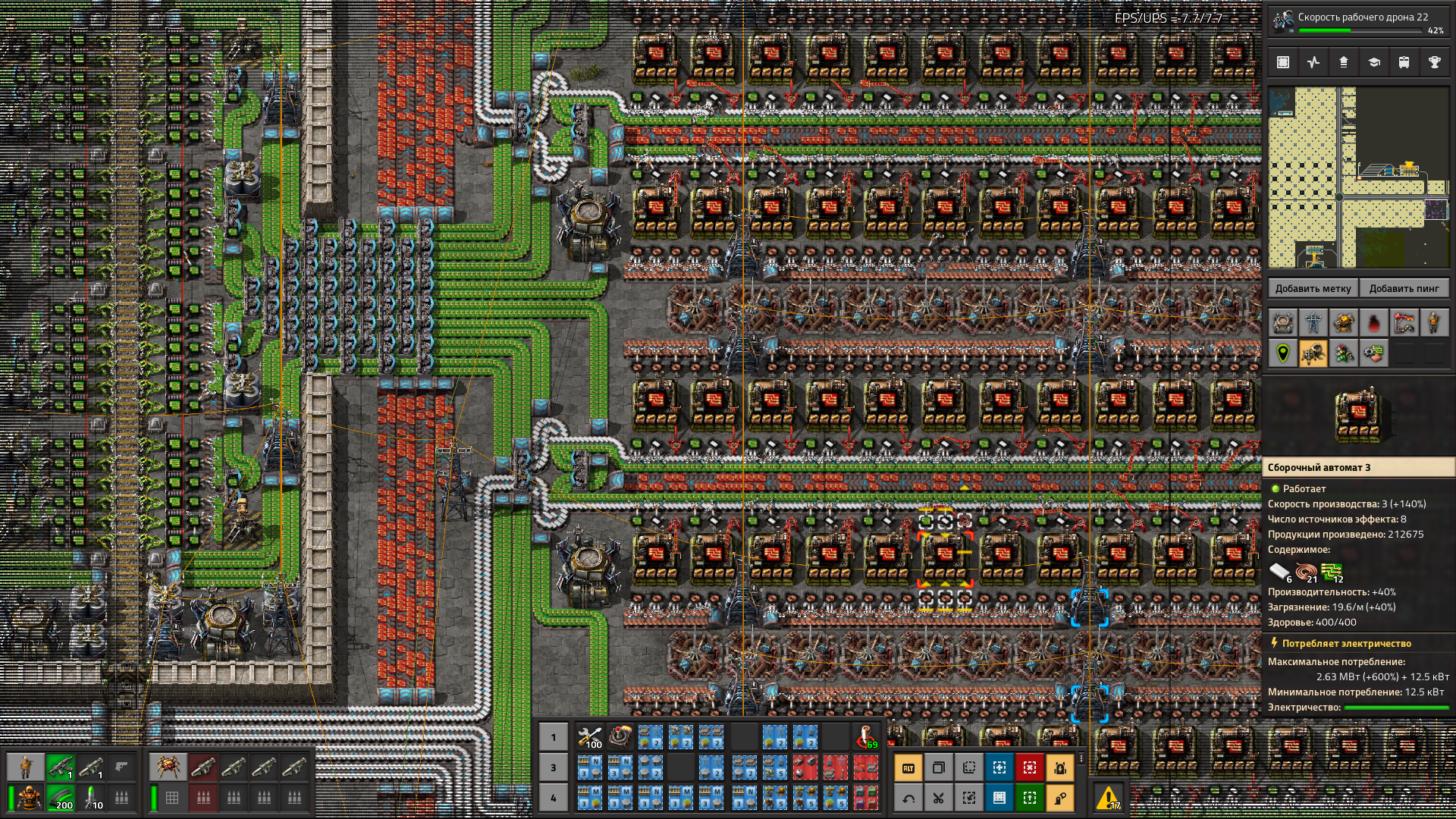

Giga-factory v1.0 (screenshots 1.2 Gb ! )

Posted: Fri Oct 06, 2023 3:40 pm

Hello everyone, I've played Factorio for 10,000 hours according to the Steam. Of course, this is not all gaming time, it’s just that the computer is turned on.

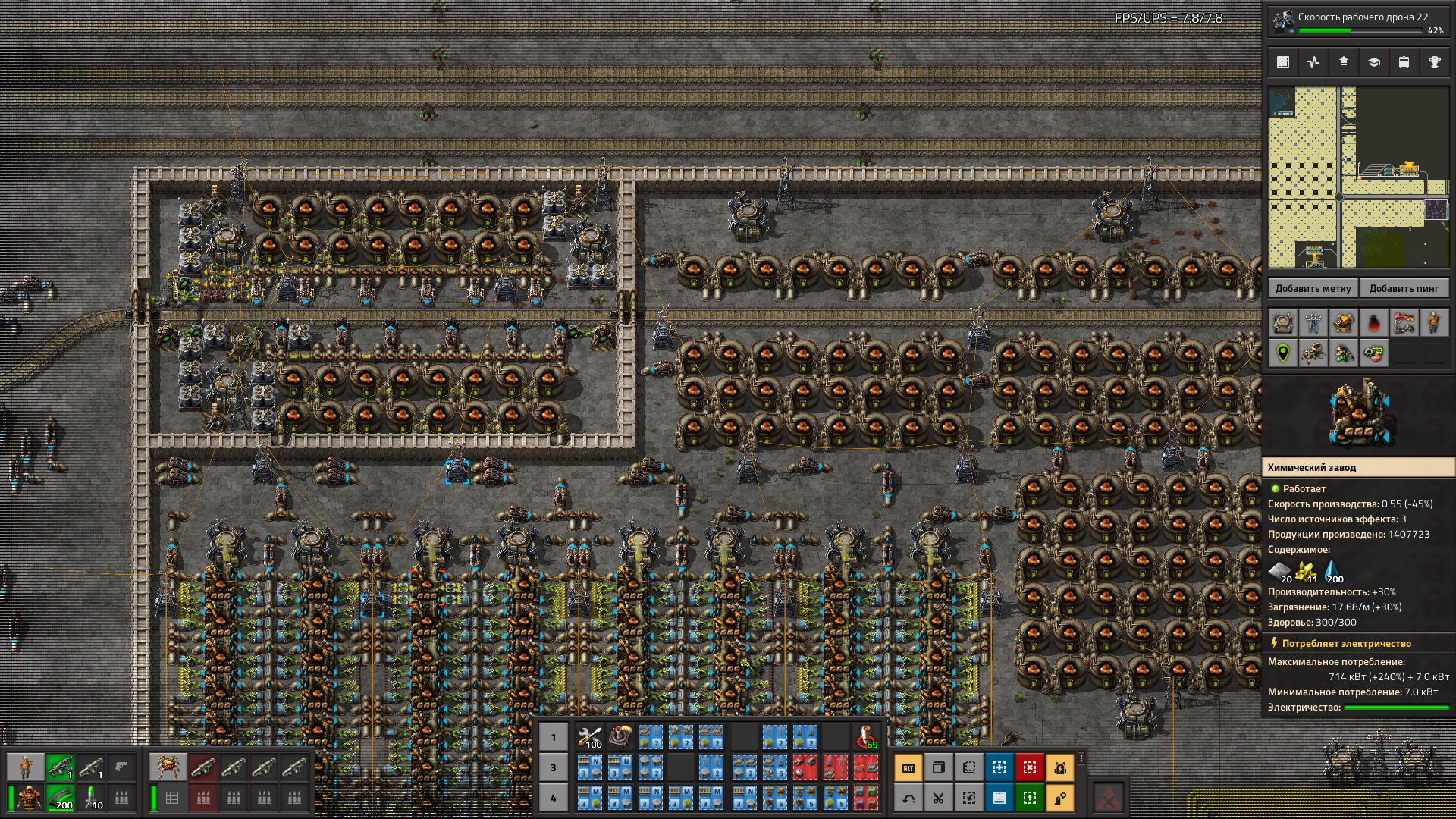

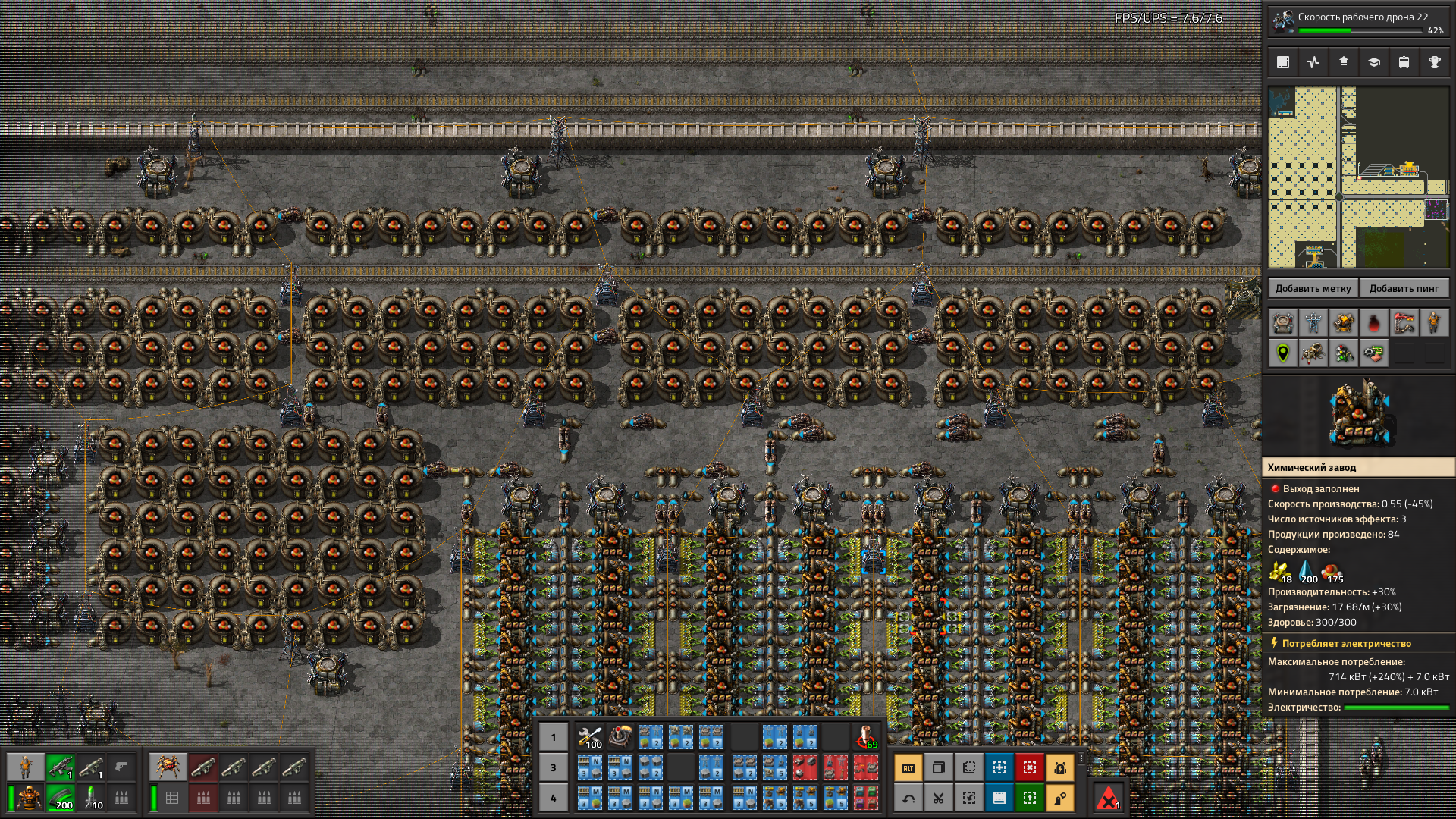

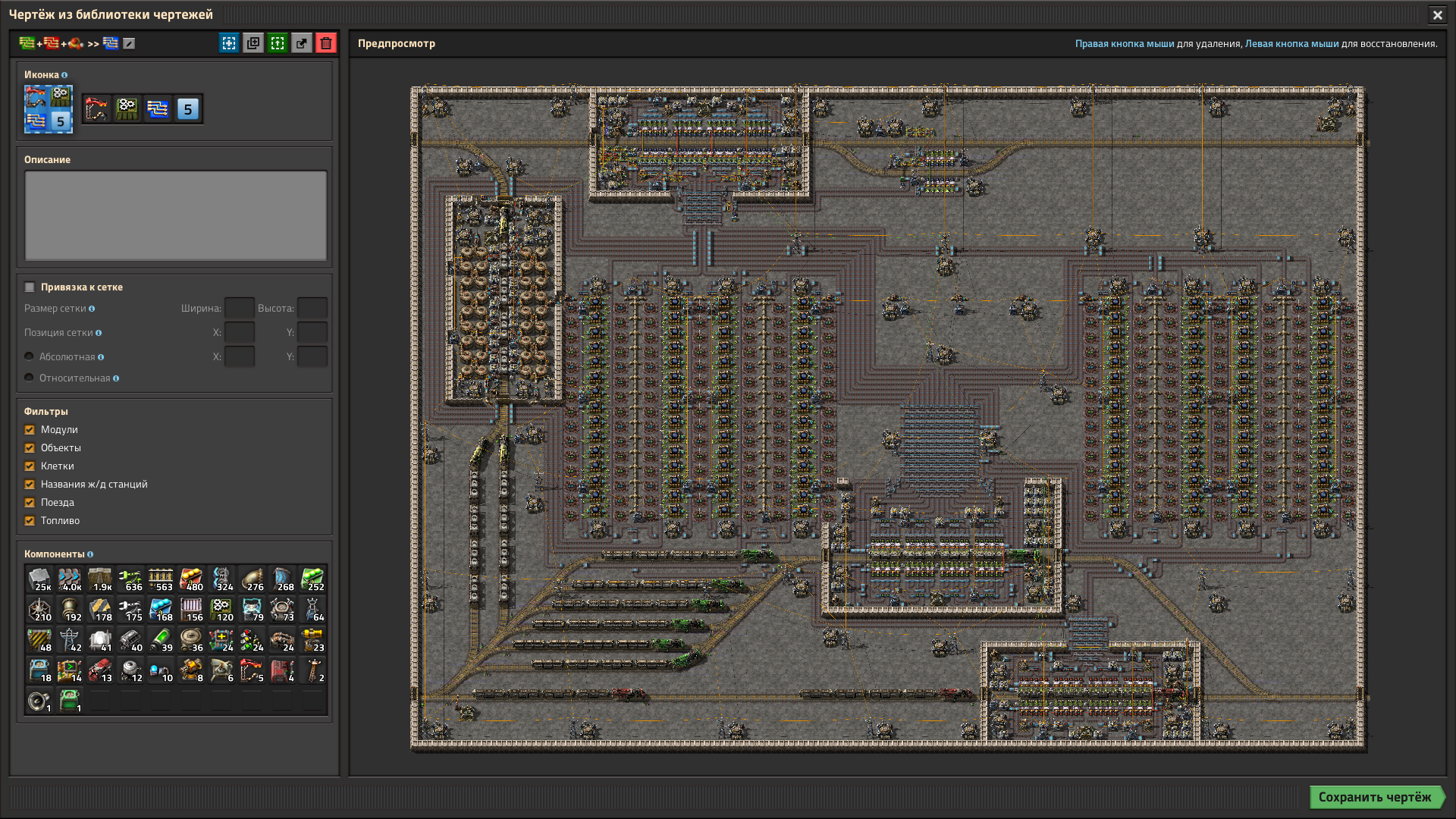

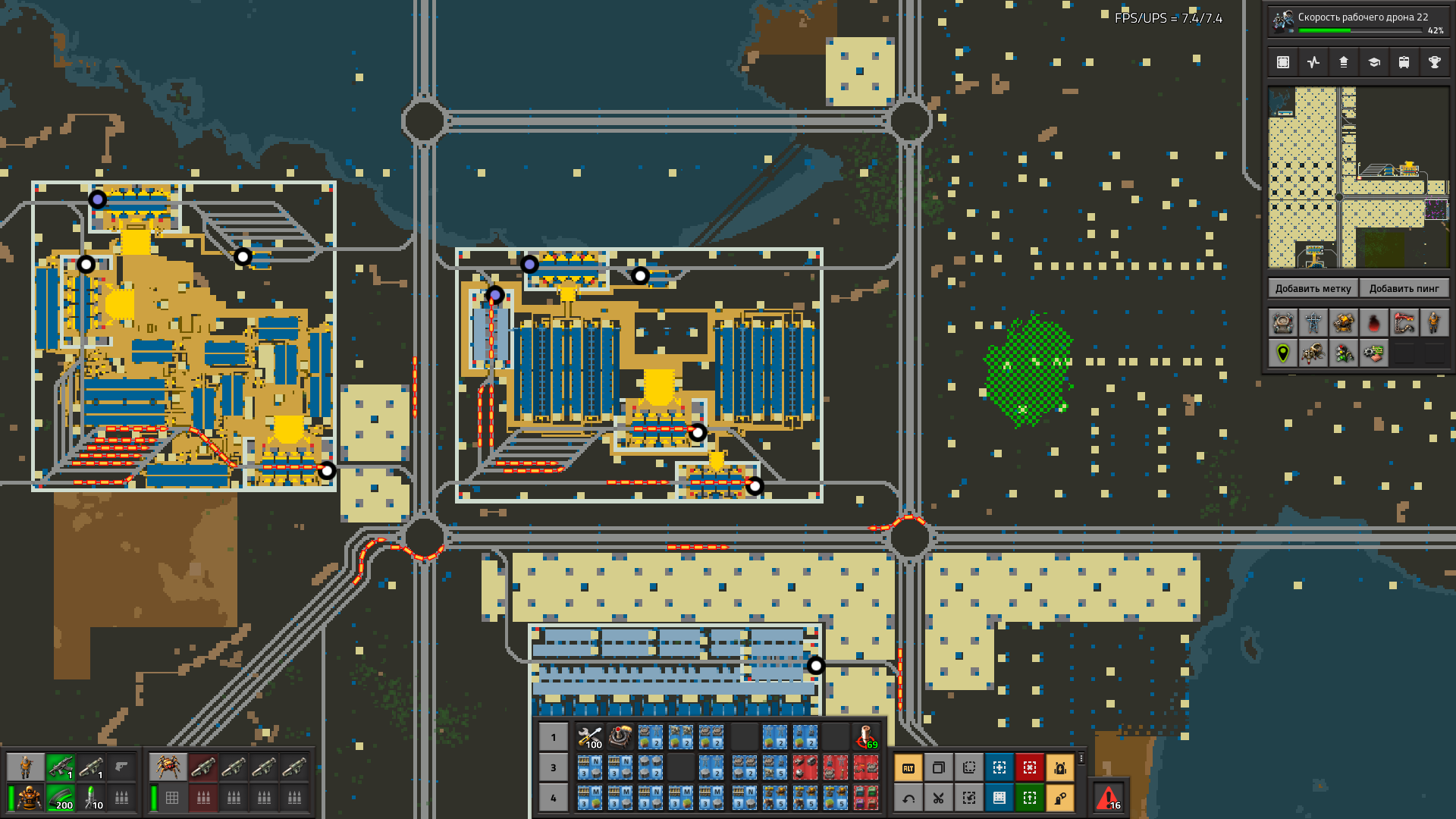

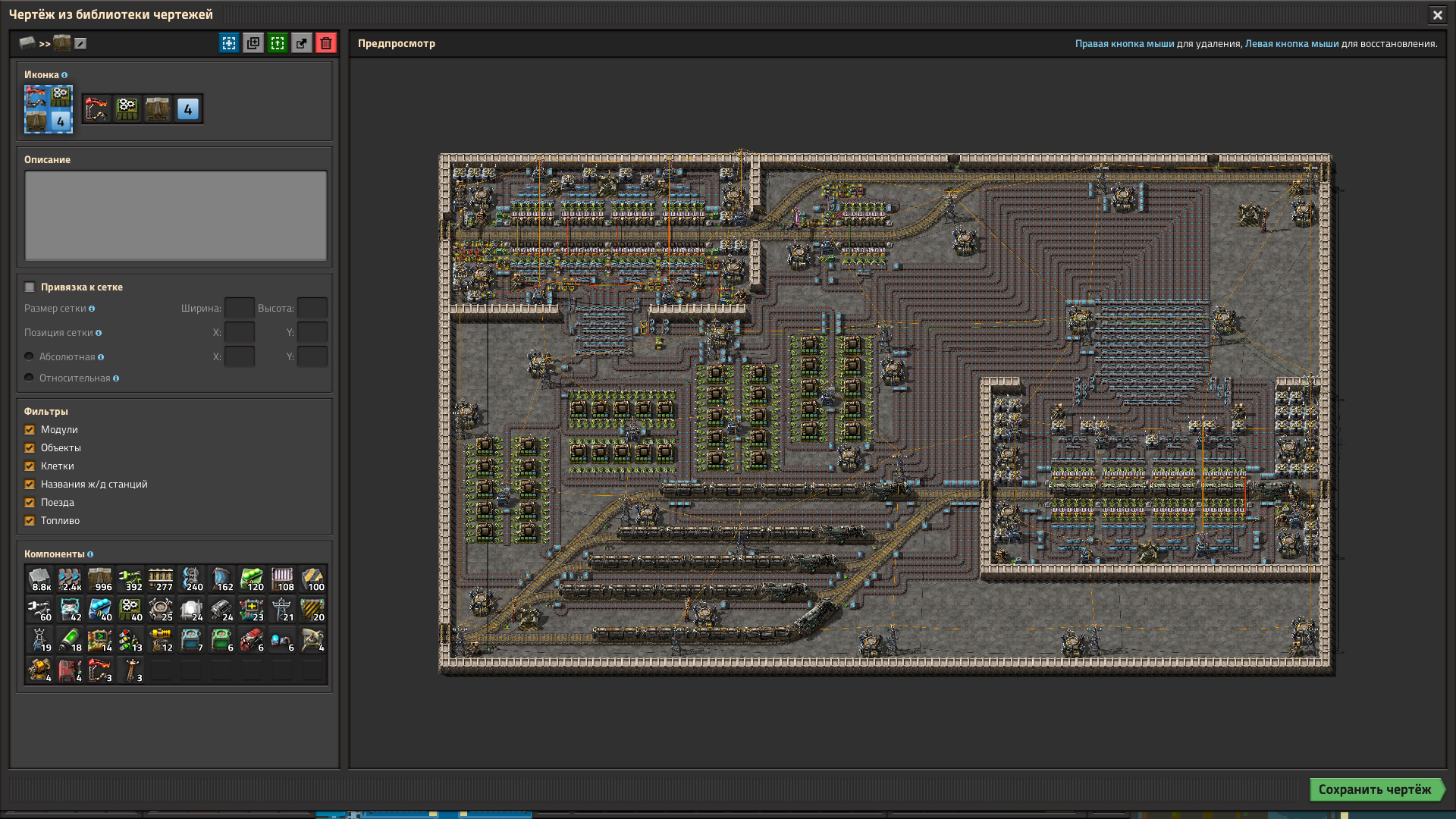

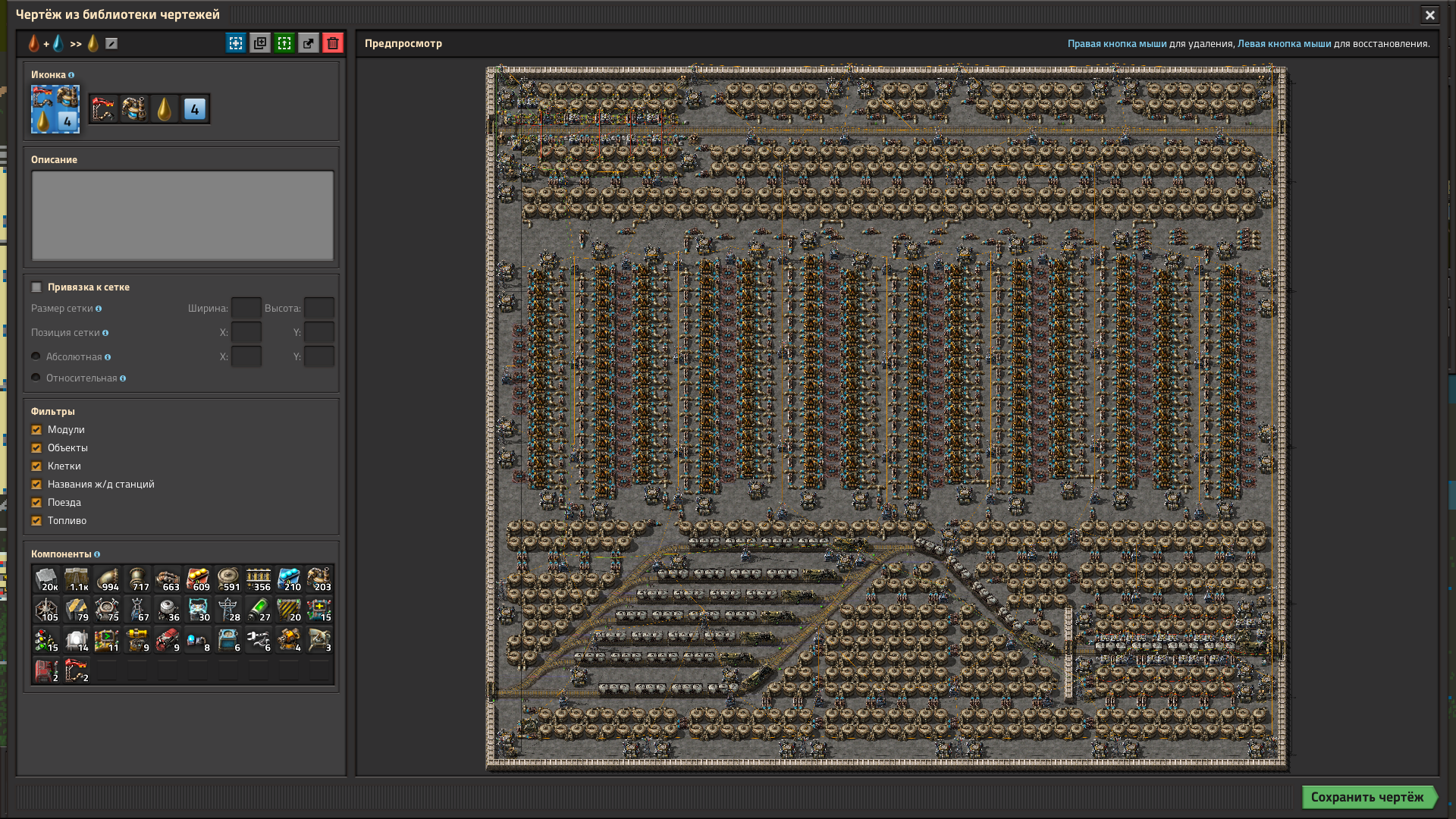

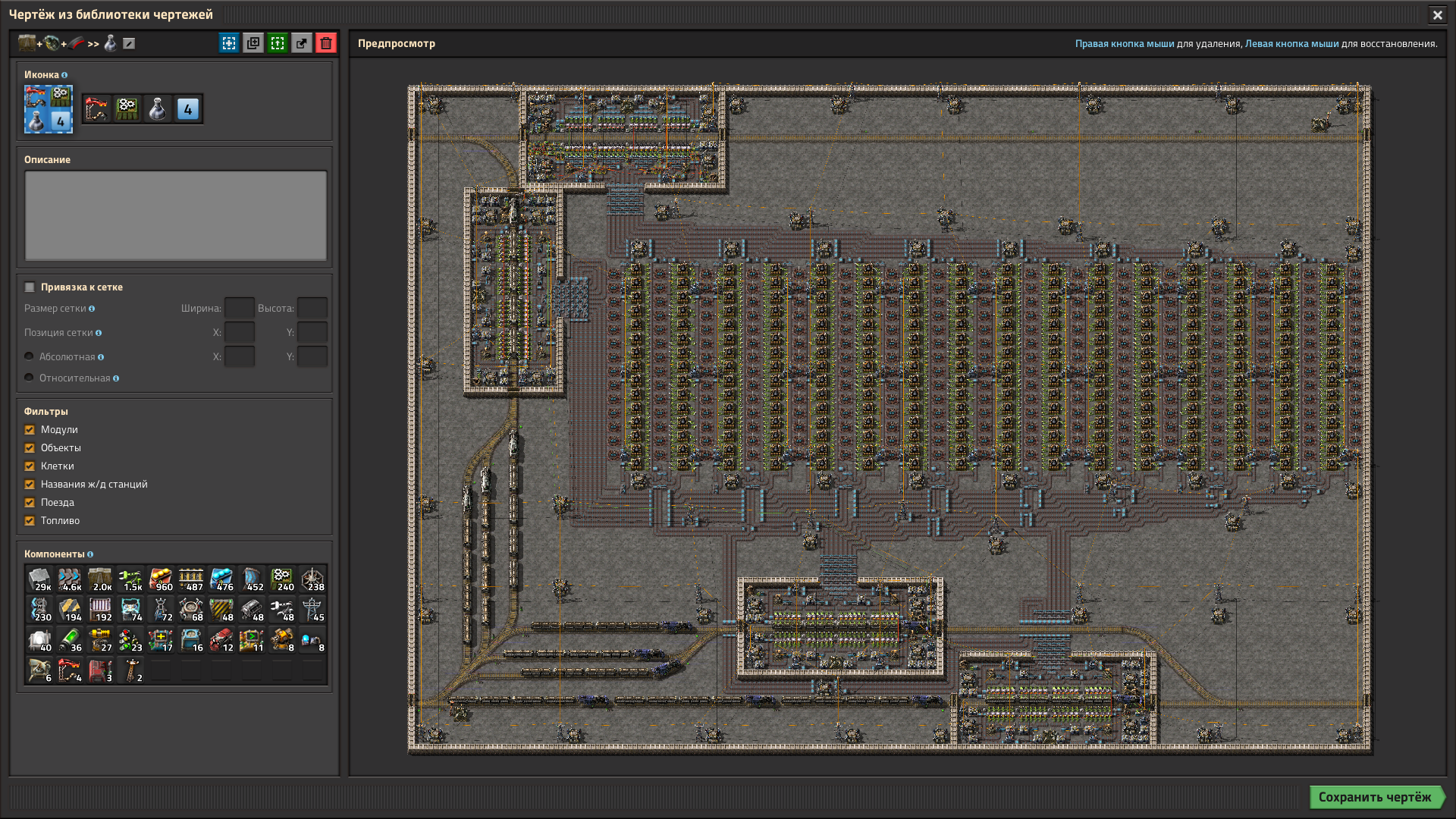

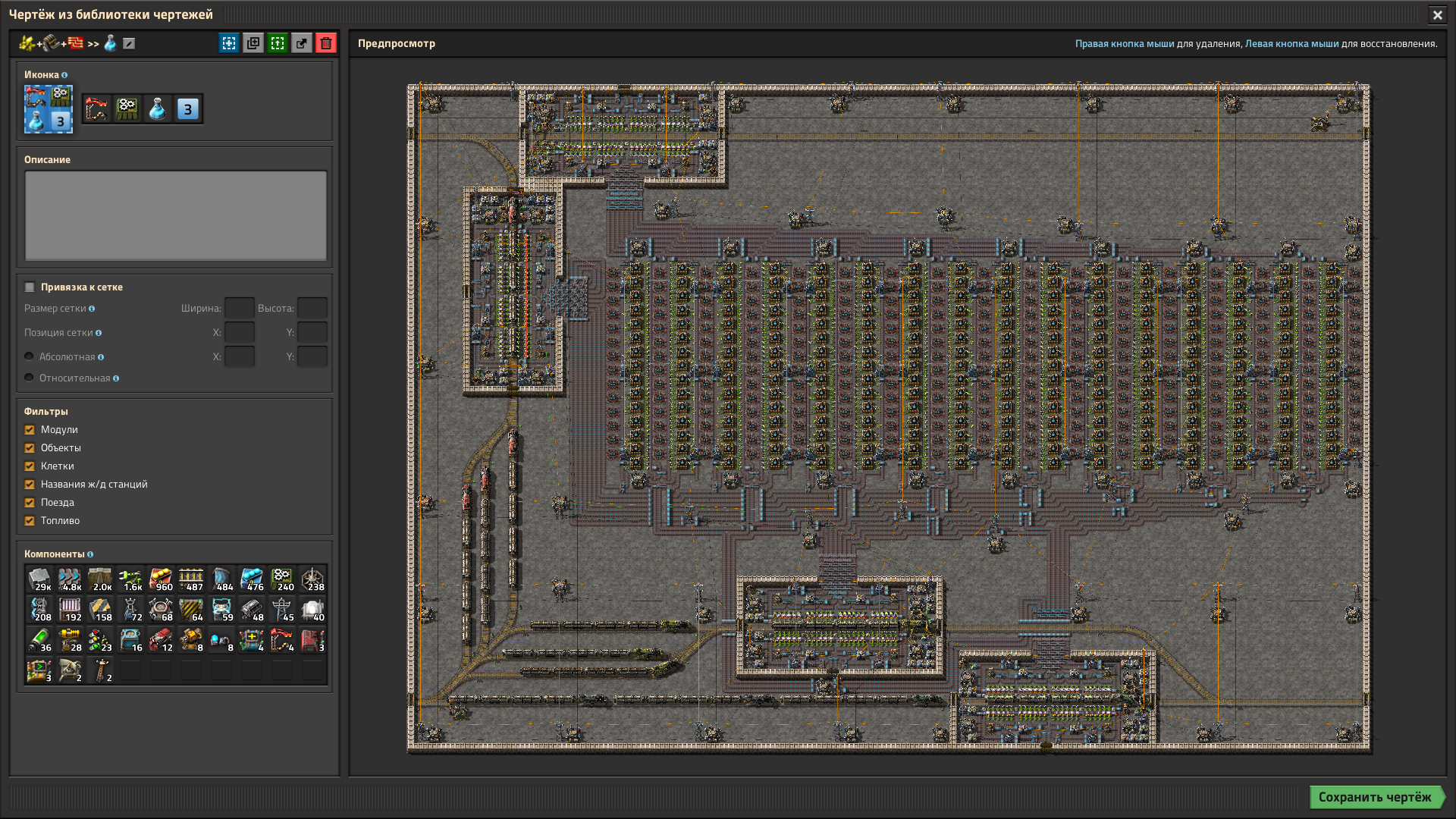

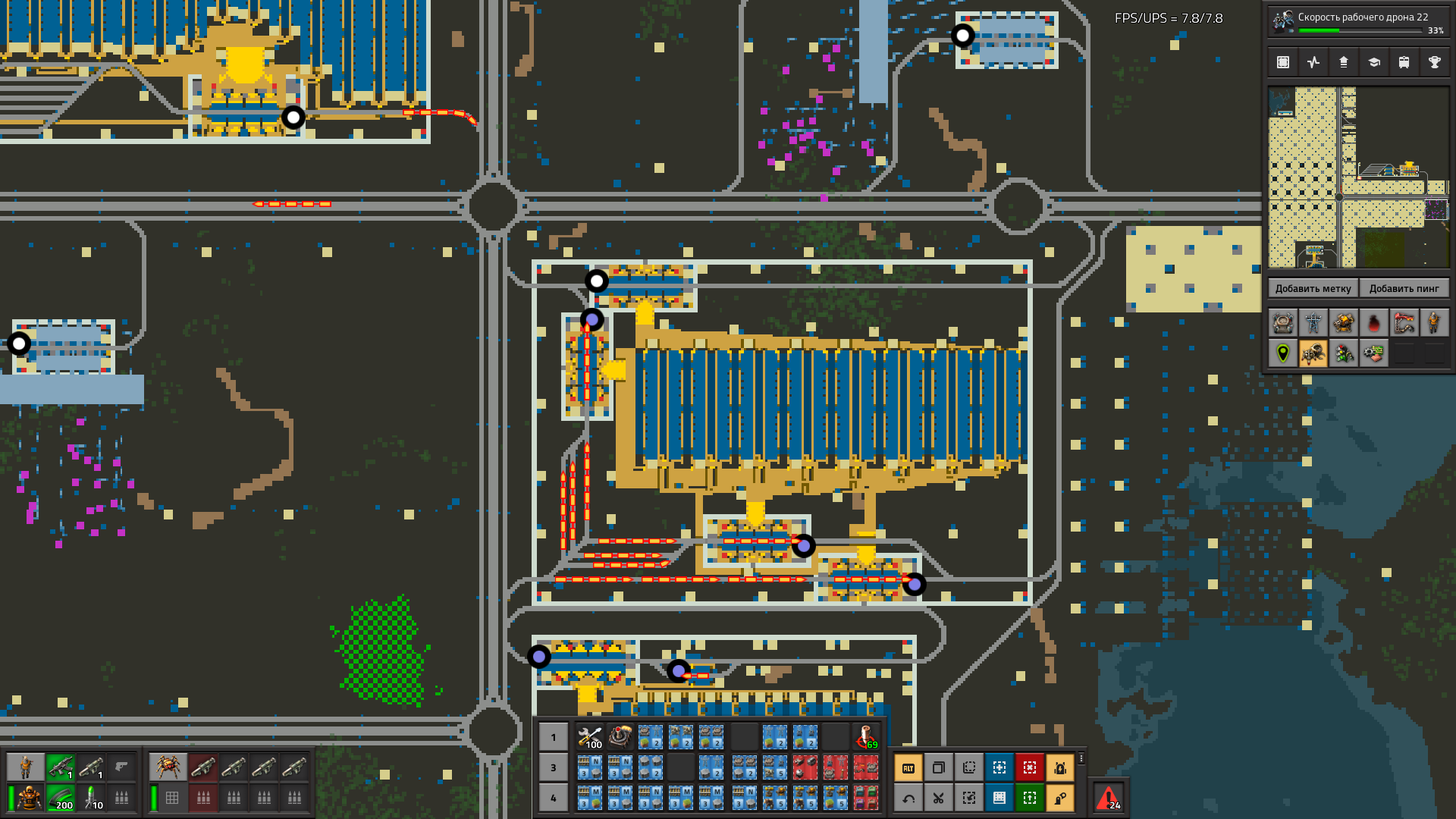

I want to share all the blueprints that I have, but keep GameSave to myself. However, I can show you in the screenshots what my factory looks like.

I guess there is some errors in such big article. Please report I will fix all of them.

My performance criterion is the consumption of [item=space-science-pack] - 11k per hour. Despite the fact that all laboratories work with the productivity module.

I can increase the consumption of [item=space-science-pack], but UPS=6 and I don’t have the strength to play this anymore.

Why is the consumption of [item=space-science-pack] the criterion for the success of a factory, and not, for example, the number of launched rockets?

Because the only high-end content in the game is endless exploration.

For any endless research you need [item=space-science-pack] and they are most labor-intensive in mass production.

I can easily quickly accumulate any other science-pack in huge quantities.

Why consumption and not production? Because science-pack can be hoarded or inaccurately produced without being delivered to laboratories - therefore only consumption [item=space-science-pack] is the most objective factor in the efficiency of the entire factory.

I do not have or have installed any mods.

There is a limit of 60,000 characters, and all my blueprints that I would like to share weigh 41Mb.

That's why I provided them as links.

Also this is reason to split article to 2 posts.

Question to developers:

By the way, I have a very strong computer and a GeForce RTX 4070 video card. Why do I have FPS=6 with UPS=6?

Why can't I view the factory at FPS=60 even though UPS=6?

And even with UPS=6, make the movement of trains and drones and everything that gets into the frame smooth?

Question to developers:

By the way, why can’t you use the power of a video card or even a mining farm to raise the UPS for such a factory from 6 to 60?

Question to developers:

Is it possible to somehow transfer GameSave with this factory so that it does not go outside the development studio to investigate performance problems?

It seems to me that situations in which many identical trains go to many identical stations and they constantly change direction are poorly handled.

So why do this? Why can’t you just go where you decided to go and change the route only for some significant reason?

