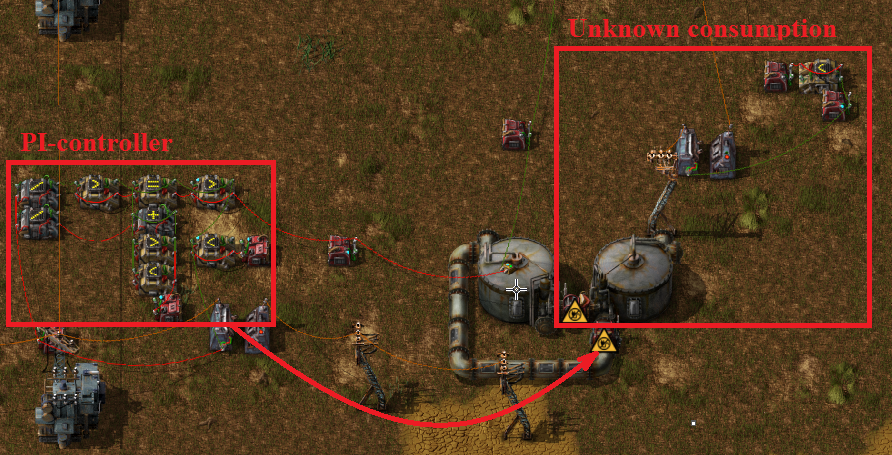

I will begin with a disclaimer: I'm not good with combinators. My brain, however, is normally ok with logic, and it seems to me that the solution on the last page pretty much covers the original question. Here's my outline on the setup:

1 tank each of PG, LO, HO, Lube

Pumps to control the input lines for each different process (which could be set on the tank outputs) as follows (conditions under which the pump is on)

PG - Fuel (PG>2400)

LO - Fuel (PG>500)

LO - PG (PG<501)

HO - Lube (Lube<2500)

HO - LO (Lube>2400)

Crude - Refinery (3 pumps in parallel to stage the throttling of the entire process) set to

Lube<2401

LO<2401

PG<2401

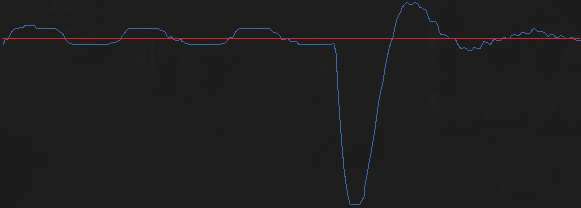

Thus, if Lube is in demand, the following occurs:

As soon as it drops below max, HO cracking to Lube is enabled

When it drops below 2401, HO-LO cracking is disabled, forcing all HO to convert to Lube, and 1 crude pump activates to push 30 crude/s at the refineries

If the demand is plastics and sulfur (ie PG)

When it drops below 2401, fuel production is stopped and a crude pump kicks in, followed by LO cracking changing to PG if the PG serves fall below 501

If the demand is fuel, LO and PG will be converted until PG drops below 2401, when PG-Fuel stops. LO-Fuel will continue unless PG drops below 501 (as outlined above). The third crude pump kicks in when LO falls below 2401.

I think I have considered all of the edge cases (given that I'm at work and can't really do a full-fledged work through), and it seems to me that these numbers should satisfy any requirement without any complex circuitry?

EDIT: actually, I don't see a need for a tank to store HO. It will always be used as it is produced...

EDIT 2: The pump on the Lube plant is redundant as well. Scrap that one

EDIT 3: and I'm not entirely convinced that there is a need for any crude pumps on the refinery input. Not sure it really helps with any of the conditions, as the output is already throttling the process and the 'back pressure' will auto-regulate the input pipes.

EDIT 4: Revisited the OP's requirements. I would suggest hooking your tanks up to a power switch for the pumps and simply set a condition of "Anything<2400" (or set up a header tank of crude before the refineries and set switch condition to "Crude<2400"). However, you would also need a Solid Fuel buffer to ensure that production stops when not required. Easiest way would be a 1-stack chest on the output line. You could reduce the numbers I have provided, but you are somewhat limited by the fact that a tank holds 2500 units. It will always be more challenging to make rules based on part-full tanks, but it should be possible...