Using one turbine to control an arbitrarily large number of nuclear reactors

Posted: Sat Aug 08, 2020 5:42 am

I've been experimenting with tankless nuclear reactor design and wondering if there's a way to simultaneously get the benefits of a tankless/pumpless design (minimal power use, reduced footprint, reduced fluidboxes) and the benefit of a tank-ed design to control fuel insertion.

And I think I've worked out a monitoring system that uses an absolutely tiny amount of stuff, and can control any given number of nuclear installations (with each installation being capable of having thousands of individual reactors within it).

The fundamental basis of it is that all turbines, given adequate steam, will consume it at the same rate. Therefore, if you have a reliable measure of how much steam one turbine consumes, you know how much every turbine is consuming.

Measuring this requires one tank, and two pumps. Either boiler->pump->tank->pump->2x steam engine or heat exchanger -> pump -> tank -> pump -> turbine will work, but note that if you're using boiler steam you have to use steam engines and not a turbine, because turbines on boiler steam have (functionally) a higher priority than turbines on nuclear steam.

The pumps are configured to supply steam into the tank if it's less than some threshold (I usually set 1000) and to remove it from the tank if it is at or above that threshold. This way the tank is only ever doing one thing at a time, draining or filling. Because a turbine's maximum draw is 1 steam/tick, and a pump going entity->tank is ~200/tick (slowing as the tank fills), the vast majority of the tank's time is spent in drain mode. The tank is wired to a negative-edge detection, which outputs the differential between the tank's current value and its value on the last tick, so long as that's less than zero.

That's the instrumentation. It functionally is measuring the steam consumption of any given steam-powered turbine or steam engine on that particular grid.

To turn it into a useful reactor control, a bit more math is needed. You need to work out how much steam a given turbine will use in order to consume an entire fuel cell cycle, which in turn depends on the number of reactors and turbines. The formula for this, for a 2xN layout, is 12000 steam * 160 MW * (# of reactors - 1) / (5.8 MW * # of turbines). The 12000 steam comes from the number of ticks in a cycle (12000) and the amount of steam a turbine consumes at full draw (1 steam/tick).

The constants, once combined, work out to ~331,034.5, which limits the number of reactors this piece of it can control to around 6000. Past that, you'd need to sacrifice precision, or use more bignum circuitry, or build a second reactor.

In any case, 331034 * (# of reactors - 1) / # of turbines is the amount of steam required to fully extract (or almost so, anyway) the entire energy of a fuel cell. The outputs from the pilot turbine measurements are summed in a memory cell and, as they're all negative, summed against that value. Once it drops below zero, the prior fuel cell has been fully consumed, which means it is time to insert a new one. At that point -- provided a standard clock mechanism also agrees --, the memory cell resets, to prevent error accumulations, and the cycle restarts.

Q: What if there isn't enough steam to drive the main turbines?

A: The steam-consumed measurement will be higher than the actual steam consumed, meaning that the total energy contained in the system will climb. Either that will solve the steam issue, or the reactor design has throughput issues you need to fix.

Q: What if the pilot turbine/steam engine doesn't have enough steam?

A: You need to figure out why your fuel delivery or pump power broke.

Q: Why use this instead of just measuring a tank?

A: A few reasons. Aside from likely saving on fluid boxes, particularly for very large systems, this setup is as far as I can figure the earliest possible way to detect a complete fuel cell consumption, and therefore the one that makes for the most responsive system. In particular, setups that rely on measuring steam tanks are vulnerable to a demand shock: If draw is low, most of the heat in the reactors and heat pipes will be consumed before the heat exchangers stop keeping up. If draw then spikes up to full load, it can take quite a while before all the exchangers are once again producing, potentially leading to unexpected brownouts. This system, while still rationing cells, will keep the potential for 100% exchanger operation at a moment's notice.

Q: Where's the blueprints???

A:

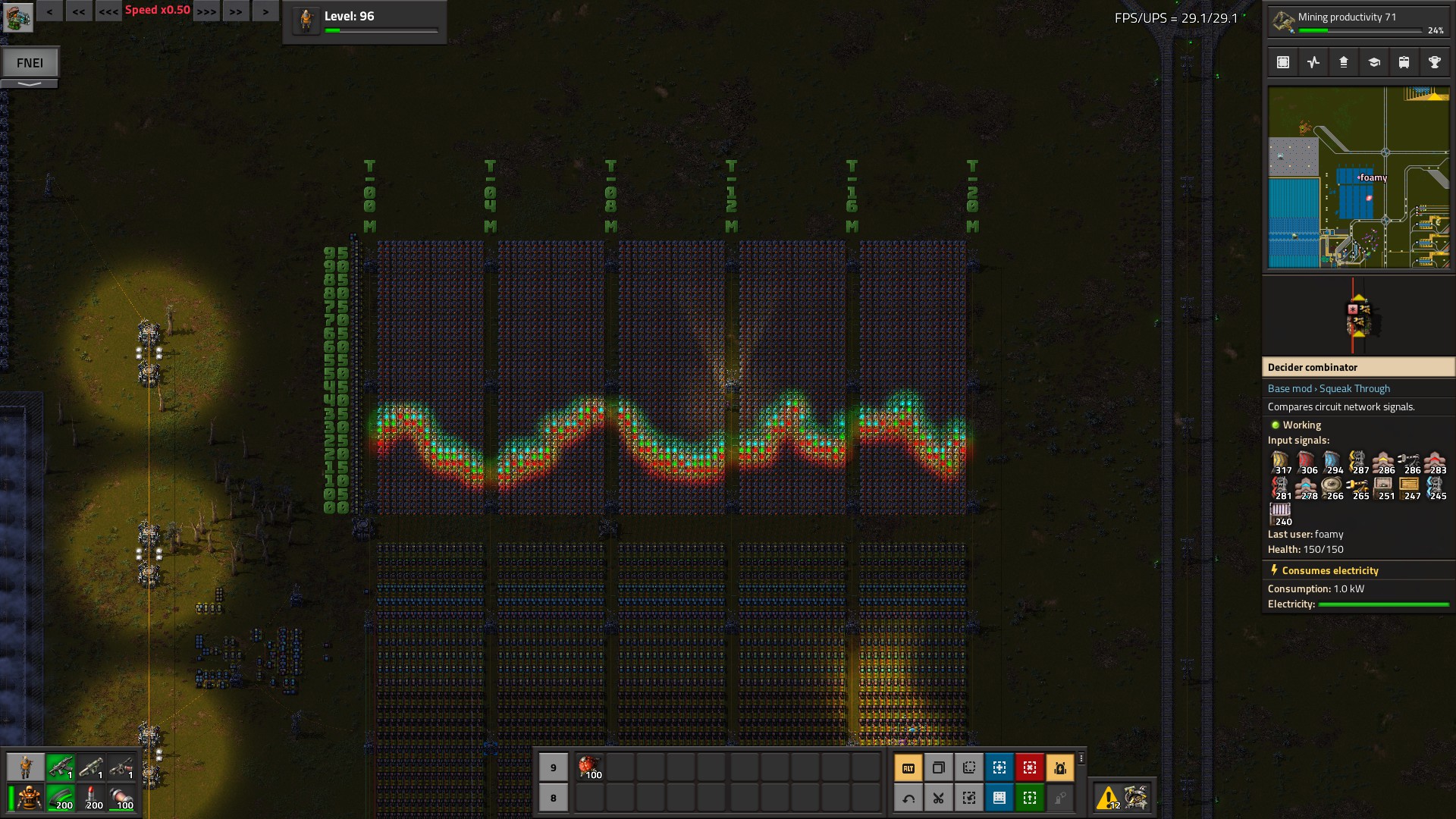

Steam flow meter:

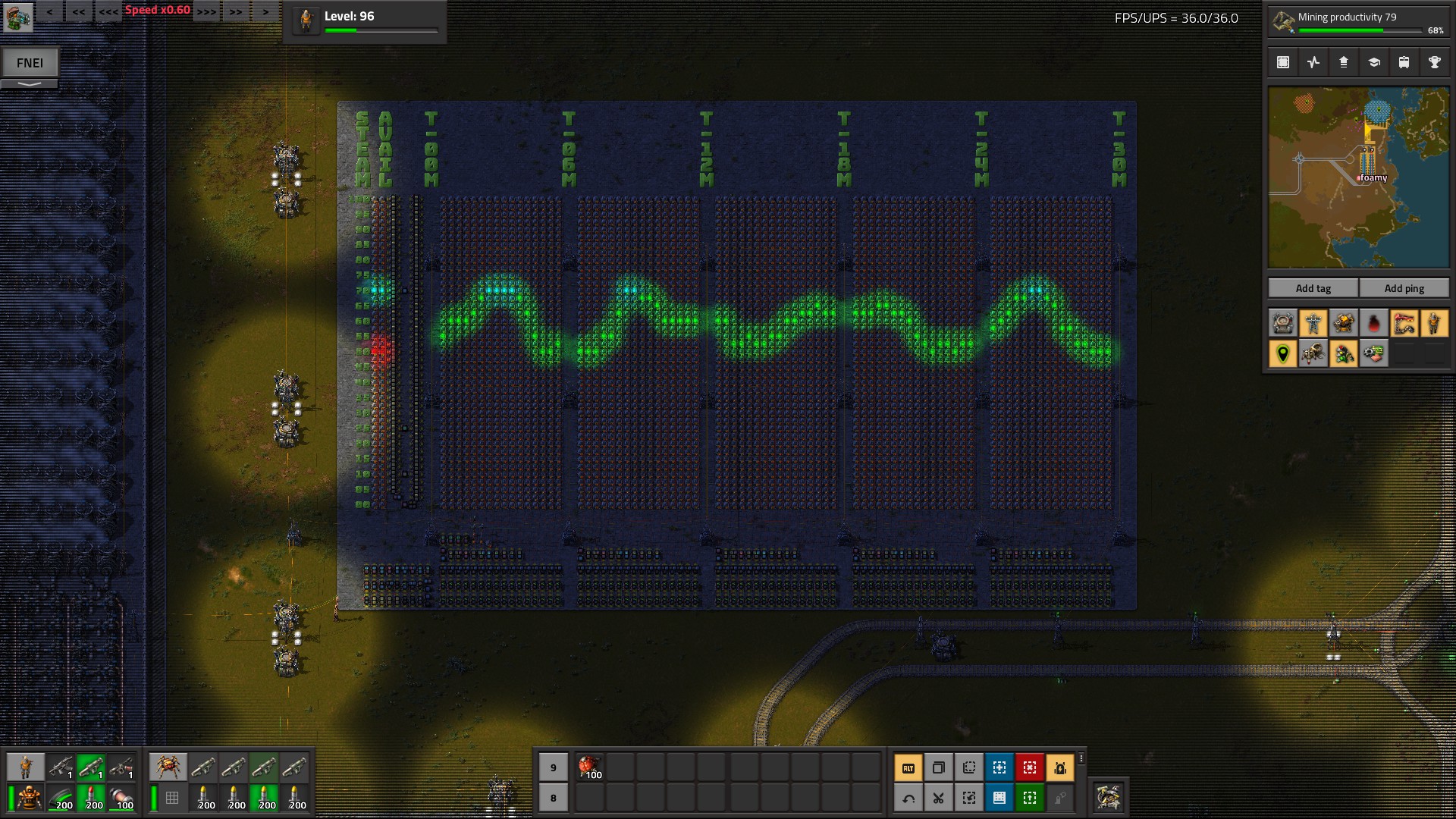

Threshold calculator & memory cell:

And I think I've worked out a monitoring system that uses an absolutely tiny amount of stuff, and can control any given number of nuclear installations (with each installation being capable of having thousands of individual reactors within it).

The fundamental basis of it is that all turbines, given adequate steam, will consume it at the same rate. Therefore, if you have a reliable measure of how much steam one turbine consumes, you know how much every turbine is consuming.

Measuring this requires one tank, and two pumps. Either boiler->pump->tank->pump->2x steam engine or heat exchanger -> pump -> tank -> pump -> turbine will work, but note that if you're using boiler steam you have to use steam engines and not a turbine, because turbines on boiler steam have (functionally) a higher priority than turbines on nuclear steam.

The pumps are configured to supply steam into the tank if it's less than some threshold (I usually set 1000) and to remove it from the tank if it is at or above that threshold. This way the tank is only ever doing one thing at a time, draining or filling. Because a turbine's maximum draw is 1 steam/tick, and a pump going entity->tank is ~200/tick (slowing as the tank fills), the vast majority of the tank's time is spent in drain mode. The tank is wired to a negative-edge detection, which outputs the differential between the tank's current value and its value on the last tick, so long as that's less than zero.

That's the instrumentation. It functionally is measuring the steam consumption of any given steam-powered turbine or steam engine on that particular grid.

To turn it into a useful reactor control, a bit more math is needed. You need to work out how much steam a given turbine will use in order to consume an entire fuel cell cycle, which in turn depends on the number of reactors and turbines. The formula for this, for a 2xN layout, is 12000 steam * 160 MW * (# of reactors - 1) / (5.8 MW * # of turbines). The 12000 steam comes from the number of ticks in a cycle (12000) and the amount of steam a turbine consumes at full draw (1 steam/tick).

The constants, once combined, work out to ~331,034.5, which limits the number of reactors this piece of it can control to around 6000. Past that, you'd need to sacrifice precision, or use more bignum circuitry, or build a second reactor.

In any case, 331034 * (# of reactors - 1) / # of turbines is the amount of steam required to fully extract (or almost so, anyway) the entire energy of a fuel cell. The outputs from the pilot turbine measurements are summed in a memory cell and, as they're all negative, summed against that value. Once it drops below zero, the prior fuel cell has been fully consumed, which means it is time to insert a new one. At that point -- provided a standard clock mechanism also agrees --, the memory cell resets, to prevent error accumulations, and the cycle restarts.

Q: What if there isn't enough steam to drive the main turbines?

A: The steam-consumed measurement will be higher than the actual steam consumed, meaning that the total energy contained in the system will climb. Either that will solve the steam issue, or the reactor design has throughput issues you need to fix.

Q: What if the pilot turbine/steam engine doesn't have enough steam?

A: You need to figure out why your fuel delivery or pump power broke.

Q: Why use this instead of just measuring a tank?

A: A few reasons. Aside from likely saving on fluid boxes, particularly for very large systems, this setup is as far as I can figure the earliest possible way to detect a complete fuel cell consumption, and therefore the one that makes for the most responsive system. In particular, setups that rely on measuring steam tanks are vulnerable to a demand shock: If draw is low, most of the heat in the reactors and heat pipes will be consumed before the heat exchangers stop keeping up. If draw then spikes up to full load, it can take quite a while before all the exchangers are once again producing, potentially leading to unexpected brownouts. This system, while still rationing cells, will keep the potential for 100% exchanger operation at a moment's notice.

Q: Where's the blueprints???

A:

Steam flow meter:

Threshold calculator & memory cell: