Page 1 of 2

single or double belt lines between furnaces?

Posted: Tue Sep 23, 2014 11:13 pm

by starxplor

I am opening a new thread because the previous was not in an appropriate subforum, nor was it appropriately titled for my question. Here is the post that got me wondering:

O_Prime wrote:Smelters also looks almost like mine setup)

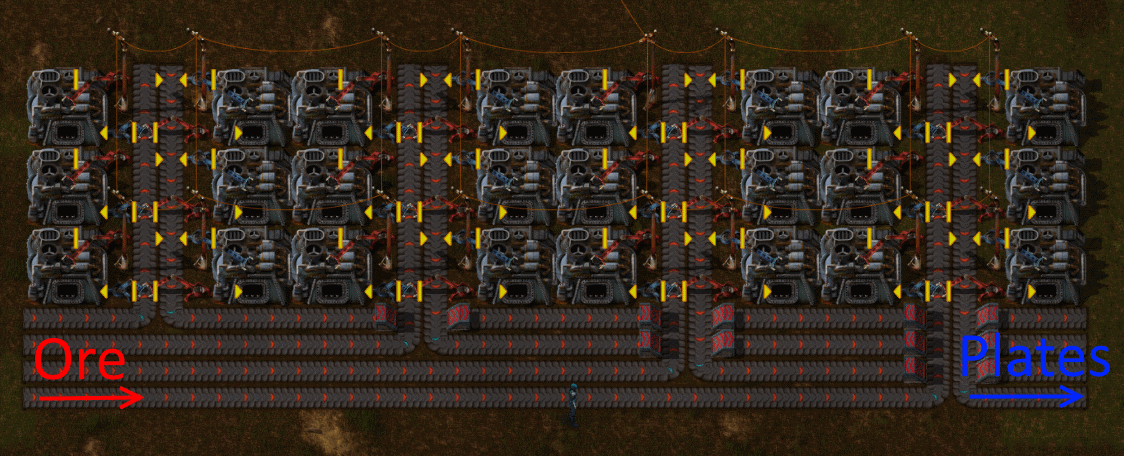

So, does the use of long inserters here cause a lower bottleneck than splitting the input ore and running on the outside, with plate output dumped on a single belt down the middle of some furnaces?

This can be scaled, with a single belt between each column of furnaces, alternating input and output, allowing all furnaces to be fed with fast inserters and be buffed with speed modules.

Has anyone done the math/experiments on this issue?

Re: single or double belt lines between furnaces?

Posted: Wed Sep 24, 2014 12:12 am

by n9103

Except for steel, all furnace operations are 1:1, so the bottleneck will still be the slower of two inserters. With a slightly less compact design, you can put two long and one fast inserters on a side however. (With the power poles beside each furnace.)

Personally, when I do furnaces, I use a double belt input on the interior and single belt output on each exterior. This is pretty much a requirement early on for the coal/fuel feed, but later on, it's beneficial to have additional throughput for the ore as well. When I get around to deploying modules however, I rework the whole layout to be centered around a beacon. (Typically broadcasting efficiency with the furnaces using productivity or speed, depending on mining situation.)

To sum up: This is an OK layout, but not outstanding, and the long inserters will definitely be a bottleneck with modules in the mix.

Re: single or double belt lines between furnaces?

Posted: Wed Sep 24, 2014 12:36 am

by DaveMcW

Why are you so worried about long inserters?

Even a furnace filled with speed module 3's is slower than a long inserter.

Re: single or double belt lines between furnaces?

Posted: Wed Sep 24, 2014 12:48 am

by Boogieman14

n9103 wrote:Personally, when I do furnaces, I use a double belt input on the interior and single belt output on each exterior.

I've actually been thinking of doing a triple belt in the interior, one with ore, two with coal. That way, when time comes to upgrade to electric furnaces, I can just take out the coal belts and everything else pretty much stays in place (well, inserters need to move over obviously)

Haven't actually tried it in practice yet (this is just a quick mockup in an old game with plenty of resources sitting around

)

Re: single or double belt lines between furnaces?

Posted: Wed Sep 24, 2014 1:29 am

by n9103

I stand corrected. I was confusing plain inserter speed for long handed. You're right, long handed can keep up with even 2 Speed module 3s (though just barely :p ).

Re: single or double belt lines between furnaces?

