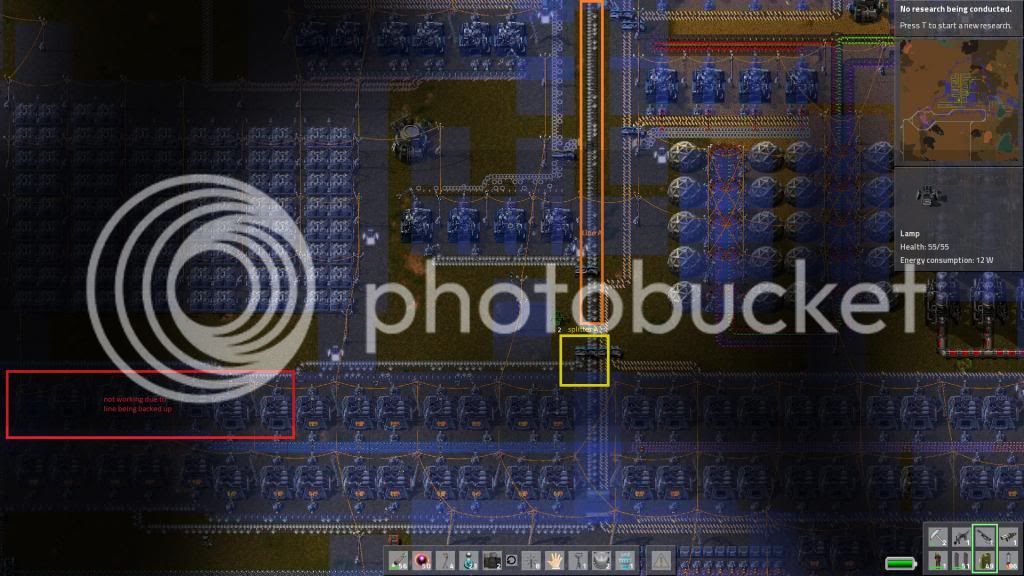

the following pic is one part of the issue, let me explain. the issue im having is i run a line thru the entire area(line a in orange), i then split off it, to the left and right sides, to assembly machines as needed. there are 3 splits to the left, and 3 to the right on this line. as you can see, half of my furnaces on the iron side (left) are inoperable due to a line being backed up on one side only(normally its much worse) ive tried moving the feed out, (at the top right corner of red box) further left, and this fixes it for a short bit, but the problem just re-arises on the opposite side, ive moved it one furnace at a time, and cannot seem to fix it, im ALWAYS waiting for iron on the left side, to produce elec circuits. and i cant increase production of iron any further, because when i do the lines back up even worse.

more after pic

so to my question. how are you dealing with this issue? im using the fastest lines everywhere on these lines that pertain to iron, ive moved the output at the furnaces further left and right to tweak with no help other than causing other parts to backup worsening the problem. as inserters seem to be dragging from the closest side of a track if possible, ignoring the opposite side, if anything is available on the nearest side, almost always, i assume this is how they work, since they output to the farthest side of a track. so im asking how are you guys controlling this? is there a setup for the track, using inserters, or some setup of splitters that will help to keep tracks evenly full? i know the picture doesnt make it look so bad, but note that in this pic the factory is only at about 20% of its full production so lines are backing up much worse than normal, usually the left side of line a is backed up fully, and the right side has 1/3 the amount of metal plates on it as in the pic. sorry if my question is hard to understand, its hard to put into words what im trying to say also lol.

i think my main issue is that ive been running my iron to the bottom of all my assembly machines, making them all pull from the top of that line (the right side when running north shown on pic) also, do splitters maintain their amounts per side when split.? im thinking so, in other words, if the left side is backed up ahead on both sides of a splitter, will the items that go into the splitter ALL go to the right side? or only those that go into the splitter on the right side? if inserters would always take from the fullest side of a belt, my issue would be solved. any help is appreciated.

i took this screen shot also, its further up on my line which still has some yellow belts, to try and slow its taking metal so the faster blue lines before it could get more. but the same issue is shown here, where the assembly machines in yellow box are stealing all iron off one side only causing a back-flow on the opposite side of the belt, this is exactly what im trying to prevent, here and on my other lines and is the exact issue im having.