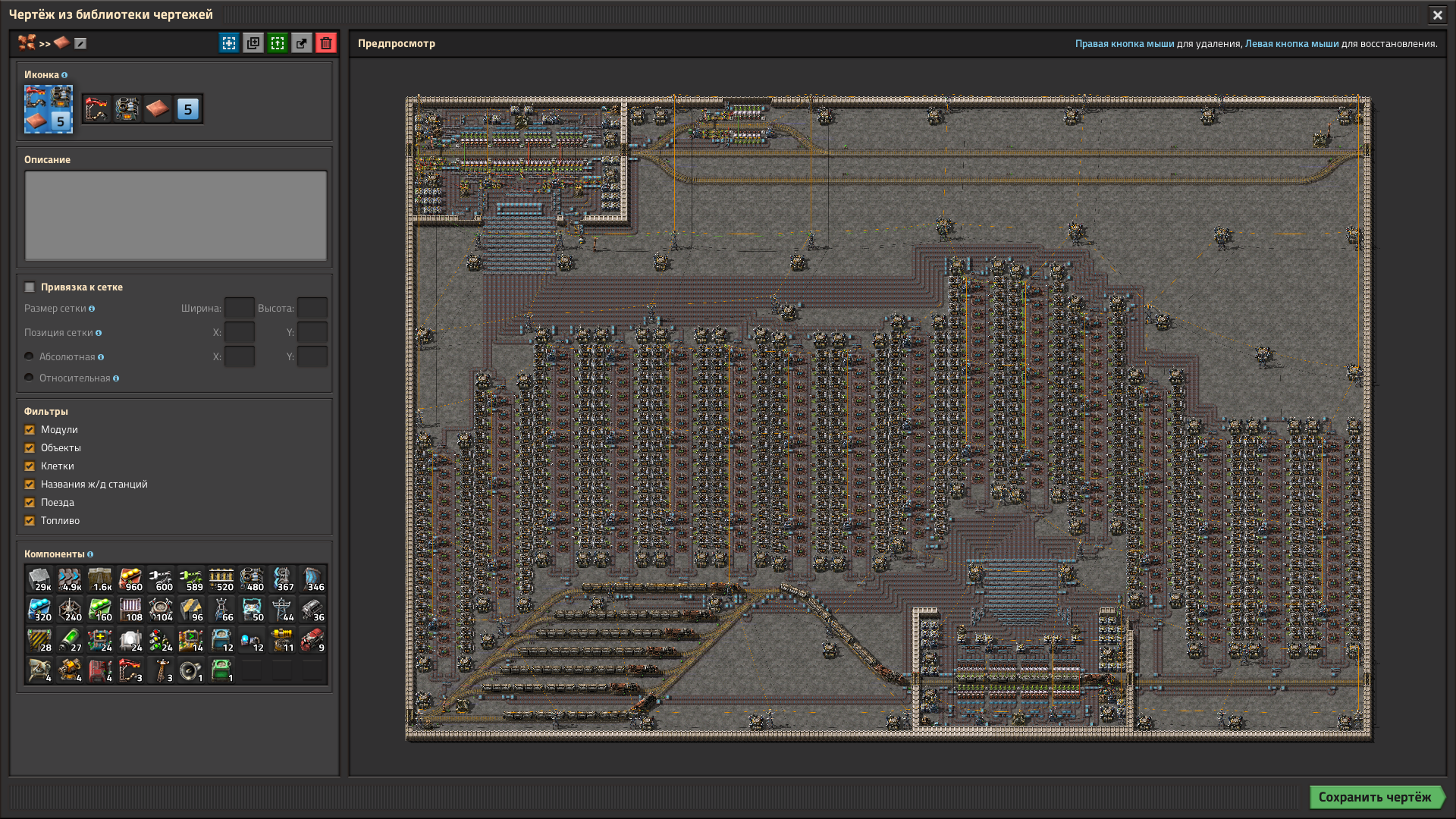

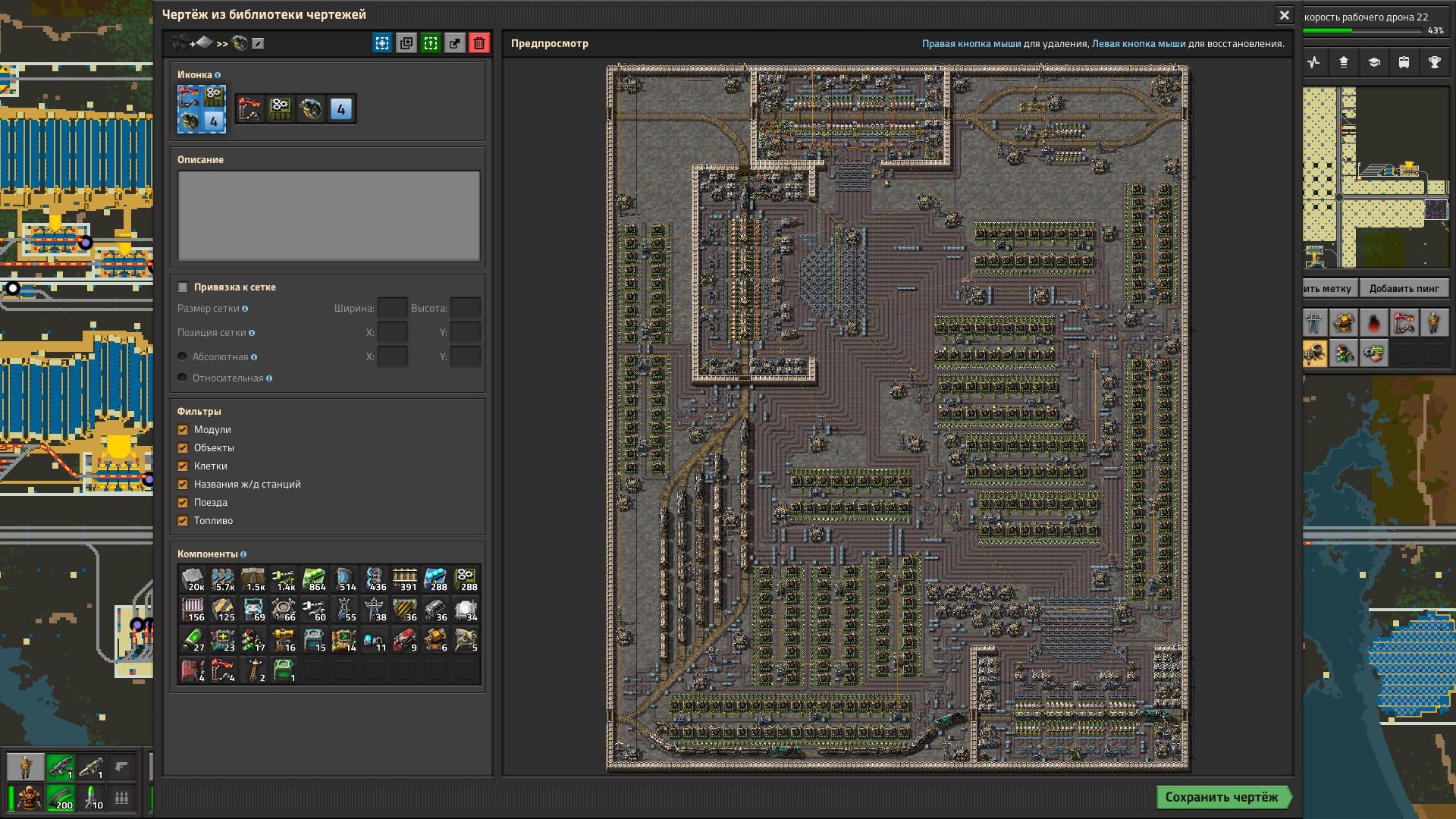

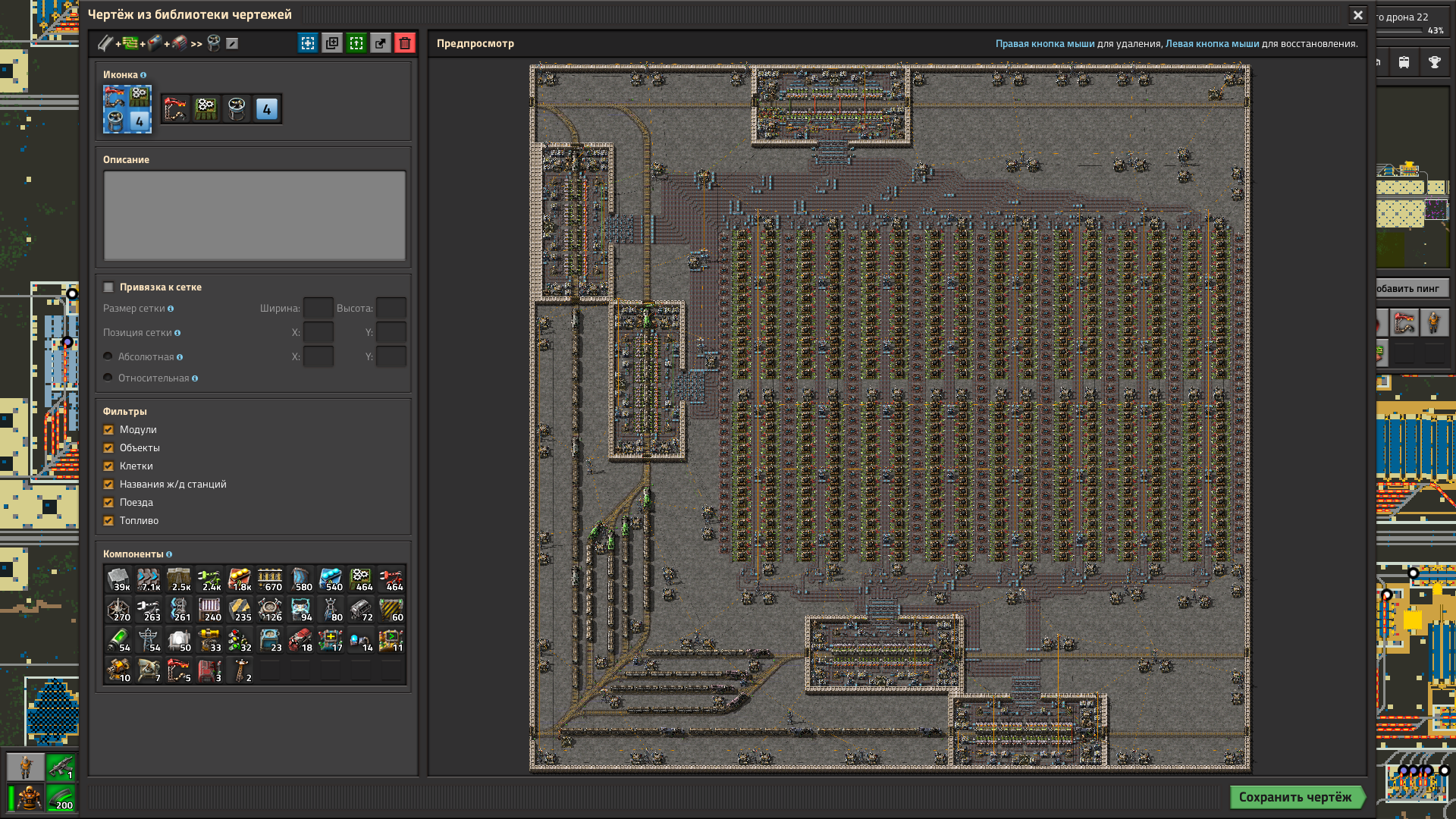

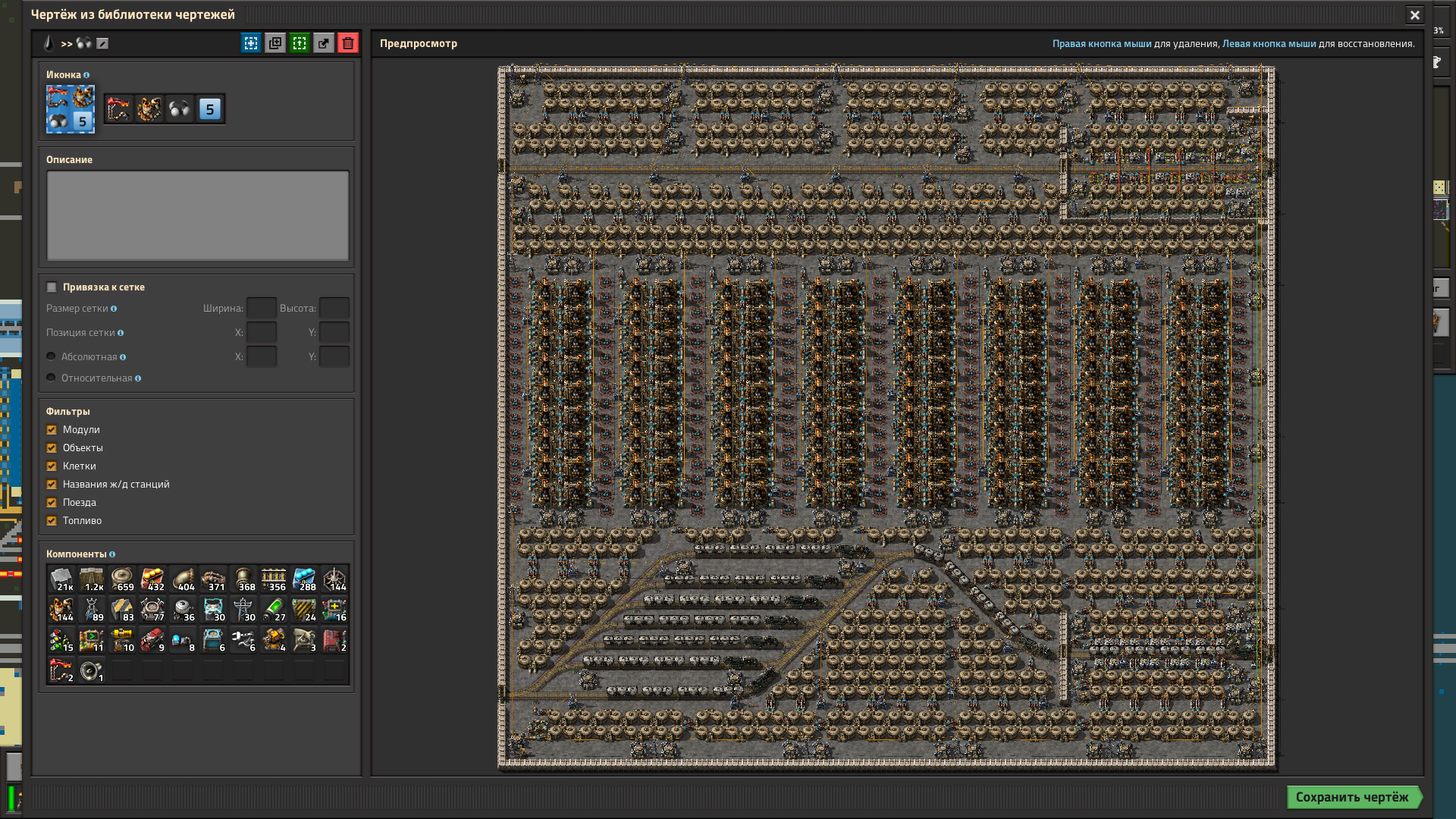

All blueprints weigh 41 Mb

All screenshots weigh 1.2 Gb

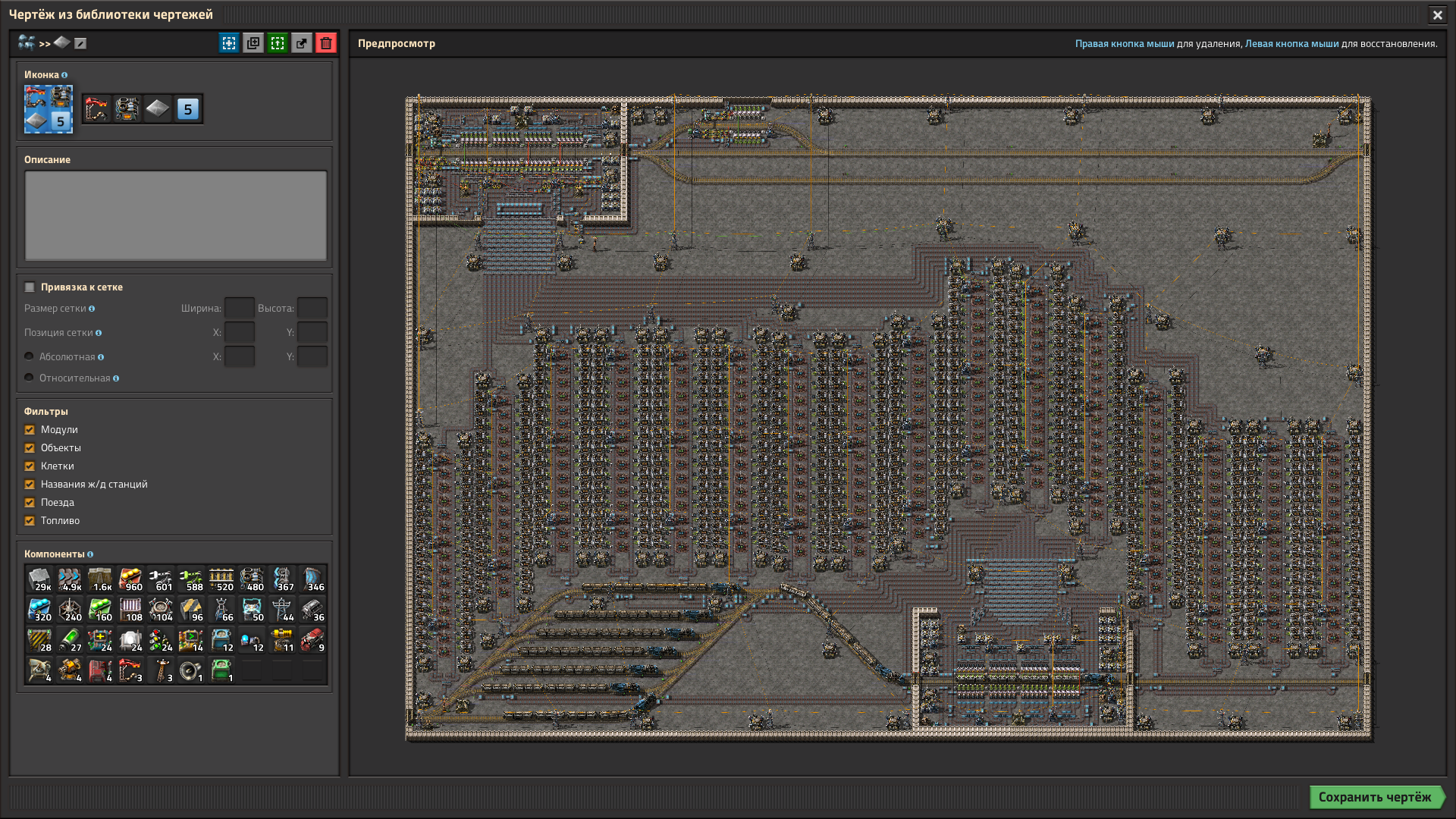

Trains: 4049

Construction drones: 6.69m

Transport drones: 4.39m

Save-game weighs about 450Mb.

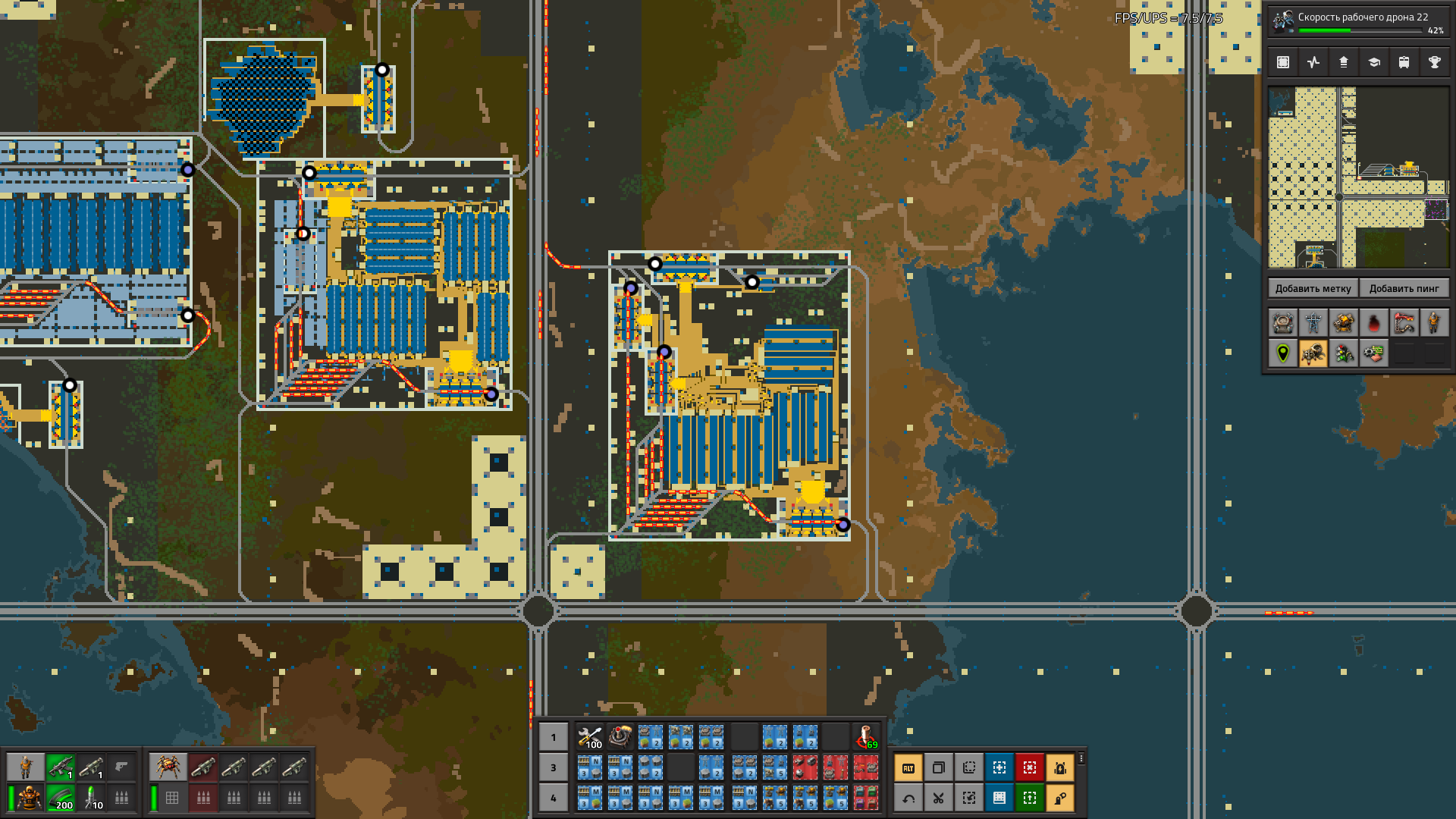

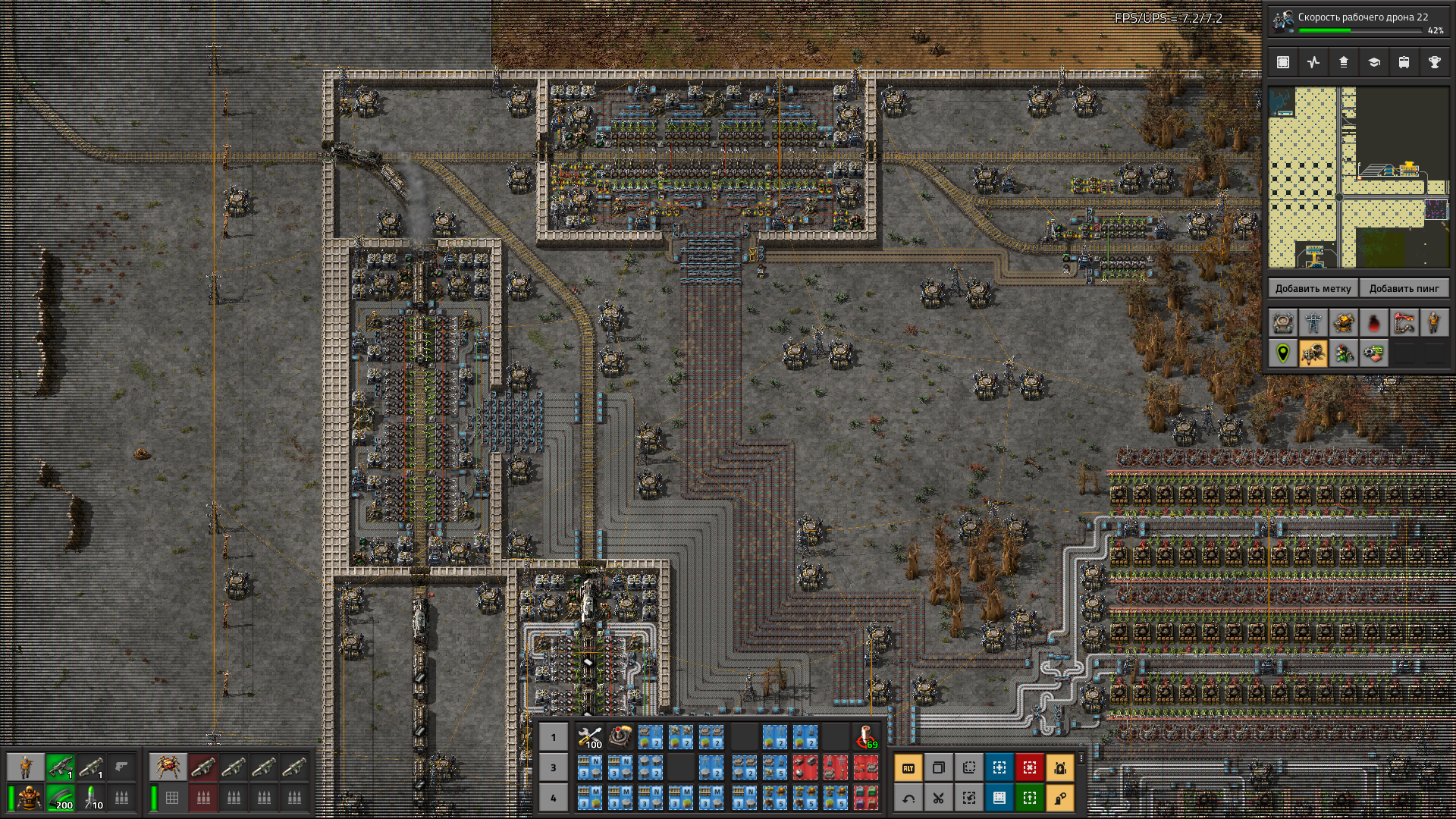

As a map, I chose a railway world with a standard beetle expansion. It was put up a long time ago and of course I won’t play it again, this is the card I have - that’s what I’ll play.

The giga-factory concept includes a lot of rules.

Main rule: The factory must function uninterruptedly, provided that I can leave the computer for a week at any time.

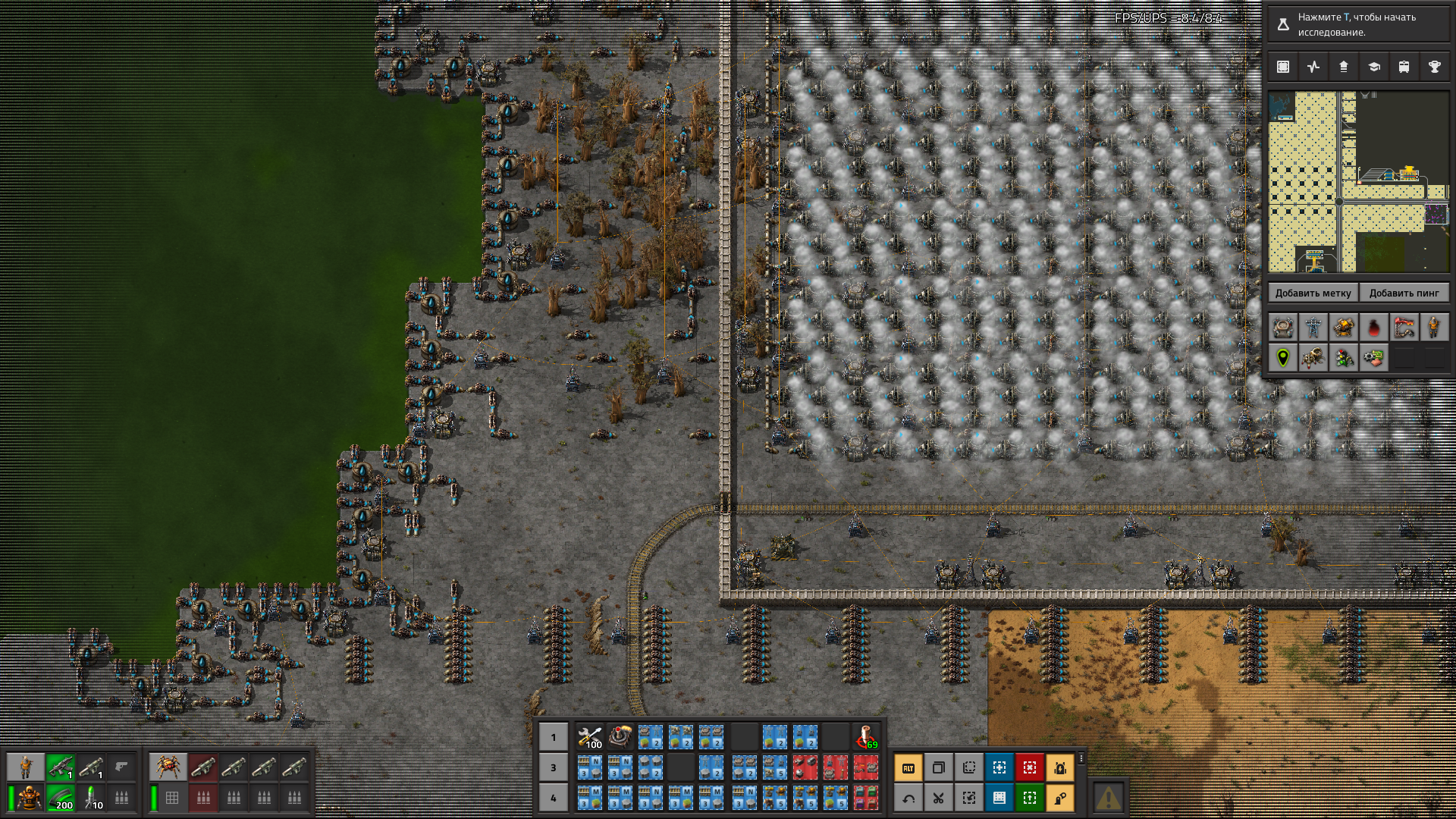

Main rule: Setting up a redundant circular defense perimeter, organizing uninterrupted, fault-tolerant production of everything.

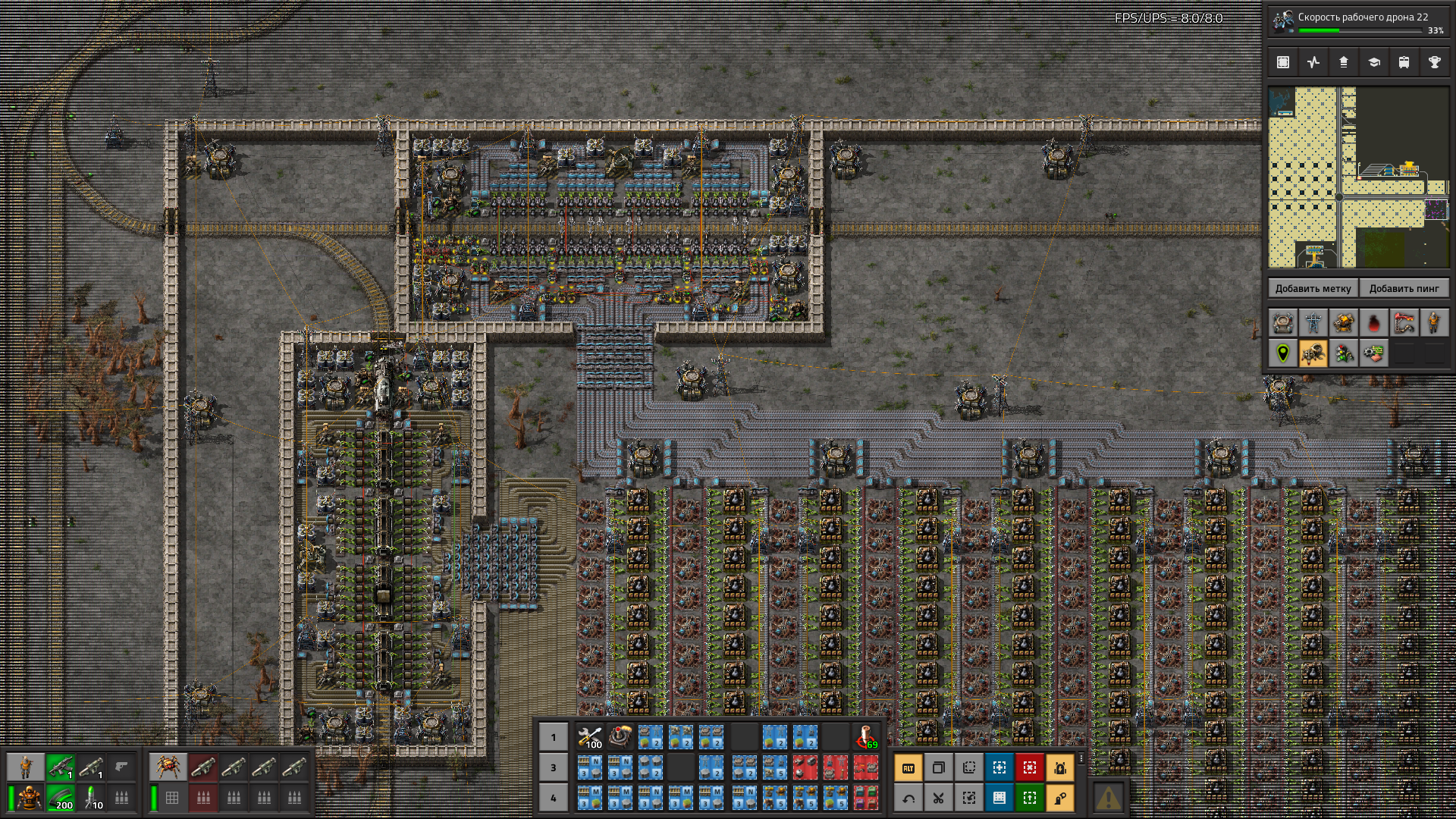

It was determined empirically that absolutely everything that can be produced with productivity must be produced with productivity. Excludes ore of any form.

The explanation is very simple - let's imagine how many resources are needed to produce all 7 science-packs, 1 each. Now let’s take and remove the productivity modules from the laboratory.

It turns out that to produce the same number of science-packs, ALL trains will need to carry 40% more cargo. Now let's imagine at each step of production if we remove the productivity modules. Well, that's the whole answer to the whole question.

Why such a rule with such an exception? Because in such a factory one of the most problematic areas is railroad logistics and it is very important that

I conducted tests in 1 wagon, 3 wagons and 4 wagons. On the one hand, the fewer wagons there are, the faster the train accelerates. But often in such a huge factory the train simply travels at maximum speed for quite a long time.

On the other hand, the more wagons, the faster you can unload at a time. From the blueprints you will see further that it is very important to have an even number of wagons. For unloading speed.

You can also consider setups like 2 locomotives and 8 wagons, but I believe that this cannot be done - because even one such train will wait at intersections for too long.

As a result, I chose that most trains will have four wagons, and some trains will have one wagon.

Main rule: that if some workshop has been idle for quite a long time and the train is not full, then the trains are still sent out in order to stand idle while being full.

This rule is implemented differently for warehouse trains, production trains, and liquid trains. But this idea is implemented in all trains without exception.

Main rule:

Of course, almost everything at such a factory is delivered by train. For drones, only this is provided:

There is a separate workshop for equipment, more about it at the end of this post.

Rule: Manipulators - always and wherever possible, instead of a green manipulator, a white one is used, indicating which resource it moves.

Rule: Fuel - always and everywhere at any station there must be a request chest for nuclear fuel and a manipulator loading fuel into the train.

Rule: Core chests - all chests must be green, some chests that cannot be green due to the consumer must be red.

Rule: In the middle of the core there are two blocks with yellow chests. There should not be a single yellow chest in the factory outside of the core, or perhaps in the future a carefully thought out module specifically designed to handle yellow chests.

Question to developers: I have repeatedly seen that if all the yellow chests are empty and something needs to be delivered to the yellow chests, the drones deliver not to the nearest yellow chests, but across half the map. We need to fix this.

Contributor request: Due to the problem described above, you need to make some kind of station at which there will only be a lot of yellow chests and a lot of drone stations around. And it will be prescribed to install only one in the center of the map. Use only if there is more than one core station and remove all yellow chests at all core stations.

To launch new drones, steel chests, green chests, blue chests and purple chests are used.

Rule: The color of a station must always match the color of the train to that station.

Rule: The train schedule always has a station at which it must stop most of the time, and this station must be the first in the schedule list.

Rule: Warehouse trains wait 1000 seconds for unloading and if the warehouse is not full, the train is sent back for more. And if it waits 3000 seconds for unloading and the train is not full, the train goes back for more.