Posted: Wed Sep 24, 2014 5:15 am

by starxplor

Interesting upgradable design. I tend to move straight from smelting at the miner to electric furnaces, so I have had no real need to build a complex burner smelter plant.

As for speed of long inserters, if we add something like dytech into the mix with better furnaces and modules, these long inserters wouldnt be able to keep up. I suppose this might finally be a use for dytech's weird inserters...

Re: single or double belt lines between furnaces?

Posted: Wed Sep 24, 2014 1:41 pm

by DerivePi

OK, so you are making the jump to electric furnaces.

First, to justify the jump, you need an effectivity module level 3 or 2 level 2s. Otherwise, staying with steel furnaces is a no brainer (if you don't have access to fuel, then you should either restart or install the Tree mod for infinite tree supply - "upgrading" to electric furnaces ).

Second, with a well planned layout, there is no need for speed modules. Just add more furnaces to absorb the incoming ore.

Third, productivity modules are a possibility for sparsely populated ore fields. Unfortunately, the return on investment would insist that you not spend valuable resources on them. Even so, P-mods slow the furnaces production rate and will not have an adverse reaction with the slower inserters.

Bottom line, standard inserters and long inserters are adequate. The bottle neck for my layouts is the belt carrying in the ore and carrying away the plate.

Re: single or double belt lines between furnaces?

Posted: Wed Sep 24, 2014 9:42 pm

by starxplor

DerivePi wrote:

...

First, to justify the jump, you need an effectivity module level 3 or 2 level 2s. Otherwise, staying with steel furnaces is a no brainer (if you don't have access to fuel, then you should either restart or install the Tree mod for infinite tree supply - "upgrading" to electric furnaces ).

...

I need to justify no such thing if this is how I like to play. However, I will say that I prefer dropping coal as a fuel source as fast as I can, only using it to make plastic. This means solar/accumulator arrays and electric furnaces. By the time I am fully electric, I have at most 4 basic burner furnaces and no steel furnaces. This also keeps polution low, making defence much easier. At this point, I am not using any modules. By the time I start using anything but efficiency modules, I have a fully built perimeter that is far enough out to not worry about inviting problems with bitters.

As for the original question, I didnt realize long inserters could keep up with speed-3 modules, the last time I tried was a while ago, and the plates very slowly accumulated in the furnace output slot.

I will try this long output/input design in my next new world.

Re: single or double belt lines between furnaces?

Posted: Fri Sep 26, 2014 2:35 am

by MaxStrategy

DaveMcW wrote:Why are you so worried about long inserters?

Even a furnace filled with speed module 3's is slower than a long inserter.

This XD

Re: single or double belt lines between furnaces?

Posted: Sun Sep 28, 2014 5:41 pm

by NeoForce

You don't need fast inserters, just use regular inserters for this. It uses less energy

Re: single or double belt lines between furnaces?

Posted: Sun Sep 28, 2014 6:16 pm

by SteelGiant

NeoForce wrote:You don't need fast inserters, just use regular inserters for this. It uses less energy

Actually, surprisingly, fast inserters use less energy than regular. Fast inserters have a higher power usage

while moving, but they're so much faster that they move for much less time and overall use less energy to get the same job done.

Someone has done a test using an accumulator powering inserters moving items and the fast inserter can move more items than the regular for the same stored energy. There was a thread somewhere, which hopefully someone else can find.

Re: single or double belt lines between furnaces?

Posted: Sun Sep 28, 2014 6:16 pm

by BurnHard

NeoForce wrote:You don't need fast inserters, just use regular inserters for this. It uses less energy

No, they don't

They use more energy when they are working, yes, BUT: They work a lot faster and so need less time for completing their tasks thus less energy (or in this case more or less the same energy for handling one item)

Re: single or double belt lines between furnaces?

Posted: Mon Sep 29, 2014 9:23 am

by ssilk

https://forums.factorio.com/wiki/inde ... ower_usage

A good reason to use basic inserter is it's lower production cost. But it doesn't work with speed modules.

Re: single or double belt lines between furnaces?

Posted: Mon Sep 29, 2014 1:21 pm

by cpy

I don't know man, i use 1 belt for coal and ore at the same time (split lines ftw).

Re: single or double belt lines between furnaces?

Posted: Mon Sep 29, 2014 2:16 pm

by n9103

Guarantee that can't work for more than 10 upgraded furnaces.

Re: single or double belt lines between furnaces?

Posted: Sun Oct 05, 2014 6:08 pm

by MeduSalem

In my early days of playing I used single belt lines on each side of the furnace... one for input, one for output. Later I switched over to double belt with long handed inserters (much like in the first post of the thread) but never have been quite satisfied with the result. It was space efficient, but not really workload efficient. Also I don't like long handed inserters as it means that I can't upgrade them to smart inserters whenever I'd like to.

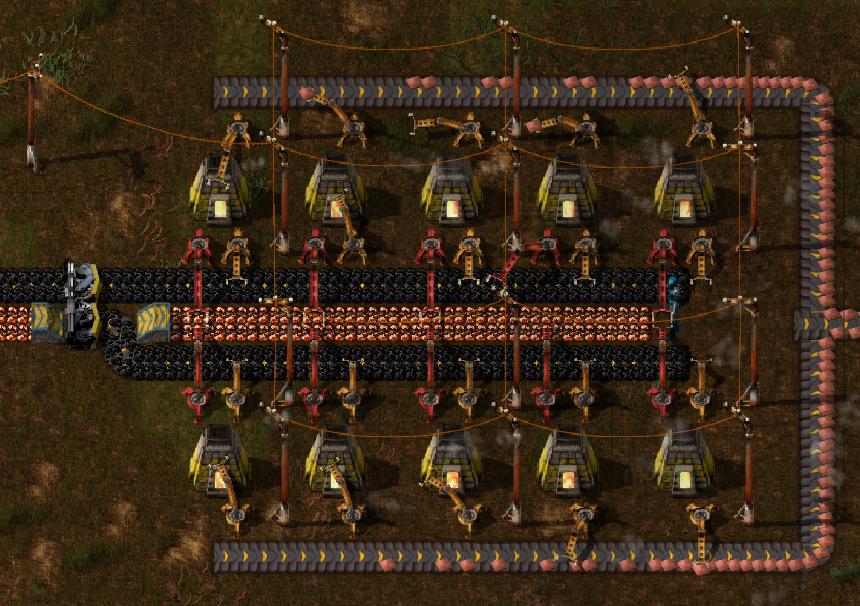

But well, currently I'm experimenting with something entirely different in my current map (look at the attachment below to see an early concept).

I basically use the same smelters for Iron Ore as well as Copper Ore and regulate the flow with the output smart Inserters so they don't mix up on the same output belt.

The thought about that layout arose when I noticed that my massive smelting areas from another map were idling alternately. Basically either I was short on Copper Plates or I was short on Iron Plates, but not both at the same time. Most of the time there's an average consumption of both, but at the peak I started to notice that my furnaces where not able to keep up with one particular type while the smelterbanks of the other type where bored to hell.

So that's when I started fiddling around to find a solution on how to feed a furnace both types but not having to deal with the mess of sorting the plates out afterwards with a too complex sorting-circle mechanism.

My layout result works quite well to be honest and even left space to place 4 beacons around each furnace, something I hadn't space for in most of my other designs (only in double belt setups between two rows of furnaces). It's quite expandable and only suffers once the express belts can't feed the furthest furnace anymore. At least I'm quite happy that it works and that it is a symmetrical solution. I just hate asymmetric stuff. ^^

As for how much furnaces I'm able to save through that design that dynamically assigns the furnaces depending on the workload I can't practically say yet, but hypothetically since my old maps used to have a capacity 3000 Copper Plates/min as well as 3000 Iron plates/min but never being fully utilzed to their maximum capacity both at the same time but rather something like 3000 Copper plates/min and 1500 Iron Plate/min in average - and vice versa of course - I'd say I'm able to save at least 25% of the furnaces, if not more during lower loads. The overall energy consumption is much better than before, because now the beacons will be useful ALL the time rather than consuming energy even when one of the smelter banks is idle fulltime. It's an overall win-win in my opinion.

One thing that surely needs some advanced research is what happens when the whole smelterbank is loaded to 100% usage. Because then there might kick in some weird stuff like inserter-priority, in terms which inserter will be picked first then... the Iron or the Copper one? I guess that it won't be 50%:50% but rather depending on if A) There's already a type of ore being smelted in that furnace so it will take the same or if it is empty B) it takes the one that is placed north/south/east/west of the Furnace or C) which one was placed first or D) whatever other weird mechanic the game uses to determine that. That's something I leave for somebody else to find out. xD

At least I'd like to see more applications like that... some assemblers/chemical plants also auto-picking what they are crafting when different resources are put into them... Would make one nice factory where everything is re-used for something else during different workloads. Would definitely increase the efficiency of Beacons. ^^

Important side-note to prevent clogging:

And nope, the output gets never stuck in a furnace so I never experience the possibility that a full output blocks the entire furnace. Only in the first iteration (with the example picture below) I experienced that, but in an updated version I regulate that problem with the Input Smart Inserters by looking up how much Iron/Copper plates are already in the main storage system so that I don't overproduce one plate type leading to blockage for the other type. The exact threshold on when they work is probably up to how your storage system works.

So the output belts in front of the Furnaces should ALWAYS have at least a little less than 100% utilization otherwise you did something horribly wrong and furnaces will start to clog! (So ironically the picture below shows how it should NOT look like on the output belts xD) Most of the time it will be probably 50%:50% up to 75%:25% of usage split up between both output belts, that's my observation and within that condition the system works well, probably even beyond that, but I never really stress-tested it.

Re: single or double belt lines between furnaces?

Posted: Sun Oct 05, 2014 9:03 pm

by ssilk

Besides that this locks quite amazing I tested a lot around with furnaces smelting both stuff and found it is not a good idea. The problem is, that once there is some iron ore left in the furnace, it cannot take copper ore.

Even if it would be much better for the furnace to smelt copper, it isn't possible, cause the wrong ore blocks.

Re: single or double belt lines between furnaces?

Posted: Sun Oct 05, 2014 9:54 pm

by MeduSalem

ssilk wrote:Besides that this locks quite amazing I tested a lot around with furnaces smelting both stuff and found it is not a good idea. The problem is, that once there is some iron ore left in the furnace, it cannot take copper ore.

Even if it would be much better for the furnace to smelt copper, it isn't possible, cause the wrong ore blocks.

Yepp, experienced that with the setup shown above...

But I

"fixed" the problem in a later iteration (don't have a picture of it yet) by replacing the Fast Inserters with Smart Inserters for the inputs of the furnaces as well and tuning them to only put ore into the furnace when the storage area (somewhere offscreen) containing the plates has less than what fits into the storage MINUS 5 times the total amount of furnaces, so that they don't start working all at the same time when only 1 plate is moved out the storage area. The 5 times as much as the furnaces comes from the inserter limt... as the inserter will try to put 5 Ores into the furnace, which it will probably succeed in because of how slow the furnace might be depending on which modules you are using.

So for example 1 Chest containing Iron Plates = 100 * 48 = 4800 Iron plates. Then I've like 64 furnaces or something... then i've set the Input Smart inserters to work when there's 4800-5*64 = 4480 plates in the chest. The same goes for the copper plates obviously.

Basically it works in a burst style... the

"free" furnaces will take in all at once when the threshold is reached and will continue to do so until the demand at the storage chests is met again. Obviously my furnaces are able to produce more plates/min than I'm able to consume from one particular plate type, otherwise I might end up with the problem that all my furnaces are smelting the same type of ore but never quite catching up with the demand of one ore, thereby reserving all of the furnaces for one type forever, blocking the other type.

The demand is capped through how much I'm extracting from my storage area - normally 2 full belts per plate type. So basically 4800 plates/min and my furnaces have to be able to provide at least that - but I'm normally producing more, normally I'm producing 4800+4800/2=7200 plates/min, so I'm not totally able to serve both plate types to the full belt-capacity, but that's a trade-off I'm willing to take. I'm never really utilizing the full potential of 2 belts per plate type anyways, since most of the assembly lines are idling or throughput is lost due to belt-turns, so even more furnace-time is handed over to the other resource type, since one of the resources will permanently hit the chest-cap and thereby cease to operate and leave room for the other resource to catch up again.

This ensures that the output of the furnaces is never blocked. It might take a while though until the system begins to adapt the exact distribution of workload, since it will take some iterations until the furnaces are mixed with the right load of Iron/Copper Ore, but eventually the system will balance itself out. But that's exactly what I want... as much utilization as possible and the only way to do it is to have the resources compete for each furnace. Sometimes the mixed system turns out to be awkward - true, but having a massive smelting area dedicated for each ore may turn out awkward too, especial if it is idling around, wasting energy when using beacons, while the other resource struggles around.

There's no such thing as a perfect system. So if one is really a hamster though and wants to store millions of plates then I'd not recommend using my approach... because the longer the way to the storage area the more caution it takes that the stuff doesn't clog on the belts since there's some delay until the first plates arrive in the storage facility, which basically means more thought has to go into how to buffer the excess.

In my system I always use a circle where possible, so that the stuff that passed by the storage chests travels back around the chests and is evenly reinserted to the chests. So if too much stuff comes from the smelting area that doesn't fit into the chests it travels around in the circle until it fits. And only if nothing is left on this belt buffer the storage begins to drop, thereby requesting from the furnaces after the threshold.

As the circle grows longer and longer the bigger the storage area gets the more buffer space on transport belts is added to the system, thereby automatically unclogging the system. At least I never had the experience of full transport belts nor with blocked furnaces once I made furnace input dependent on what I've in my storage area. Seems like the Circle buffer works as a natural Plunger that grows with the storage system.

Re: single or double belt lines between furnaces?

Posted: Mon Oct 06, 2014 9:14 am

by MeduSalem

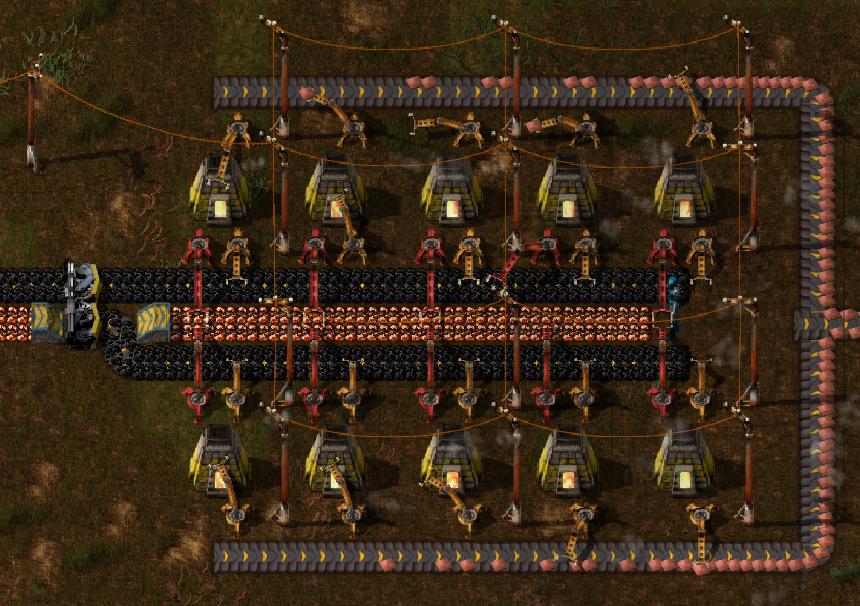

Sorry for double-post, but ssilk's concern made me think of if there's a way to react to full output belts and yes there is (look below in the attachment)

But it wastes more space than managing the overflow in the storage area itself. The benefit though is that it works independent from the storage system (doesn't require any tweaks to the inserters when the storage system grows) and it doesn't clog at all, since the inserters stop putting ore into the furnaces once there are a specified number of items in the smart chest. As long as there's enough room left in the smart chest it will continue to unload the furnace from eventual excess plates, thereby preventing clogging in the furnace.

I've set the smart inserter connected to the green wire to run until 4795 plates are reached (again resulting from the inserter-limit of 5 ore that the inserter tries to put into the furnace). It works pretty well... and once the outputbelt clogs then the smart chest will have 4798-4800 items in the chest. If one wants to be completely sure just set it to 4790 and it will always have enough room, since the reaction time is quite fast, even with +60% speed through modules (that's what I had in my inventory, was too lazy to get some module 3s). When using in companion with productivity modules then you'll have to expect the excess item every once in a while so eventually 4790 items might be the better choice.

It will take a while until the chests are full when using 4790 instead of just 1 item, but I like to have that sort of output buffer, because when there's a chest then why not use it to its full potential? Don't like having chests that only contain 1-5 items.

With the additional infrastructure I guess there might be more room for layout optimization but the one below is just a proof of concept.

Re: single or double belt lines between furnaces?

Posted: Mon Oct 06, 2014 3:05 pm

by n9103

Interesting layout there. Possible for some pretty extreme buffering. Good fix for the conflicting ores problem.

Entirely wasteful, as far as resource efficiency goes, but I imagine the number of beacons is a sign of a purely post rocket defense setup.