Classic "engine-unit-when-you-want-it"

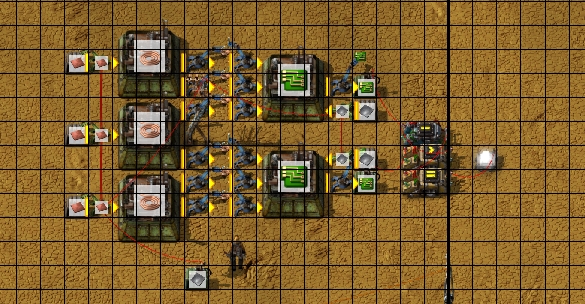

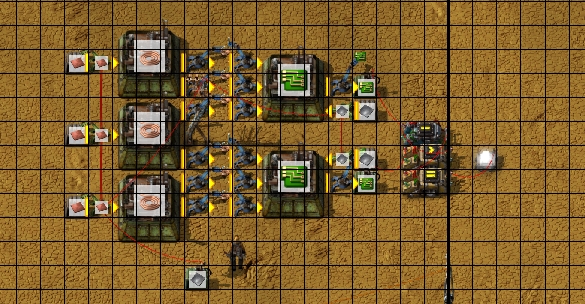

I put exactly 12 steel plates, 12 iron gears, 24 pipes to make 12 engine units. I had inserter bonus of 4.

After a while, I've got only 6 engine units.

The assembler at the top has 3 steel plates, 3 iron gears and 1 pipe.

The assembler at the bottom has 3 steel plates, 1 pipe.

The assembler at the left has 5 pipes.

The assembler at the right has 3 iron gears and 5 pipe.

So you lose 6 engine units because of the bonus which broke the ratio and so I am forced to use combinators and smart inserters to keep the ratio right which makes the system complex and not easily expandable.

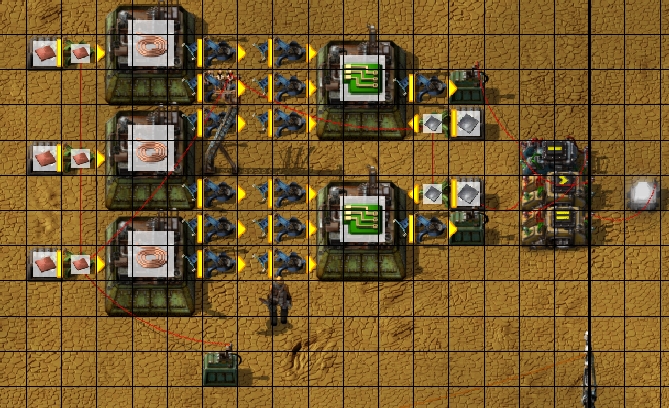

This is just one example of such a situation. It's not a big problem when you use belts as inserters take only one thing at one time but when it comes to logistic network - you start experiencing losses. They are not that great, but they may matter if you produce multiple expensive things and don't get a few just because of broken ratio.

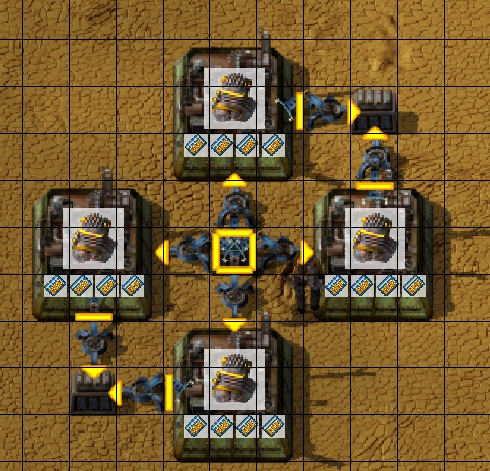

Even when, then just use only two wire assemblers plus speed-modules?! And this setup will desynchronize very easy, so this is not very stable, to use it, so I have problems to understand the background of it.

Provided everything is being fed equally, it will never desync. just because the wire assemblers will always emit 6 copper cables every X seconds which will be converted to electronic cirtuits every Y seconds. The ratio is preserved and both electronic circuits assemblers will always have equal output. In case of "inserter bonus" the output won't be equal. It will try to balance itself, but almost always there will be some difference.

