Domonstration of supply with pull strategy

Posted: Sun Dec 27, 2020 11:04 pm

by biggerw

In most factorio setups I have seen the main-bus concept. This ist an effective solution.

This strategy is called push-strategy. Berause you fill belt and box as fast as possible in order to supply all following processes.

One consequence is that you produce more products of all levels, if nessesary or not. So you waste ressources.

Another way is to produce only what the following processes need. This strategy ist called pull-strategy.

In todays industry it is widely used, because it is much more efficient.

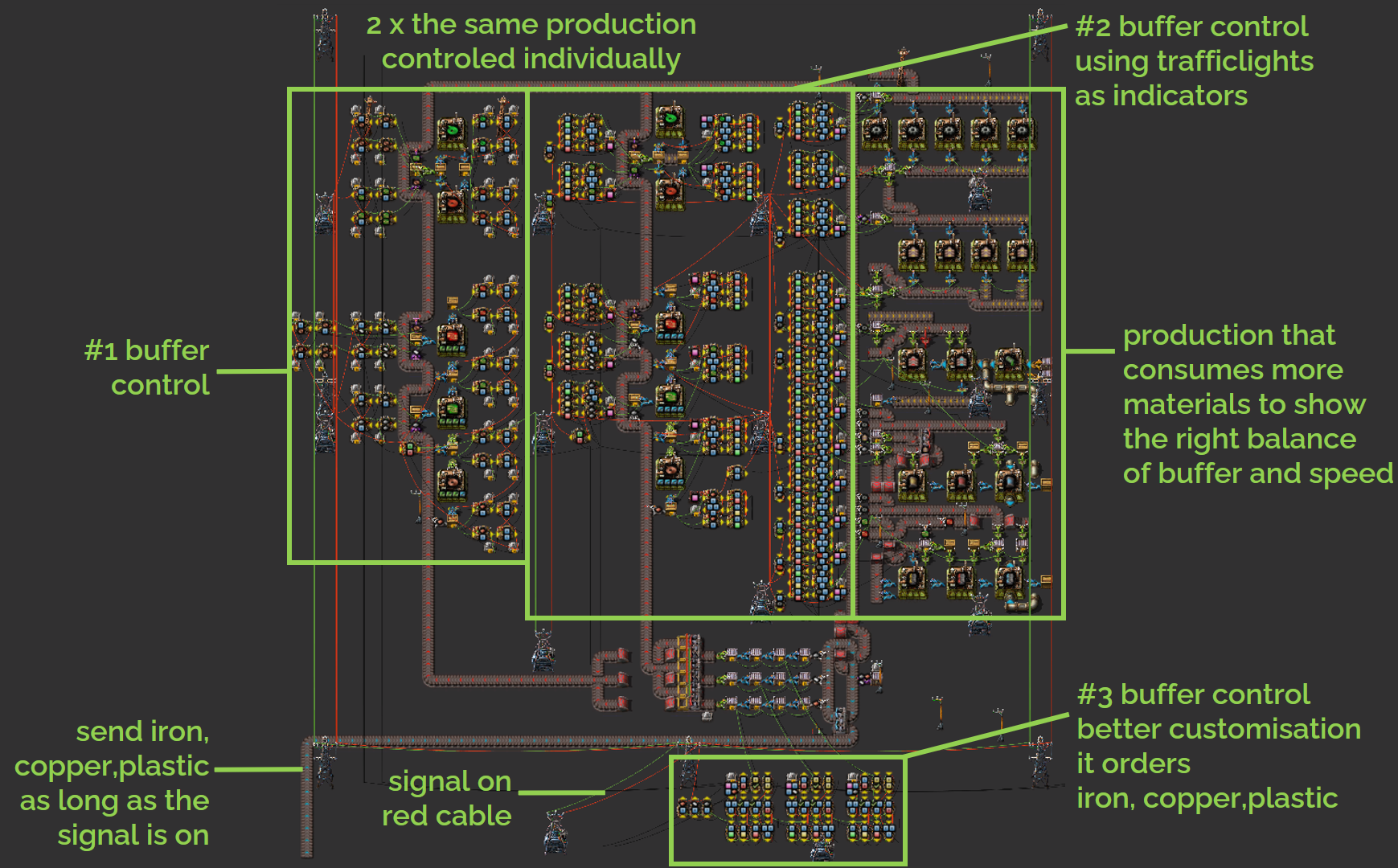

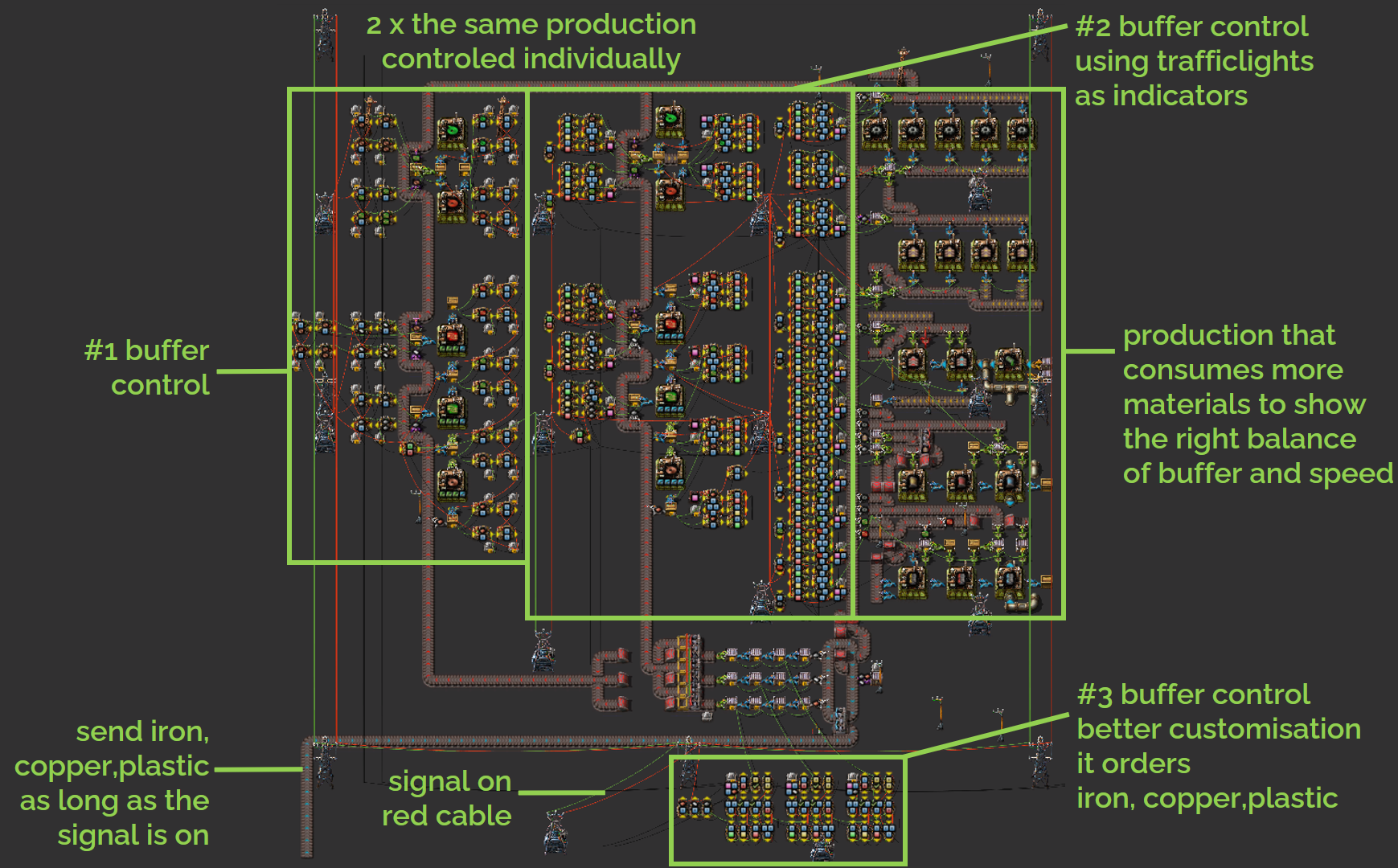

Starting from the standard flip-flop solution I improve the pull-system step by step. Parallel the curquids become more easy to customize.

I made a playlist of educational lets plays https://www.youtube.com/watch?v=1xZbaNd ... zjpfefuXnI.

It´s in german for my students. The automated translation is accepable. I think so, but I´m not a native speaker.

It ist possible the build a whole factory with this strategy using only one central belt with everything on it.

Such a transportation systems a called sorter. It is essental that there is all time capacity on the sorter für all sources and sinks.

Thus you should only send material if it is required down stream.

This strategy is called push-strategy. Berause you fill belt and box as fast as possible in order to supply all following processes.

One consequence is that you produce more products of all levels, if nessesary or not. So you waste ressources.

Another way is to produce only what the following processes need. This strategy ist called pull-strategy.

In todays industry it is widely used, because it is much more efficient.

Starting from the standard flip-flop solution I improve the pull-system step by step. Parallel the curquids become more easy to customize.

I made a playlist of educational lets plays https://www.youtube.com/watch?v=1xZbaNd ... zjpfefuXnI.

It´s in german for my students. The automated translation is accepable. I think so, but I´m not a native speaker.