Rule: Any loading station or storage station can calculate the amount of products in chests

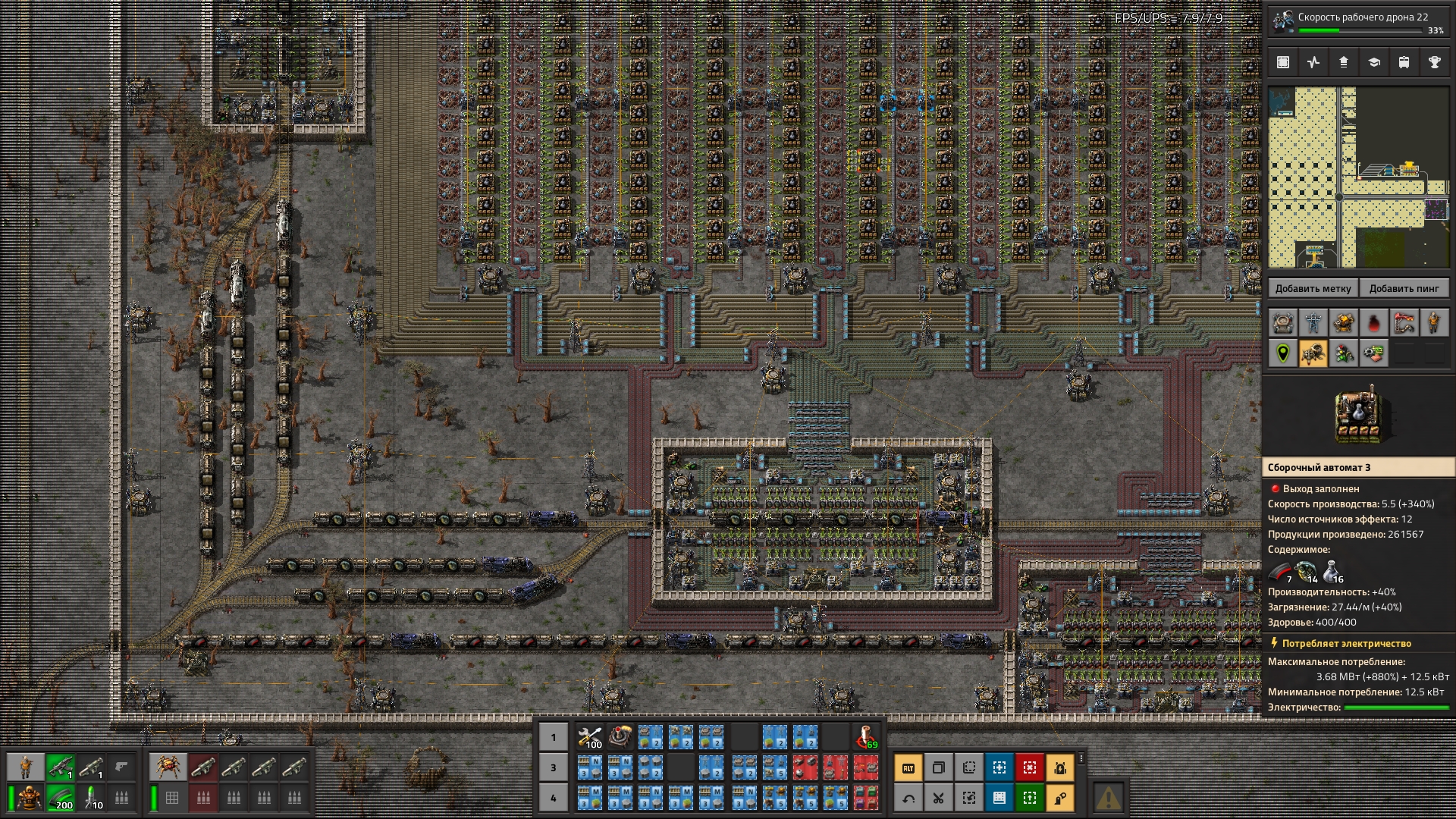

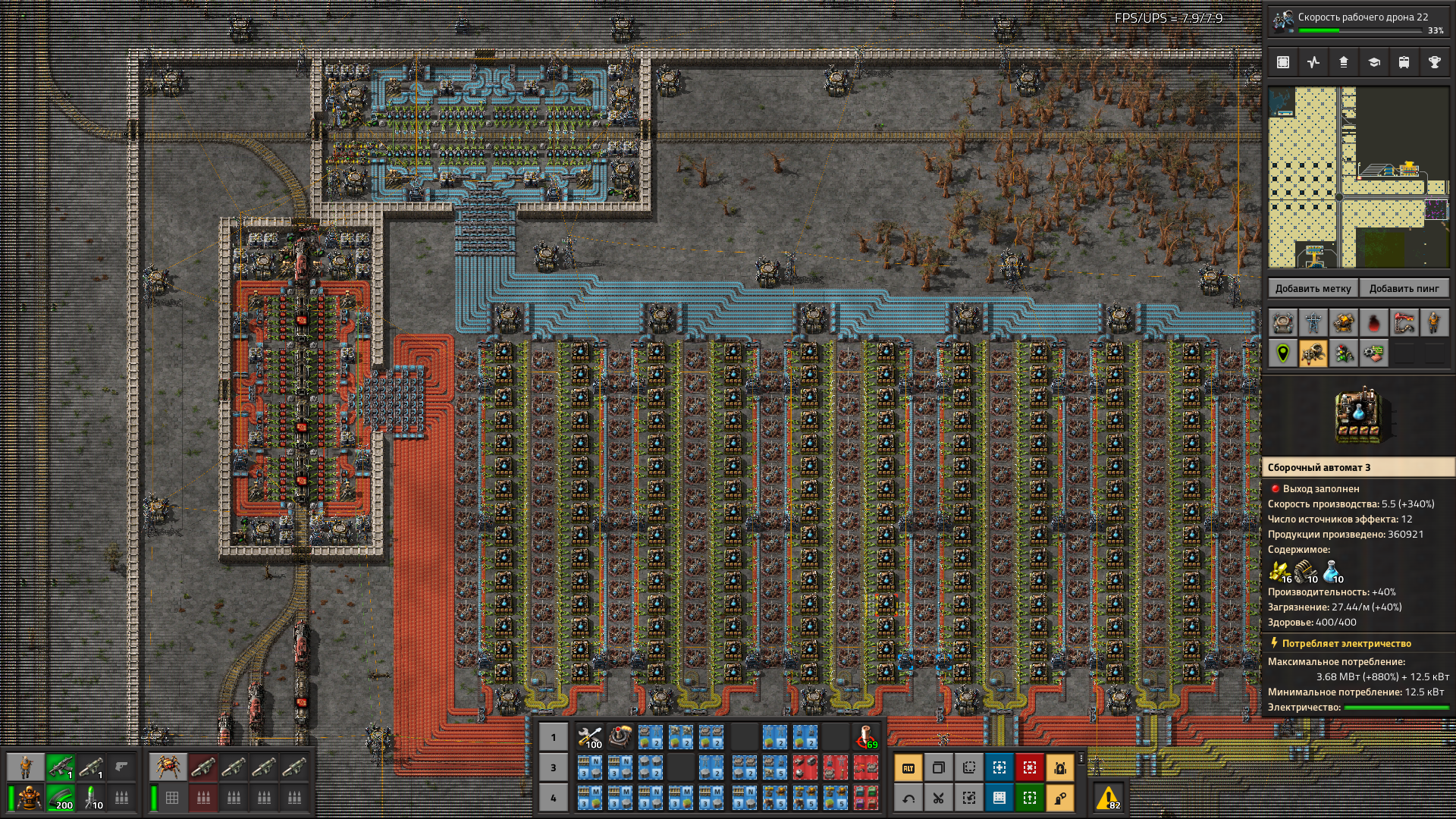

This means that at maximum load all production units are functioning (for example, an assembly machine).

Rule: Each workshop is surrounded by a wall and thus forms a rectangle.

Rule: Each workshop can have the minimum number of train entrances and exits as possible.

Rule: Each workshop sends its own trains for products.

Rule: Almost every workshop has a speaker that turns on when idle for a very long time (for example, if I forgot to start the trains after construction or for some reason the production failed).

Rule: Almost every workshop has one or more loading stations and one or more unloading stations. Either for 1 wagon or for 4.

Rule: Usually each workshop produces one thing, and often has loading stations for both 4 wagons and 1 wagon at the same time.

Rule: Sometimes a workshop has secondary production, this is allowed only if it does not require new loading stations and there is no need to build a loading station for one wagon.

Rule: This rule only applies to: marked reinforced concrete, pipe, fish.

Contributor request: implement marked reinforced concrete, workshop pipes in such a way that this too is produced there.

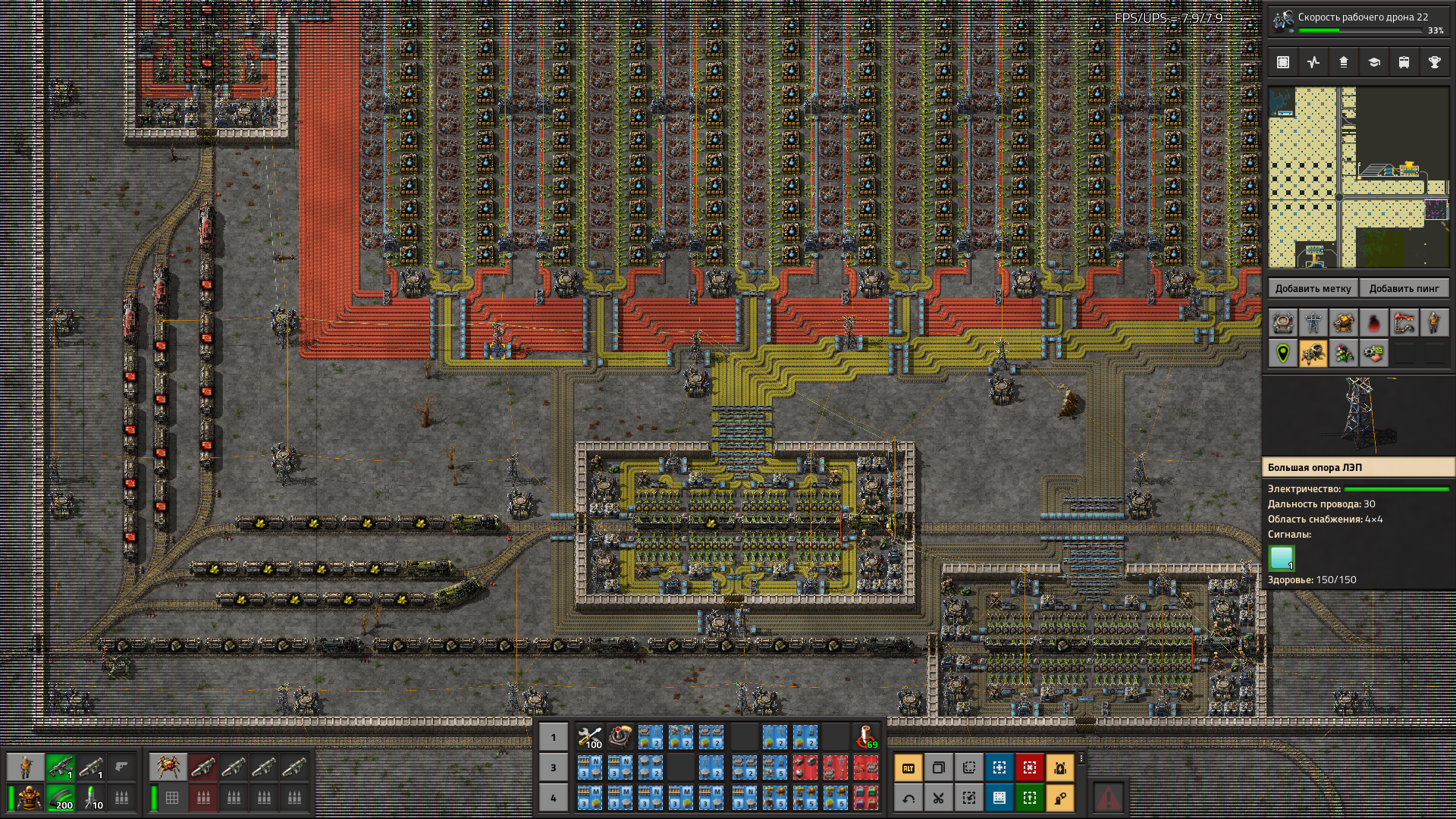

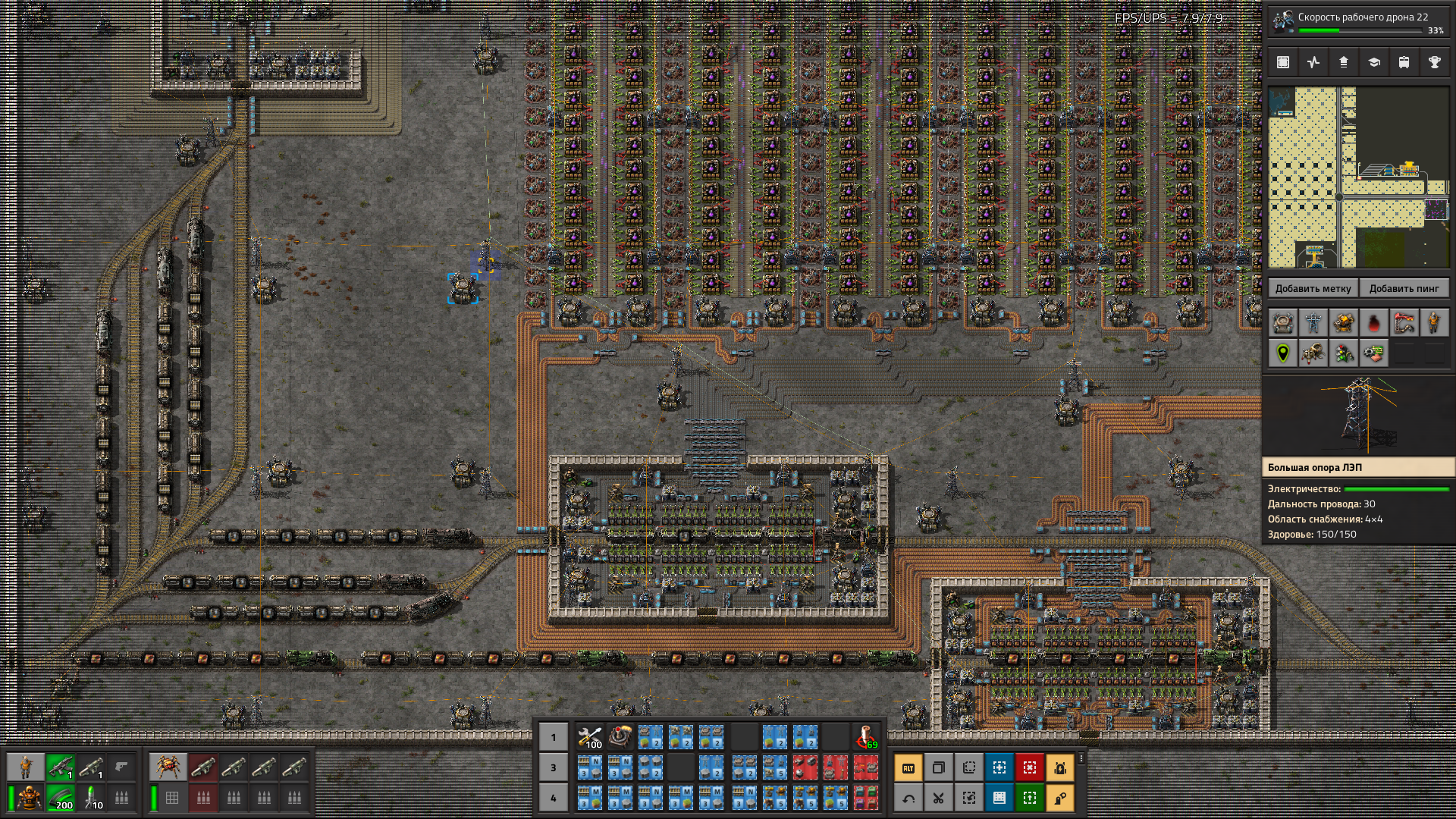

Rule: Each workshop must have a large power line support along its perimeter. Especially in the corners.

Rule: The entire workshop must be covered with a zone of drone stations. Strictly and necessarily. It is advisable to place drone stations more and more evenly.

Rule: The entire workshop must be an electrical network - avoid unnecessary power lines and have no gaps in the power lines (this is important for the construction of new workshops according to the blueprints).

Rule: A workshop must have 4 request chests around the loading station for 4 wagons with a request for the products of this workshop. The exception is that in warehouses in red chests.

Rule: If the workshop has a branch for loading into one wagon, there should be another request chest with a restriction on passing by this chest as long as there is something in it.

Rule: Also, any workshop that has a branch to a one-wagon station should have a green chest there without any settings (if the player requests, the logistics network should deliver).

Rule: any production in which productivity modules can be applied must have productivity modules (with the exception of ore).

Rule: any production in which productivity modules cannot be used must have one speed module and the rest efficiency modules.

Next I want to talk about the supply concept.

Theoretically, supply can be implemented in two ways - “the workshop produces a lot of products and delivers the products to consumers with its trains” or “the workshop itself sends its trains to pick up raw materials for itself.”

I considered both options and chose the second one for several reasons:

----------- Station Book -----------

Blueprints: https://anlide.online/factorio/book.station.txt

Rule: Any station does not have a shutdown condition - in such a huge plant it is simply death at any second in an unpredictable place. Perhaps the developers need to redo the reaction of trains to turning stations on and off.

Question to developers:

Why if there are two stations at which the number of trains is regulated and switched off and switched off. For example, both stations have a train limit of 1. 2 trains left for them.

Then suddenly one station turns off - then one train will continue moving, and the second will stop in the middle of the movement and will stand waiting for who knows what. Why this logic?

Rule: Therefore, in principle, any conditions for turning on and off stations are not used anywhere. However, stations can be manually turned off for various reasons (for example, when building a new workshop in a busy area or to direct traffic).

Rule: Any unloading station limits the number of trains equal to the number of trains on the blueprint of this workshop. Without exceptions, it is not regulated by combinators anywhere.

Rule: Any loading station always has a limit of 0 trains and the train limit is always set by the logical network.

As can be seen from the list of station templates, they are divided into groups. Unloading stations and loading stations. For liquids and objects. For items on both sides.

Let's consider all the features and rules of the stations. This is a very important detail in this plant.

Loading stations come first because the plant starts there. It is at these stations that ore is loaded. By the way, all forms of ore loading stations are presented below.

8 conveyors are supplied to the station and it unloads everything as quickly as possible, first into chests, and then into wagons. You can see a huge number of combinators and signal wires, everything is necessary, now I will describe the meaning of each element in order.

The station is grayed out and named "NoName" in case the player forgets to rename the station. Two traffic lights are needed in case the station is carelessly connected to the main railway network.

Lanterns are decorative in nature.

Radar is needed everywhere and putting one in the blueprint here is a good idea.

White manipulators without marking the object are a reminder that you need to mark them.

Green manipulators are needed to ensure that all possible garbage under the new workshop accumulates in chests (these are then conveniently and easily unloaded from garbage by drones).

Turrets are needed to prevent random single biters or spitters from destroying the entire plant. Having a little bit of turrets in the template, we get a plant that is all studded with a little bit of turrets.

3 permanent combinators: setting the number of items in the stack, setting the maximum number of trains and setting the maximum idle time.

If the loading station chests are not filled to the maximum, the idle timer starts.

If the idle time exceeds the time specified in the corresponding setting, the station sets the train limit to 0 (this means that arriving trains will continue to travel here, but there are no new trains).

If the idle time exceeds the time specified in the corresponding setting by 10 times, the speaker will turn on.

The train limit is calculated based on the cargo available for loading (and for each wagon separately). Thus, you can be sure that if a train goes to this station, then there is enough cargo in it to fill all the wagons of all arriving trains at once. I'm proud of this algorithm.

And immediately predefined modifications for all types of ore, 2 modifications for each ore.

The blueprint book also includes blueprints with settings for permanent combinators - this is convenient for expansion and mass installation of ore stations.

Any loading and unloading stations must be built so that each wagon has a pump attached to it.

Moreover, there are 3 pumps for each wagon. And each pump at the station would be directly connected to the reservoir.

Using a similar scheme, information is collected on the entire storage facility at the station and on the tanks connected to each specific wagon separately.

So we have a natural limit of 3 trains arriving at the station - because 3 tanks can load 3 trains at the same time.

However, inspections cost not 25,000 per wagon, but 22,500 per wagon. To avoid a situation where a full station can only accommodate 2 trains.

There is a separate station for one wagon with acid - it is needed to be installed next to each uranium deposit.

Combinators are convenient for managing the configuration of a station after its installation.

Contributor request:

Implement a loading station for one wagon for all workshops so that the limit of 3 tarins is reached not when the minimum is available for loading, but when a maximum of minus 3 trains is available for loading.

For example, usually 12 full chests can load 14 wagons in a row.

Accordingly, for example, if the chests are full for 12 wagons, give a limit of 1 train, if the chests are full for 13 wagons, give a limit of 2 trains. etc.

The number 3 in this case should be customizable through combinators.

Make the template so that it would be convenient to use in every workshop.

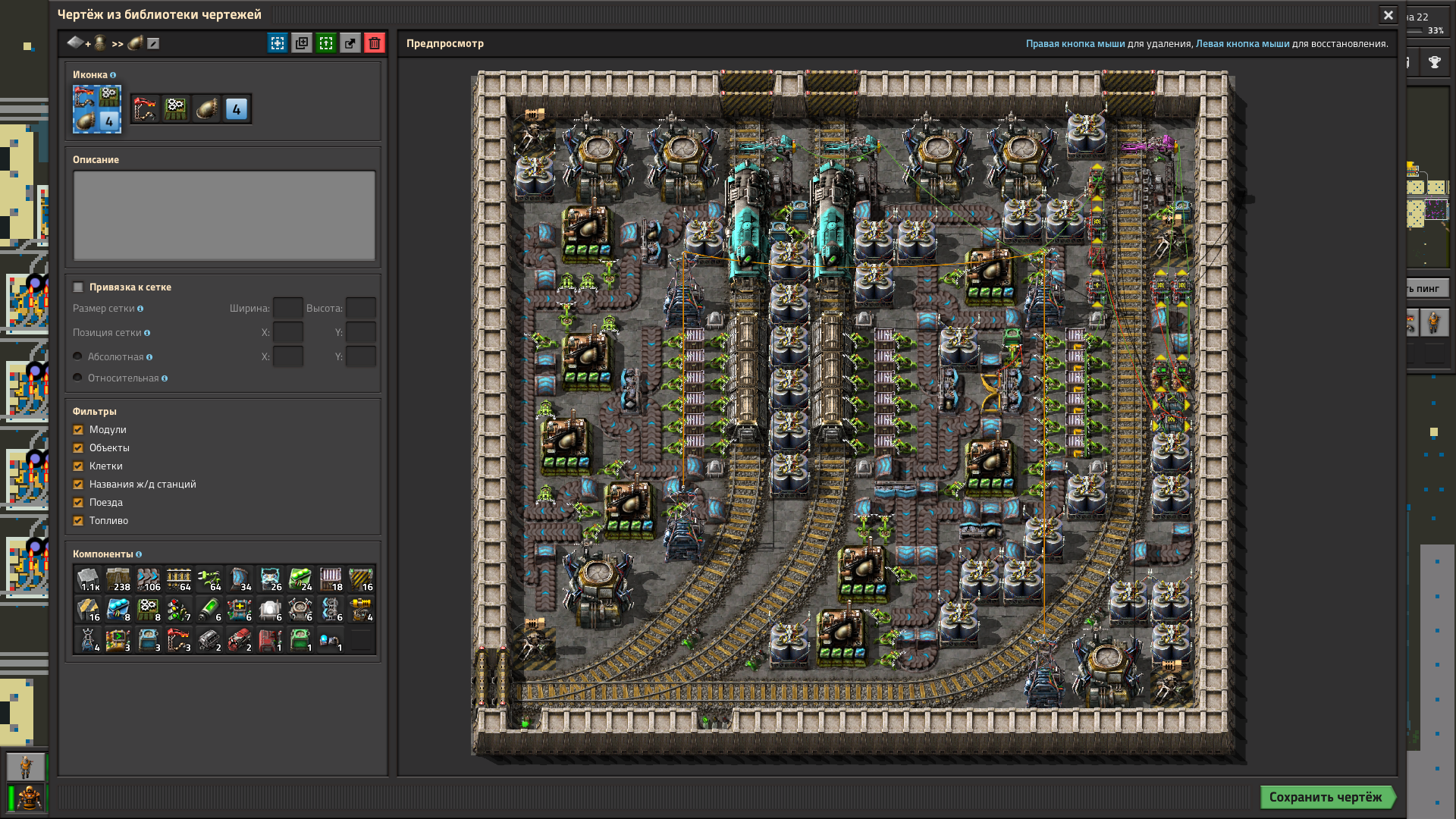

----------- Logistics Book -----------

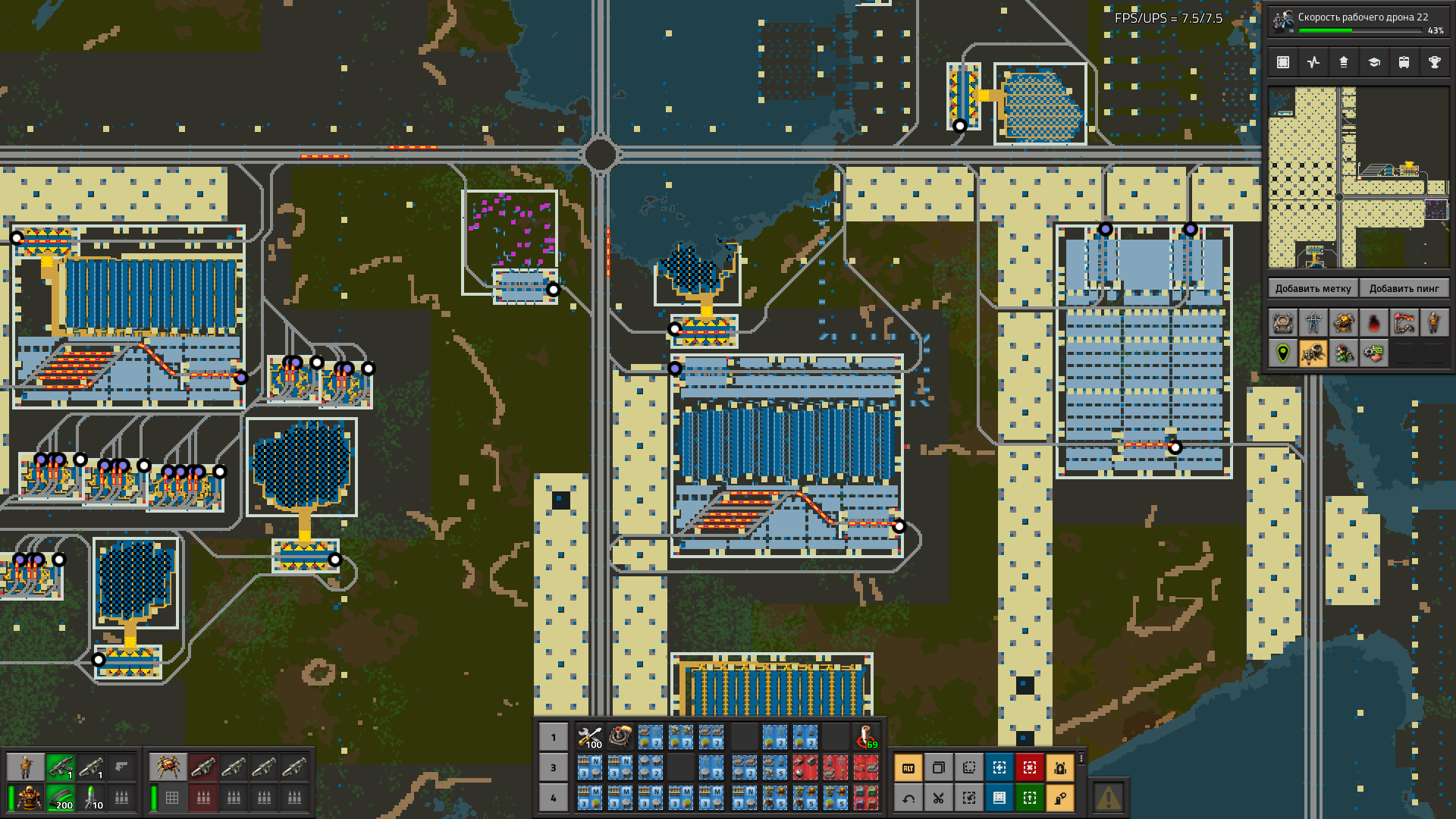

The scheme is similar to citiblock. But much more flexible.

Blueprints: https://anlide.online/factorio/book.logistic.txt

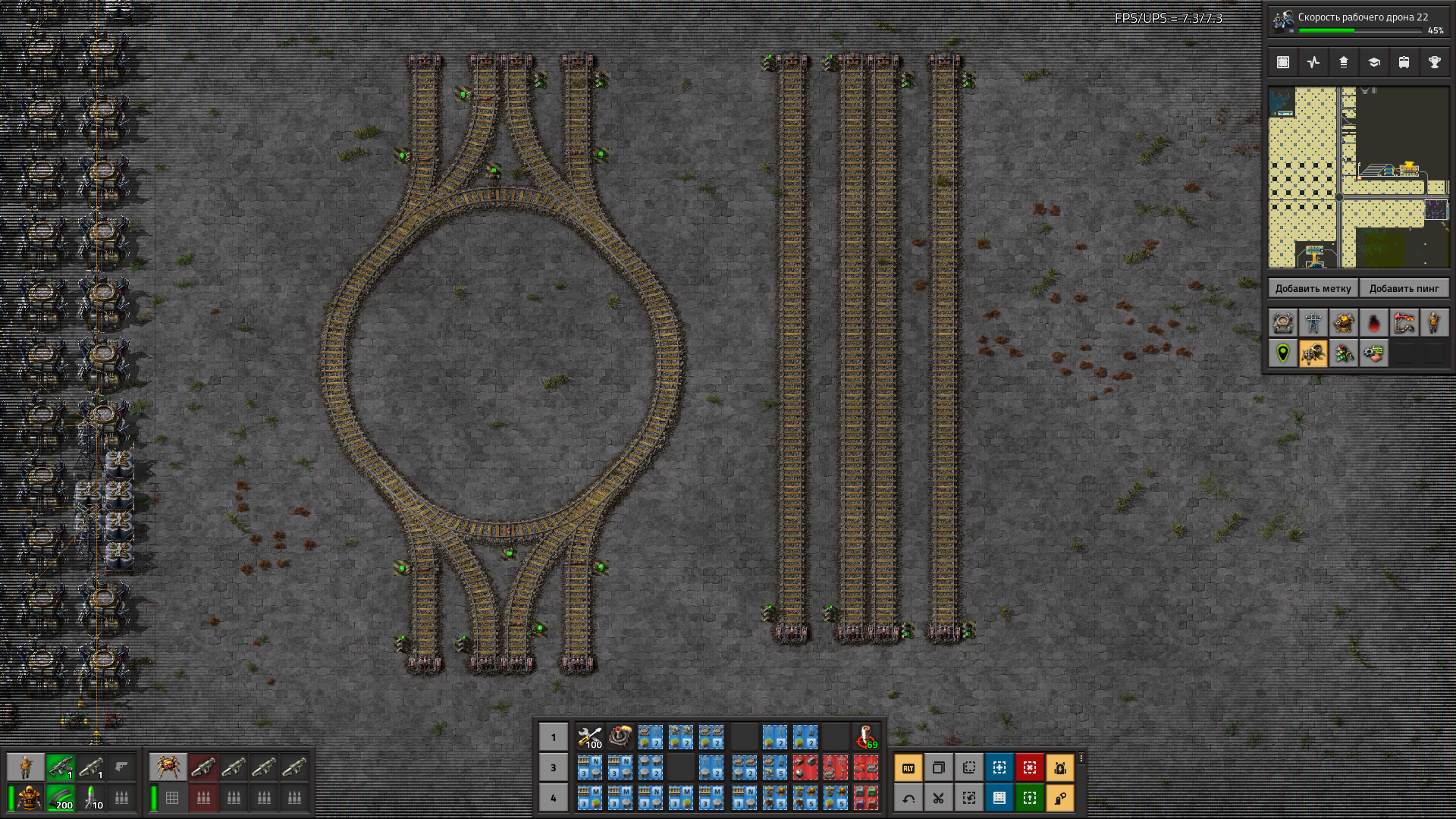

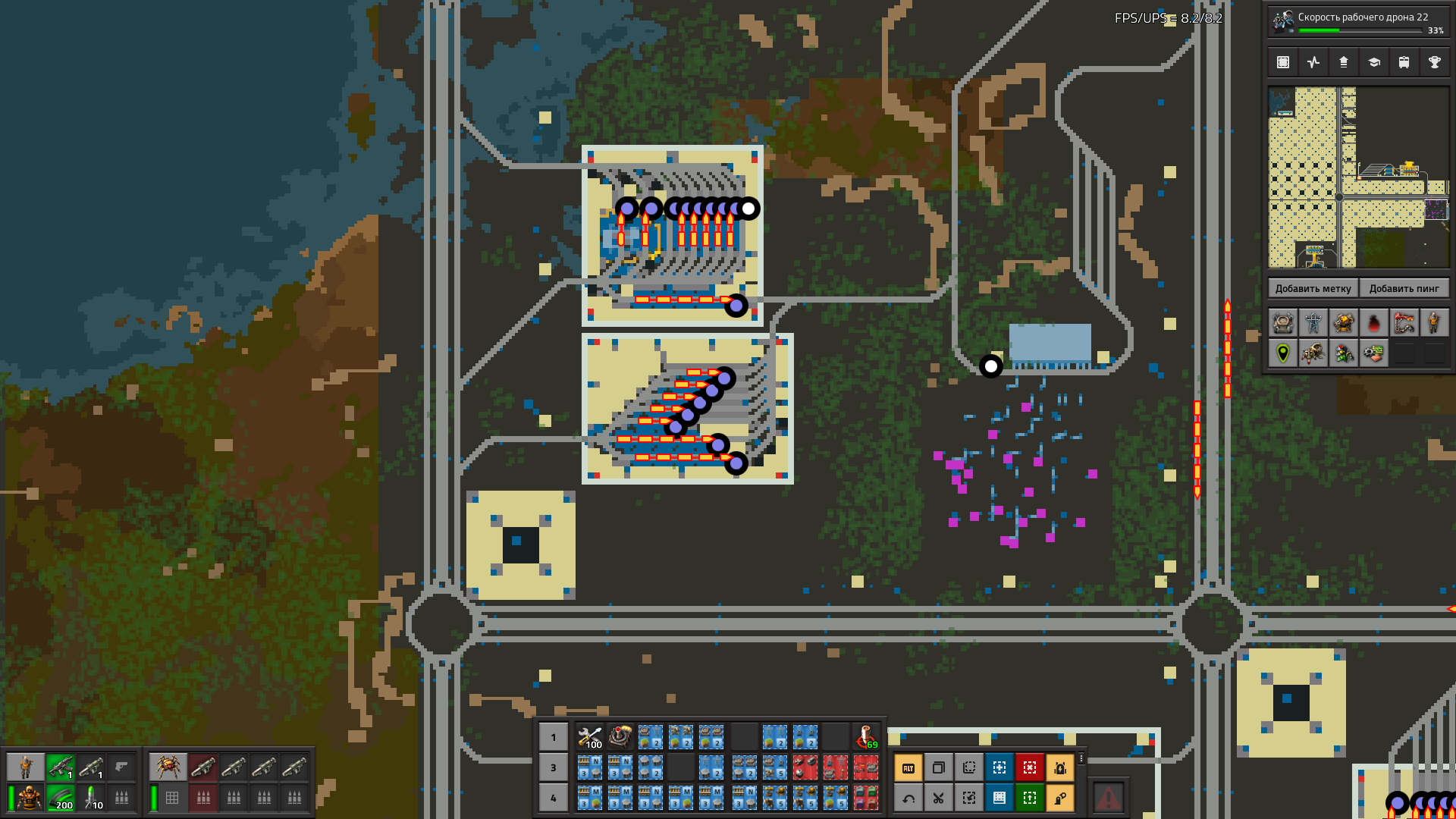

It has been experimentally established that trains constantly need roundabouts - without them, when changing routes, they can easily enter a plant and block local production.

Why does the train change route? For example, a slot has become available nearby where to go - why now go across half the map when you can arrive at the station nearby.

It has also been experimentally established that such a circular route is often sufficient. Yes, near the missile silo workshop such a patrol is often not enough, but this is rather an exception to the rule.

Contributor request: make a circular drive for 2 circles.

There are 2 forms available - with fill and with reinforced concrete. With backfilling, new territory can be developed by water without any problems.

It's not a matter of saving filling - one can say that an infinite amount of it can be made. The fact is that water is finite, it is not known in advance where and how much it will be needed.

And why the excess filling?

Question to developers:

Why can't the installed fill be removed?

If something is upset there in terms of balance, it may take a very long time and be very expensive in terms of resources, but it is possible.

The main track lines are made into 4 lanes for 4 wagons. It is easy and convenient to set up huge long lanes.

Unfortunately, the two circular patterns are slightly larger than one linear path. Therefore, it is very inconvenient to make a replacement if you really need to insert a circular one.

Contributor request:

A circular fill has excess fill, here is a blueprint of an arc railway with the minimum required fill:

(See in the logistics book line-2 column-1)

You need to apply this in the corresponding blueprints.

Contributor request:

Everywhere it is indicated how balanced the workshop is. If not in terms of loading or unloading speed, then this is already a request to remodel the workshop to suit this balance.

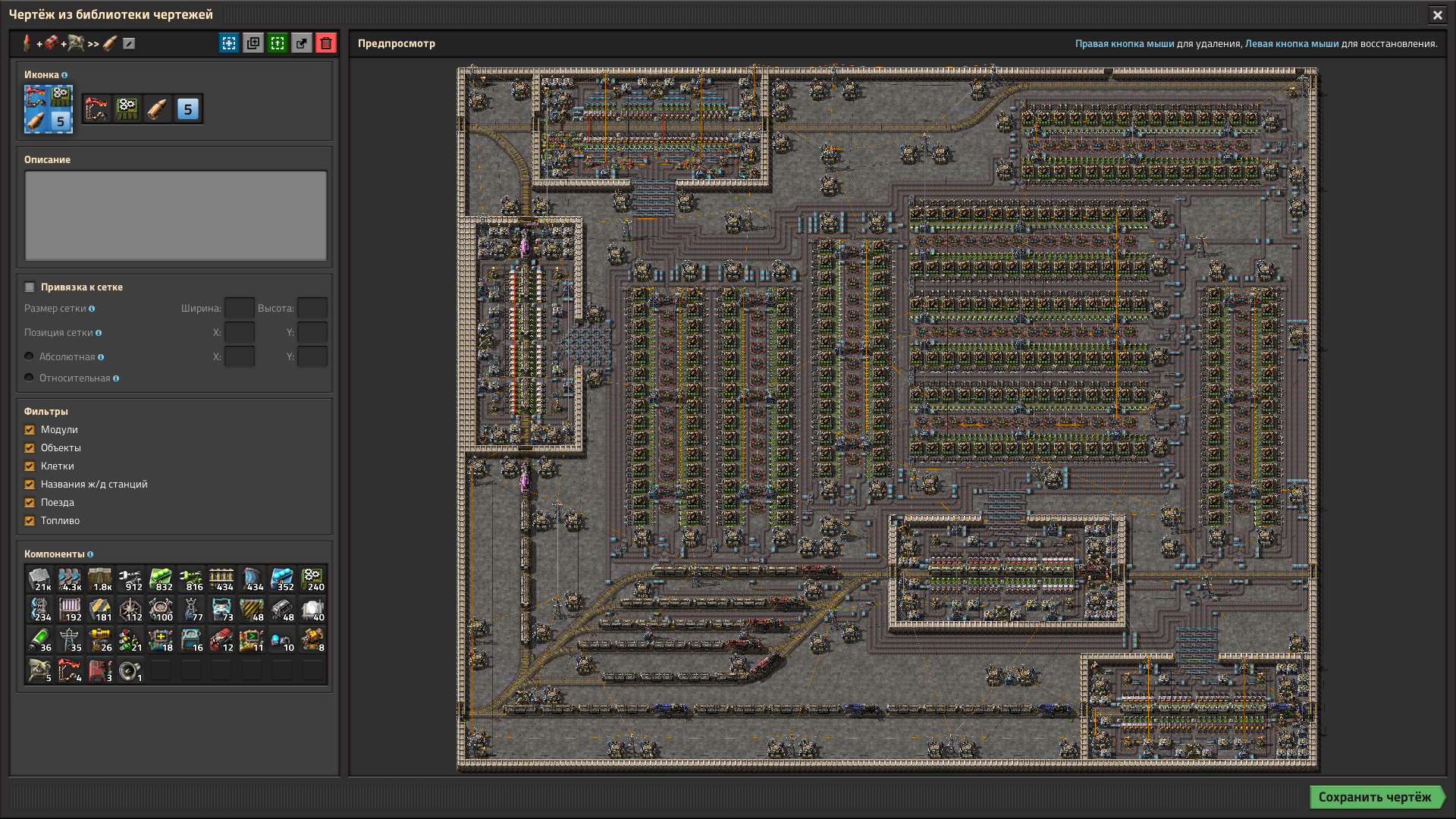

----------- Main book -----------

Here is a list of 62 workshops that produce everything needed to produce all the science-packs and all types of consumables.

Blueprints: https://anlide.online/factorio/book.main.txt

------ General components ------

--- Copper ---

Balanced: according to maximum loading speed

Contributor request:

1. Move the loading one wagon lower.

2. Apply the updated loading to 1 wagon (described above).

3. A lot of free space - make it more compact.

4. It has been experimentally established that 9 waiting trains for loading is a lot, you need to do 7. Reducing to 5 will most likely be a bad idea.

--- Iron ---

Similar to copper.

--- Stone block ---

Balanced: according to maximum unloading speed

Contributor request:

1. This workshop has most likely been brought to perfection or so, but if you really want to, you can try to reduce the height of the workshop, because there is free space (width will not work).

--- Cable ---

Balanced: according to maximum loading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Instead of many beacons, reduce the size of the workshop.

--- Rod ---

Balanced: according to maximum loading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

--- Gear ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. There is free space due to which the workshop can be made smaller.

--- Steel ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

--- Microcircuit ---

One of my favorite workshops. Very nicely balanced.

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Does not follow the path placement rule. + add iron train.

--- Sulfur ---

Balanced: according to maximum loading speed

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. There should be 6+ trains with gas

3. There must be buffer tanks around the station (see production of diesel from fuel oil)

4. Loading must be in 16 streams.

5. Maintain a balance of water supply from 4 sources, provide a source capacity of 3000 water/sec.

--- Plastic ---

Balanced: according to maximum loading speed

Contributor request:

1. Despite the very good balance of the workshop, there were few trains with gas. Looks like we need 7 or 8 trains with gas.

--- U. Microcircuit ---

Balanced: according to the size of drone stations

Contributor request:

1. Redesign the workshop so that the speed of production is limited either by the speed of supply of materials or the speed of loading. Now the balance is very good, but not maximum.

2. Apply the updated loading to 1 wagon (described above).

--- K.M.P. ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

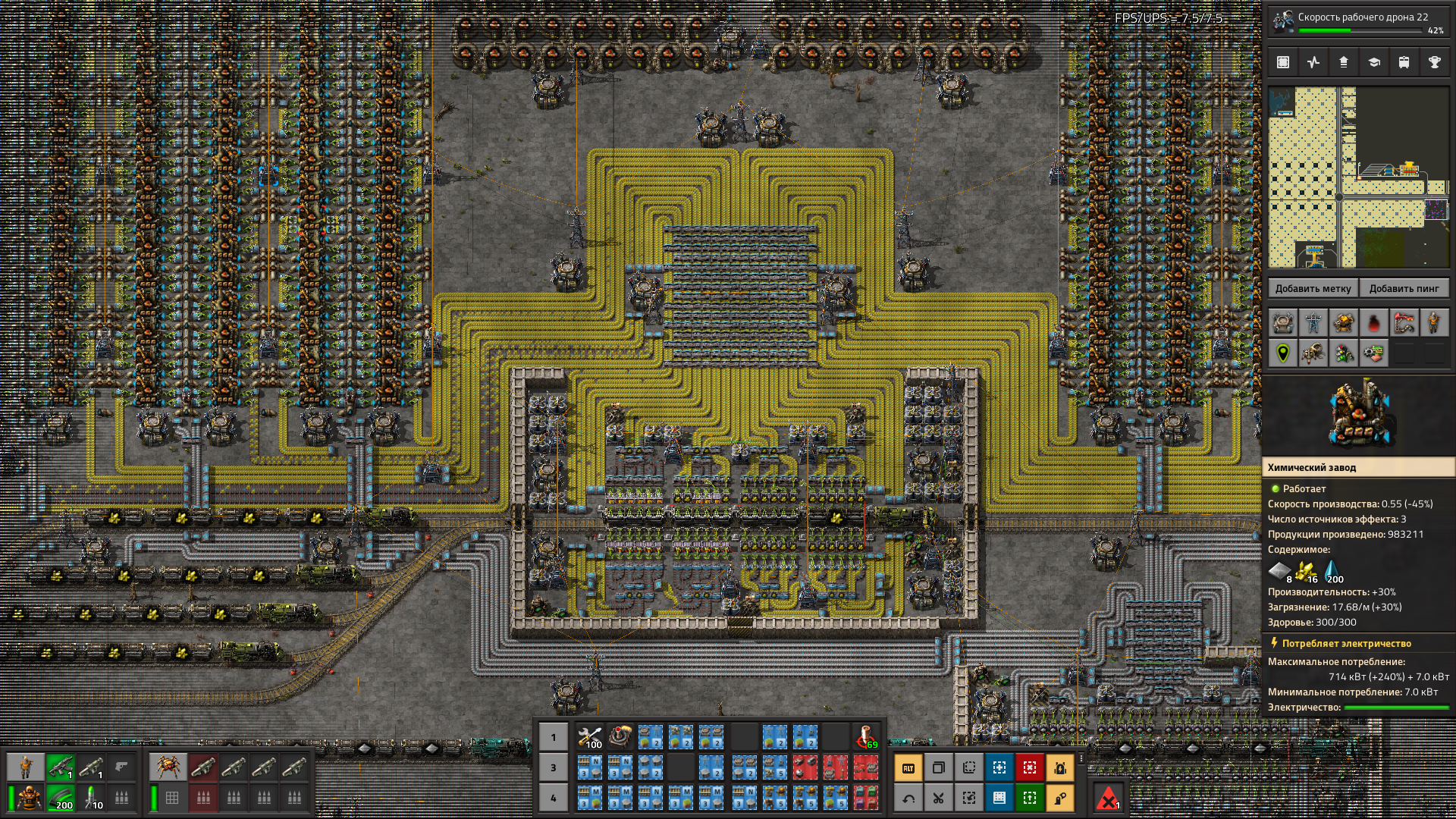

---Acid ---

Balanced: according to the size of drone stations

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. It was determined experimentally that all produced acid should be poured into one barrel in the middle, then poured into tanks up to the loading station in small blocks.

The problem in the screenshot is that the left side of the plant is constantly working, but the right side is not working.

3. Make the space between paths correct.

--- Processor ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Similar to acid production, the left side of the plant should not go directly to loading, but through the center.

3. Make the space between paths correct.

--- B.U.R. ---

Balanced: according to the size of drone stations x2

Contributor request:

1. Remove loading for 1 wagon (it is only needed for Y.Raketa).

2. Make the workshop larger and balance the speed of loading or unloading

------ Consumables ------

--- Concrete ---

Balanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. Apply the updated loading to 1 wagon (described above).

3. Loading for 1 wagon must go through the main loading (so that there is no extra exit)

4. Rework the train supply - 9 standard blocks (bottom) and 3-4 iron ore (left)

5. Processing units for one conveyor are already balanced in terms of material supply speed, you can use them

--- Reinforced concrete ---

Balanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. Put here the production of marked reinforced concrete + its loading station (example in "R.K.S.").

3. Processing units for one conveyor are already balanced in terms of material supply speed, you can use them

4. Rework the train supply according to the standard.

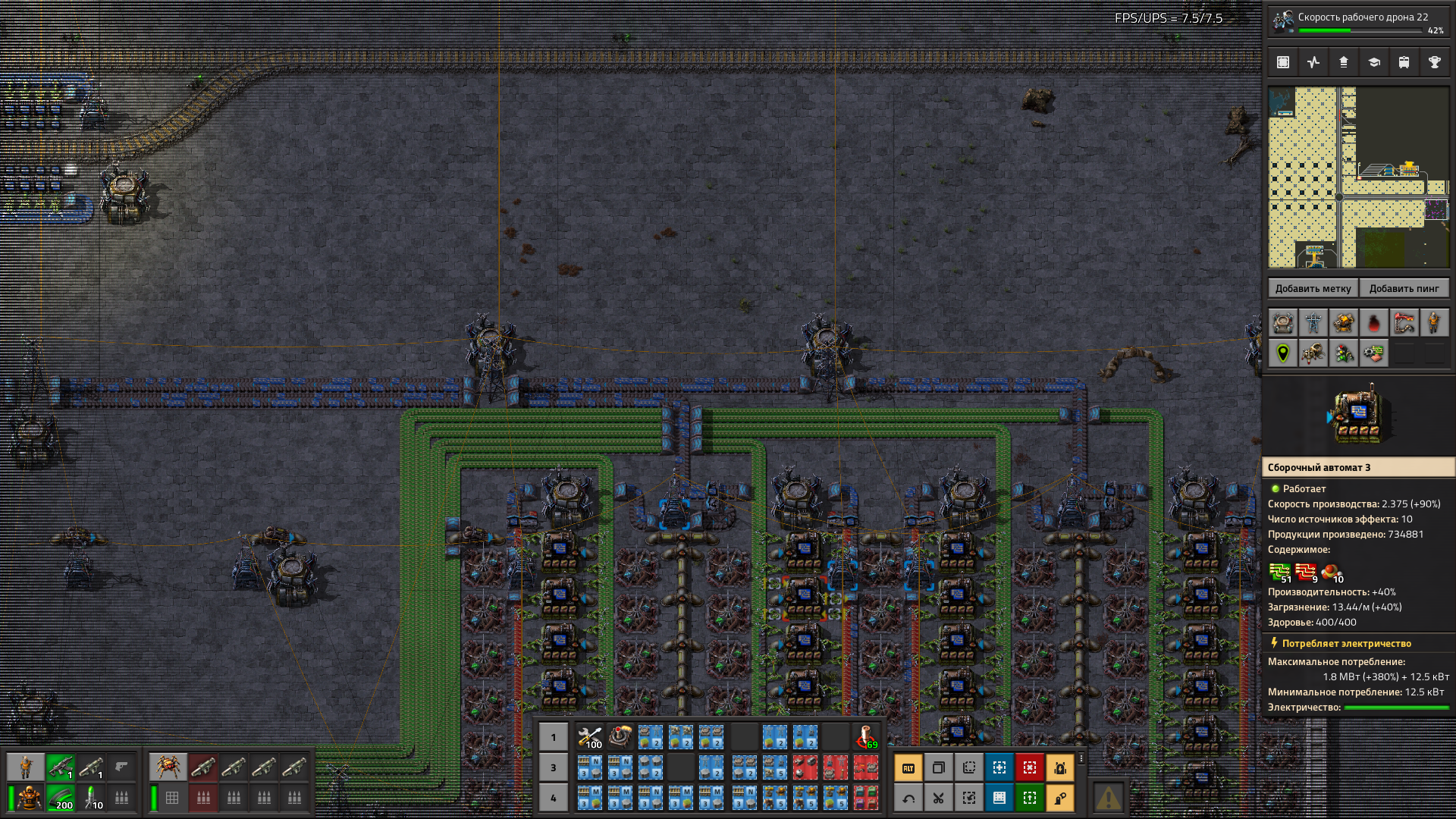

--- Construction drone ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker)

--- Transport drone ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker)

--- R.K.S. ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

--- A. Projectile ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. See the descriptions of the core - you need to redo the loading of shells.

--- Backfill ---

Balanced: according to maximum unloading speed

Contributor request:

1. This is the 4th generation of workshop, it needs to be converted to the 5th generation (no speaker and incorrect manipulators)

--- Explosives ---

Balanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Apply the updated loading to 1 wagon (described above).

------ For science-pack-2 ------

--- Manipulator#1 ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Remove loading station manipulator #1 for one wagon.

3. Add the production of a long-distance manipulator and a loading station for 1 wagon.

4. Add production manipulator #2 and a loading station for 1 wagon.

5. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- Conveyor#1 ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

------ For science-pack-3 ------

--- Wall ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators)

---Grenade ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. The 5th blue chest is positioned incorrectly.

--- Store#1 ---

Balanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- Store#2 ---

Balanced: according to the size of drone stations

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. The 5th blue chest is positioned incorrectly.

------ For science-pack-4 ------

--- Pipe ---

Balanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Add underground pipe production and a loading station for 1 wagon.

--- Engine ---

Balanced: according to the size of drone stations

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Place the 5th blue chest.

4. Add pump production and a loading station for 1 wagon.

5. Add O.Turel production and a loading station for 1 wagon.

5. Make the plant larger and balance production based on the speed of loading or unloading.

------ For science-pack-5 ------

--- Rails ---

Balanced: according to maximum unloading speed

Contributor request:

1. This is workshop generation 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Reduce the number of incoming trains to 5.

---Oven ---

Balanced: according to maximum unloading speed

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Make the plant larger and replace all unloading stations from 8-outlets to 16-outlets.

---Module-p#1 ---

Balanced: according to the size of drone stations

Contributor request:

1. The modification of the module production system will be discussed separately.

------ For science-pack-6 ------

--- Electric motor ---

Balanced: according to the size of drone stations x2

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Make the plant larger and balance the speed of loading or unloading.

--- Frame ---

Balanced: according to the size of drone stations x2

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Make the plant larger and balance the speed of loading or unloading.

------ For science-pack-7 ------

--- Battery ---

Balanced: according to the size of drone stations x2

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Add the 5th blue chest.

--- Ac.Block ---

Balanced: according to the size of drone stations

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- S.Panel ---

Balanced: according to the size of drone stations

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- Radar ---

Balanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Rework iron unloading - there should be 5-7 trains

--- Satellite ---

Balanced: according to the size of drone stations x2

Contributor request:

1. Convert loading into 1 wagon. Practice has shown that there is no need to carry satellites in 4 wagons.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators)

------ Other ------

---Module-c#1 ---

Blueprint: https://anlide.online/factorio/main/speed-module.txt

Balanced: according to the size of drone stations

Contributor request:

1. The modification of the module production system will be discussed separately.

---Module-e#1 ---

Blueprint: https://anlide.online/factorio/main/eff ... module.txt

Balanced: according to the size of drone stations

Contributor request:

1. The modification of the module production system will be discussed separately.

I want to share all the blueprints that I have, but keep GameSave to myself. However, I can show you in the screenshots what my factory looks like.

I guess there is some errors in such big article. Please report I will fix all of them.

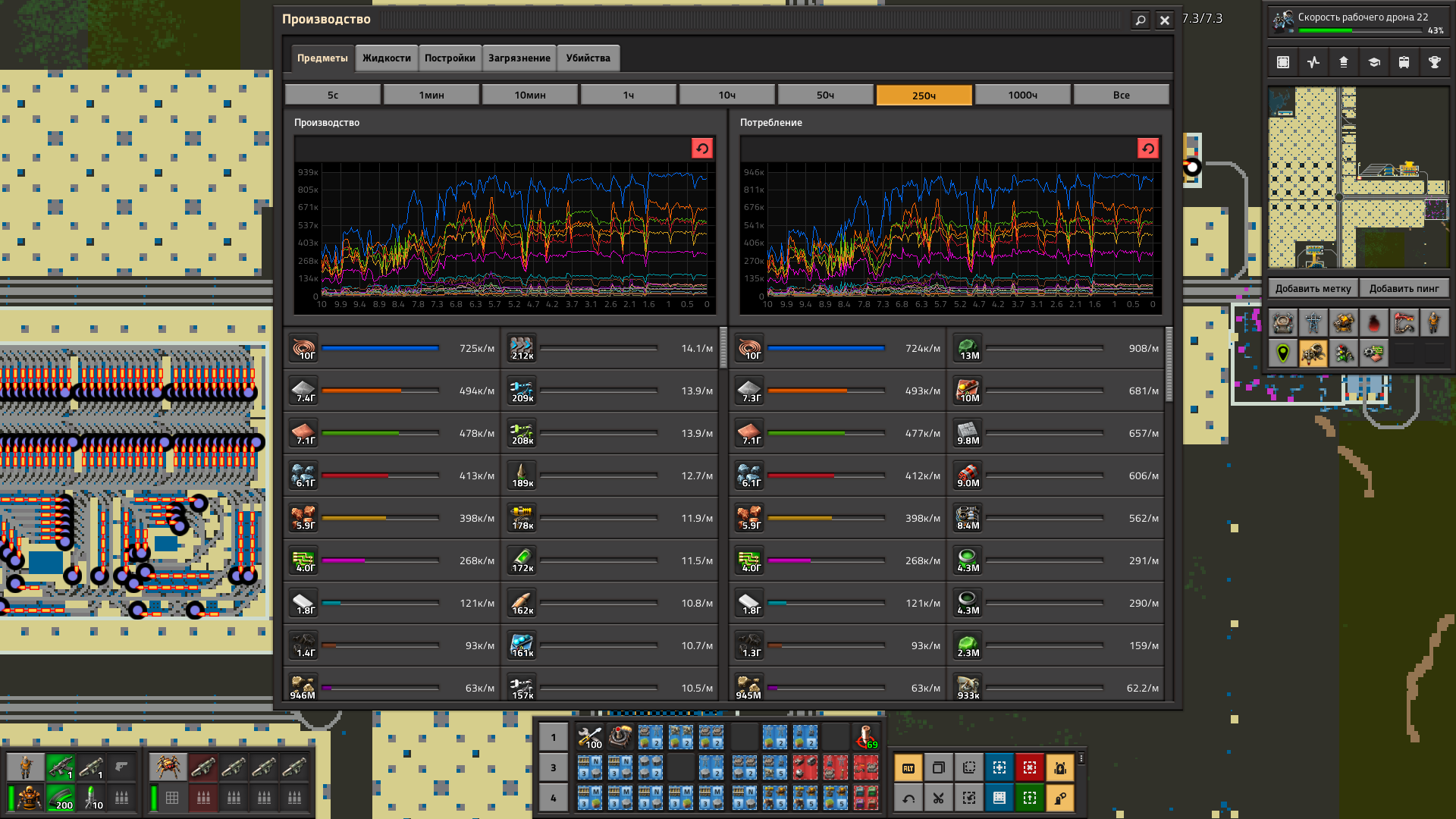

My performance criterion is the consumption of [item=space-science-pack] - 11k per hour. Despite the fact that all laboratories work with the productivity module.

I can increase the consumption of [item=space-science-pack], but UPS=6 and I don’t have the strength to play this anymore.

Why is the consumption of [item=space-science-pack] the criterion for the success of a factory, and not, for example, the number of launched rockets?

Because the only high-end content in the game is endless exploration.

For any endless research you need [item=space-science-pack] and they are most labor-intensive in mass production.

I can easily quickly accumulate any other science-pack in huge quantities.

Why consumption and not production? Because science-pack can be hoarded or inaccurately produced without being delivered to laboratories - therefore only consumption [item=space-science-pack] is the most objective factor in the efficiency of the entire factory.

I do not have or have installed any mods.

There is a limit of 60,000 characters, and all my blueprints that I would like to share weigh 41Mb.

That's why I provided them as links.

Also this is reason to split article to 2 posts.

Question to developers:

By the way, I have a very strong computer and a GeForce RTX 4070 video card. Why do I have FPS=6 with UPS=6?

Why can't I view the factory at FPS=60 even though UPS=6?

And even with UPS=6, make the movement of trains and drones and everything that gets into the frame smooth?

Question to developers:

By the way, why can’t you use the power of a video card or even a mining farm to raise the UPS for such a factory from 6 to 60?

Question to developers:

Is it possible to somehow transfer GameSave with this factory so that it does not go outside the development studio to investigate performance problems?

It seems to me that situations in which many identical trains go to many identical stations and they constantly change direction are poorly handled.

So why do this? Why can’t you just go where you decided to go and change the route only for some significant reason?