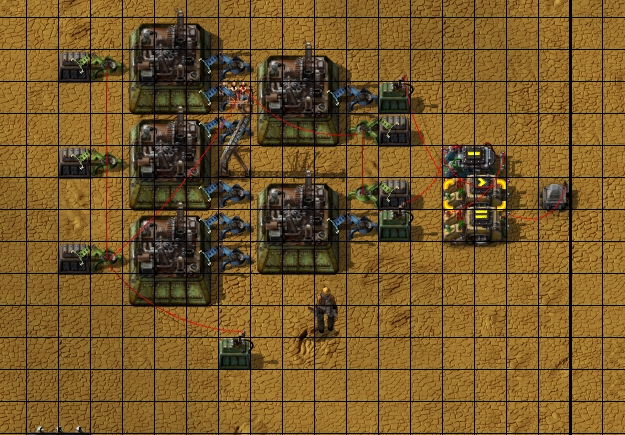

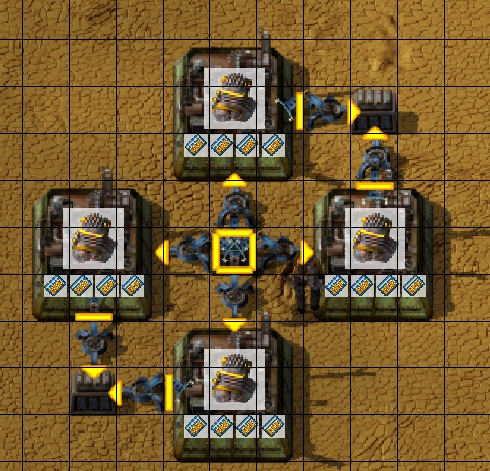

Here I made simple EC factory: it has 30 copper plates in each chest on the left, 30 iron plates in each chest on the right, it should yield 60 EC, 30 in each smart chest. If both chest have equal amount of EC - the lamp will turn on.

While it was working, the lamp had never turned on.

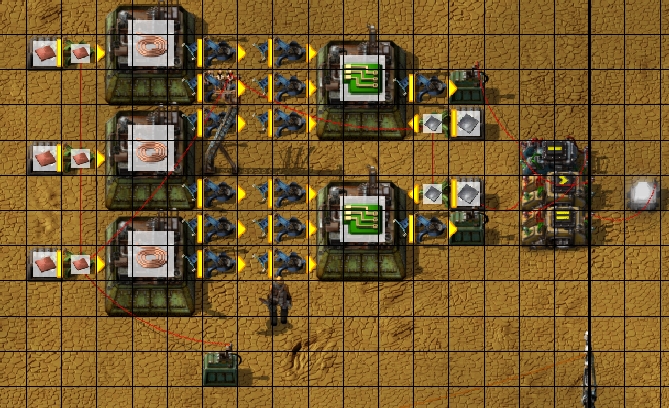

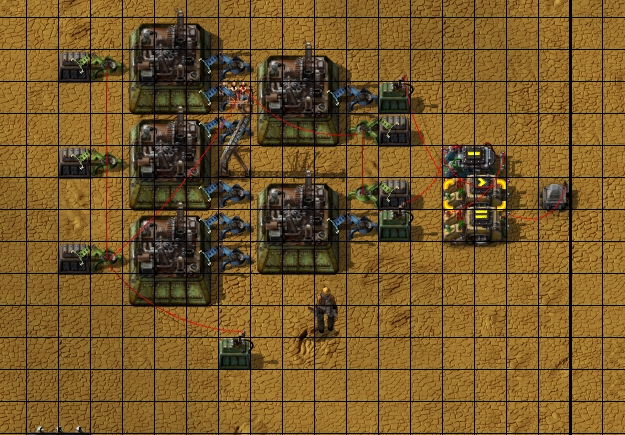

Another setup:

While it was working, the lamp had never turned off except for updating (blinking).