nafira wrote: Thu Jan 31, 2019 6:35 pm

Thanks for the math correction, I didn't found any number about that splitting time, it adds a lot if you goes through 2 splitters, but it's not a problem no ? It only create a gap of 6 ticks per splitter but doesn't go against the "equal repartition" thing ?

Consider a simple case of a blue belt with one full lane of plates arriving at an inserter. The inserter takes roughly 12 tick to swing from the chest to the belt, then roughly 36 ticks to pick up 12 plates. It then takes roughly 12 ticks to swing back to the chest, and drop the plates. Approximate cycle time of 60 ticks for 12 plates, or around 2 plates per second.

Now add a splitter at the end of the belt, and a second inserter. The exact result depends on the relative timing between the inserters, but consider the scenario where both inserters start swinging at the same time (eg when the output chests start full, and then a train arrives). So both inserters grab plate 1 at roughly tick 15 as above, and plate 2 at roughly tick 18. (I think the splitter has 2 plates "stockpiled" per output). Also on tick 18 the splitter sends a plate to the first inserter, which picks it up on tick 21 (the first inserter now has 3 plates). On tick 24 the second inserter picks up plate 3. The splitter is now sending a plate to alternating outputs every 3 ticks, so each inserter gets a plate every 6 ticks. So on tick 75 the first inserter gets plate 12 and starts swinging back to the chest. On tick 78 the second inserter gets plate 12 and starts swinging back to the chest. On roughly tick 87 the first inserter reaches the chest, and the second inserter at tick 90. Also at roughly this time the splitter has filled both output slots, so it stalls, and so does the belt that is feeding it. That cycle time was roughly 87 ticks. Since the 2 inserters are now out of sync, that particular probably won't repeat until the next time the output chest fills up.

Another scenario with the inserters further out of sync is the first inserter grabs 4 plates in roughly 12 ticks, whilst the second inserter swings from the chest to start picking up plates. The second inserter grabs a plate, and now the splitter starts alternating sending a plate to either output every 3 ticks. So at tick 15 the first inserter gets plate 5 (and the second inserter grabs plate 2), at tick 18 the second inserter gets plate 3, at tick 21 first inserter gets plate 6 .... at tick 57 the first inserter gets plate 12, and starts swinging to the chest, and at tick 60 the second inserter gets plate 10, at tick 63 a plate arrives at the splitter output ready to be picked up by the first inserter. At tick 66 the second inserter gets plate 11, and plate 12 at tick 72. The first inserter finishes it's swing to the chest, at roughly tick 69, and arrives back to the splitter ready to start picking up plates at roughly tick 81. (Approximate cycle time of 81 ticks). If we use 80 ticks as a average then that is 24 pates in 1.333 seconds, or 18 plates per second. (I don't know what the actual throughput is, and building a setup to measure it is more hassle than I can be bothered with atm. It is also probably dependent on the initial starting conditions/inserter timings).

Now the above is filled with lots of roughly and approximately, since it ignores things like the inserter arm extensions as the inserter chases items, and the actual timings are very complicated, such that they should be measured rather than calculated. For example just look the the following image from the wiki to see how even minor changes to the geometry of the pickup location affect cycle times (

https://wiki.factorio.com/Inserters#Inserter_Throughput)

It is also simpler than your case, since I constrained it to just a single fully compressed lane, to avoid considering the inserters changing lanes.

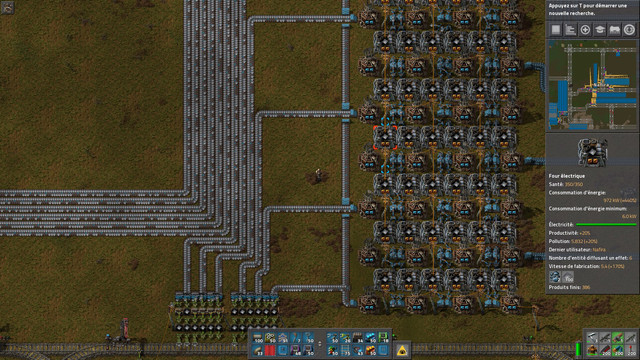

So whilst adding a splitter and a second inserter does improve throughput or one inserter, it won't double it. If you really want to do that, then you should add 3-4 belt segments after the splitter that can buffer items whilst the inserters are swinging, and allow the inserters to pick up items every 3 ticks, and also prevent the splitter from stalling. Doing that to your loading station I can get 2 inserters to cope with 22.2 items per second. (Actual max throughput is probably around 24 items per second. You could probably improve that slightly by using underground belts as per the wiki image above).

- 22.2itemspersec.png (339.48 KiB) Viewed 4090 times

nafira wrote: Thu Jan 31, 2019 6:35 pm

In your picture you show picking lanes. The problem is : the first arm gets maximum amount while the last is often empty. It's not problematic when you just want to fill a wagon.

But if you want to fill a wagon the fastest way possible (12 stack inserters), you'll need equally shared amount between chests, and not the 2 first chests to load it.

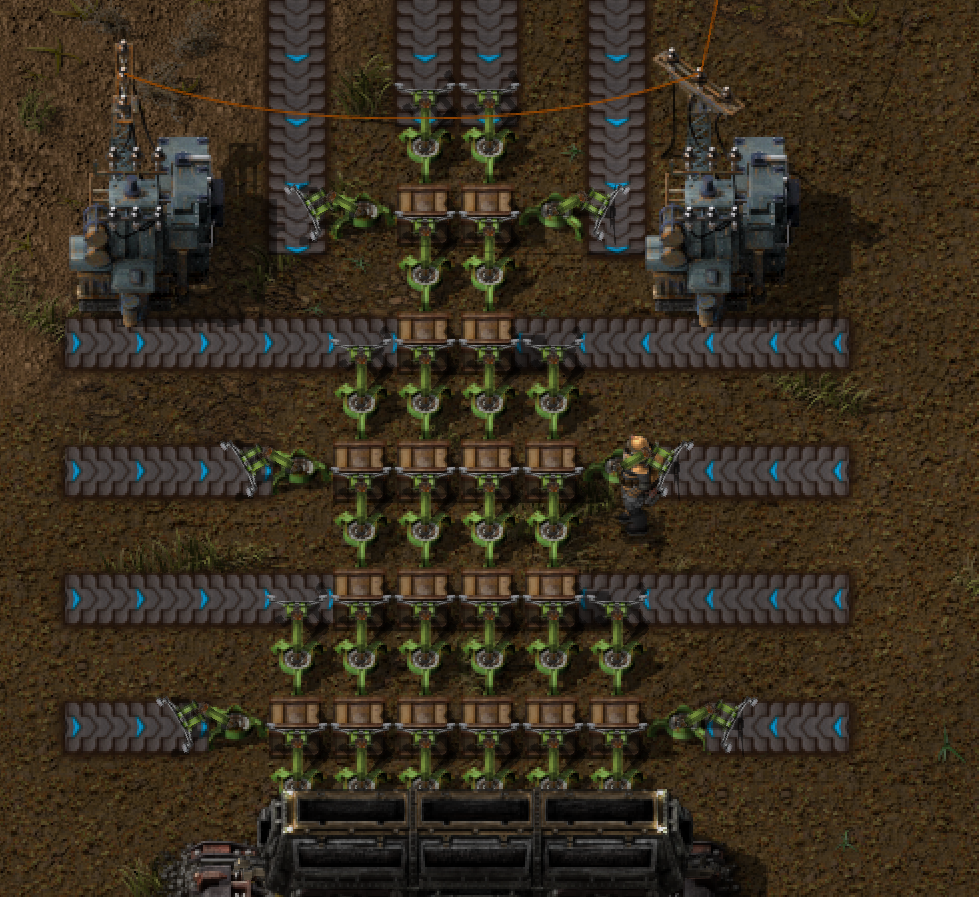

For me a design is only rarely about doing something in the fastest possible way. I'm much more likely to say "I need a loading station design that copes with xxx items per second". In addition, I prefer simple and elegant designs. If you really want max throughput loading stations, then you need to either use bots to feed the loading chests, or at least 2 stack inserters picking up from belts per loading chest giving something like

- ugly.png (733.15 KiB) Viewed 4090 times

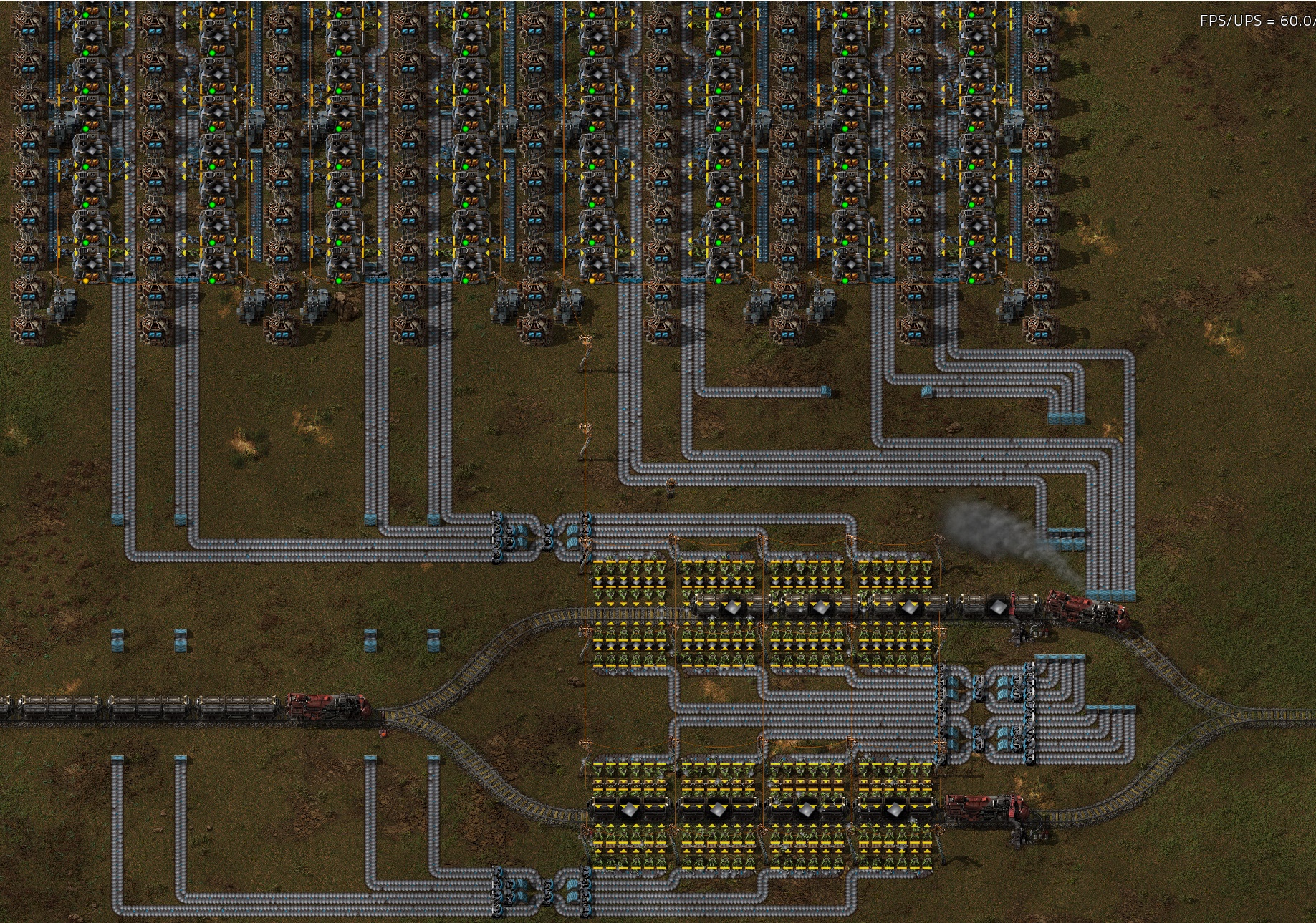

Note that 2 stack inserters can't quite match the chest to chest throughput of stack inserters loading the actual train, but since the train will be full fairly quickly, those stack inserters will be idle part of the time, so 2 stack inserters picking up from belts is probably enough. Also I think that design is ugly. I would prefer to use a dual station design, and have multiple loading stations. eg.

- dual load.jpg (1.55 MiB) Viewed 4090 times

Those stations are loading 618 plates per second, and such a design can be scaled to at least 4 stations.