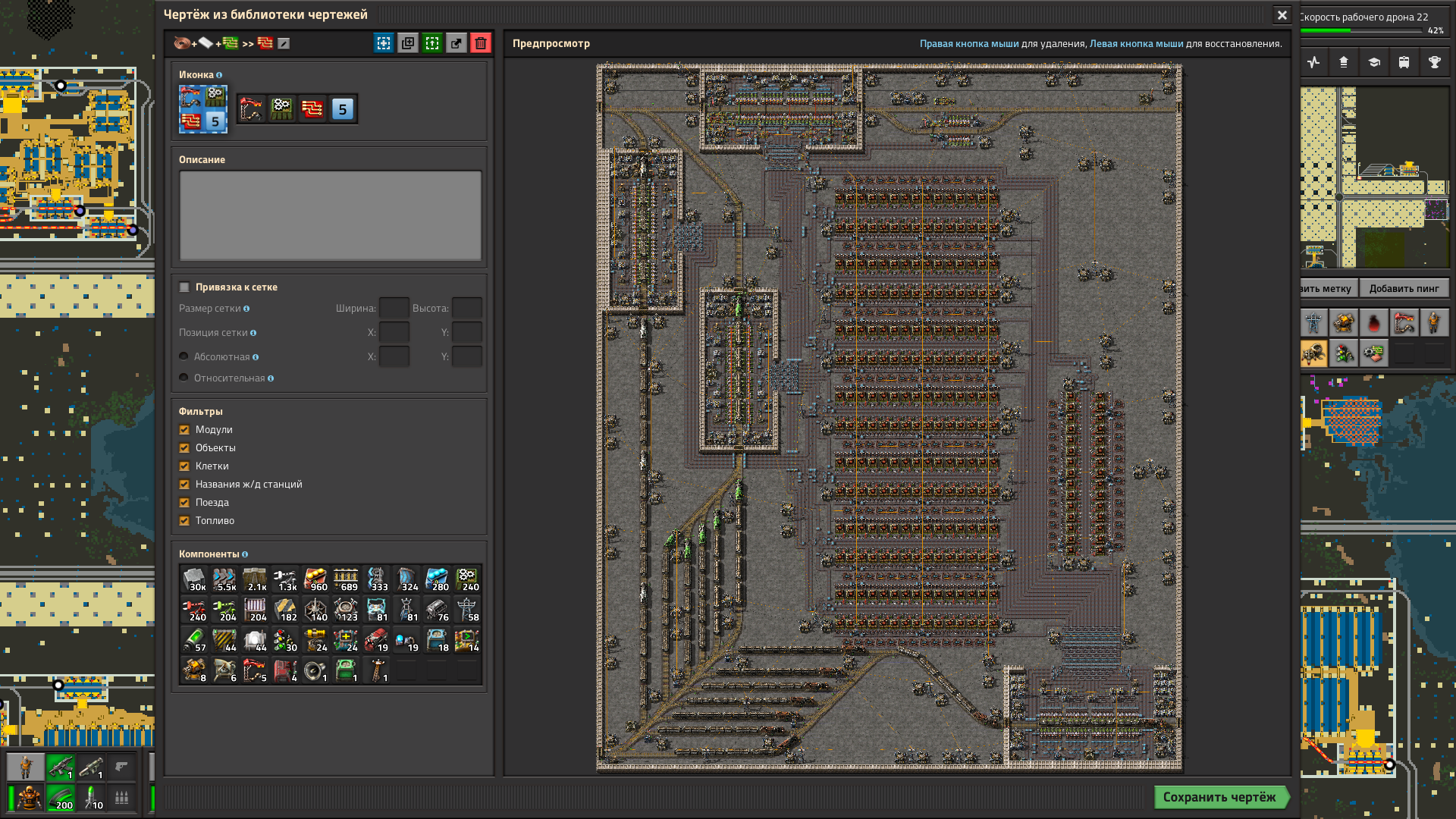

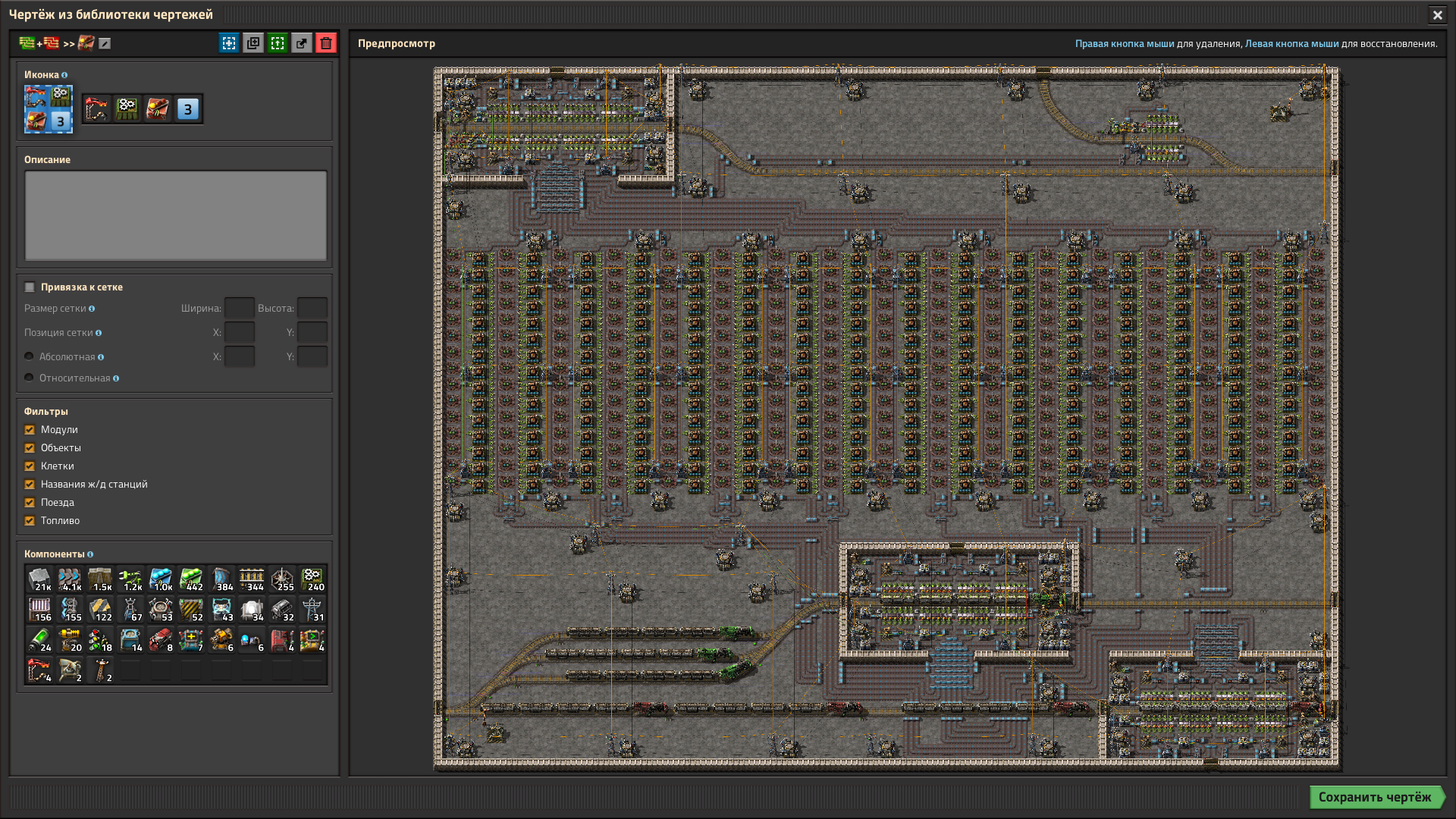

All blueprints weigh 41 Mb

All screenshots weigh 1.2 Gb

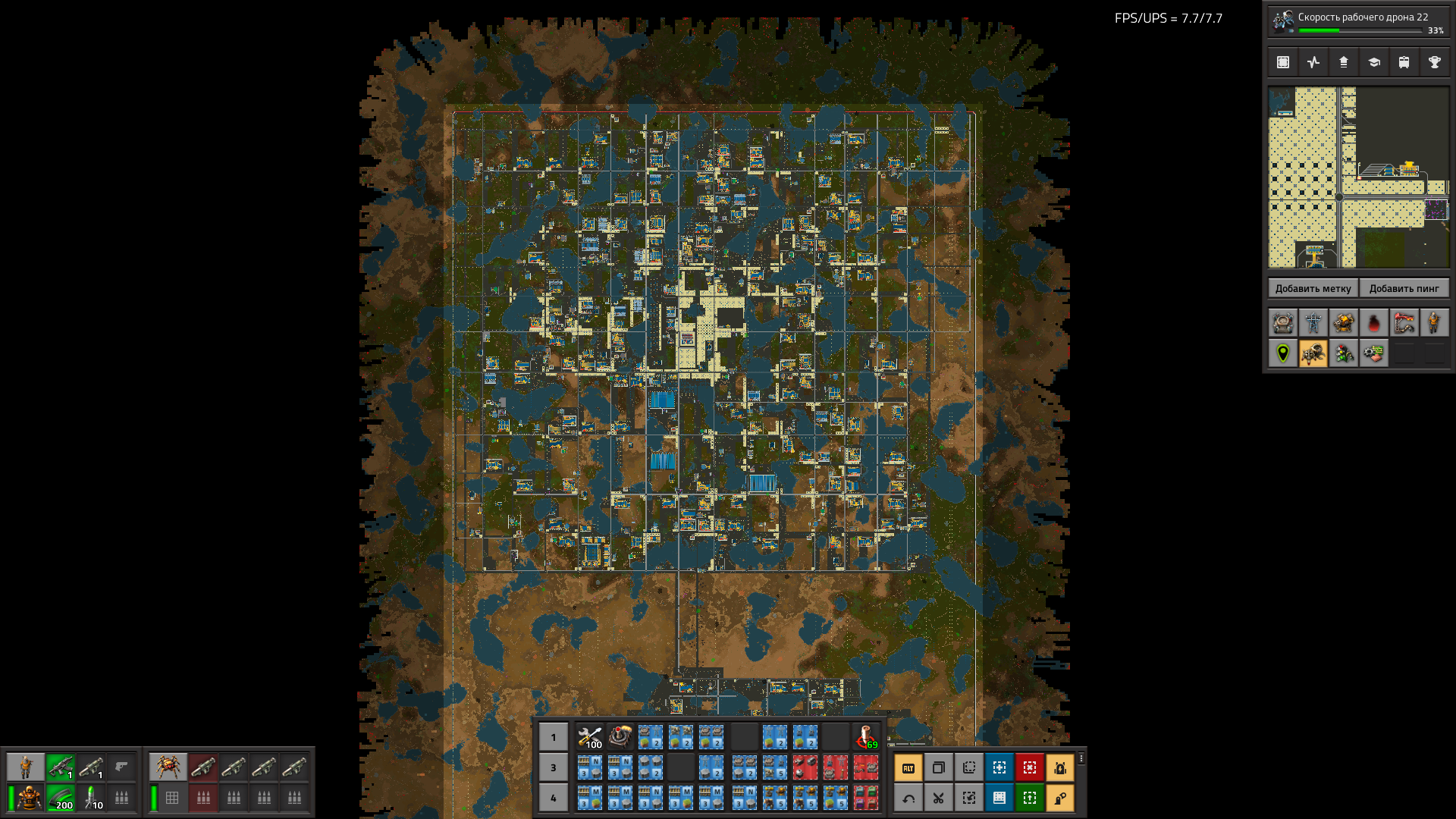

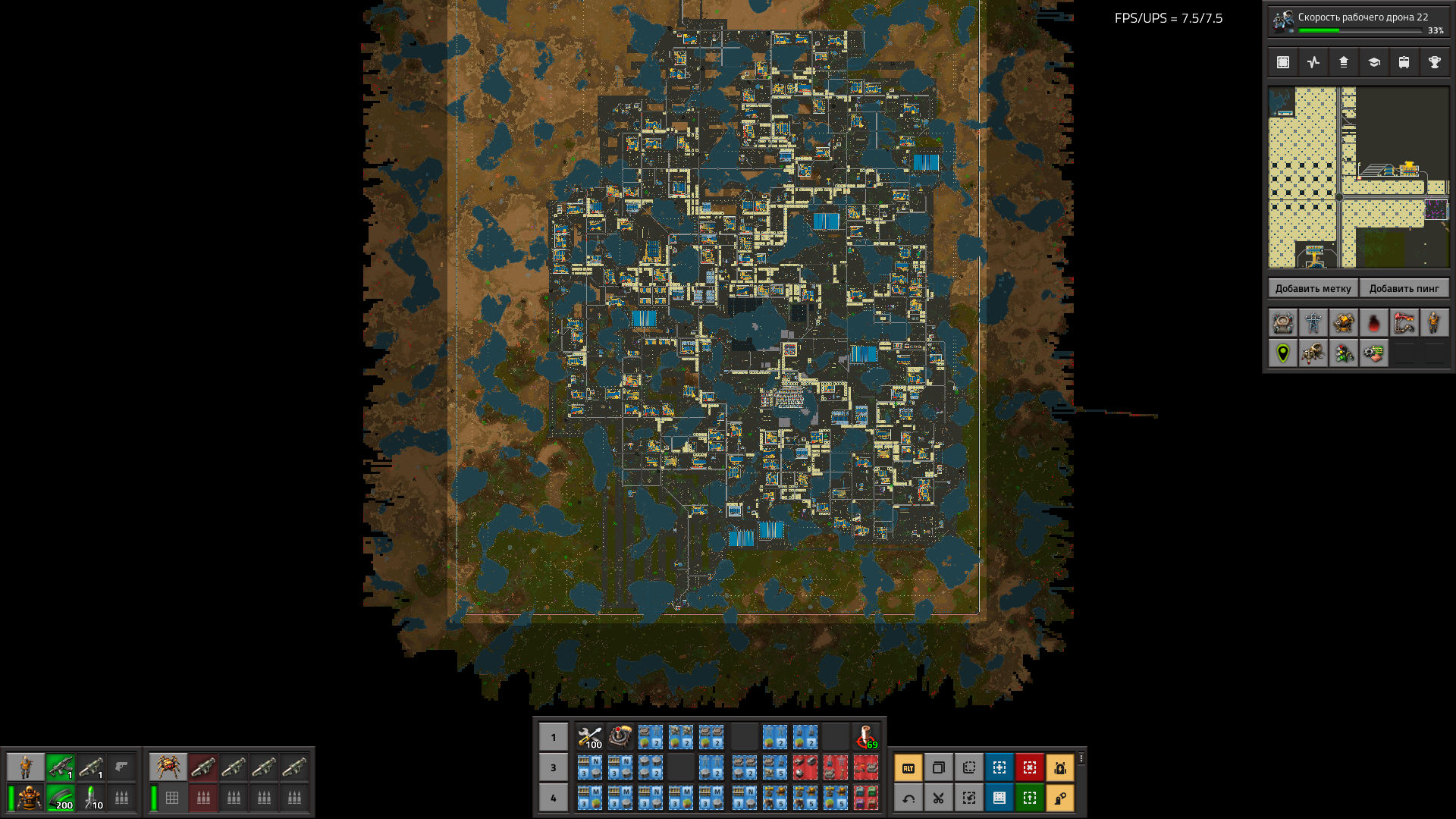

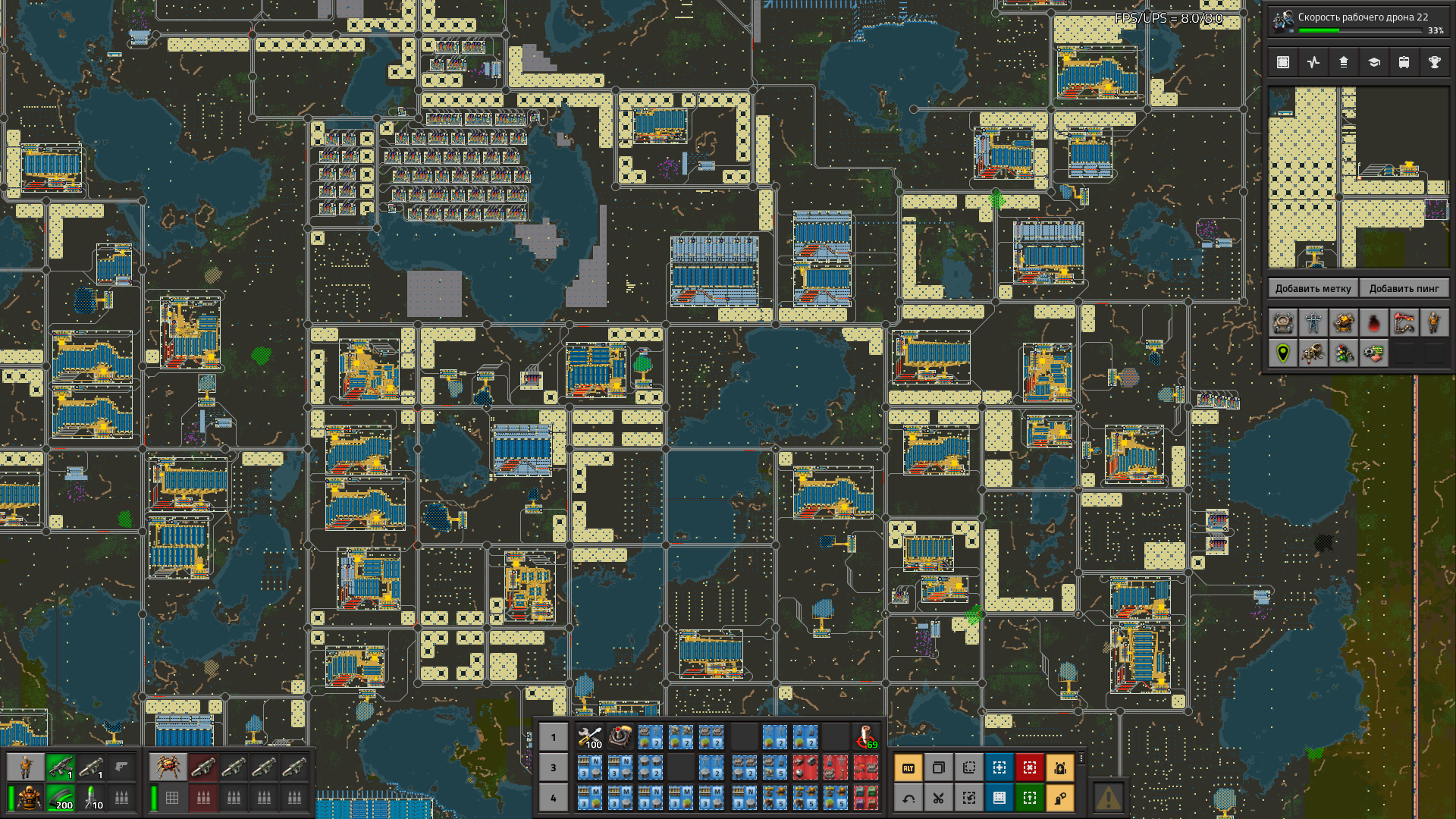

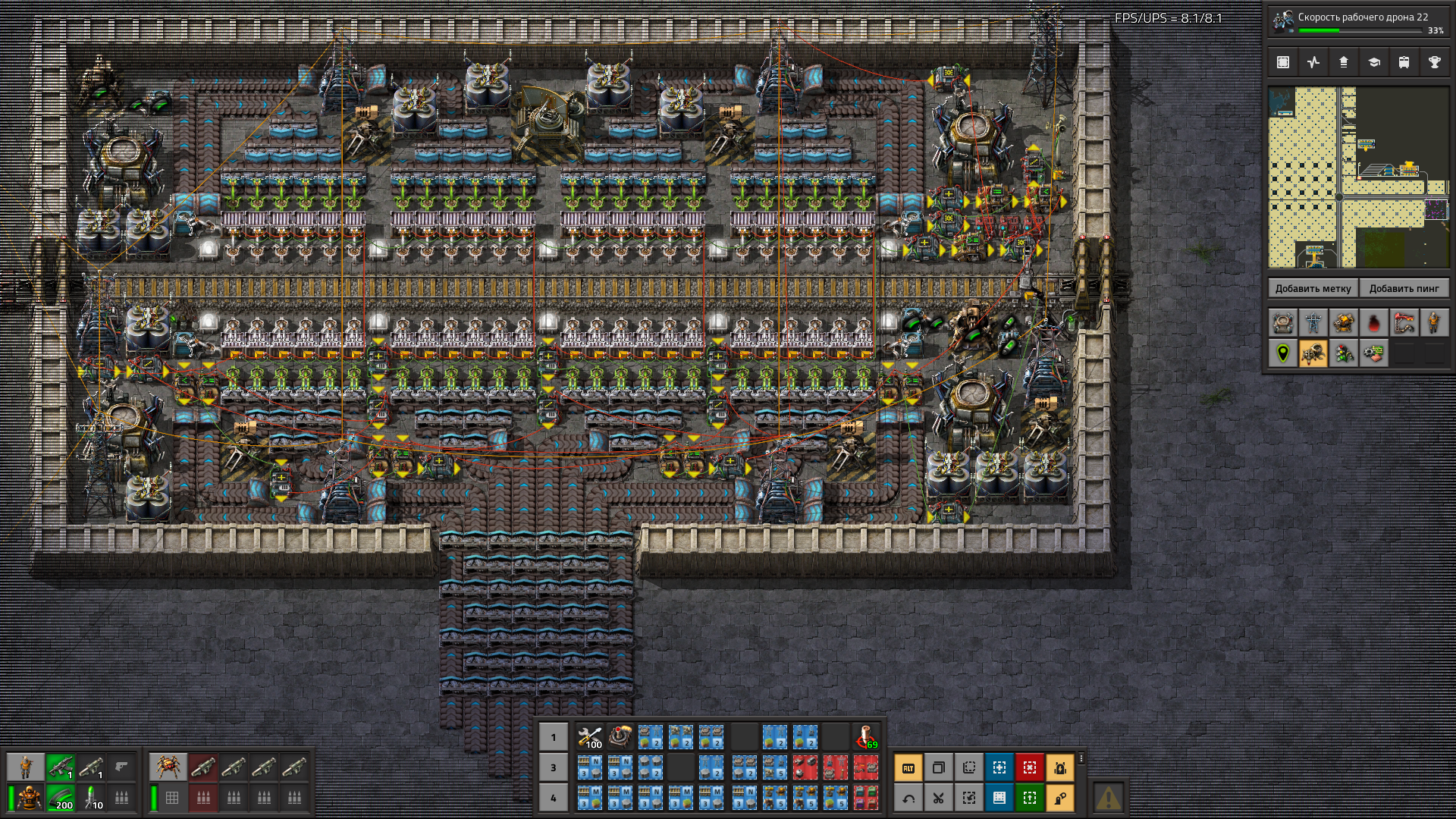

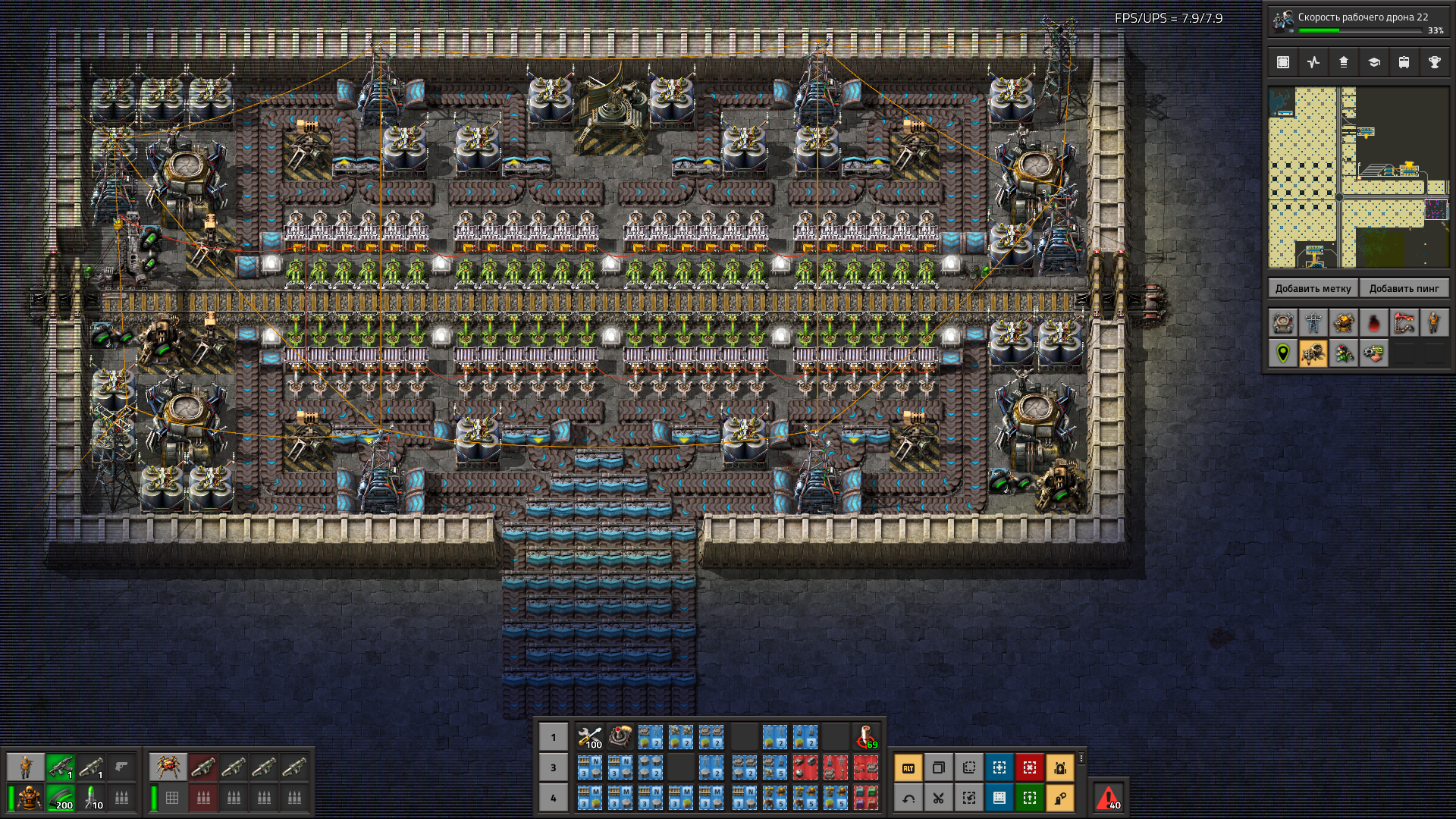

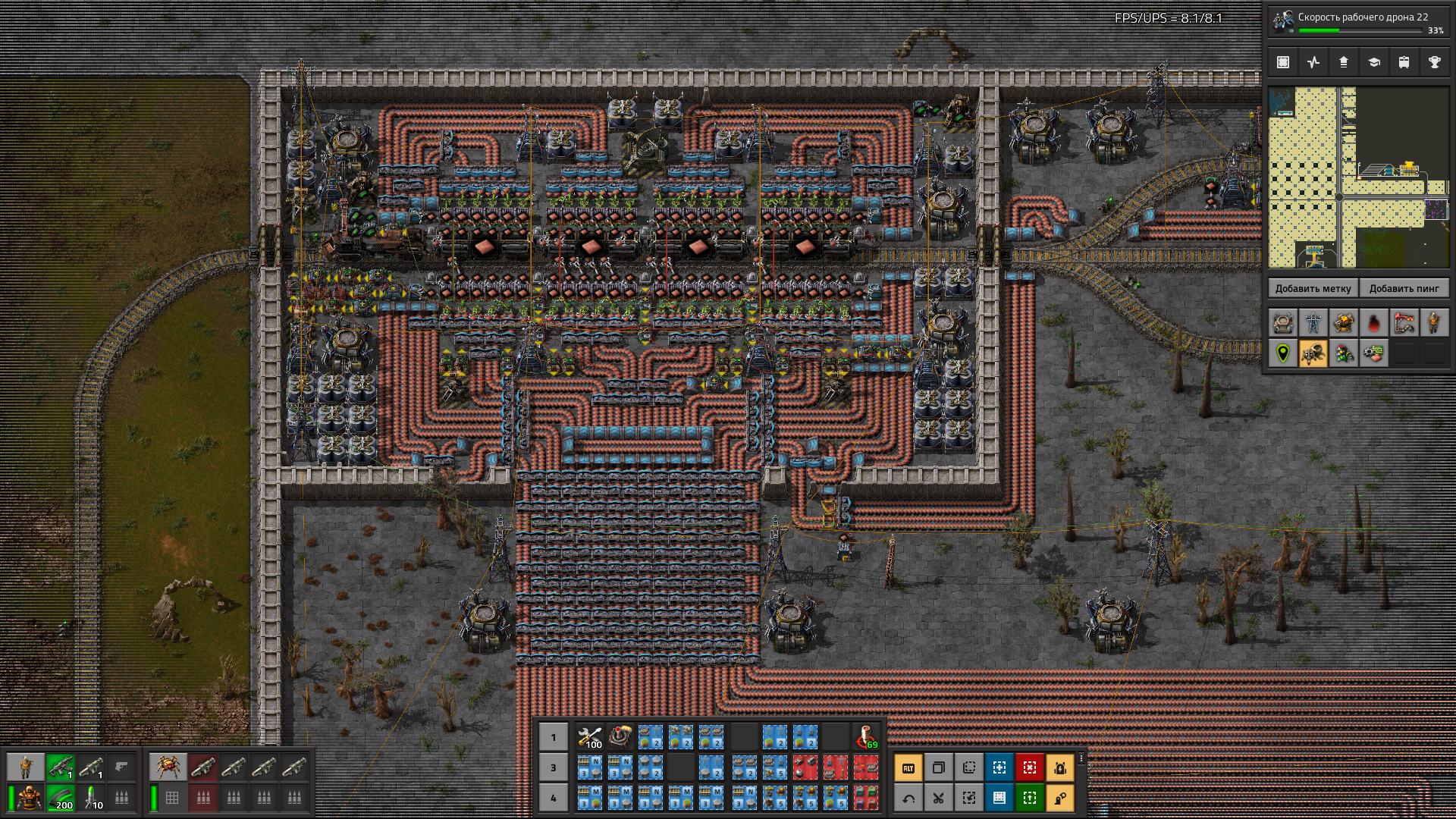

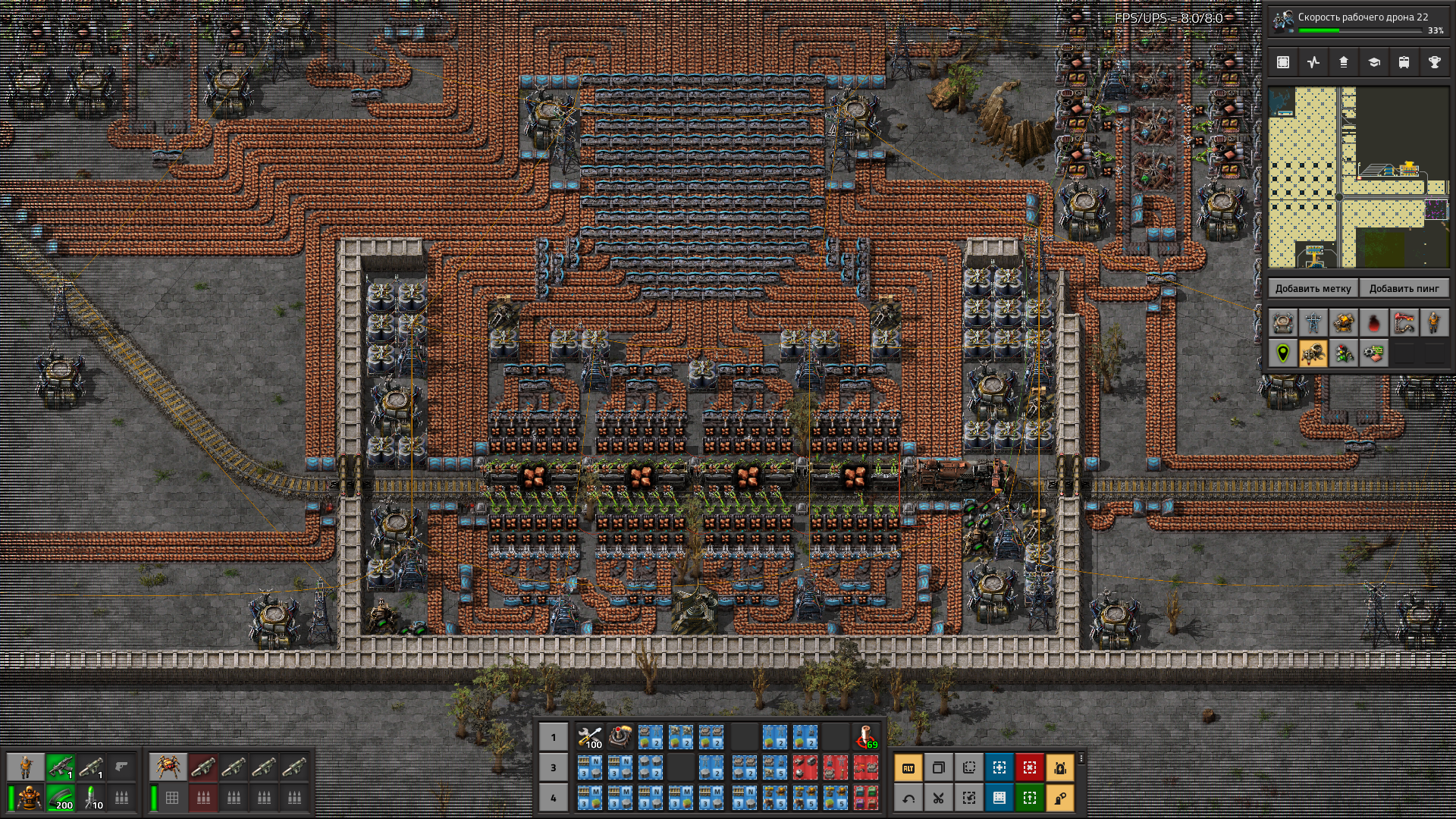

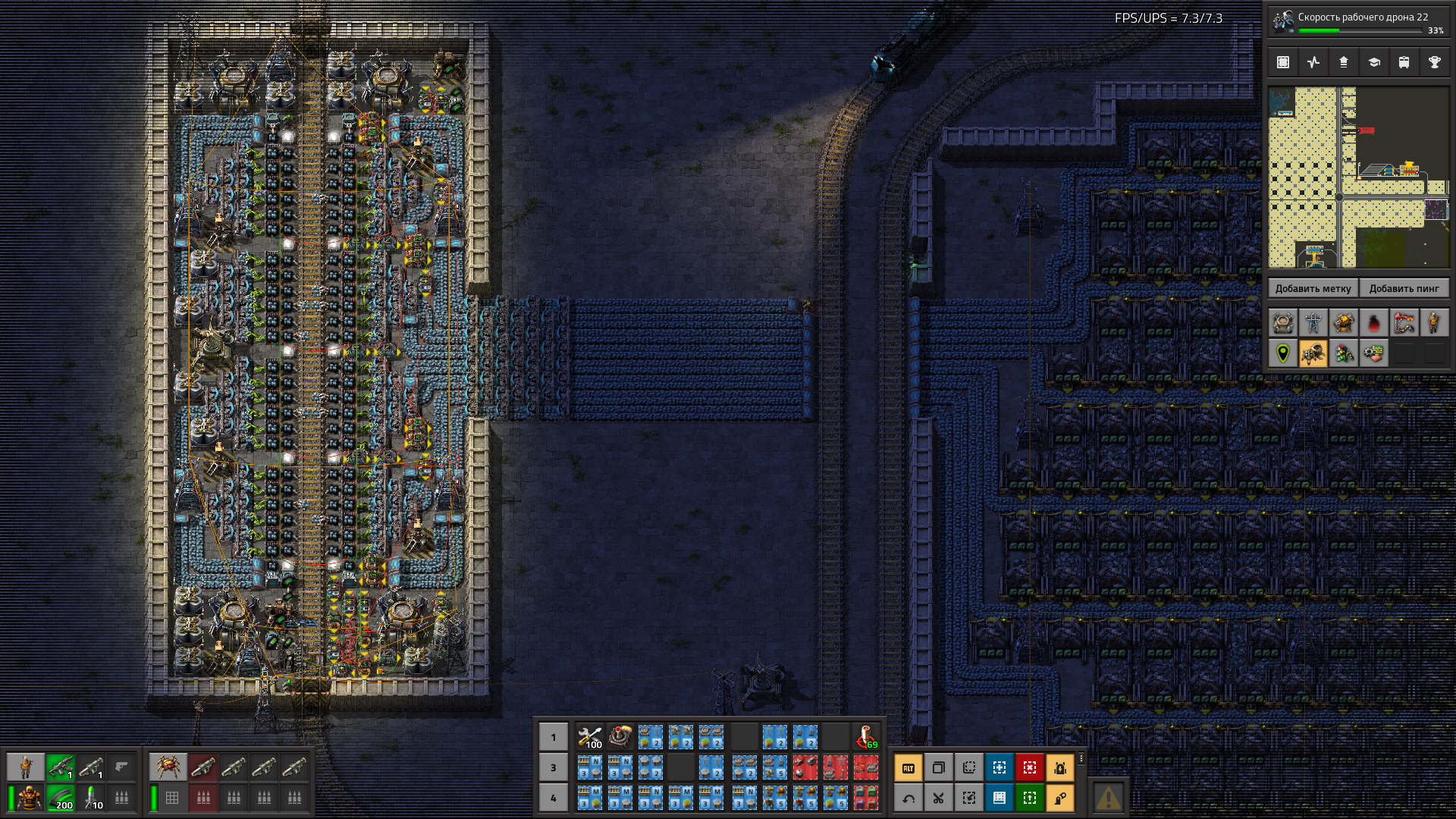

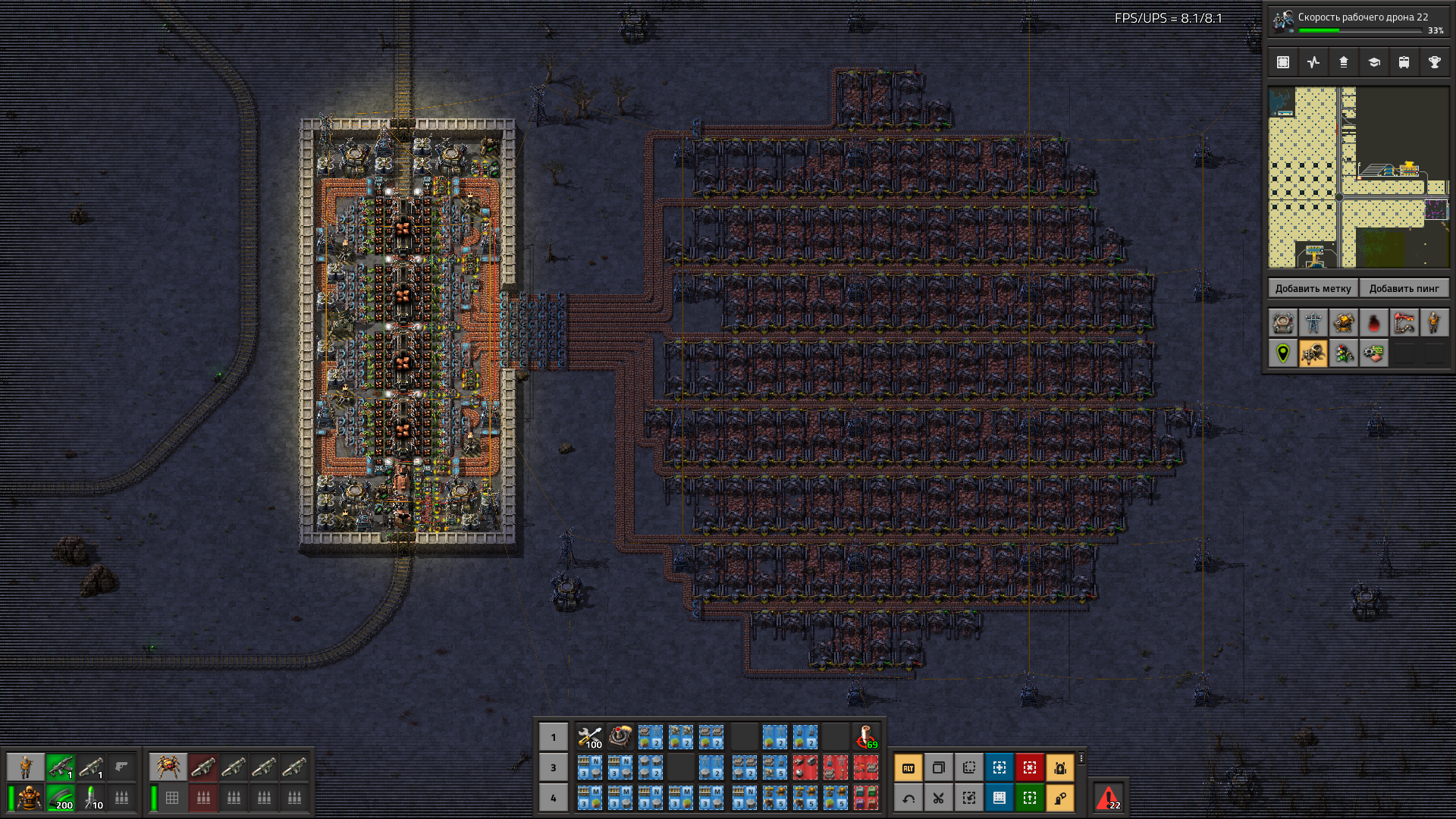