0eNrtfUtvJEeu9X/RumTE+2HM3N23voAHdzUwDLW6bAujlgRJbY8x6P/+VZXUqlRGMIOHmfVITW5m4O5qRmSQjAd5ePifi0+3X9cPjzd3zxc//ufi5vr+7unix3/+5+Lp5re7q9vtnz3/9bC++PHi5nn95WJ1cXf1Zftfv149PV8+P17dPT3cPz5fflrfPl98W13c3H1e//viR/1t1ZTweX1983n9eHl9/+XTzd3V8/1jR4D59vPqYn33fPN8s36Zz+4//vrl7uuXT+vHzQhvcj7d/Ha5vl1fPz/eXF8+3N+uN0M83D9t/uX93XbwjbRLl1YXf23+39vNEJtPvNv8/Gb3pf+50Nv/eVx/7o5ys/kv73eT+O1xvb6r/t23b9uv7M3LIPPSWjCtHOlpbf+uOi07qLhywWz6wb/OTf3gN7P7fPP4Mrmtbkr5DpWfMfkelR8w+QGVHzH5EZXvMPkJle8x+RmVbzD5WqEDWHAAjQ6gwAEMOoAGB0B92IA+rFEnNqATa9SLDejFGnVjA7qxRv3YgH6sUUc2oCNr1JMN6MkG9WQDerJBPdmAnmxQTzagJxvUkzXoyQb1ZA16skE9WYOebFBP1qAnG9STNejJBvVkDXqyQT1Zg55sUU/WoCdb1JM16MkW9WQNerJFPRl0ZIs6MujHFvVj0I0t6sagF1vUiwec2NXko04M+rDt+fDN3dP68XnzN5VDBpu5g4/hN/ma9eDb++6X9eebr1+ab/D3vlsTiXqrAqcMH7ugfNBZFahRLxWvWeL3rvr05er2tqXP0FRn7Am8vfryUHPJN59xaTfR6/u758f7218+rX+/+uPm/nH7w+ubx+uvN8+/bP7u89u//vXm8en5l0aY6fr+4WEbZbr6tPmKF+lPz1fbaJfa/seXh6vHXezpx4v/ufjGD8Okjf1/n9T2v6l4kEvMVbATr8IfN4/PXzd/sh9+94vLn6SLUI04JcNchiwOELlcty+v5CITIVLzlLWPzhxYWf+YVlmBpyxvmMtgzt1ma46bmIuwPy2unp7WXz7d3tz9dvnl6vr3m7v1pR18RLm4W47Nfnuz+66dNi7/3GzAF7WRnPi9SfqGl4ukfCMMRe4rN9F3ltE5fELdTl6F7u3kabyh6J6h/H3zD+6/Pj98BUS+eNJO7MNfm9l9vXv+5dfH+y+/3Nxt5Fz8+OvV7dMackNfscDVhSHsVSvPNNiIHeD7uzZpRQlTeTykyt+f6jeP93eXD7dXz7sz/Wm9FcHX6f++6PPdFoJbxk9Sq6hpWSsyqxNsw0DiewPRdH4oFL+sm1KWPqtK3dfumkGJ5WeW/M45/nx1/a/LX29uN6+qoeeVpUcIcznfC0vYbRWri5evf0mjfk/QVj3p59paGvyJSp0hwXb0sl7fXl7/vn4afIy+akO8t+rOLF6WKPFcILieCQ18tx6wnZpoL33nlvKruczA1ZhqKgyMr2hwpkn4pGWKZ0dXbGshIrhjWWymEYyEGlD83odbkj0o2bIlO1Cy4yovNJXn2ZOM4CQDW3IAJUfu5zdftTGxJ5nBSWa25IRJTgoNL7q9fYX6OiSNXWfd+9fcaZ4wCnjCtAJfE91Uy+fLih8cou+xLvbPat04zI1TxOmdDKhqe0hVcwOSSZ3yVVK/Uga9V1r1Fy71tNKPjFI3rAQHWPagq52LswMsSY5O2xlETaSXi6S2JzDAYsntyUxus+/Wt2Oxpm+xfxNY7D8mttjUsFjf30cS802QInoo7VFqpNbBGIu1h9S68J3691NHT6xmn0kBOZO86Z9Jlru7ZUyvJp3BZeM846VZIyrLihcuzUqooHBMBf1jegX9tb69vf9zWg1BF72ta7z/dd/HLFOF4IV+Cyo7/S3PneEtz6ZhnzLcCHNft9T2mI1QdeHoxx6aXPhpkuTCPyY8HssNdNVw375DukZU1Xpoi2abU38zJ83J8jLWxvVeEIcK7F/d/fW8ecf81ozvry6+Pq03Q93ebwP0z49f18i1J1Dr4cQo74qH1QbwYpQ3c4Agz2ATb7Yc5SKJ23tOnQ3/RcvD+9geB82+wHezN2z7e7i5+9eL7X19vTcMVuY1EqU7GVu8zVt1HiLk/zpCtsDxVyEvWU3uFpaLRI5uZXpau5qLzM0l8zaXjm4/wOaSE7EcWoE3Z+1PdnOe/9m9W+1BM1YatPMW3kQ1HMvRr2utLM+ndrMWGdHRo12oDf1fYUN/O/X9L9EKcwG1Blr3hqt78PKvzyHmNcXTe7vAk77bFBYaScXewXxp734oUlmYucoOEC2pbOnDLti8yCSuFh2oxT3gIvZQV6cLNv8POwP6HiQ4of6gA9V4R+rDyzC1cQlBjlSKD61bVeD6lBAXPfcw8vRn2VhY9KpE1BIqizJcc1xij/DdswS7r1p+uxpnF2w0dChDBq04Z9/o6CuuEDofzh06f36vm+NA54sDgVY9M1zke5HAeYei6d22Q+3Di5H6H9CA0bmESF1UkwRJXUcMFCZtw98DuNuWEjKpaC2u6gicqg4NUyw5OtheHwCGpBkKkbbbZX9bXz1e/vn7en17UR3OgcOpUaN5cDQ7arQAjhZGjRbB0fKo0ZIQSOxPiTs4N9BWYmO2tIECJqmVGdL0FpZhzgI3m8rnGnK7vgxGCeHT/qyANX87KlZeiJ9uoty1Ia+aRsPkEu5MKTb4jl9fic7VoFnr6VRvOSoFknt5Lxjf+7ub68vXqdQLJTVM69aZh+dRTKKwDqfREbx8BFfHSGjDrkfs