mrvn wrote: Mon Nov 01, 2021 3:05 pm

And that is AGAIN the problem with your made up hypothetical designs. What you describe and what other people understand from your description are 2 completely different things. Maybe you describe it wrong, maybe the other person doesn't understand. It really doesn't matter. Each one thinks of a different design and you can't argue about it then.

This is why i'm asking for the method, otherwise i'd spend hours making a design you'd just discard because of misunderstanding in the rules ending in you disqualifying it due to what be like arbitrary reason/interpretation of the rule to me.

mrvn wrote: Mon Nov 01, 2021 3:05 pm

What you describe now is just a fancy and inefficient way to load the train. Since you have heat exchangers for all 5 fluid wagons you can just drive in fully and load all 5 at the same time. There is 0 advantage of stopping along the way and you are just slowing down loading.

And this has just become obsolete since your design isn't a conveyer belt design.

the advantage of stopping along the way allows for not having to wait for 15 or 50 or 100 loco when it's time but instead have a train LCCCLCCCLCCCLCCCLCCC; This means the time between unload in averaged.

No it's not obsolete, you can think of it as a belt maximum troughput, and a belt actual throughput. The belt maximum throughput is the same all along the way, not the actual throughput this depend on where you load. Depending on where you look, on the distance , on how many producers on the left side/right side.

You can saturate a belt with 4 stack inserter working 100% of time, and then have a long belt maxed out.

Or you can saturate a belt with 120 yellow inserter working some % of time. This will take much more space, the belt maxed out will be so only for a few tile if you take 70 tiles measure, 60 inserter on each side, only the 10 last belt have to carry the whole throughput.

More distance allow to earn more time to load given the max throughput, and the max capacity of a single unit. (do you move 1 by 1 wagon to average ? do you move 5 by 5 ? do you move 100000 by 1000000 ?) the more distance you take, the more time you have to accelerate, if there is a fix distance, then there is an optimal.

mrvn wrote: Mon Nov 01, 2021 3:05 pm

And to be more clear I count fluid wagons as they pass with steam content and time between trains and fluid wagon count of the train. This then gives steam/s transported or steam/s/wagon if you like. Nothing hypothetical about that.

This is getting better, if you count the number of steam wagon, and the steam content, and a notion of time then it creates a metric that is possible to apply the same way to different design to compare them.

I shall say that my arguments would then go onto the way time between train is calculated, not because i want to be annoying but because i think you have the notion of distance in this time. Those value are linked together in the acceleration formula, which include time and distance. ( wagon count is non-interpretative i'm ok with it, sum of steam in the different wagons, i'm ok with that).

If i want to apply the same method of calculating time between train between different design it needs to be defined because it would differ if a train needs to fully clear himself before another take its place in this case acceleration can be high, but will be capped by the distance if you set it like 1km. OR if a train doesn't need to fully clear himself but only N% or only the locos/part, in other word i think time between train is in theory a value that must be optimized for a particular distance, FOR CERTAIN DESIGN NOT ALL I AGREE.

mrvn wrote: Mon Nov 01, 2021 3:05 pm

Apparently you still think it makes a difference if I measure trains leaving the reactor, trains on the way, trains arriving at unload, steam unloaded, electricity created from steam. Maybe even weather I use 100 turbines running 100% load or 200 turbines running 50% load when the average steam produces is good for 100 turbines. There is no loss of energy in factorio other than reactors overheating. No matter where you measure the result will always be equivalent. If one reactor is better counting the steam leaving the reactor it will also be better at electricity produced. It's all the same.

Try it., then explain your method, then i will apply the method, realise i'm wrong and shut up, what do you have to lose explaining how i should proceed to evalute design before spending tons of time making one ?

mrvn wrote: Mon Nov 01, 2021 3:05 pm

And obviously I'm not going to take any measurement at the beginning of the test. That goes without saying. Reactors need to heat up to a working temperature and all that stuff. Which was already one of the arguments why an infinite train wouldn't count. It fills the train during warmup and stops. If I don't measure the first train or the first hour or any other sensible way to define the warmup phase the infinite train will always produce 0.

Again this is unprecise and does not allow me to make a design choice, like if you set a distance = 1KM and a time = 1hours of waiting then 1 hour of counting it would be what i'm arguing for, then i can optimize my design based on those value.

look :

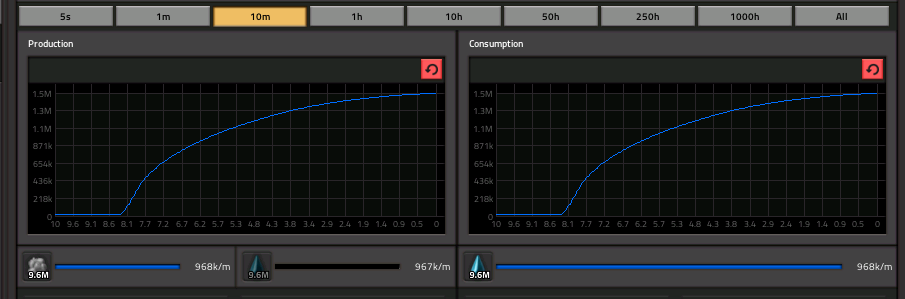

- curvetemp.png (18.71 KiB) Viewed 7762 times

This is my steam production overtime, you don't measure the first hour? why not the first 61 minutes ? i know it's arbitrary, but the curve i showed you is from 1 design, if you say the amount of time you let things heat up precisely, with a number, like i'm arguing for the distance, then i can alter the design because i know where to crop the curve and plan my train for, otherwise i can just say, this design require 129 hours of initialization. And you know i would

This is why you need (imo) to be more precise in the method. Doing so is enough to circumvent many problems i'm causing you.

[Edit: ideally instead of /wagon it could be /rolling stock required for continuous delivery, this way you count 3xLCC train as the same as 1 LLLCCCCCC it's almost the same as per/wagon but if you say distance is 1km, then the math become 32 LCC train vs 9 LLLCCCCCCCCC or something or maybe 28 vs 11, the number of train is not hypothetical or interpretative, it makes it so that there is a theoric optimum for each compositions, depending on the design, you'd try to reduce that number of total amount of rolling stock, by limiting train-down time.]