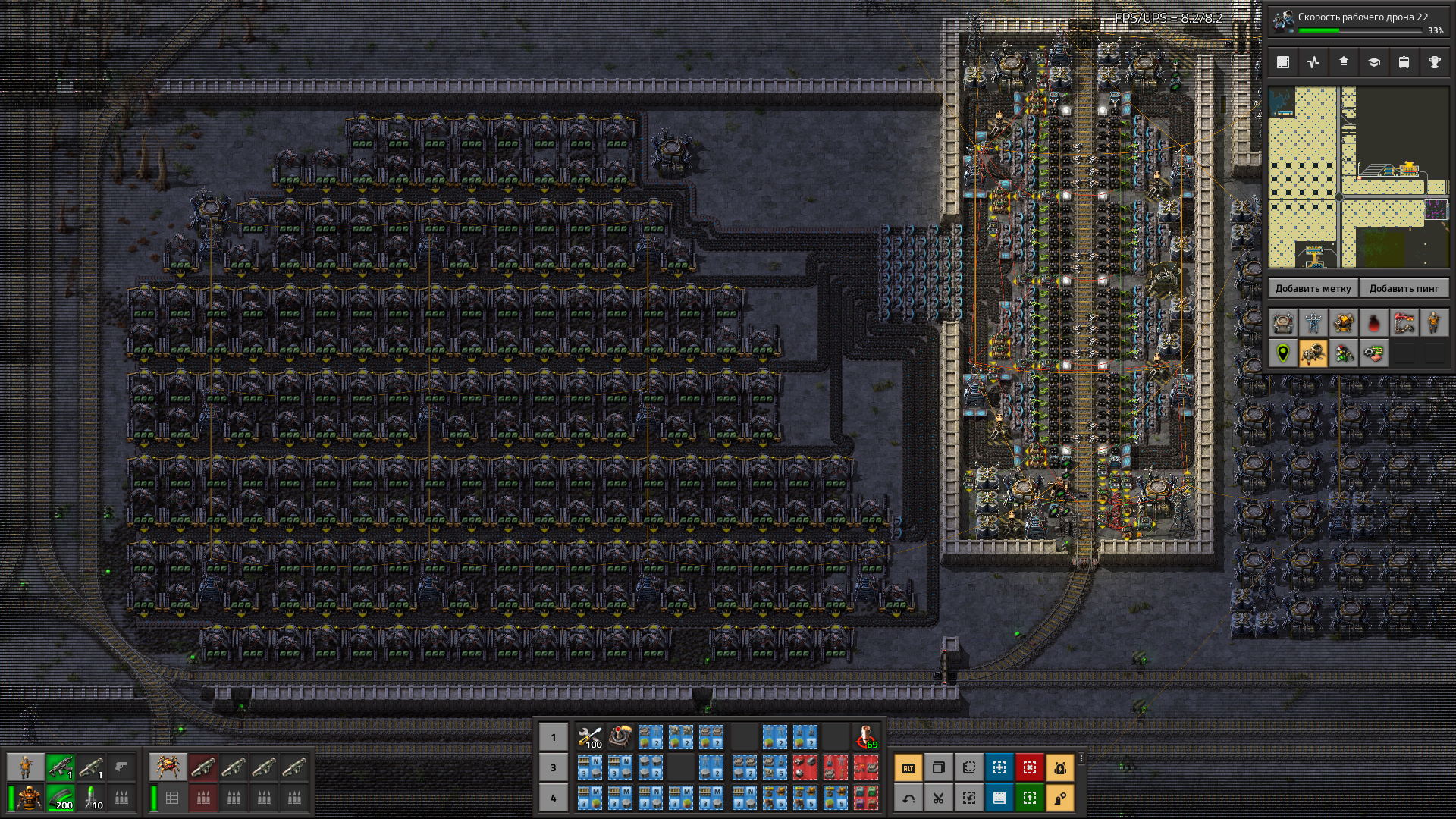

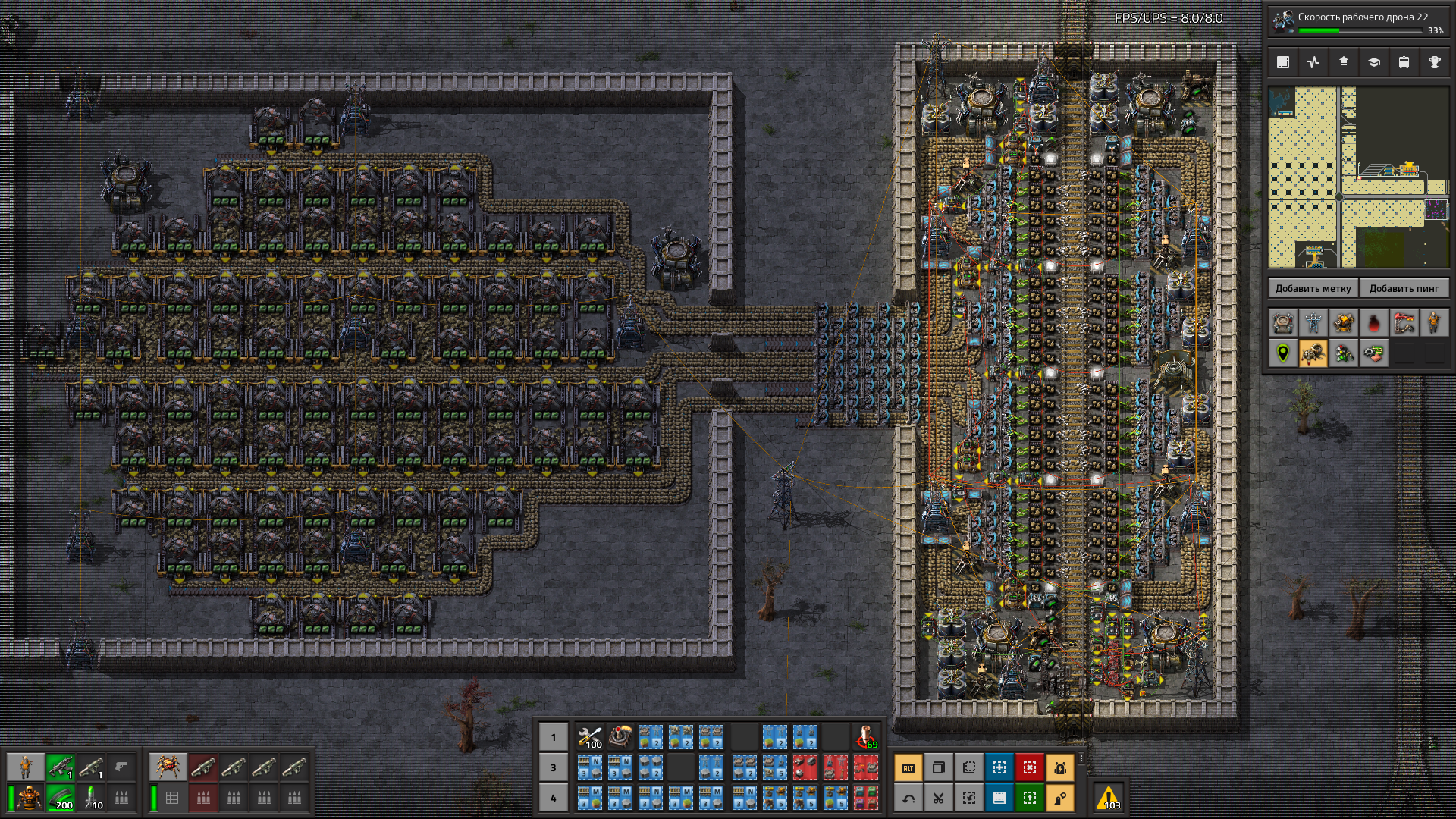

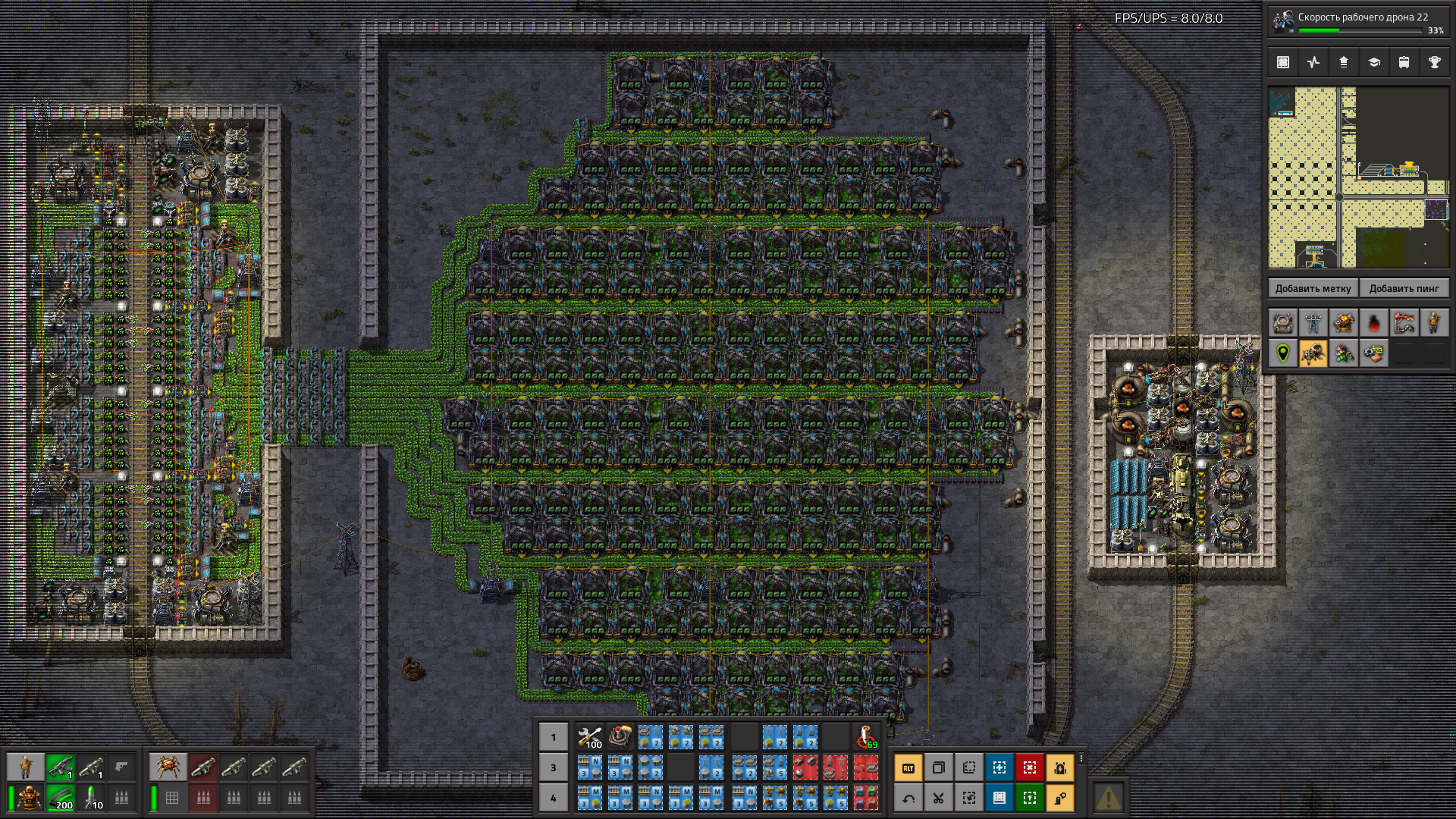

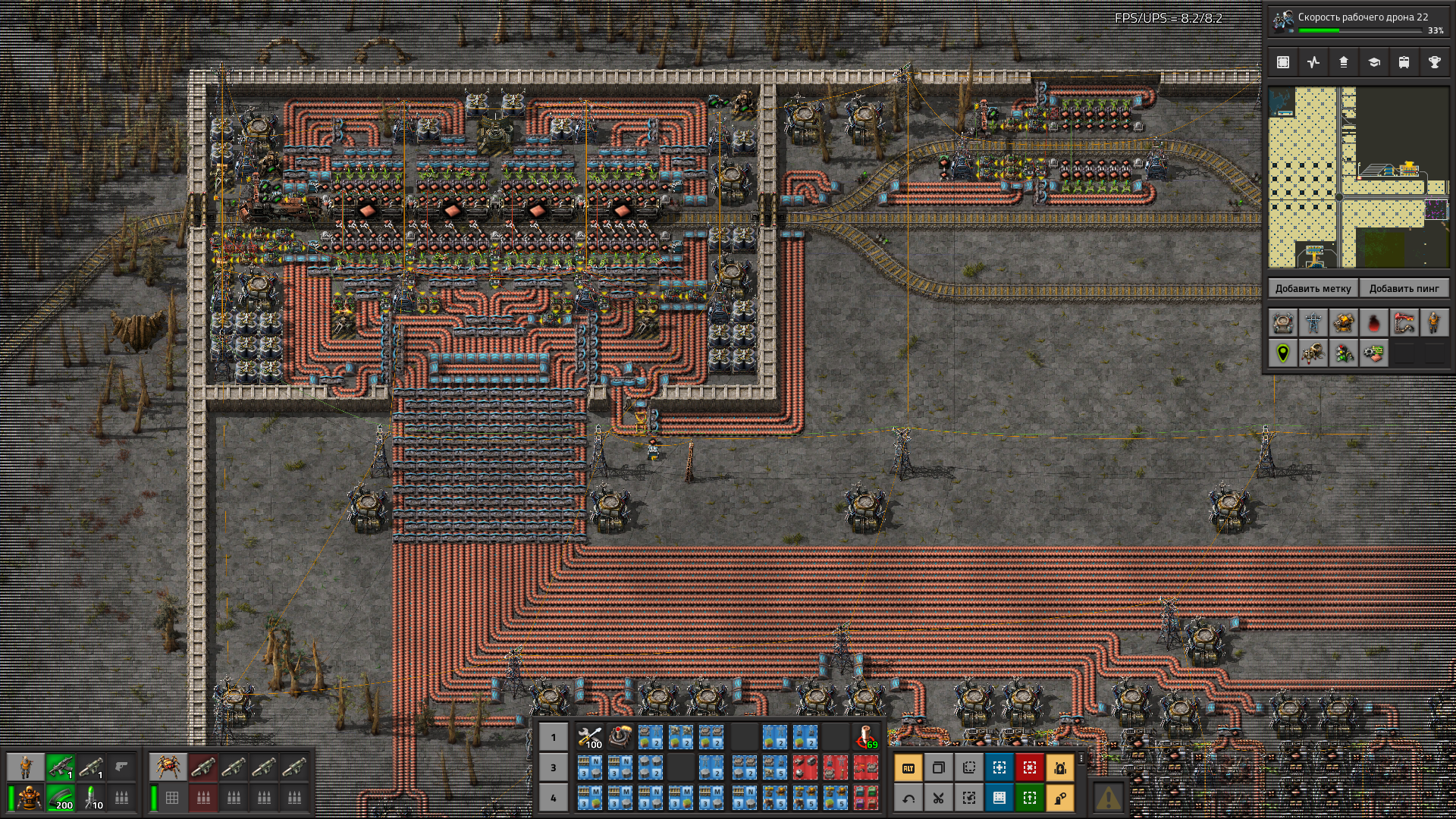

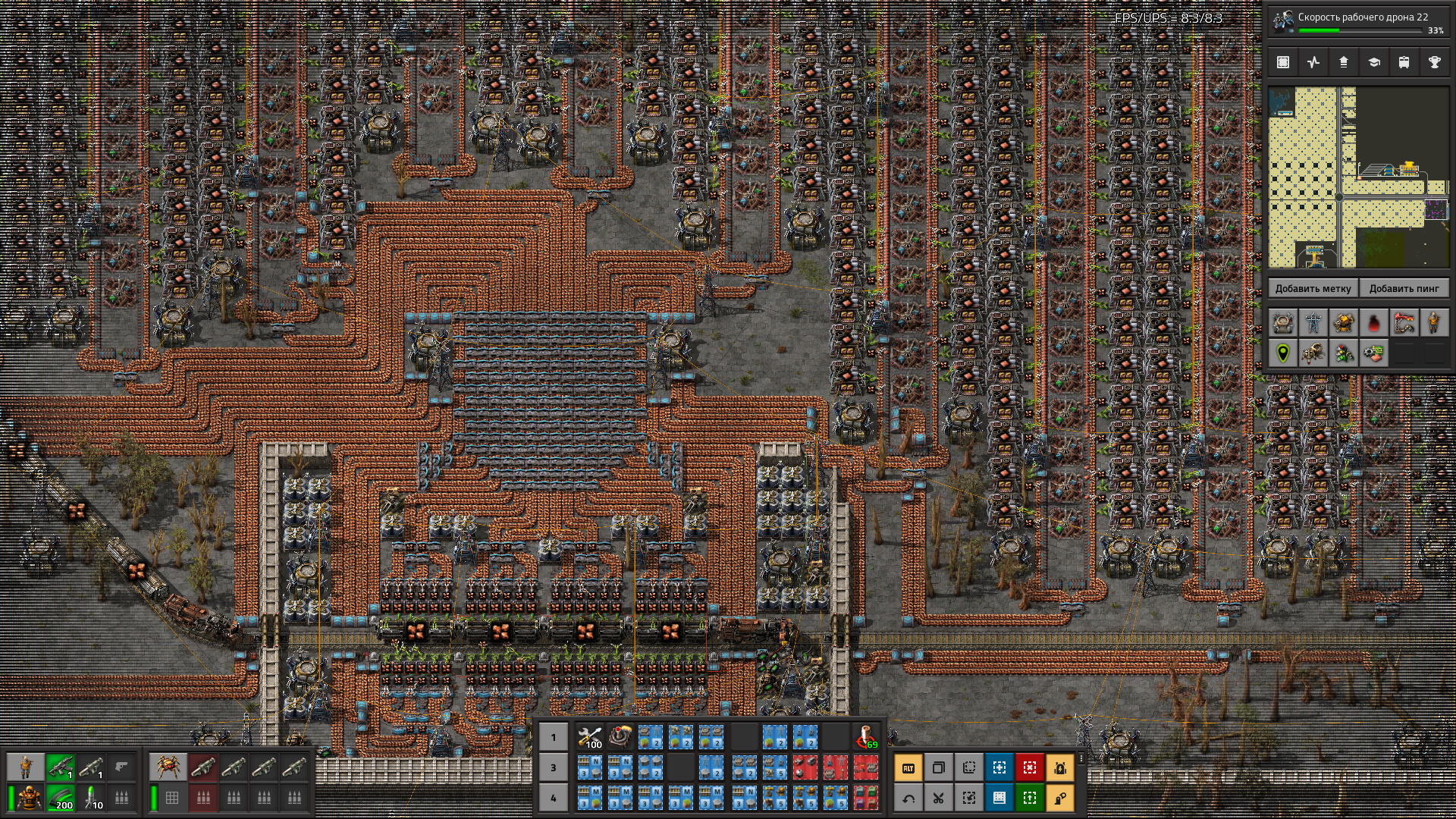

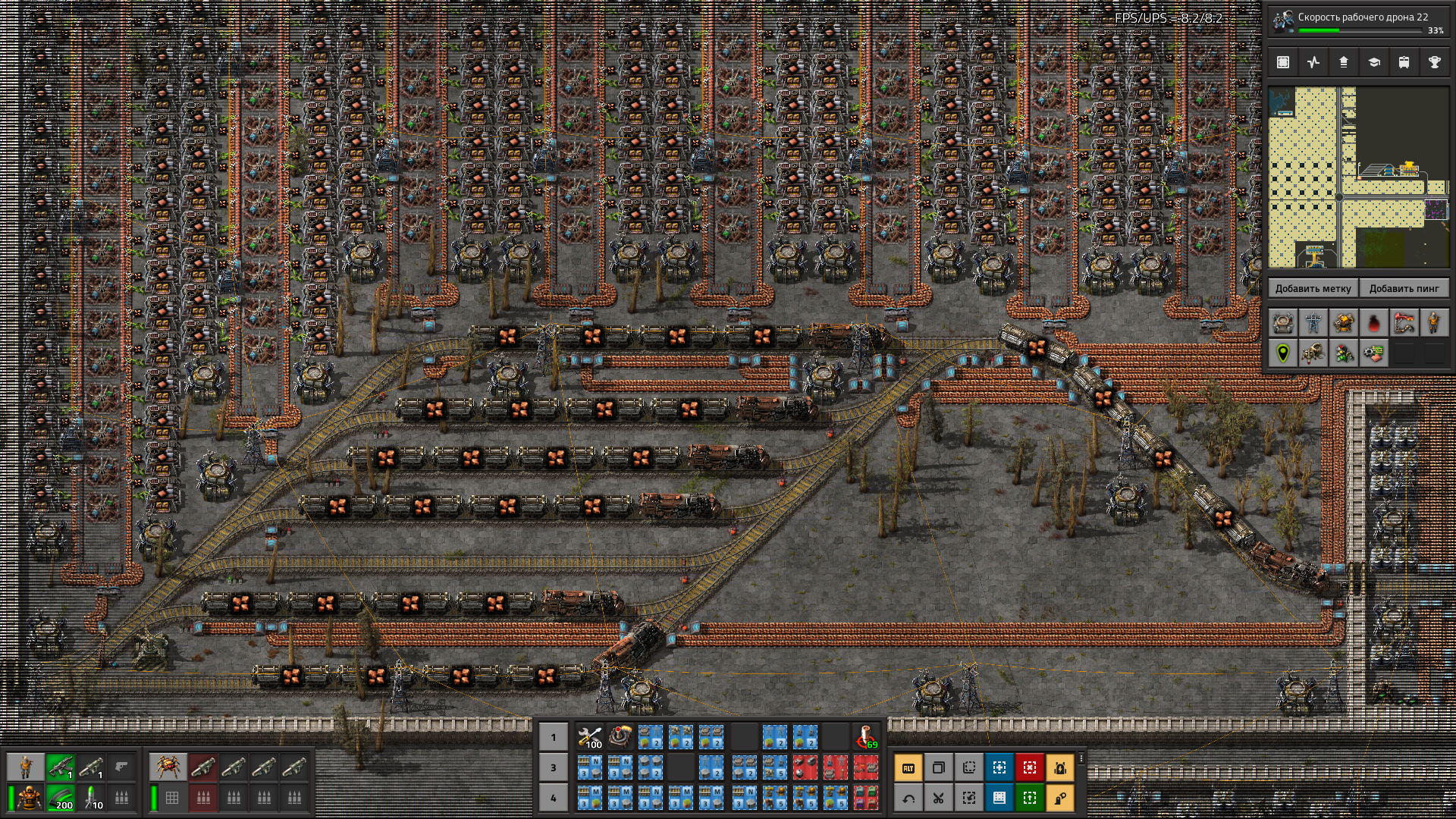

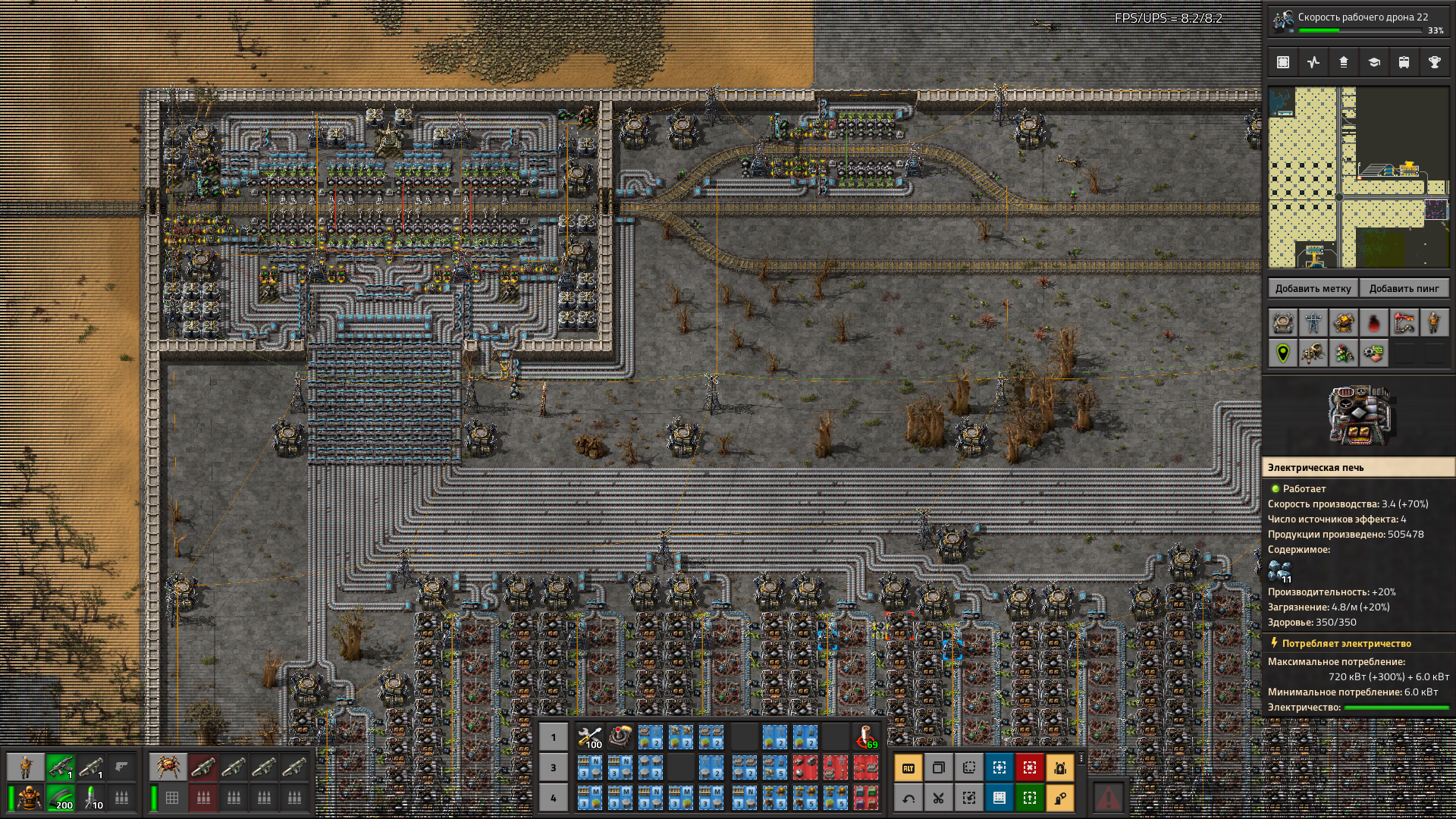

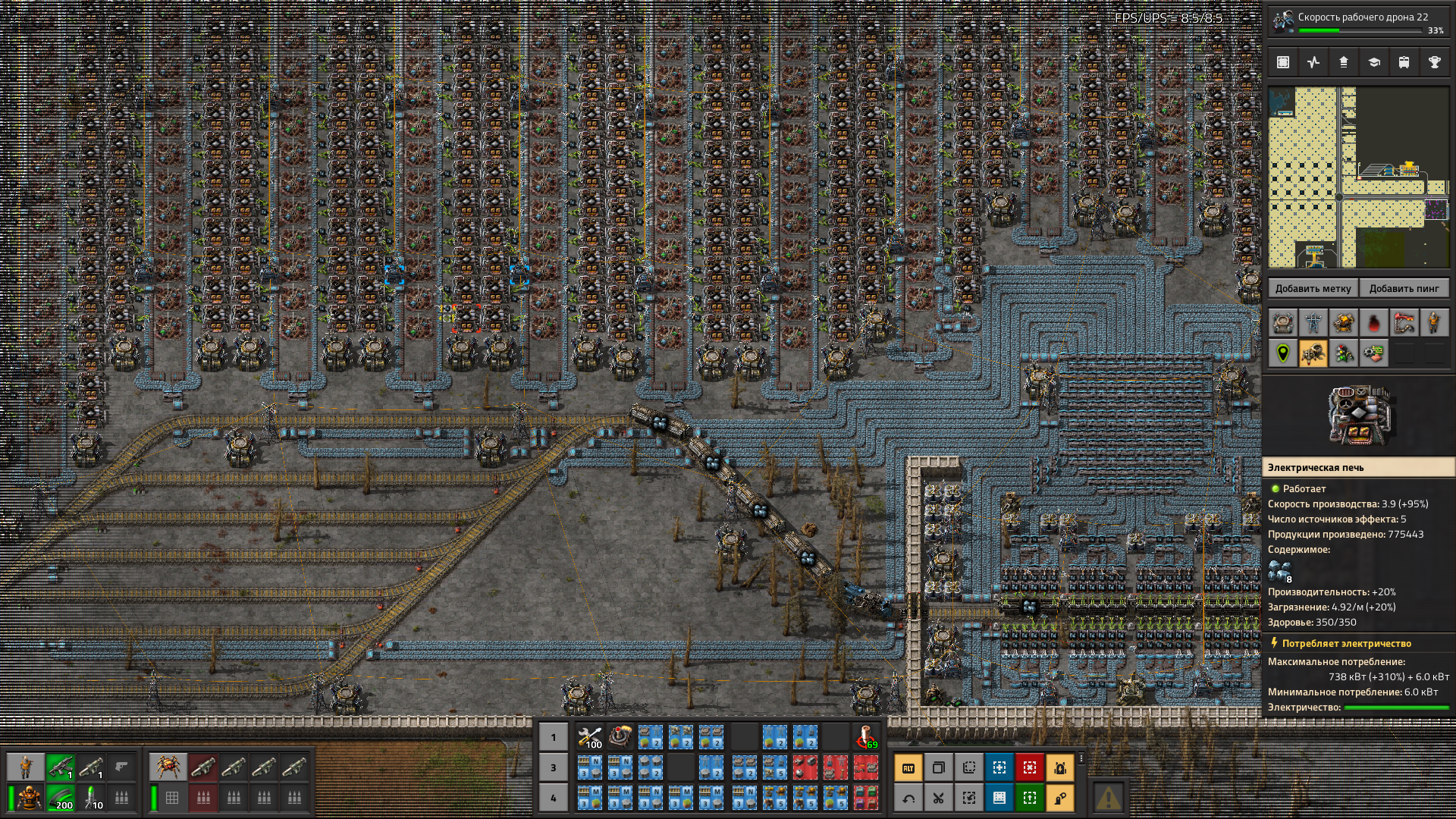

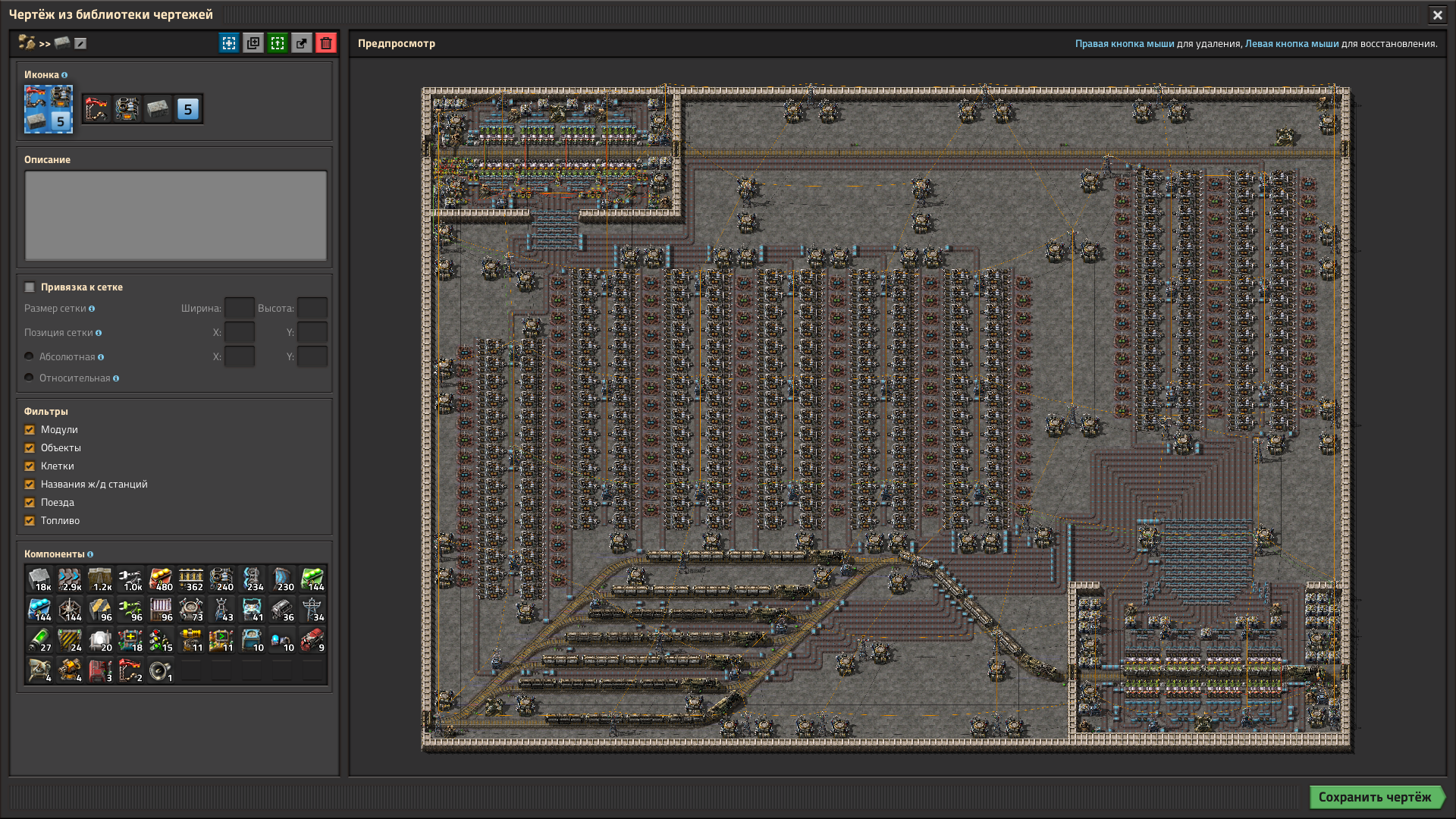

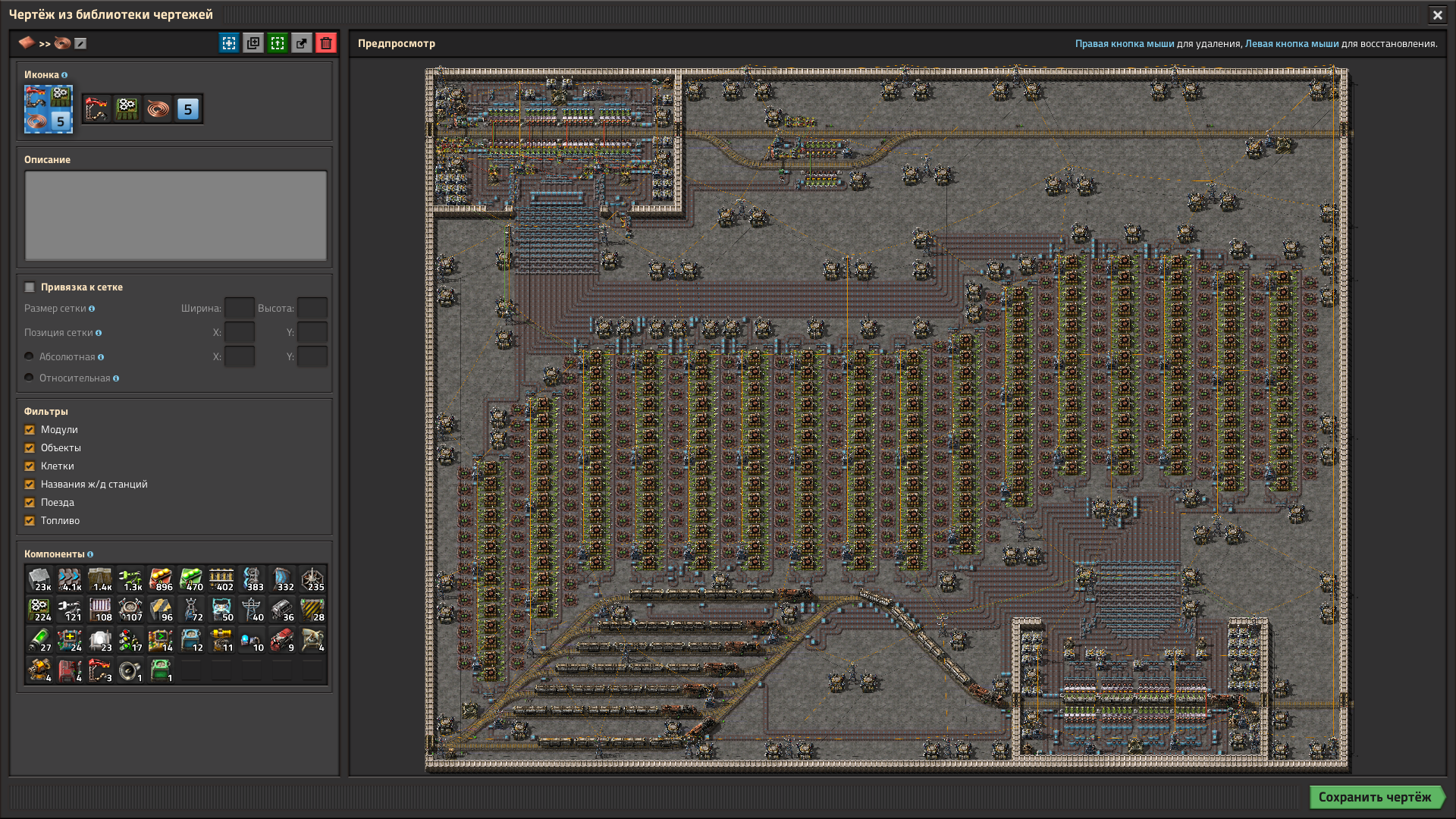

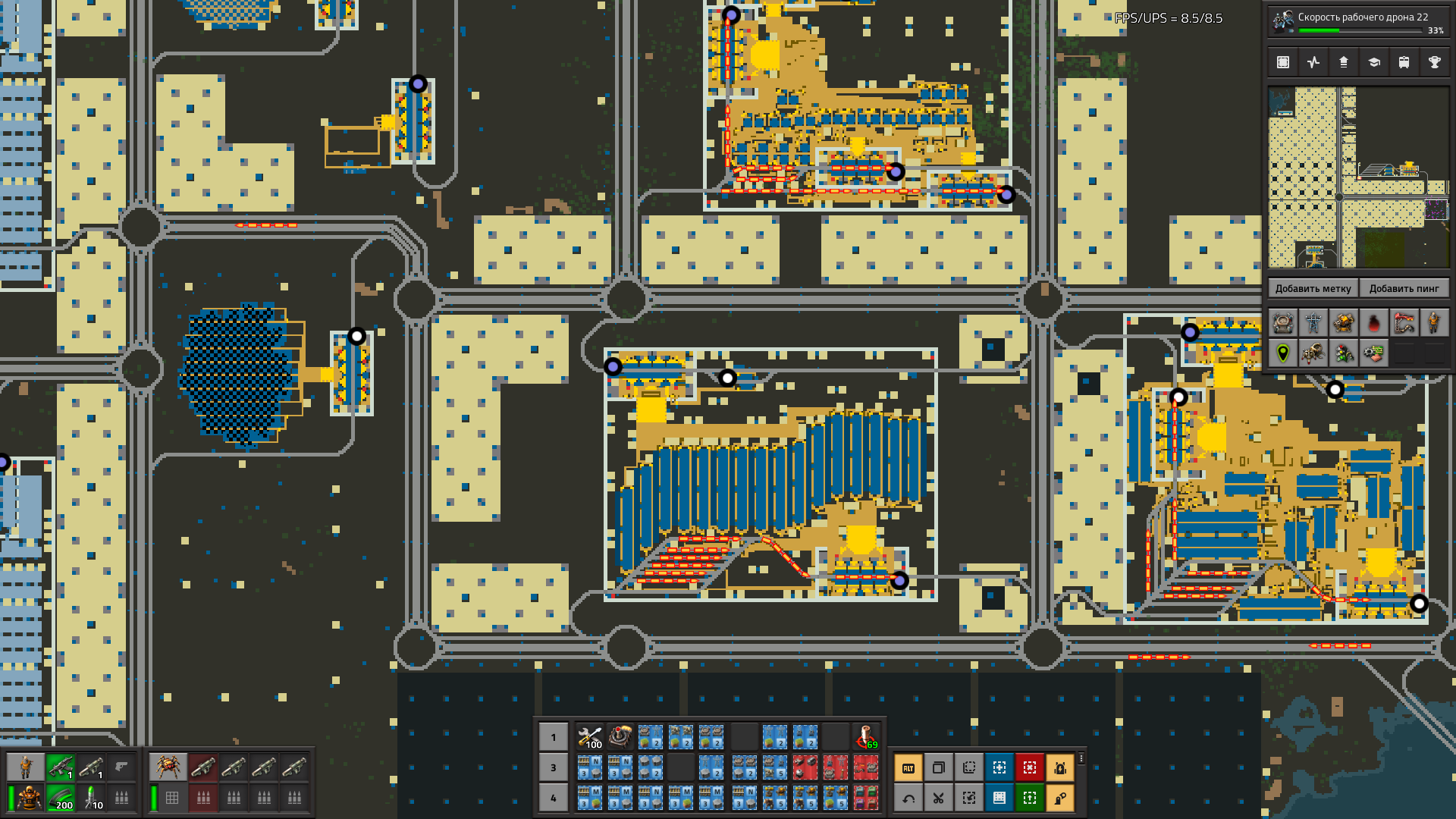

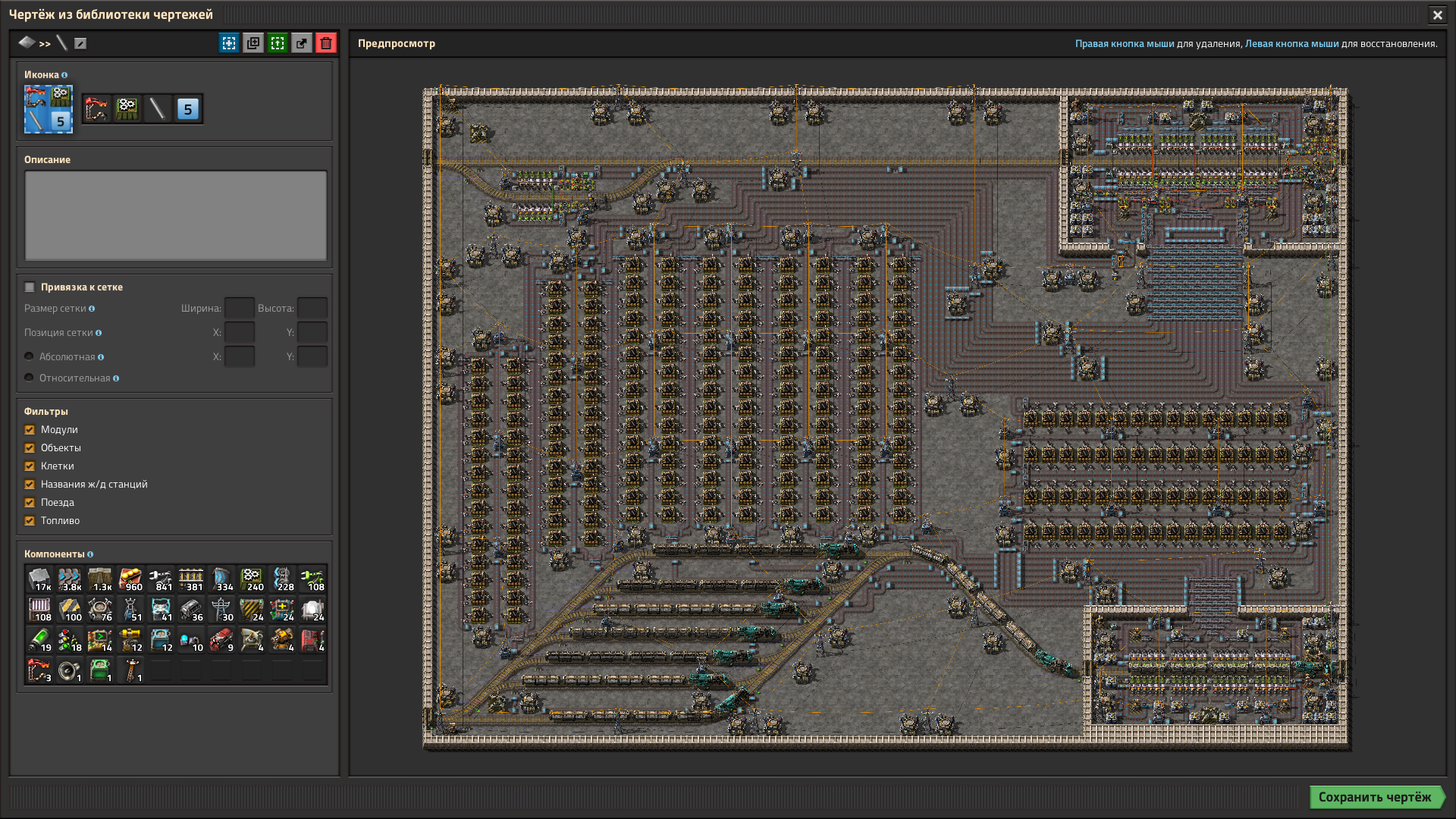

