based on assembler prototypes where you have to choose the recipe. So you do have to choice to change them.

Note: Sometimes all you need to do to update an older mod is increase the factorio version in the info.json. The furnace mod should not do anything complex that would need adjusting to 1.1.

Re: Why big output buffer in Furnaces?

Klonan wrote: ↑Mon Nov 09, 2015 4:07 pm Because in the early game, you can setup furnaces to smelt without electricity, using burner miners and burner inserters. It would be incredibly inconvenient that they would only stack to 4 or 5 in the furnaces, meaning you would have to keep emptying them very regularly.

1. player can feed outgoing burner inserter manually to make standardized wooden box buffer. 50pcs of coal manually put into coal in burner inserter lasts quite long. And it also looks far more factorio-esque.

2. optionaly player can make a feeder line for burner inserter like this:

If non of these challenges are still not good enough, then there is a programmer´s solution:

3. it is possible to make smelters pass fuel, same as burner boilers do. (see previous picture)

Massive buffer for basic burner smelter is only usefull for fast-runners, otherwise it is non-systemic.

Massive buffer for any higher burner smelter is ... not useful for no one. Just non systemic.