0M6+aqYdcj5pGS4Ti0zYbJTXEHhqrRN/rUNbc1lYkuBPV5JwjvDKZkmCtkoKNNcdmj4uaY2bEcPQzghZ/mS1sJTCHzOu+9P0t/Ipo2kp8W/lGbqVN685oXABWtU4Q5E7T6KmUSeItcIaBr8kn0YBmFuYLBKYqy2YgjedM3+GKfgDFSFXEOSDGXj68PTCOoSTvnTPsexyshKSovyHVl4AMwsd+L8/EfoawTxbaWGU7vLiNp/DHey/bz+H31tl9SHcYc398/7+8+aaTvL8VM5nWVFgsySlhLEWyxsb6V9juOlfm+XlEdTTzsmJ9ckHntN8liOj6bd5qAoHmKMGIiFzefcrbqyqw0Pccg8ldY+X7bg+vGOTtnQpLR2vhYhn63zf1IA2+cBdKZ3EK9UsJCnrRHo/SLG1bzCrIrWLQlS8P3dU/PlRLh4JFe8SV/dJCLE+ZfjiPBkD4JIX7r3KZRnY0y2kDv019xgInkvroL2SIe/ckZB377AFH4G5Nnt68ytffb2TUbXUbvkbLfeQ9XKckmPBiLwcp+R5A1j+LevcA6DE7uD6l6zM3aO9w+lP57U2xcPVe3IxPE6BOnND8WTs1QecUnRei+GLxYjkYggIRue1GLQdJBjlZQ4Am6kBSyYLRxjtuPtlhkFEZkb5Y6OZ/RN0l5UewRCZSsRqkHKdEULtMNg3Ih+diVgs8pFMKyPbYgII/ZRtsdglZSs3uB+MHIlkiXhSsHKZhpIJEMV3ADyWFUINXgKdMrNJdRtPlo0Eduyv8+WgB7ygM+vDRwmQyrCu74GdH+mIRp07tJw7t4KWuuXKkevKGUYomRndNIqVIk+YqGDYipkNvNwYw10GLYSt2CWM1t/BooPCaJGtIyPUkVm4CcpVt5iSGoxOxnBjIdEK4S1mKXXHI6GlmlctZ+0rFkUgtCyJHz6NXPam6IQ2ZQ8fYW89qWfIvQvpkIsZ73TE4fKlmvkXqRtDhoQ6jXwgwJRF3/7saqIY5XAf6v0bk1wm9f6NWU41a1iP4KQkOCI7H7w3ty+v7nQwwnvS6veFzpuJkA1TdDJyqlymUq0EKGRZ7+tOvxeYldcurLyI5XoUC6VTat2BuHnc5GFe3g9wiG2sm1yQIESPmYWYF7/tpxaVSoqgpTcu882QXqKJkHRie5UUgmgPD0HsnFkfgbhq68lSBGJpDLTquQjEJEUg2oWXt+X6w8osQAyJW/SK9pl605lZiHlZF/EhtbWuMpYLWkSbUeVTBMRnosSMBVtdqxtV5mZ30HZU+YNEzCffPbF2YrpZjZtJeBzahioeUmWTg4XP8MozBBb2CinqRaDBmRsXzVZmD3ZJl+C24Jt+2yK+B7d6wGJKjC23FZnu9N5i8r/aDxCVGNhjvZj/1Sz8r2BAzrcge61egM2SjY19k5oO4roHHnAK7uDmwMhxp59bux4ajhnLocKVy8BkCDxanWhmx2LoRtNpJNZc7SYQ0yigll0N6K4qu8M39LxRAF2HLIYieub5YhQIYlWoVkCSQY3KBykGDSof3IVgq43s+nmHik5s0R4VzcNg+qabdejcW3MM4Bw7BOIt0REVbdiiEyraskVnVLQTEk3rEwIlEUY7HnpnkueGcWy+6WrJyMC7wqcCGq2KP2E+QY32Qu5lfXp4VTpH7s0mAbPPRRWL4yoryAtKNLXBRjmNsOZtKwmFkdj9fqv4MBKjs5zhlvcpRslHUIQCjBay3urjZkDPmw+uzXkbCr8zTAyqMUZI9apPmPU6twYMpkx9kCei0RjuuDz/Mle1Uk5TvaRRxmHFTQuuEkidyUlN9QxJTQ96T63hvUXcpsZIuU3P4CZ52hONwo6vDg7hL0p7aO2OID/V509+qqNvVz0J6TkN3HnBtK/tJsllkjfRLMTi6fPG4p0hi9VxsHgFIog0UauEuC69sAEWeyqIs2Vi74wVAn7UUsZc+IXBWqoHroqEAB917n14z28LNT6zt8HgG/pN/B2VG1i1Vpw8VpzksbFOPIDmDYA251L0F1TTnBYNZ2p0gCgegLlESZocZeq4k0b7+mmzp+5+W2a+3l63NSEdJvchIZfuNbRh85iumqsWL9j7H/hMMYcbp2XpqG3M9dQPyrMLvlX42agtzkEwt0r2oh+LI49LZ1BmvC350lwIahwTyW2cleXgzsHQR3RBnS6uJUzFVbKkfdN1pM4cSmM4kekeitSRvxfU18OLM2M7M67KDHKZiZIZZdm20teOlW2bZYdJ45I4JeMSyt92rqcCsTSR61NZlnY8jK3OtMNkjSduBWhm4OZjWnTzJN2k8TA134FtfFKGkeBbzk/afIctf/Cxsg1Yoo+VXTdEiBCr+EHB/x00uY95OasJeSR6K5dJHYkdBvvBJd+CGuElV65VAFAcFL70Iz8sxBbNXK3rm6BtlfcEY0lNgqlNrfaLPsOE8/tQ4XRRV5+wqCt5+fZBFAk/zHtp3vXLqFJsK+DjubcbH2VKTAvwZjgQDiczehoM9ImWROmN495HP0i9aiVHtWp57mqcYfCzIL7Fu+8b5EEm0Jt7lhlZOvcc2vnVxxc2pmt7wRGyap7J7W6CAqudX/eeeROJ0jty0NJq59Jfzpx60E1S7Ky9sNa5crFZtRLSfWciwwFB3MKtVGM1kRjE2ejy8K4P4ABGW/sDmqo7wzYMtYvztwYdb/cA+bm6jJ5Z+WvKDU6IfdFtO6asNggKqisqr8qOUvBB5bZZHSDBffvICErIwhpm5lyjEsIMuPI13LaPXItohPXQ3LlaYT03Vz4Iq/GofDBR5lD5eNdBWpcRr5DmTjPhdd1c0RluNUiuQFJ4tTVzmknjNeJc0UaeOA3USli5zEjJdPJoNinTy2WS3y5mmtmJbN+ekphpZrcOjAHQGlzV+4K3Ctze1KqDZXAwO2KwDpclb7AwZjCUET+PGWyEF3vCkvMIL3aUTAfn6+fU2dVqbkQ7ezip62YDZ7M6cZchyHdg0m7lJVS03aL80+Gd0g4KBbr6/MfV3fX68zmWK9a9xKrBaKCtAOeJaKBV3KqlDmUYs/NG7Hne8cn+gJBTsRBF3ttSKWur0IIud0jjnnN6LWMJ0pwLJTFbY1slK/Bim/J/T4GXVVCBl7WBqyJZgddhVPT+yChulB+gyMtadg7JNspmrc38A4hZ5GWVPKzuOO82q8RFXrurFGMAL6Agpa5UVsFXP3q6oTqAuKKLO0ASD0AuShaHsh1rzlrhoex5vcB0caYy8aRWC0Lb81qbPveR1fRiGDw2PHND0eQNWVs8TDyvxaDtwMmjQESzT6tHFAAZSub+OPnz/v7z+o5Mh+4ZA63B8qFFeKcwocjMh1otrS2yS0ChopfQqjHKrvD2xFVVEpbW2IXRb7/cic1xWw2iDr2iC/h+4t7JdZYx+lm7PKP7WjPYM9owG5BZo4Q6OkInpM3qPWznc/Xpdj0LCL/F2DJ3DjIYVUyGq0Yto/yz5vAHXl+Nh0WEt0xomv3W6FYdlGmp1mEO3SiQt4mmKSx2A3LHRul138zInnI3OEP2cZsiqk/6wObeejsMuoNZzz0hpP0AfbFt8uSCwKgW01uZBr7HGhjjYtER2CiyS6N+QN8xcr6L4WfMgVoT2REEnuR7eQSBJ/leNmzk26XOtEVUA8UdhsjGW1znnkHIc21l3I9J2W5RskQdTvEK+Ci1ajm1EtWtm4sFE3aNi4mzdOfPIiFLG5ERGpE5dUDnDEljpkSIWM/VIPNy0gGGfID2mFsQArUgTogLsUsD96bFNjatNpzHMx/e1gu1aBa65kKJ4MnDRfNYIUmFXUgqmtiNlqM1bxuRq0QhSYVZSCqGgTwwIKvP70Mf+UKSCjMHiNb5cQgUUDtdU9URQFs2cu+EQoIJu7CYjLeOcituPh2xvR+wmBI6YwPThhzMQ/EBnhUDm66T81CYmfFQdBkk5DwUQUhDUbm6rFqQ2f5+rEgtymkoeEFEJ8fLWt4ATgJnpeKpDgDH2iNGwct7xOFj4C7AzBRg9Ld9k7BceE+H5RlgprCs1IhLYjgvlQtwWcrvwGrsbb2S8lMw5WspJwNTvphTginfSjkZmPLFnBJM+V4qn9r5OgybfHoG3hbtJaQShrcOoGsGVH4WsEHwViUoARsEb9ZBC2bNFG3YojucuEzZzNC93wvWB+iwQANAxpVTB24cMYARe/+dGfuUfd8QqOpRsFOO3wDHhgC9OIPtJx9bLXF2TY+o0SN5qwlMfgGXJvaI4zRGqK57fSHA0PpbZyu1AMZ6xqbI7s+EjhqmbQOJi+pQunG7PR1iQ3+43VwNbq4vP109TrqfJ67xJmFbs3nu58VyT7SdB/Z2HhW2ncdiOw+M7ZxQdobbRM1qy45cxH9Uwh5nR9iyyR3hHHfs0DBGp3NzD29FCAMJH+kyRTZpXt3+Zq7O9GbOO+Q41K7vZ/NzdfHg8Gr/adOKTUU4vqrREZx8BKLvvO1QYvJY1Trlnia/51UrYHGrndXsNP70sN78xZf7z19v15dmp7z1r79uP/ePzXxe/2Ibj69OckQzOk19eGTjdTsFrqzWtDbiXdTUrE4eLgNAzMKqXL2AOAVVuRvDE5duJrwrmppNVzTb6pXsAnmNTFpYrqyXToCDDIYrYHcZKqls3agSmXNNRlgKq+deCjs5xgwtbmzBcekSrwR2bDadu8DxGsJxQSG46tZ/rB+7sieiE4D0R3detMkJC0pP6lMjWmlPETSfqqK070SWjcdK3OKuDsc3D23UqT0tb8/nx/tprLgkv0tV3nygdwpP55Q6q/EdTPA875CwNyocTeX+KWTU0K0K/SK+Yxp3DRe55W0pycuIqSdtynKZVHwgK34xsv6BDpdXZaOM7t3yViWMPdjtm706GyNuNKu/zaa17G/rq8fLP39fr2+nPauyn6a/rM1WVvWhFwahQidYLj1zURHZyVSkluqqkX6z847BOIbjJoWyl1ViqKUSA39d5VYT9RxaesUqJbNn3/xz61aUW7ciRQZYcpAZmT5SP9n3p+H8Obudc6SindIto9LTGZVl3oNzRIt51PyLeXZqItYjias0FCs3lbN4AFbyy3W6X7zg/5GepGq2PUmrJzmrJ2l3E/q5uqIaLv9An8aZWXznFB91fGmw/LbrMPoDlSOst6aDyfwVPUB98p6/MApdGH5FwKVGZfNLAmDR/D6T8IqIu77ytKnFXV+Z8rW0qoYp30irgpjyxVU7TPlC4L1Jp8winB1JdGAD753GHqItLLLzFI7NaS9DkJ9Wt+eYIXI6YhDyZnWEC4pUW5Bhp4+hNjau/PQemfgeGTGPbOUmAnmpQ5snfAcIn1S1IxxyAlw8bxPFAcJNwLsLhlRjEgGESy26xrPl3fpVnyydRgCNfF5nHhl8tJQFNKv29lhdOaPEyNrdrKsytVxmomQaPmg199a19ULicknvQauvhjOP97njlks441Ak5IEXYspWwi5q7jJ4GTiuYm7/7Zm4AjcwfJQ7E7g6CkIdnfLgPtNUnDMRU1Ijp+Oi4WoxyiBzpRbNobV4zE4eB6peNA0Sp4qzNkA+LUOJ3LRJ4fj0hSUJTSYvJX0IxhJSnucqL6NdOw58wThO0itSkG5n8ZTRHgZYmvT454vVYiQd+R6wRi6Teg9YK253UrkCVEdw4lYZ3BG8oHFG9c06i0oky71/dziseUDrPY8++3p3QqC1a5GPukTvF1HWG+IYF6b17Ub24/3dZn+ZS7tPlxo3mBIXTR6CXJpAh1JFf6fRP4wOZ0zv7Sz2brGhcDTucxNlb9adGON/PUTaZYgLJRiqe7ZzSoS/PW5gZg6eg4IqXQuk6UiVaZnK0hJLK5Rmoe0uMbmhnDMirOoxXtQTYFXPr3nBEFa1ikebBJlaAOTJC4qzMntIC3ZZZg/Z0lrLjVJXv+05N7QNZMW3EM21ECcl3mdvGmdDvK/UFMz7Xkmp93NoVSnEdikMA/5eV7SXYqYrcYrqAEE8QOYNEAXc/GQoC6ZhH4g6VeF/HVJ2XmXo/qER39eF1uZXGxGlab9UzVVCmdkvNa3U6iqh1OyXbYBBh4399n6z5L9fbZz184C1tHEQnt8WgrGm/K4Q7Yhsh2idZ2WuZ2XvgxBvNrf+98Pj+umJZXZ8v3Tt70ng9yTm93x5eP7r8vbrp8eb6+0Z9+nq8XF366hMIaPE4a9DzwI7oZkVsi4olC16omU4EktjFS1cXwmNEg/PyiC4kbMOWT+Ti/YgBjEB/zIfq1pfCDlL5m5FqjKdmNuz3PiqOarAz1HZvUuHgzcjaiUbRll3UNyHUJDzc3IVEOUjBMpskoABtJzvXBKPJA2eC2ywbmcdAgbWdS2wrtfMkmGH0lnboUvOkv1zoYlJLzixChQprSwhe+ZhlCV0tFNXjfjKdWsFwJyH8E2u8EMujCkK2TMrW/68wKeT56FQQGGLLIRGWkUxeaaJC3kmiWybiDzTRSF55kld6gwLsQSwzr4LsakzC5w3rV05dSb7ODwlostkMQQeZvjvABkDK1gaoxx+yRyB/54wClbsuT4SaZhKzHLoKPXUT0ouk3oHJi0BoAZW3qXDMN54WulcRn6EALBiM0vcpxXKrf0GrAynf1qdYceGKYGViVvLihJw64PeIT44s59rtYQvfK/8AXb5R0ym1TstkiGhxGx3qeORwvbHKVGxgVyQIIQrx5nDlQ9RaQmafLtSgJt9SFGoxXDCXi5nisNMIA6TmypLSQaVjQu78EjIeYF8Kx0tc5WYZUoMC0R9GPgIo51XJciyrrKsZHjXuBBCC7DPrVthboEXQcMA8K82t56T3BqvrGUmFRZI/fQQamcRSD1iMClz7cGAZM8f4lExsOVaMYA8zAxAbqcBkGsxgrxi/83LzQorQtjYN6lpJwZ48wKNWQ5Rj7wBAjdKakBsT4cC/mELOC0EhmYIt8Oa3hJBRZY7vOgDaGc14IAVqb5Dhs6SGjmZBs8lBNfNgLrv8HlzRQVKlIWhnv4AGMfdyf5we/U8Zd8zr5jQX6+ckCbVnbDUEwG8DK/2NHgXb7l4F6+gJkcbI+0HQX3jXPA5kbr2MKrXz6jPd3Vt6wsRhASy7kg3/cp+cIZsVN63OnwX+1BhrcqTSopymLTnnUtJDu5mjpDlIzji3Opw/TPbEHZgsPZ9uVklSUk1IjS7i/X611+3H/zHZkavf7G911anqeUQaE99upFAoD3nwui1FcJ0/ZJLFsF0vRZjOb12MPmvm9NJpi3zJEObE7zhlf0JM0RT4JUnjUNVSIZXgGYGwlKxRQSgA6naAPM6u/MkuOZBxFe9ap5ILkwUArn9wk7TV4OBMm5eJ+6+lIQ6OuEN+0yzol5nTEcNiI8PhqvELIR3u8Nfid4r8Zg8z4cJIehGNLfiqX21WsxMMjdhUng9eS0zSmgwfnlXv9P1hLqLXN1pmOXZzT/b5YMjF4SNhTaVG5jw/NUtr6b1Z+UFA9R72zi5TCp8Yfi16Ub/QEebq7JRhpQujN2JQyN2G1KozifKYEXLRbVwFItdVA33omqE8D23wPfKRccuqq3OFj5yk1gmy4A7bsGC4TdV07qp2tZNNWI5MMO/7ZjE4V2s2pAV4gmPcHUlCbo+AI1mYQwD2rWuZUl6Okvi3putRkFiH+HaHMkkM9w3xNGXvGqiBm4i4sBMkHVo/3r42m8V17r6KfuXa+nmUvpwf7se5Ez0YFlmC3DW3vhd8SeJNpPAr2KlDaSadLVR0Nqe+cKwgh7xXNEZ72zPFN1h4Gd3VueK1mzRFhXNzva6I+FVpm3xOXAZ6ZB5s1vVc1e1s7t9/bT5kt1vSwTid6H1+fkGgDE2YwsdDuEWBpIU0UJithEFroXETG0R+Z2Iy+f7zft3cy/6PCSMio50eH3r89GqOaEOkW9rQlq1Z7T3wk83vzXPH/c9kWP5t4n+SaOVoQsD6j+uu5G3QnCjOV08+uzIvCpQUurS7B0GbmyBw3ImNeuECL4TanYE8dD4nJMUwNeCmwalSB15WX93gzZI7K7Oz9WZBEF7dwve6VWLvsA75qXfRzlq0FLb+Aiso6FkZkl7d8u6pnApqTsILzOju19QzNJkz2Wk7sCAzGwYqYNW3GWQsjfaeQNKpq7QhmECqQU7IBOowQrRAHY5o0eBAXontDbsqGdgcgP64OTcgPb8u716o8WoqeDHdIe2k19+YLbzThKfuk2EEeyE1G0iJDmnouHdKUYw/PFGiIrft6gDPTBzIGnncyNV1Ysya7/xvJnDgwnpxiNnSIAedGzw9Sb2fh+56KIOeTbc3ducPxdssRAFHN2Qz1yUo/qNpMssnaF7SoA4YjY2WShJczcjJ0P92IXvaRyUo/WaoPPK0ctUZhYsXaG0iHX29lyvCjIIjZ0ThOb8aJQqaIKKV60AKMI0EJrIjXfGKLObI8TyPyLkKhj2BTG0AHXBhsbmEfn2wq3+7TDXozxU9kR3USkPlZ+ChcoKOai81W1ILgORV1diFsO4DAvGBXPvD0So6gNoONBjfxjKMLfjPF0GwGqwJ5kRc7IHmpMVt182LMBXcuIBLG8AL+62zPyCIG6NzBwgigdgOkPCgIpanGe1vn8GOfLRkMBNBl3WDO4xqF1kkETFovJBsC7qmRl0fY/KBz3fofJBx4+ofNDvAyo/IuCtLWUPit0yBRzLKfKKV/9x3XU7HIlDOMU94EwDk94M+34mNjQuNja0QhfKtRgtmE0ofc4wM6GeTcq/RpZXXYagFExXp8+SoJEPlquvA5g5cd/dWB0zwHziJoi7+hWA8if4Cm9i32H79UZRuwZejm6WGJSRI7B0PWcalJVz5GlORjMoJ2klrg7eJY5O2R2niXhQXs5vx1z6EW3KFWUwkZ+g7lDo6Zl2EafptUKH/JHfRVxhb5UC5VeEz7znmlsW0hPqU6bPtTrD/LlKLdBzUAWGilmwF7QSEvLppYF4xy0it+agCqQdyF+E0gUjV7Wa9yLZhlvhF4nvz8s2O/E1MQvatEANfXbpFN3ASjfaLe3+MbF0KHo3kifl0sdbCOUduJpqK2kFrGd7ySMrxoJ2coggdUnXXi6Tusd1yUEBoKHixHJDh2CT3wVYg2HcFjNq0Jm7LychslAvHWQFfB26deqk1g8ytm0B2eqWTWXa8bPQiNQp79dnSPw9ITw1GGY5QjAK7v+rPwILCxkzNFoIStVL/9+mxbZwqU0sMbOUJBgj1KJa+v8WSsROHS6UOHR4NwdfhdsnEP4q7Eegi26X5auwCGPr8mplC5NsJa9C6y2ZG2x+yStyCUE0doe1QrPCkseImfAJpEtM4XRWbkBoL3kfMkK4tV54MUcqpcBBludH4O5NQaZEtZQ5DMNgYcR8HzVL74VCLLReqEwFb9nY8rTmD0DDiPy3T4McpzAy+nGUZCal5gCvP8NyjBhbmHk1AIKPSDkGZFCBay8ZZTT9AG/pgS25wwyMlhuomZUb6EnqDYKw3qBysVmB5Sgmk1rU4nIAXtR8BPGt5g1gR2D7lQjbP8ArEd7R5KLT0eh0+idFfUoeZu5FER2Bu4vaAM8FTqFwM9cWQP1oEKXUYcQFZCue7Cyuu1AcfHRwSjyA5g3Q23WeHm5vnutd1amYhvnuGTUy2NeLzsPj5iDZDLz5yePNb79vb1KVuRhpsQJvf3JWKp+pLCctVuBt4B1S2+G0Z/98/3T1+P4o2ovkp2kDuhp8n47NFLVLvM1KjISjmcBDhz+39SEJ3D86bLrDGs1sjXbIdeHuy9vsU7fF0Lu83kR9l4M3YtToNptfl2nlMhMl00mQqLsptl3ZexlashR/XLKhM0znNtGSwQcxpM4HlOVzZ09z6eNcwHvJSK2PMtjoYQx2pn2ca2yiK0AzQ6AF1QJyk+ebTyiB64FtfEqAfQWp2y+ZoRcmy7v1vS4RdpRSffpCUGKEHnlmBi2XSZ2ZQYgHeF2t8wCXnzrqH7KbKEeKEtxmas/+r6ekKsIqDZ0Ebu1kkBG9lQ6zpLFDwI7M0IJB5cxVohclsE6w680/J1rR8qrlqr0TX2nMTjw7hRVaOdHMfXgEGVXdYbbuKTvbnx/dWFQDNUUFmUusFeBOZD2WaxxRmskpt5xqeCIkMMN64BfBUTKsOzsgFlzMBcaMB0UlZYhiajRqfjTLNN8O0UjZmrjTteIBmAvei9V/vdvshi9dyJqpleom+2rBLxtZNb3RIYjlPScVFZctJlsdLqBfqDkf+LLJVgfkB/xV28KSMJdSmXtVPvq2d5Qy6otbGzPxyfd9c4GSxtMrtDADrkaiVuM7jy1vQSzemZDp34kfvW+nF5IXNCzkTjRIZFMBGJhGr5MIiZTMJJcZKJkZjquHGXXPiobZNipkBQdfw2yotCK7SCWPCEZSdotyB3ZlUnab+YXoOvc0Nsf2KdXSsvrKOFl9ark4B8toVjjSzrB9SjS+8aI0w0GGWAHSUk/OzEWLdYgm0f4qbA2fsL9KsRBF0MiQaaIchEmPsPRXGZX4yEVsxnAjtjlKK/p0nGFF34Fa/6ERdzpTlZMsDRKWTFURxVKITqLl1nrnLFNRXGr1xqUfXCudQYUto1KyJEI4Qr+bHdPz/d3N9eXrx32QZIKN5G0rWo+kDqJ1/Htc4t3jIsrVGw/pxVPmlc6vzm4wr1Qr05gmi5Qz1xTE9UCVB211ACseIPIGcNLCN7Y9n0+fnWka7Ugr30p77WfdUxs+wcik1i3Vw8kaM2BK7VxGVEFeO1Y9Pse3qYkqinOEgVOxEVWCl1mPXOYsTvPxtiCtuPG6AYMJVcmaKzmgkg2zKET3V5+sCol8Ak2t0Ok6rLFOh+JdO7JIh0d93ttQAlVcGzXe83zPFv86TcCh3wccq96s5eTp2tej01GPyP44Smbi8+vHdzOcIx87DZOPHQJGNh/7gIHz8kaliXMv+kYJK4z8KePx8Qzj8Tq3CoxSLgKR3KsNyoP4VlfjFzr2/XJHdl1NNTM7FGPuM+0XY9GqxVsd7smrS/1OcOYYK8+IUmeOkRNSk2eO8Ti/8+uCyZMNZRotchUdhKlPv/A7T1Ed00h/mpZiGxFyfjo1Gm7sBWVRezMZd8rT+QzZnFvZckR7lr2zJ5TNeb87zZiBKntyQbIwBe4XNuemxbZuKK3tzjKxaNEqoRbdwuZcKBE8YzJXR1oMXHAzBC7U04TTqclCiBOaIjpaI8uO+6WOc6RSitxnuQFarnMJ66XdAnEYTnTDGJRVmVQnVOZk+Wy/lN4KEtqqpafW2ww1DMe/vLeSA5bZqyVaYTW3mwtq5gyhEkOoGdWKiSc1nRVZrpEEtEL2A7wAh/bhKIZiuAWKgUAx2v5gLbgLlxICqeckxvQ4VsbeykutPWsAp0ZAO+BMcG3HrsbmnR4xLX8YxIkzYsSJYyFOnBUP4HkDOCl/LvcLvBjBwvMHF8RfwFyiKP4C5gDglqFRFWQhrS9TvlfS+fPWx2vp/Jny4TzkiP3u6vMfV3fX68+N3Q4lbEU3Fg/6vUXX1Evnz5QPer1D1yeiUL+B+5phIP08uAl4dMGydMF48lEGxgjeSlA2xggeIwE8ygO6PqBDZ9BgA8zXkjgGS9O1xODlYDpLABvCCNCfoWRGmErBzIiiuEC8kdHbkISIN3vKnLo+x6R6E/K2sToxLipkmPLCzIZvOGrXWhjSgKMSYgHtwrE9yDmyAraWoSStHH8eR/CbUIdJHMFvQh0mUZgBs0sddoFJxVId0XF3CSFjsFkyzeWiB0xHjcBqUmwlCnNM9vA5pvIF/xHqstO2TQhxDiQFFeMWVjOQT4rcfFIU8v2aJY8tKBdoUEhX9oXVsMWY6SymAUtPim1SEU1RmvmnKHd+TqyHPHVlWDGWKE9dWdYASYGllpUXlBDBUybdc8snCstlIzDSmFyYPVDIOsmTYZYV4kpWnOkxvAHciPpuQ9d3DwTRkhd/E/XsSUGcr2LqIUrzMUw1JNS6+18wTca5y8E61FNRizeRVBTPZZKrKHNbIdredOii98ynSDa0DqtF7x1uUdZO7Jpm3WEWZTb3bH+/A5tm4gouCl8ziRDKHm81yvSoHARc2KQiIm/VsnjVBpwgCViryQ/J8mQD0Yc1KSWXqSiZI2Jj5DxHxMbIeVpx6YWeYelFLQ5wqsgLXXiRlDAcphfM/rgnrWs9kROpMi9TmVqCzIXSoDKzxC0zS0oYjtLziE+eHwJ+KD5ZxKtgBDw//lSEsDVpIlFmIupITJJddOuHiGBbmk6yGloZ2AfKYhnaHjzXHpK4AkDPrALATlIBoL20AqC5H8TYzkyt2jmQup7lUU7FiXImrcQDaN4AegSdpJbEwZKWBw+ZiyYPHlJvKO3EgTbNebYnLW6Ilt83nXp6uL153r6Sq6MELoEdY0n4Lc7ab1TNf+zbtjBxP7NcaWc2uKBG0saMmreRtDEjhYnbmOWKVxc9zYZXxQpCN+SHOHGYJVMi5XDWRIkM4iALOcsoFknOMknDNmmunT7eX32ne21aPVHQxsh6SeQFwjRWJ6oBfUhctqCEsgXlvZsucbeBpxscwlmVz0RCY7LeD3mBGAnCObGlJt36AWYXwJPepAZQg0tjmFDWo3jAPWDyENAZBgkHQkBlsr2wwemCQlymxNRhVOJh0PIHgKAN7MDihiVpIclAQmQV22/ec5potf4PLKlmL41gJVawxwap/MyTL+40wpx/kspnzj/zu/TSDlaT7BQuOfMka7hTCVOwgRuVMAVbuE9JHkYspT5dB6dNCXOykhbuPGt28qJeonV1cvJGHoESmcSRFXKWWSySmmWHa+Pp66fNAbn75xXnMq9TA+iLjS1ojlp3cNUq+DHM4uTUJ/l4iyVWzvz9ErWNz4ubuEWefMtSyCs9eah/u3vnewMBUcrSvG9ISE0JoSFh7/WkCLlTekpkEot0lEi5U1KzRLkvOiKpWQYY86e6Itt2i/JddDpJONaBghJeXOpEDzD+xTPc73nwpfN9mPXd1afb9S+fb562///y6tn/7eP66vMvv19tHtDbqW5W4+n1/brqznP3Fy+//bK5EmxGBO7sieKXT332j4Hdc8+57zha3G8s37M8TUUGUo/VLGeH84M9hAONPeJDePAr8N6AvruvoK0BUxDDDFiENSnCSGZMJ3DFv6WXqyrfiI8OAjCeohWLNJRIx7vPbV/ju6kB9zk90ARXkxGpiL7Nje9+JEMxQTyA5Q0Av84dOUB1U4y4rxtLD8HBx0T5rYWy5iS/tVDWnOS3FlZZUcJrDBVmO/0aQ04JYGaolt7HkxNfxJhr5sUXMXPwi9jmDvb0fHN9uQ15zOgmFvpP5WxIND9ej5mGDOq/7SJcPb+yyeRyR8FV2HD8CH2L6oAdK+/qTYcRUjvWQUJ29TaXFa9ob0cG2BXMz9NnMraTNT8obMHvMtzvMuLvKvKGZH1iypb/pRr8Usf9UjVCg/0vDb0/0Yq+OWbP/vgMfntgfnsSfzqt0jjiBUzdvTp1rLhQ6vaVM8wKEWk9cAjSB3qp5k4lLP6sZ70kcqcwFh/C8oYw8me9lSDhs0IfmfTzy1TlO+m7m3WK5U7x4iCiwTTMOasRXLCUSDhCnboiGR8Px6sjOABcsx6wAeDiEuvBAeC4jwMHgAM/FhwADgMZcADYRTU4AIx1V+AAcIwngwPAMR7QkzWcDgY9WcMRHdCTjRLH2QiGh2y0WCRzzkYcumMOYEeE7rQkdJfxBvCqqQcvFkkdjf1aFSjwpQWBrwyXsuzHUzxdJ3HgRR0g8CJn155DCjKbLF5tvYQZqXdp6j/As6fCLNkqPPKlGH5ktTjwxduUrZEEvlg1tLkLsGYGvjQWO8iW9AnrBIEv5nd5OPAFf1cR5LaxCAdxG0JmGwShMeZaRDg0JtBxfy0y+aUJj4MxPzSjcTD4Oyl6uuzUiJAVdesQNPWjr9mtkNW7Q6Aas4L7+YXWTa2DAcZDVCxmg9zBBONDaN4QXsqrS65LZzcAuGtFbRy/p7fe/t5QbWfefmEJo/k+3OtZfvHpdmO0tzdP9Ruu4+5LpuknSfrwIhWQpS8t3uW73xQQeWgp0TvLa/kLRkkeMDC0+O3Guzwv8MRu9sxSubfbJ+VM3knvs0zT94LrrGJdAHxAb7MKvAD4VFzxynJYSkMRv+4yvzuht134u4uHVlDkd2b8Ksv7zqDQm+xo/eZAPiiDhi+yzM804D0W/Upad8HKr7HUhhKcXCZ1Pgcvvhkr9GL8/hZUvRmPAWnzggASjDZ5JaneYkOZdB+qMnqVbThzz4K5f7dtFgQiR0k6PWNDSNLpARvCCIaI2BCSF5fDhpC8uDw2hKDuwhlsCIlLW2wIiU8rbAgBksZpbAiBd1vMu5PAuy3m3Ung3Rbz7iTwbot5dxJ4t8W8Owm822LenQTebTHvTgLvtph3J4F3W8y7k8C7LebdSeDdBvPuLPBug3l3Fni3wbw7C7zbYN6dBd5tMO/OAu82mHdngXcbzLuzwLsN5t0S3KvBvFuCgjWYd2eBd2vIu7WSIF11BscQ+LcO4BgCB9cRHEPg4dqBYwhcXHtwDIGPawOOIXBybcExBF6uFTiGwM21BscQ+Dno5lrg5qCX625M5nus6/LT/b8Hoj0Gr3QocviRF+DdTNDII13cNRDsEOAmpEdkTFk1l5shvHwIomhkIzTIaQy4SxOxTK/pLEtdYMIExuYi5BGBMEdJNWPCa56UqkdIDaRUM0JqJKXu/e7TzW/NDP82I70Vx8cOem/K1BLN10n9nNiZOihbzvQ1PP3tChUTcqr8owaBtFbb5ATx0dxByPzGRoAHKTTfrleRyWM8CYXmFi46mkRTRzUJjaZT73g0a2Le40l7uJGSGNQhZJwbpZV1lqZB0Lmxi8A9tjvg7uHUuevsPTNnmd16woCfBc0jpntRBNQf4fsVPH47z4YIlMj1H+vHrmKqlMw7JaBaoFYW7TxhOit7pMYT66vr36df6uvf19f/Eq4yiV94I68mTN6xr/lo+4m319pJFZMmYCPfS53G+h1NMU5pKXO11MH78076vBz06EFfFI6MO+dteYq3aLS18pptEZp3zuePdMzboet08NxjHm3VkJZTvqcEamHBtuBxOeQHK42Gjw9v2ZsF2Bg8LGd83fZrS95QkmErCX3NL495+Izvc6CNPOLLp7xNzSPesQ2C+ZT/UC95O/iSz+wjHnzJL89NegvTjF2OHZ+yYCBgibD0vYNaWPQhv5zxxBkf4DOeHW3pVNYyUhfbHDGYeMkRSrwQP6dmPybHlahslBuT48qkVPAp8oYEyt8mb8BXphCm3GnypD04y6zWcKu8WhaMtB/wGfKGajqATvhsuLhG4sE1smpEEs10OvOgzuLhdAZQu+BKS1MrzTaV5jBHMyWcx9lWBro/yICmA6hp19H0MXuDz78l7i5V1srxNn04NA0ssXUfhem5I+r+7WWD6v9/J9H/T9PqPzeVV3RNHkCSpOY2kMBDPeLGVSBXHP8LAjsq4pIwRz8HUz2/PsvVXWSF5J0HzSyhyBfDcJTCENkxWCfNhh/7DDyzYAW1L4HX0souQJuaa0ZaDff46zDYQAnBZUuRbSle8beUgZQLS3Y7yV5uGL55rQ7sgGeHq4hlW3m5VYvtyiqGshvmo5vmo9jbipGlXZfDpLYRWAceJgk4THJzS4hsrQtBEMtTSuj07YuA5R83trn1lwdMY0ex+I6yatjy4FMqsY8mMB67BHxGWKlvIgGaR1Pb0NlhXe9ladjlxiu88XrgxhvADcajmJPKptZ8Zkc2NNUHGfZiOQCFW0szllhqd+AAbIZTPJgg9AHftwrrM/wviOxwj48yzMRyQa9aDhjtqehpxYVRDpxsaQScQCsKT+DH1CJrTYntsoAONQXfRtK2ggyUZHBDOQMa5xG0MBOo9fEc46f3jqF7jvF3gWO8rNSUW3Mt8jyMJaqUhwa27QcjzI0cU3H/mF5xf61vb+//PHDWY9UoKy2PtQCjxUMzNBks2xisMKd7QmMwExjDVp2n9WHAYZ0w33RMHf2/j/IGr6Ck2JlMAybMB3TuZQmB5XBl5GCGHbNSkxkCW29BliRcztZ/4vHOZkgjwNXWoc3WwvfhKIvxL0frSA8G3DXJkm/LySrxaCNP6BswfzKg8izLZywnKyPW2zhZQzNgTOstKlnAeNlNR2oNUJGW5YuWy88/4Vh3aMbzo4LPzSbAIbJhLdHIoubLySoxlyhPHBowMTOgcjsm+k0yhna6qwxGv+OLHPtt+/G7mqBtP8av64fHm7vt0H+sH59emA+SdtHlGOL2vh++ffv/ccC3Ng==

It ist possible the build a whole factory with this strategy using only one central belt with everything on it.

Such a transportation systems a called sorter. It is essental that there is all time capacity on the sorter für all sources and sinks.

Thus you should only send material if it is required down stream.