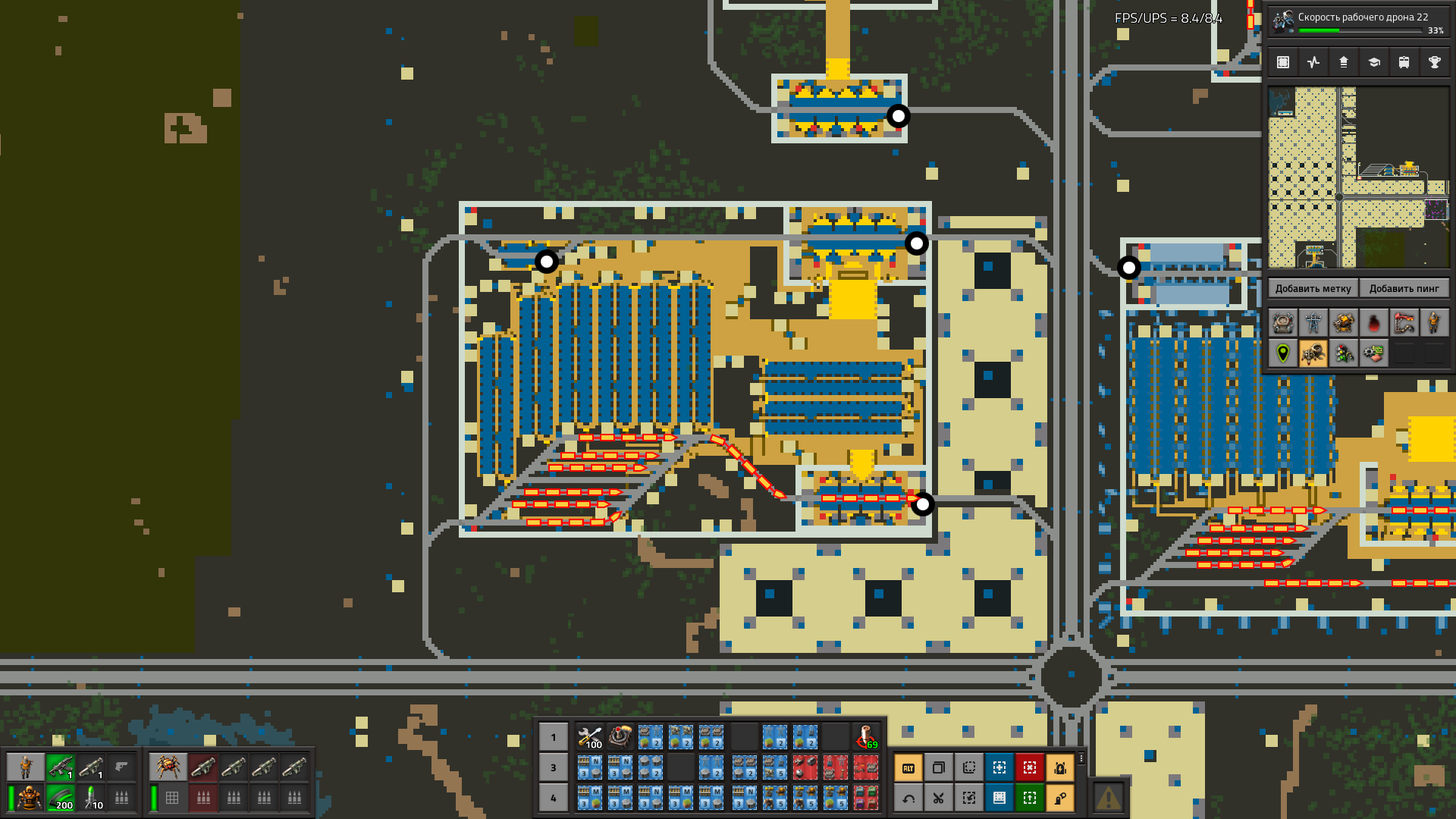

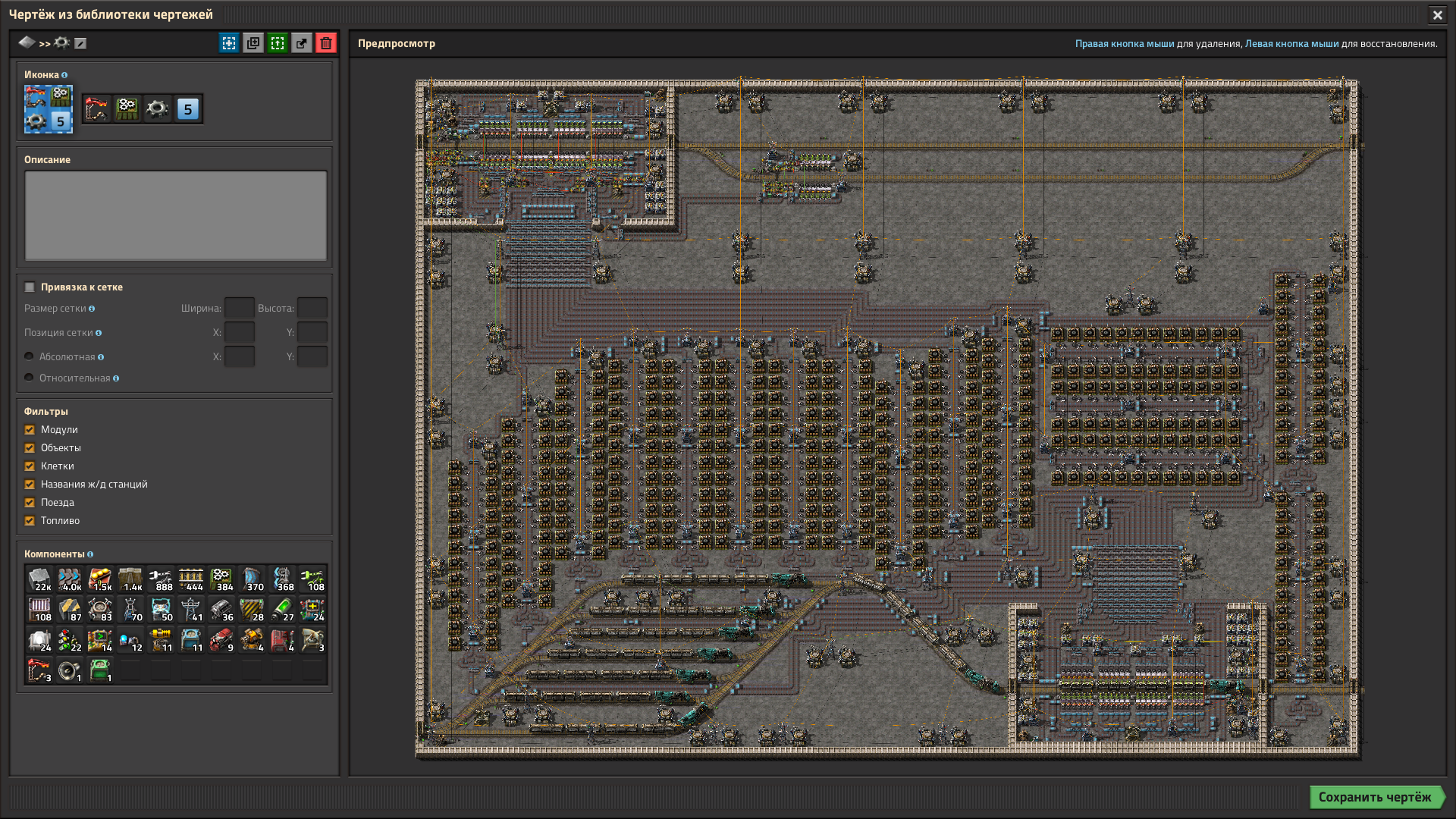

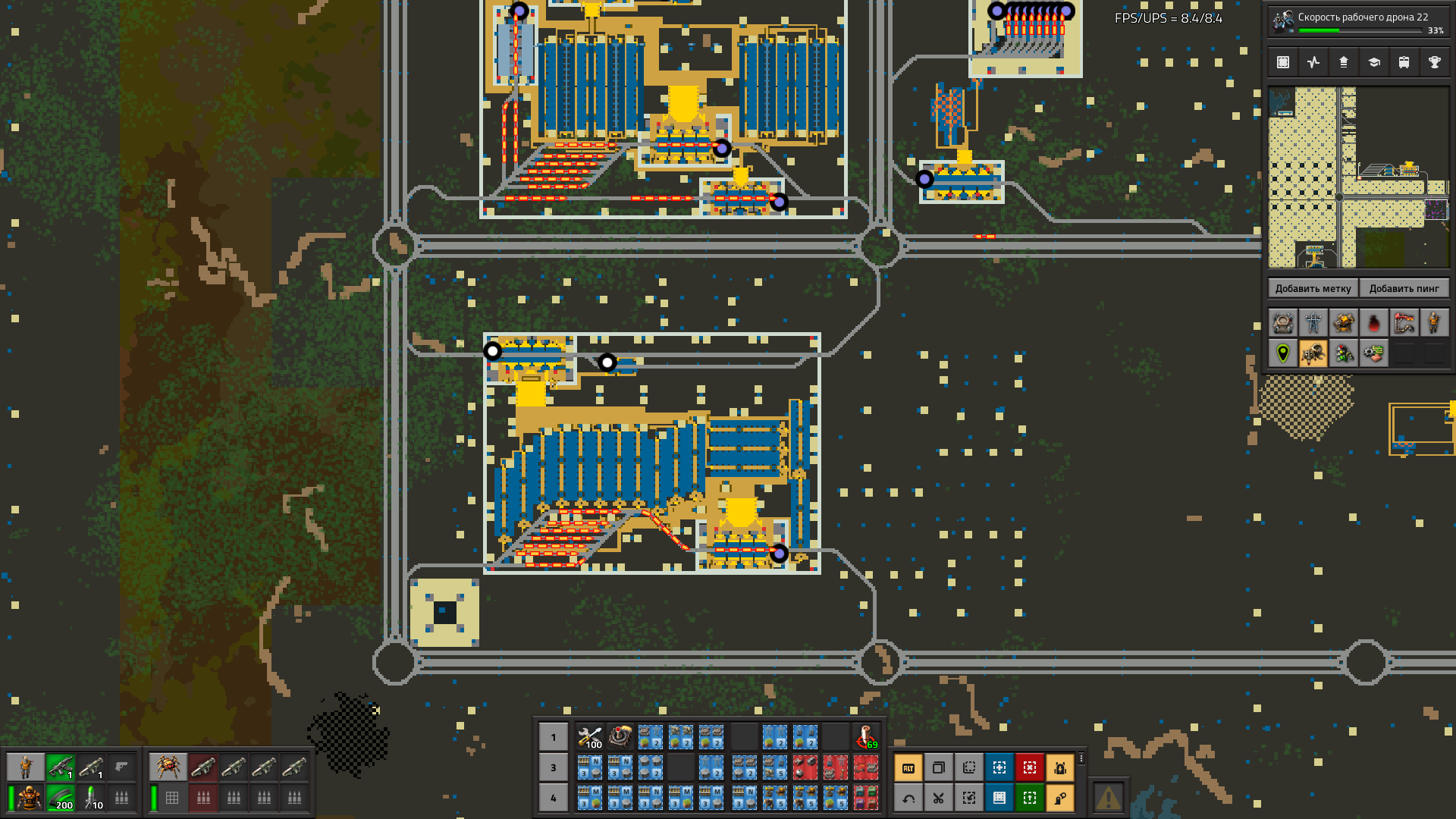

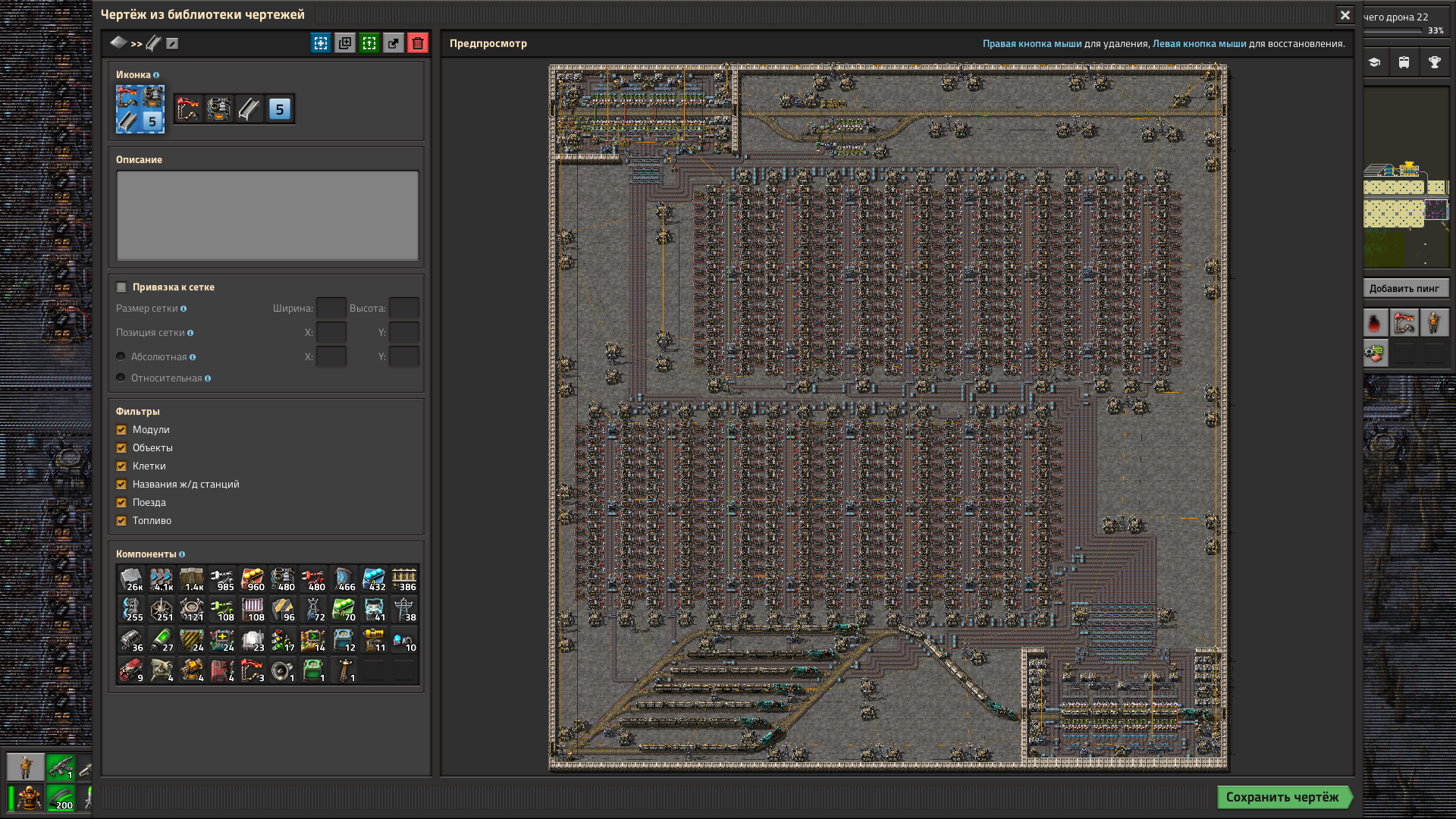

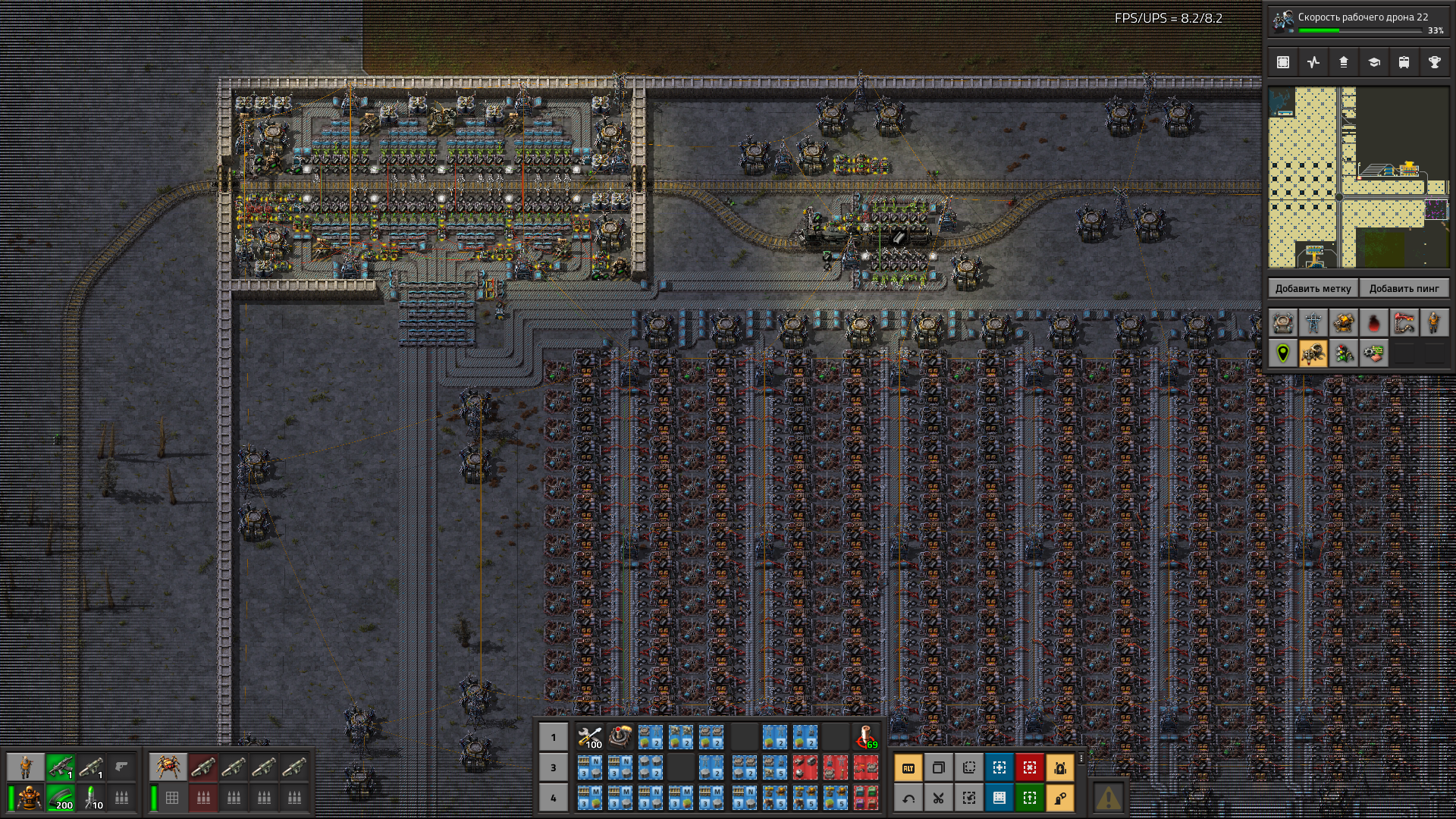

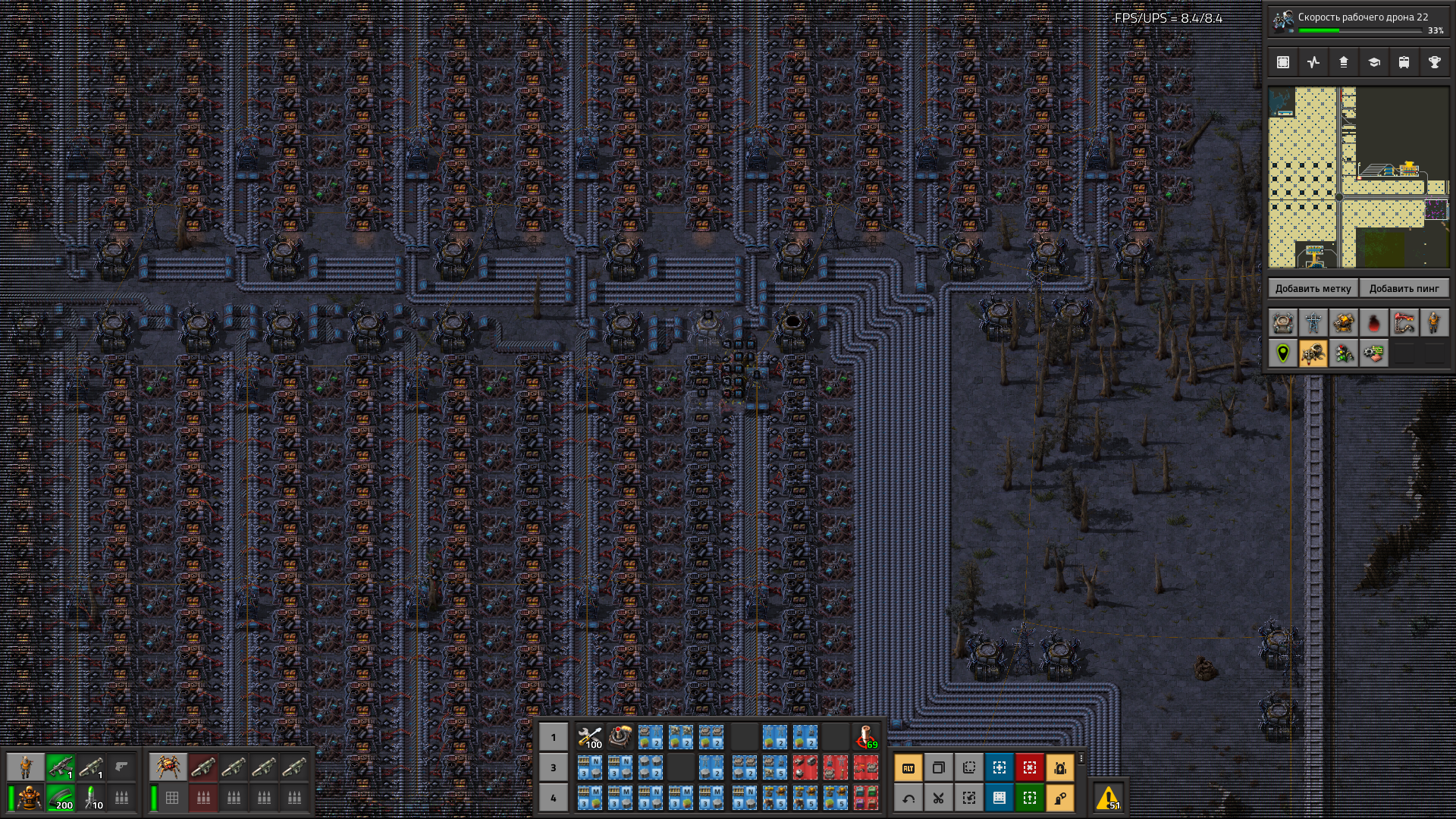

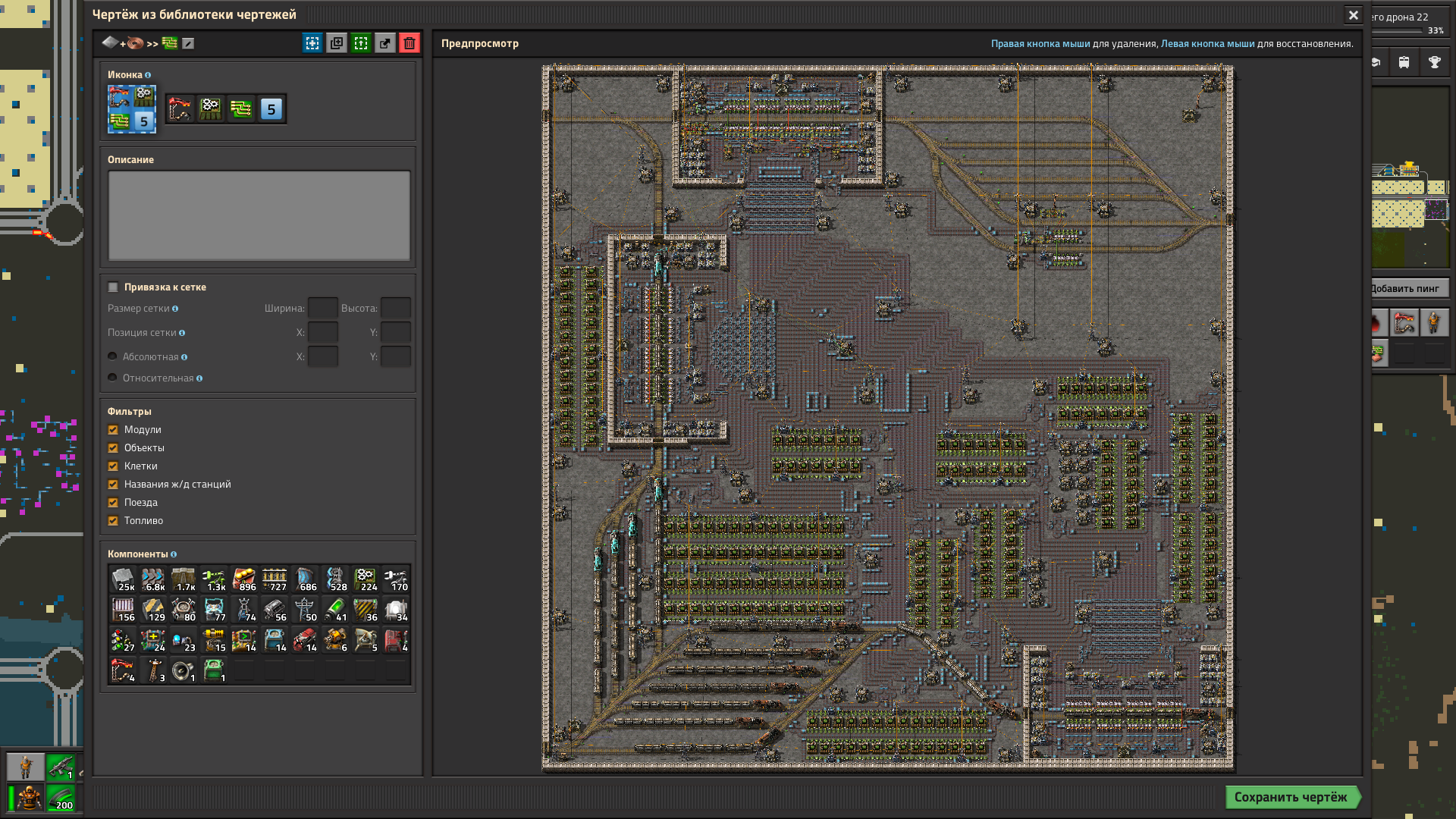

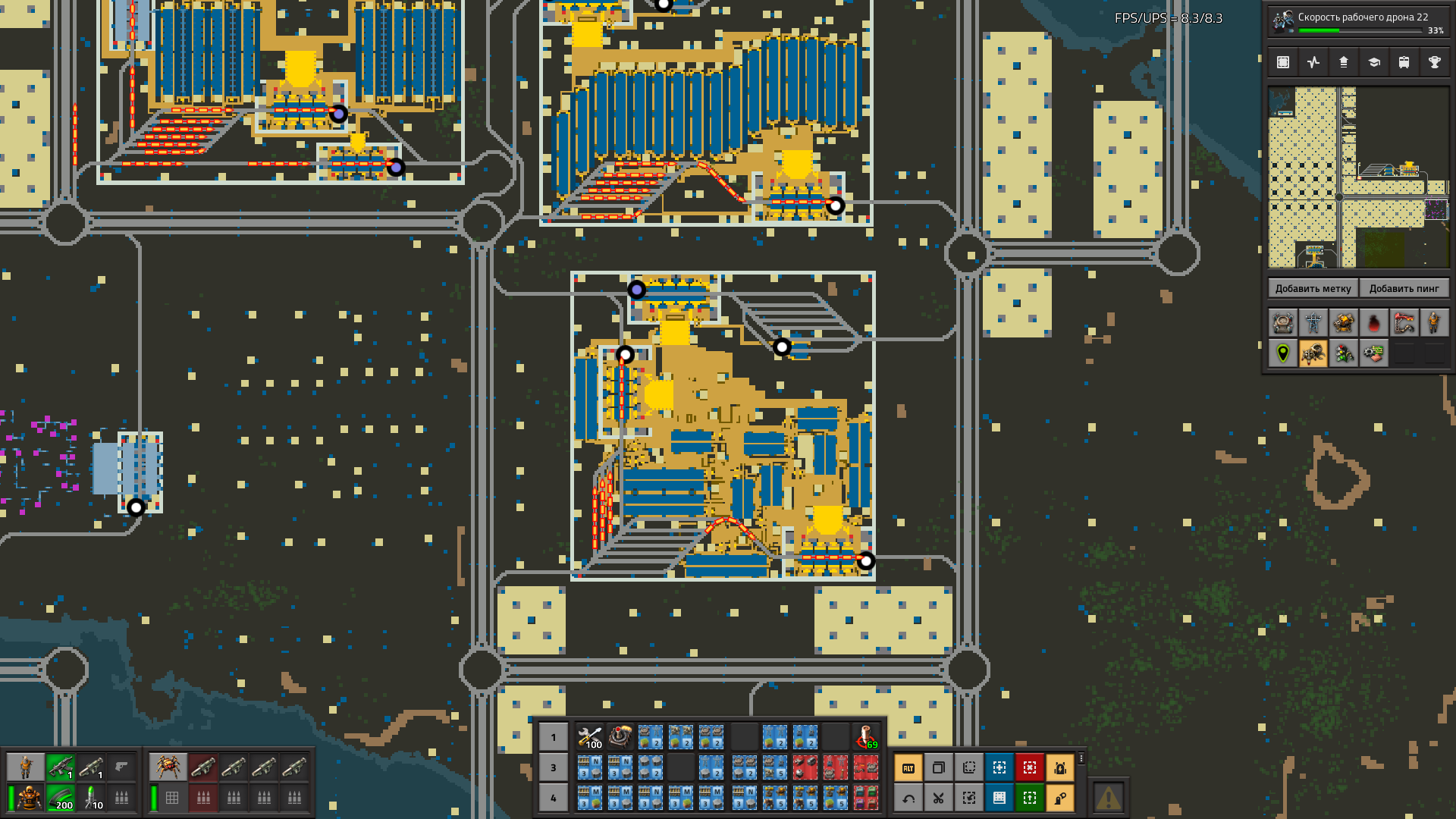

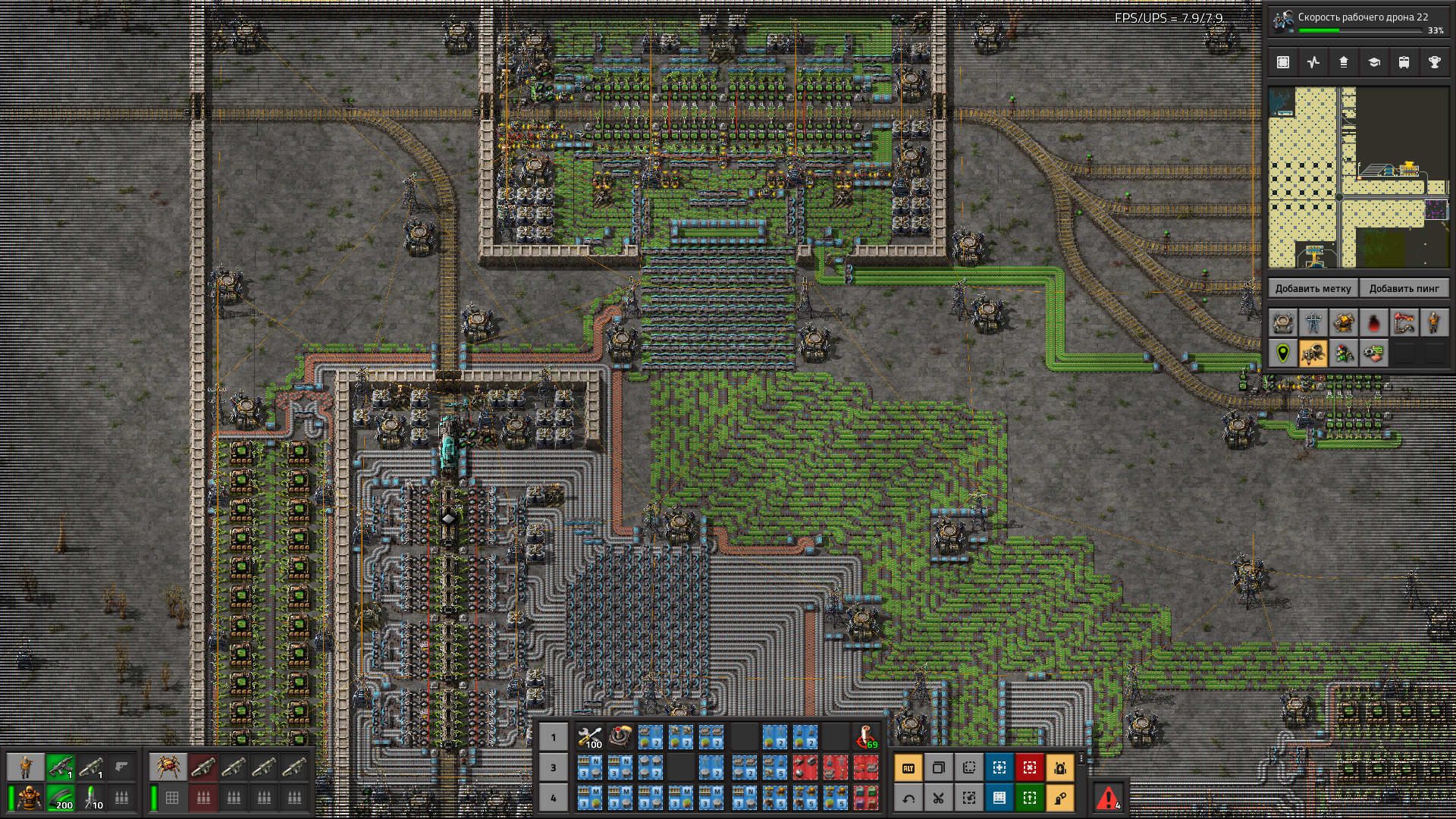

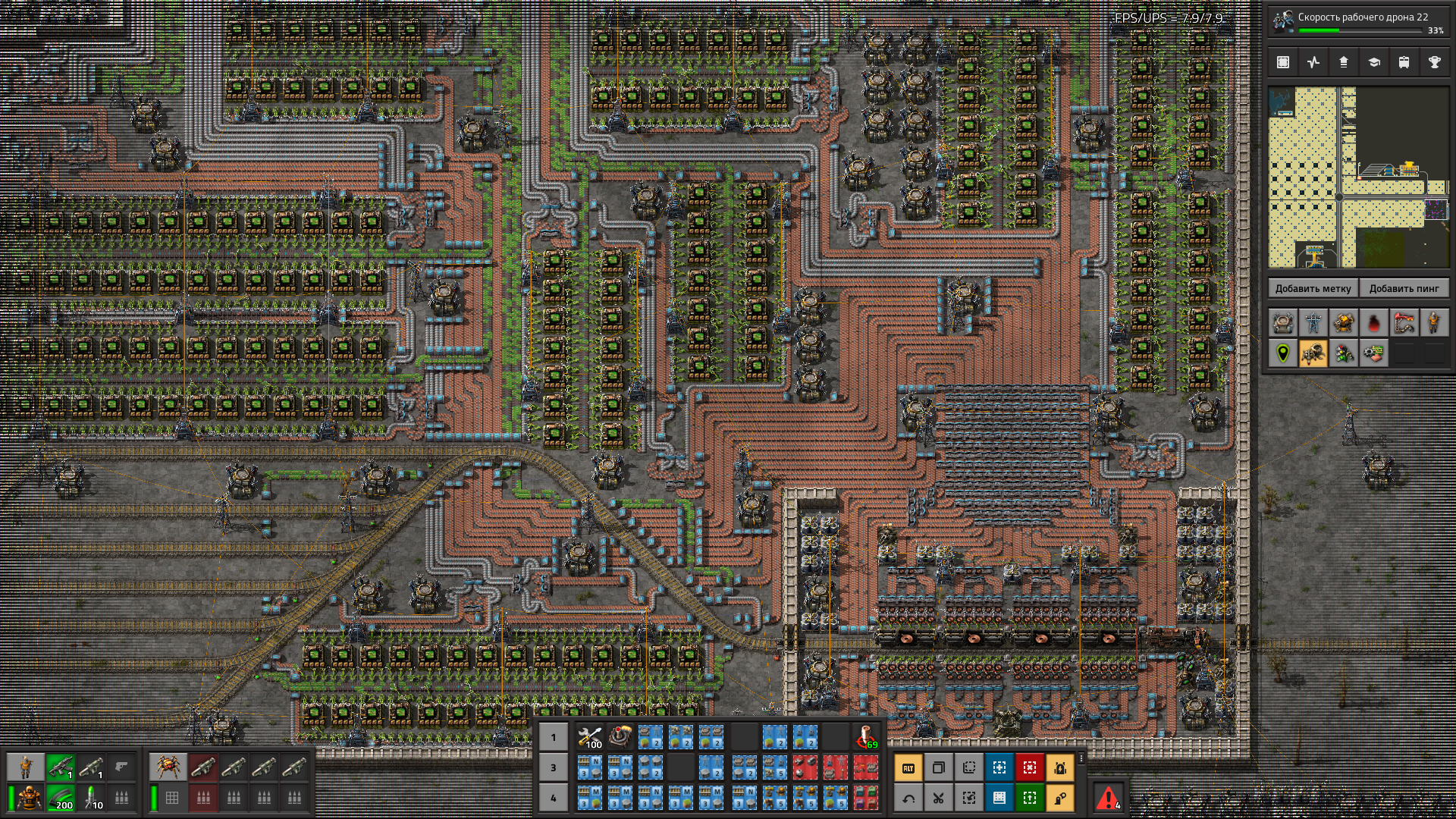

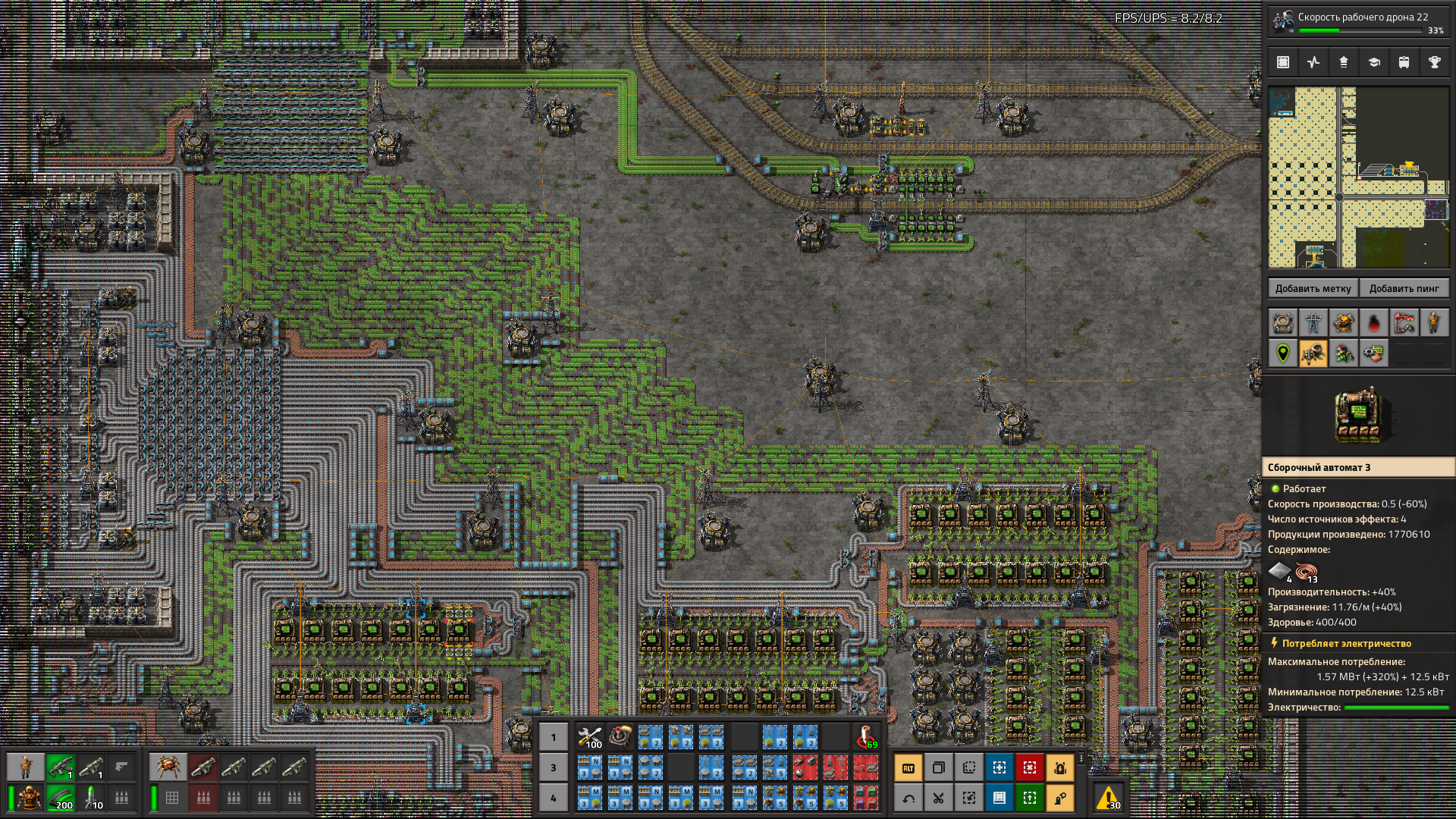

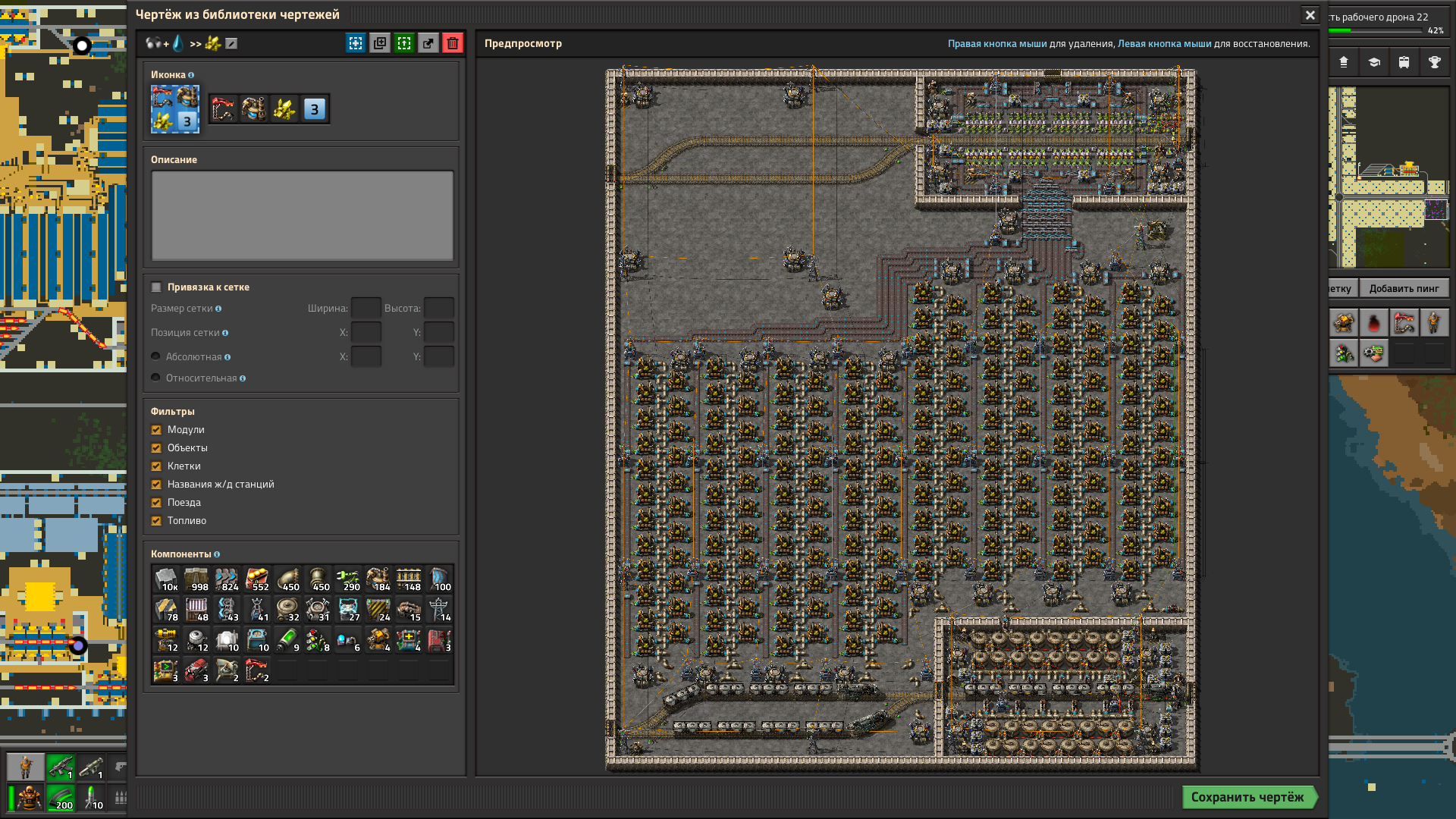

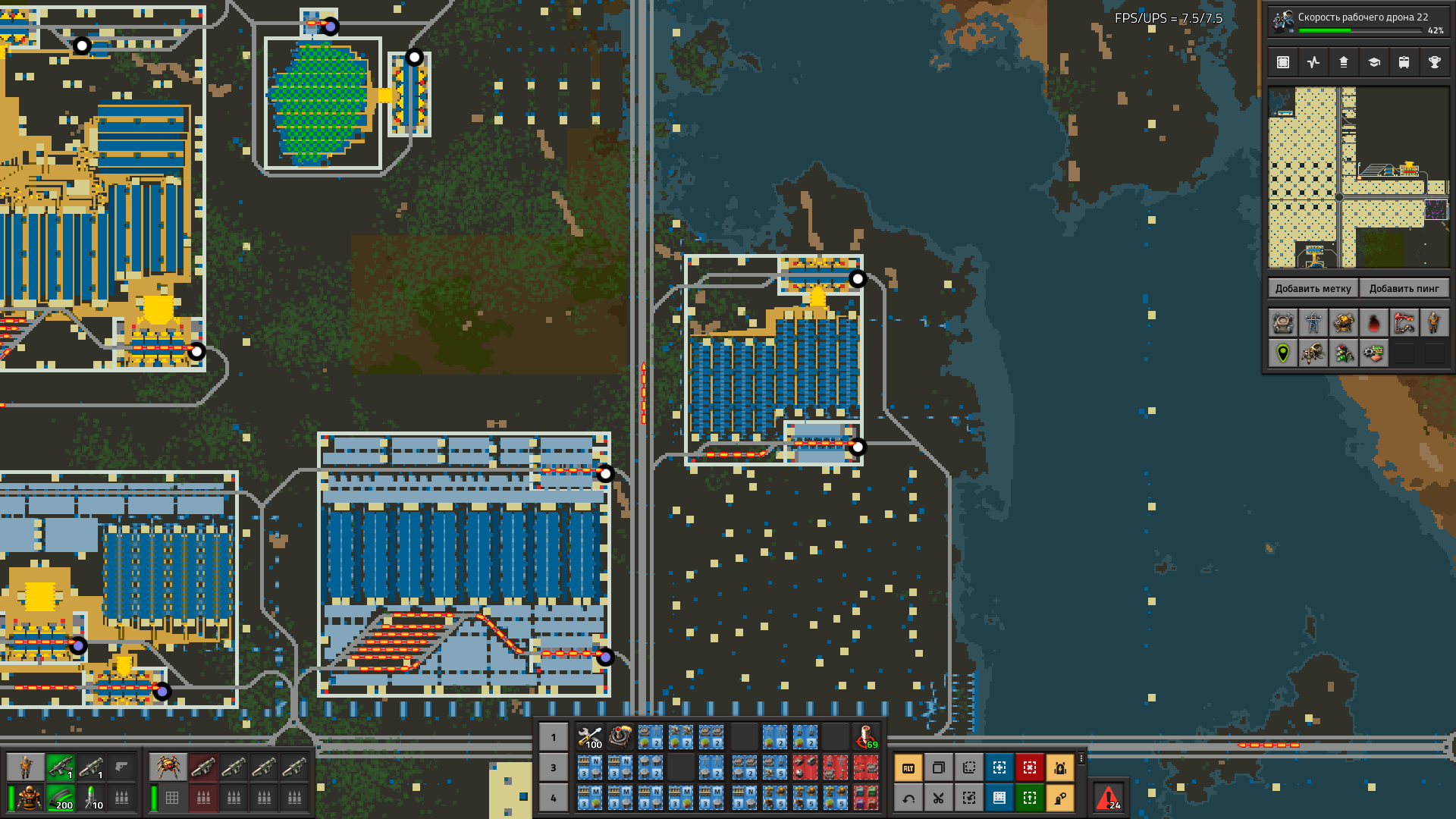

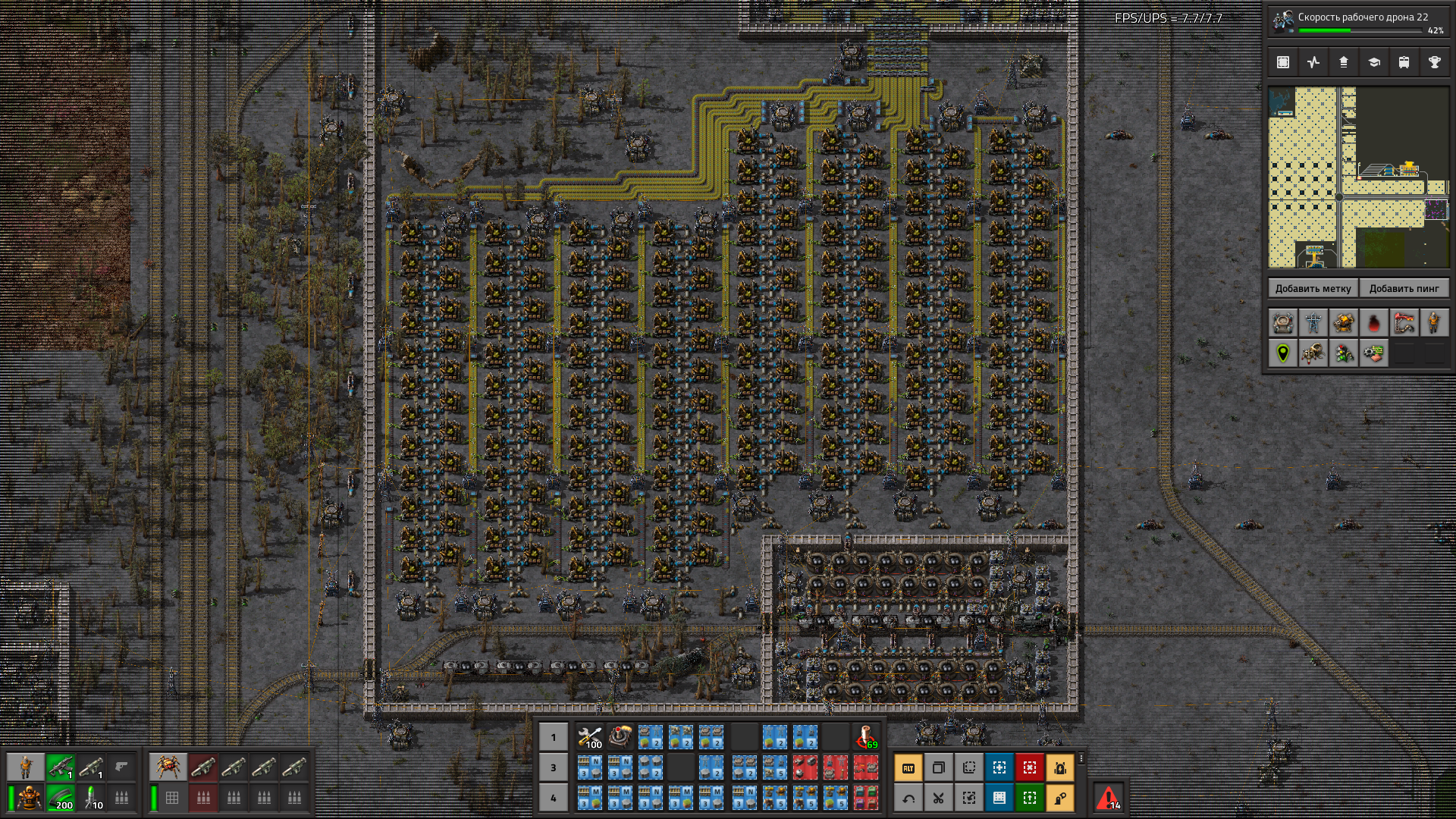

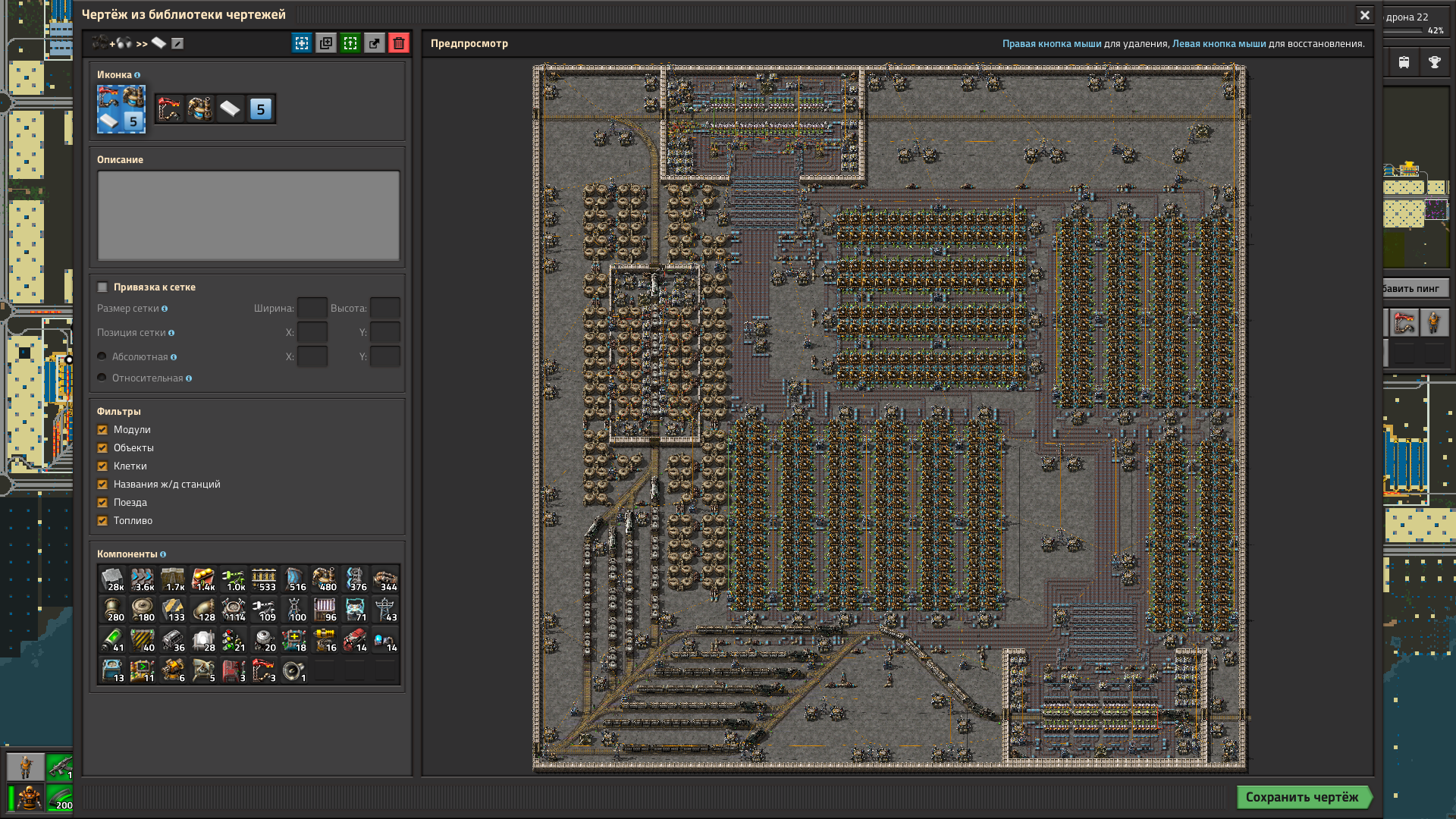

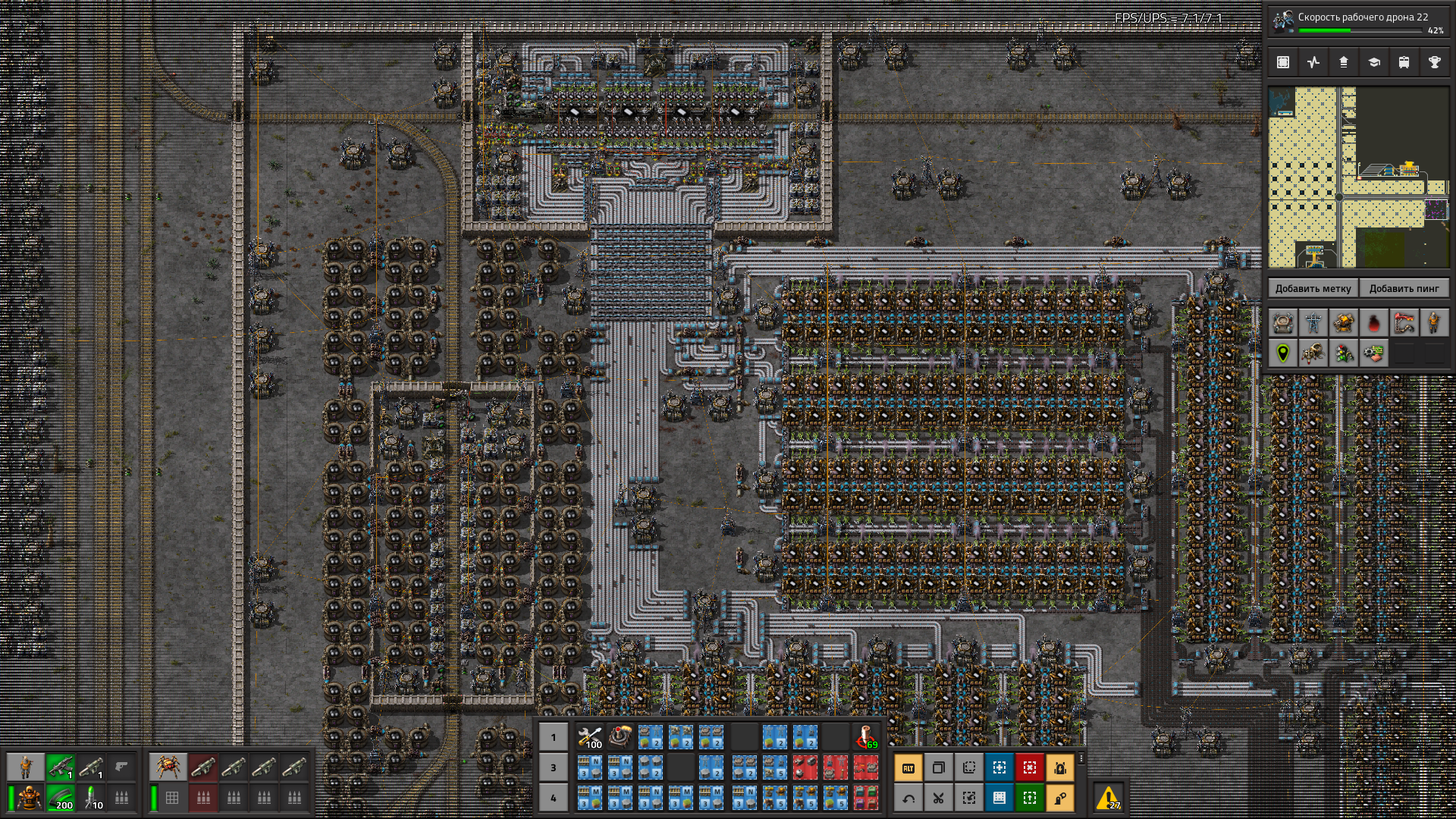

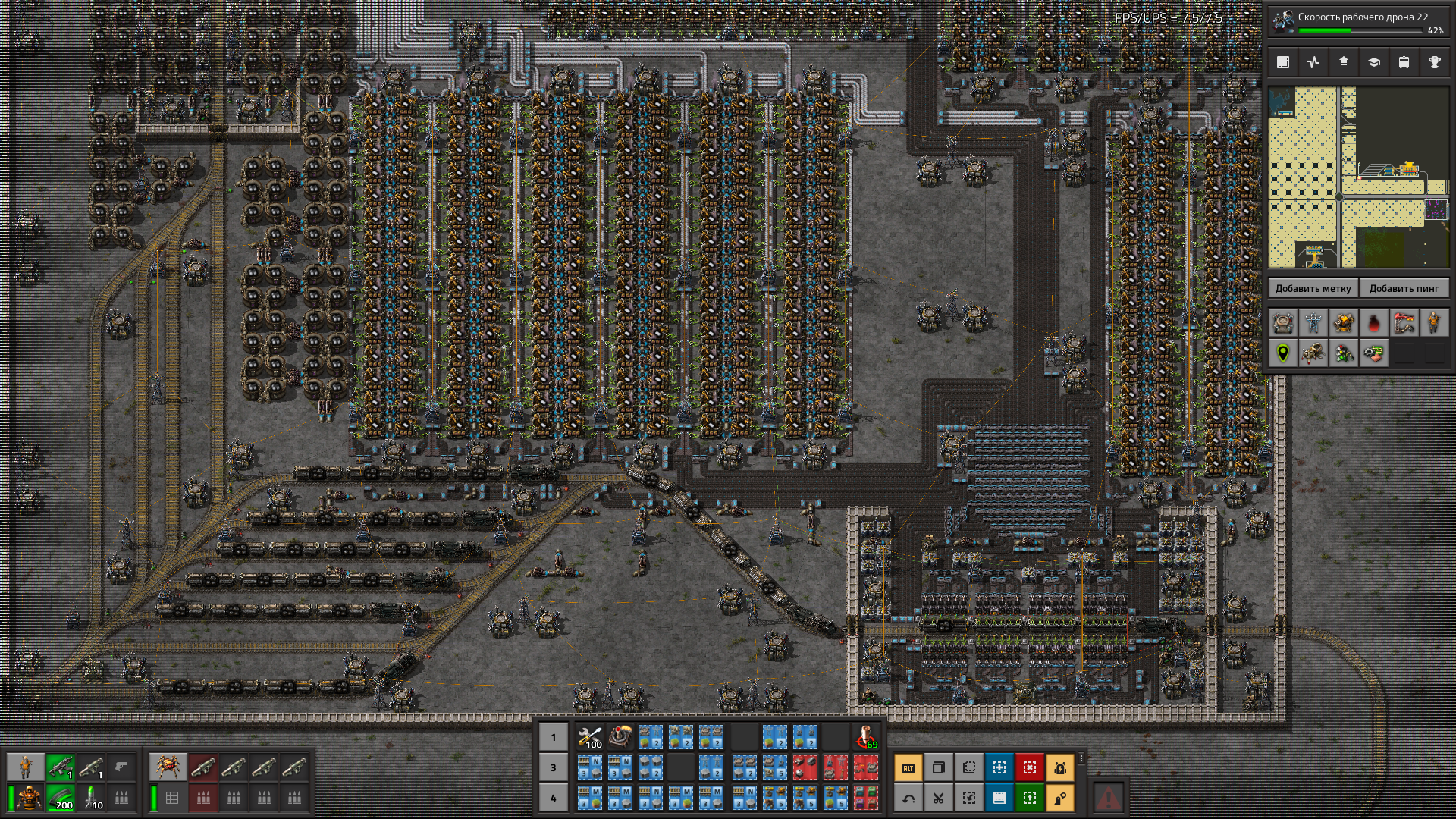

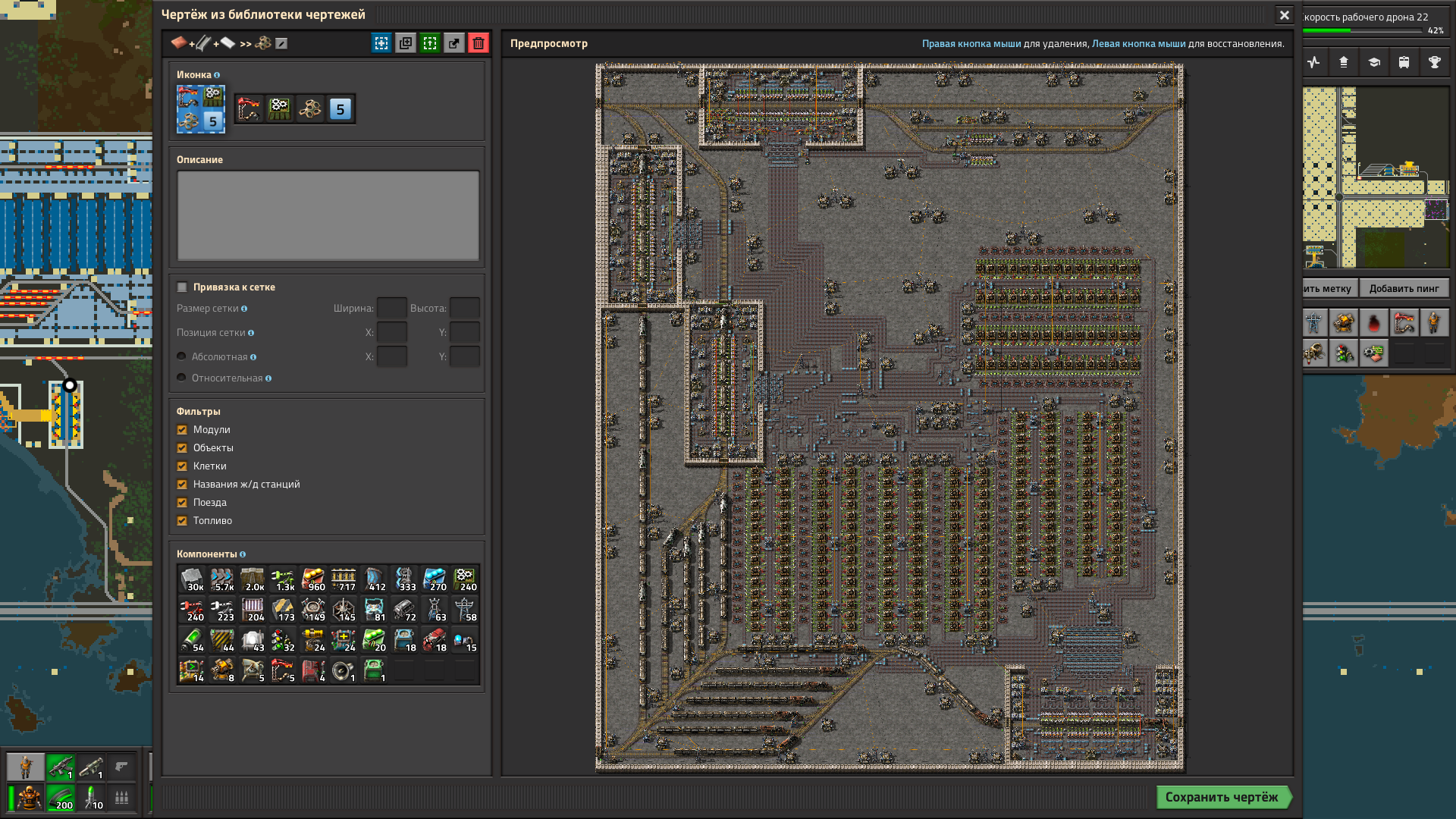

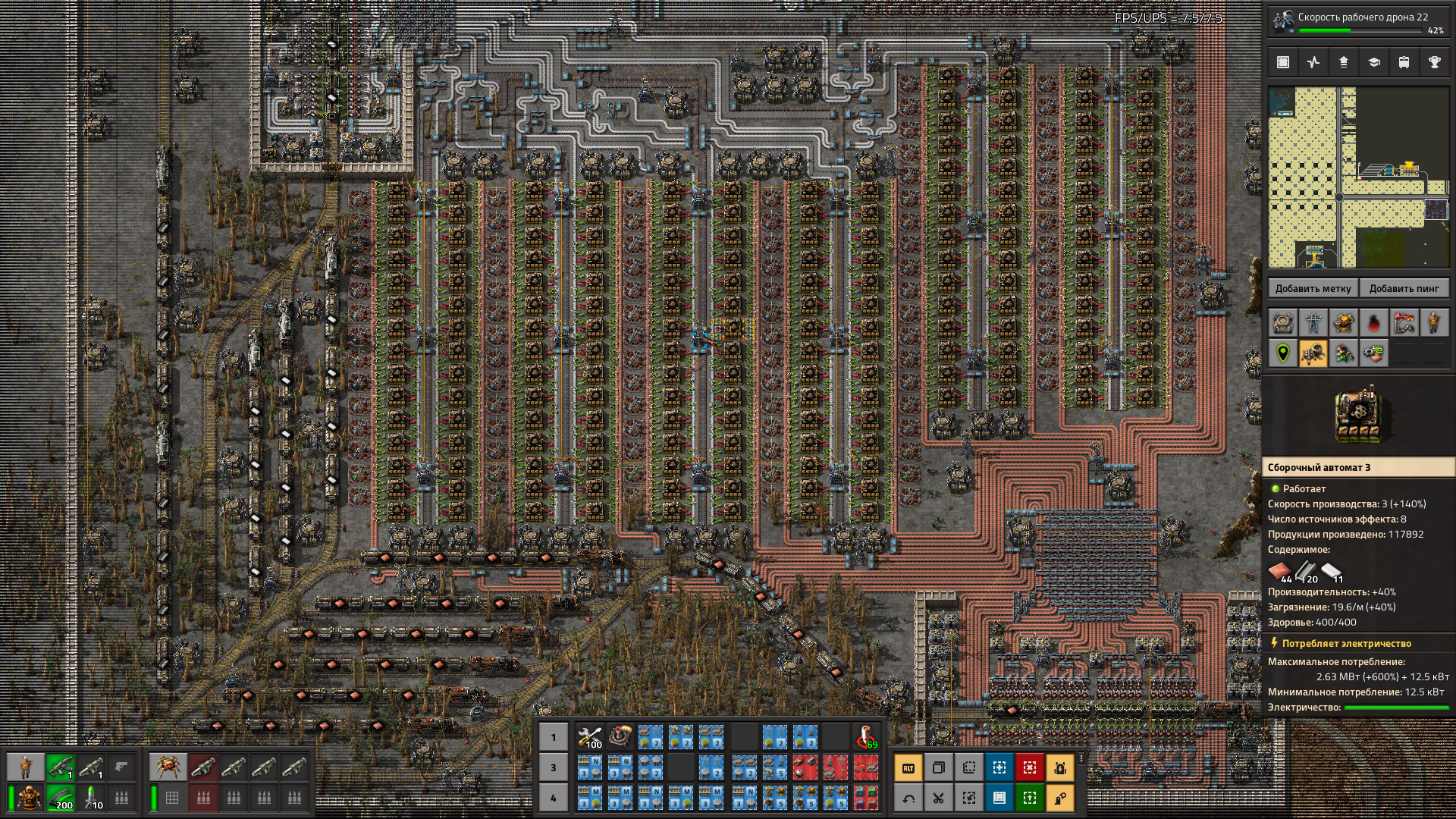

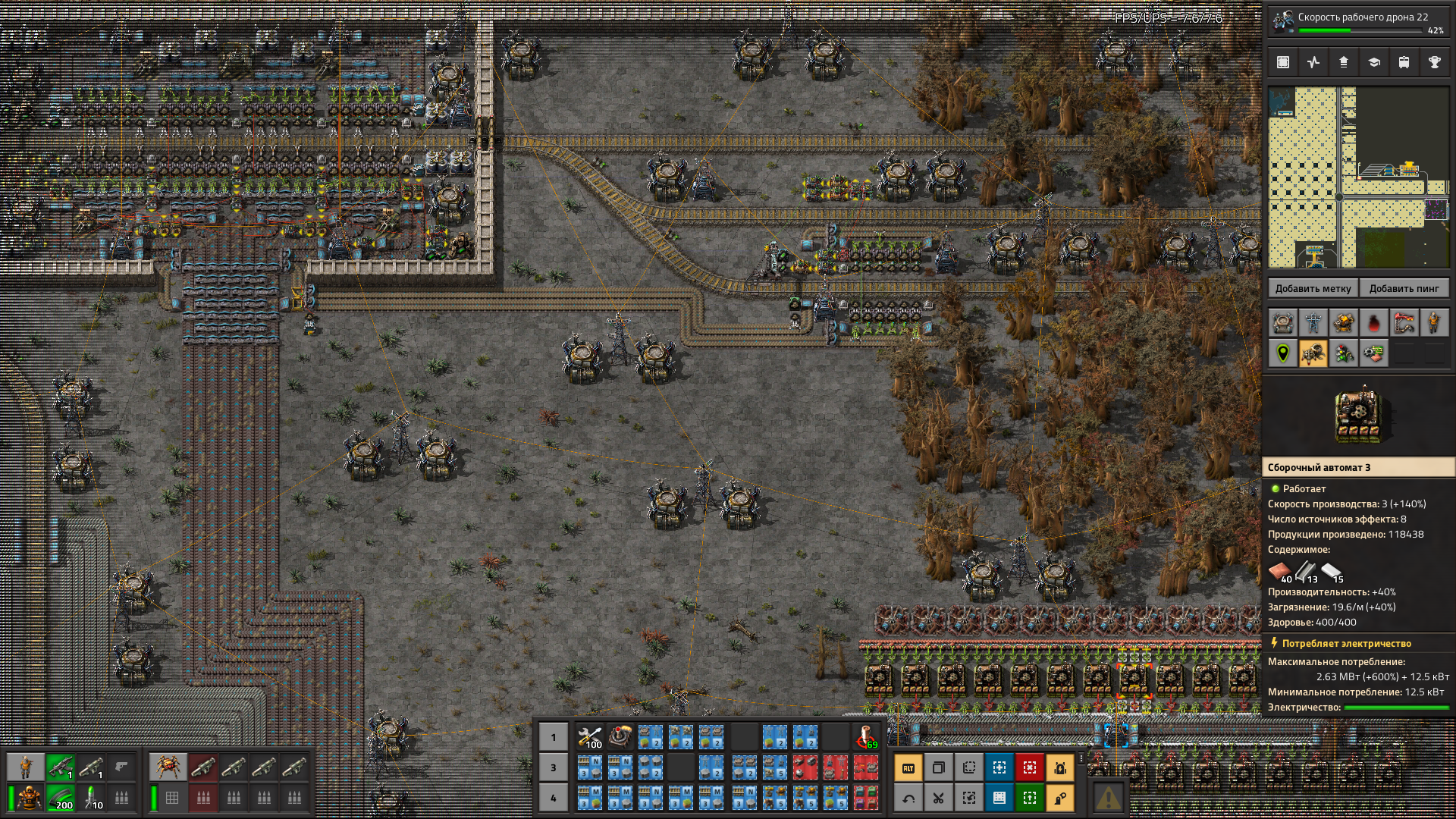

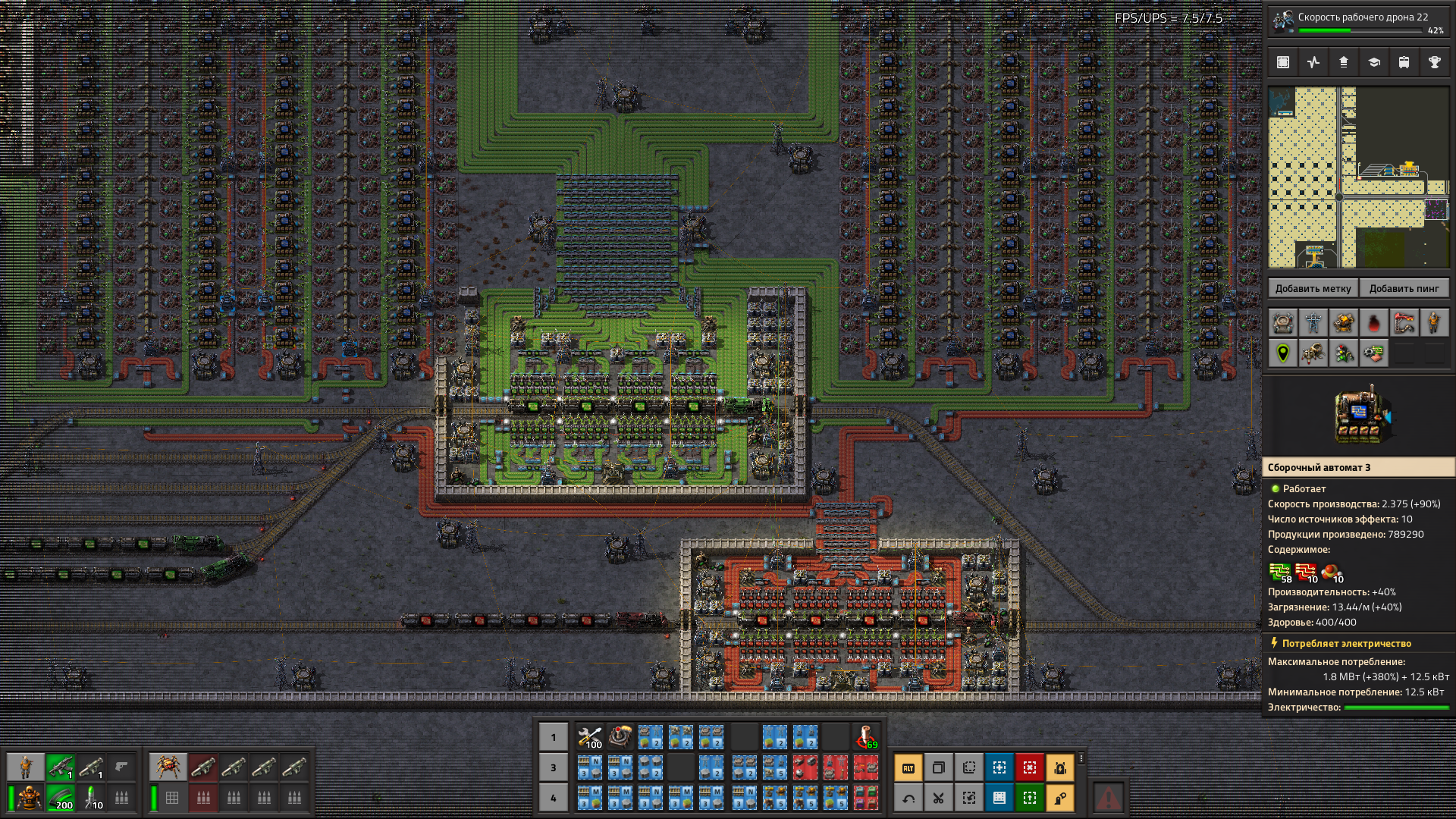

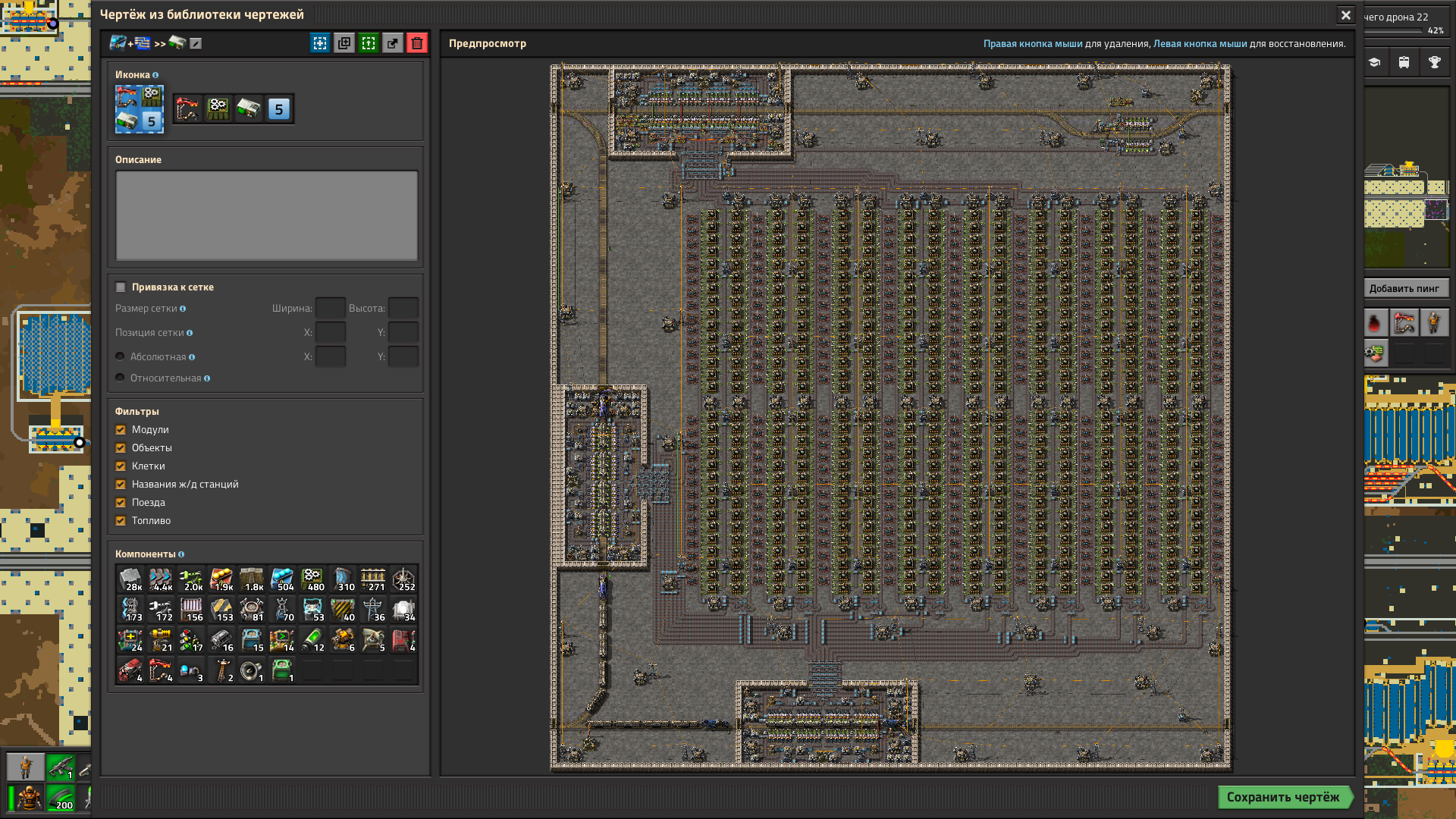

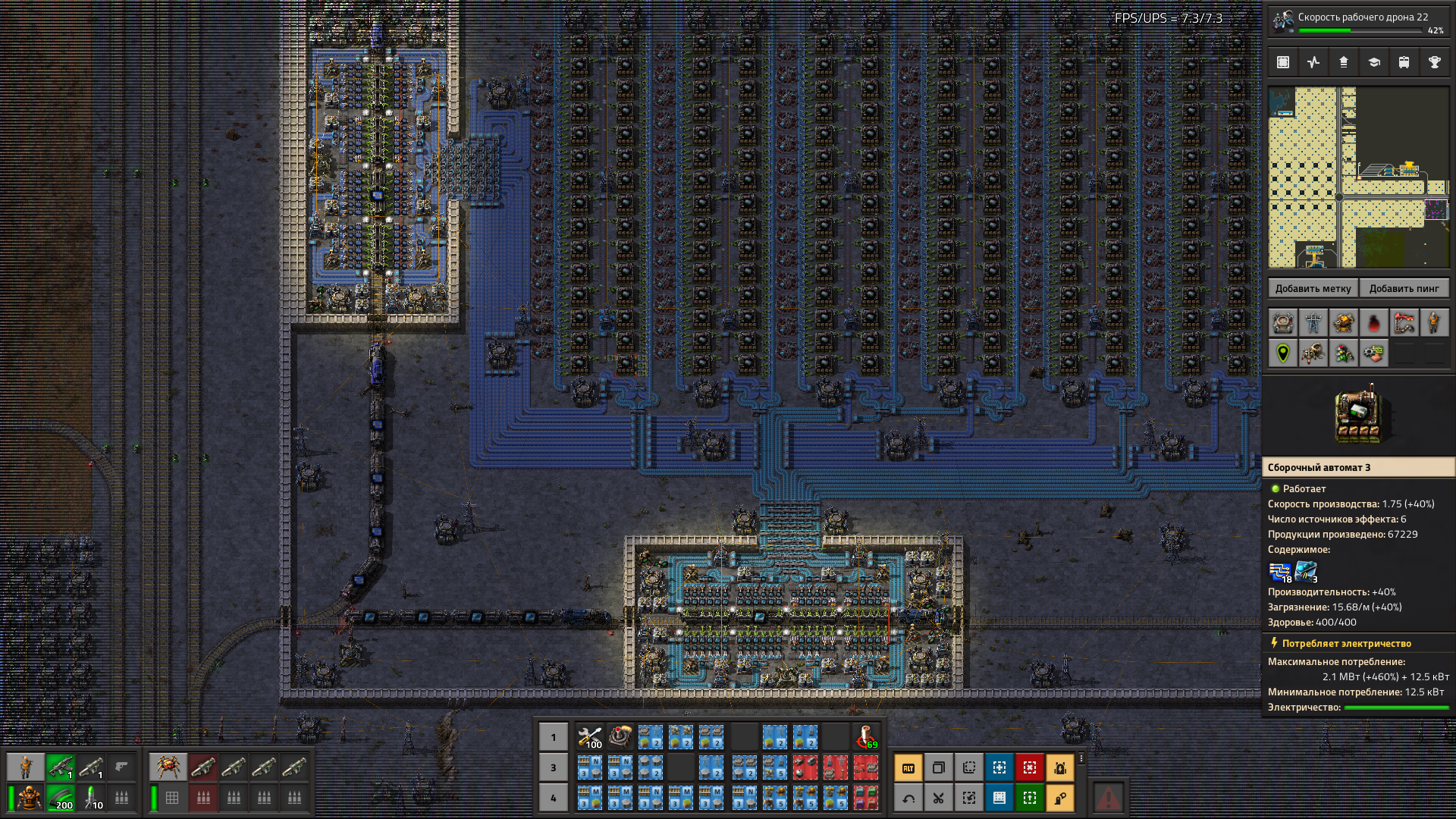

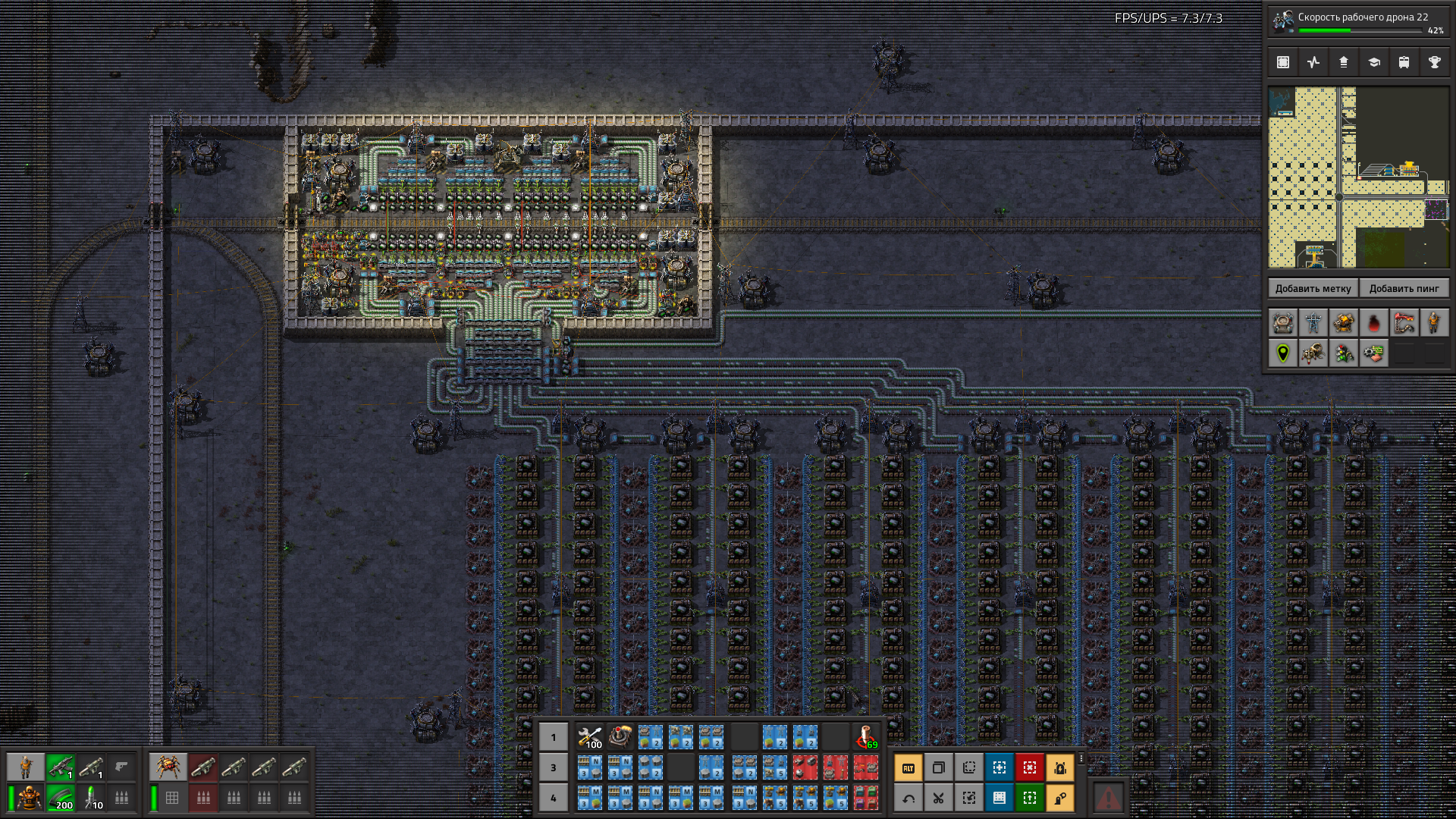

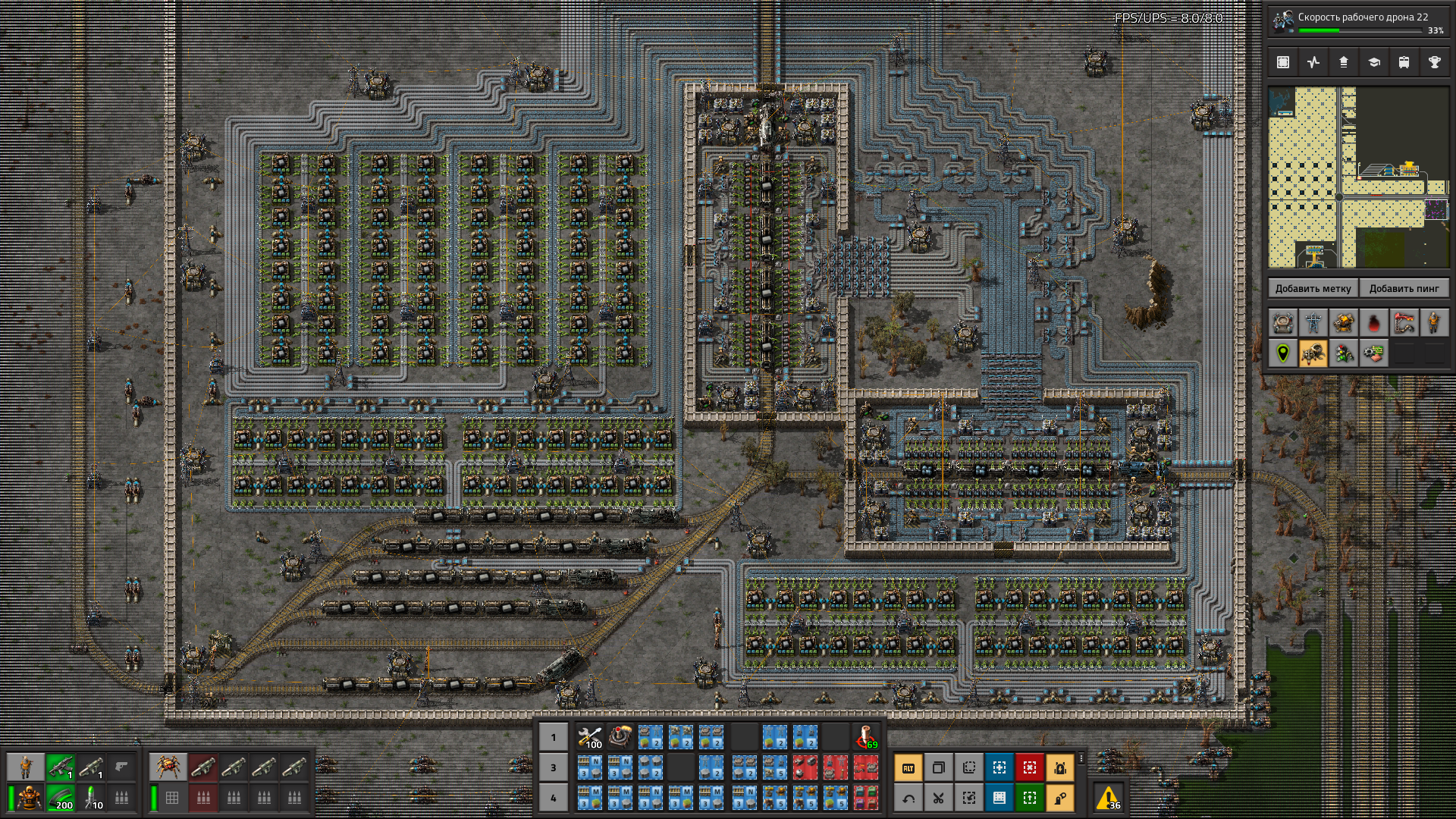

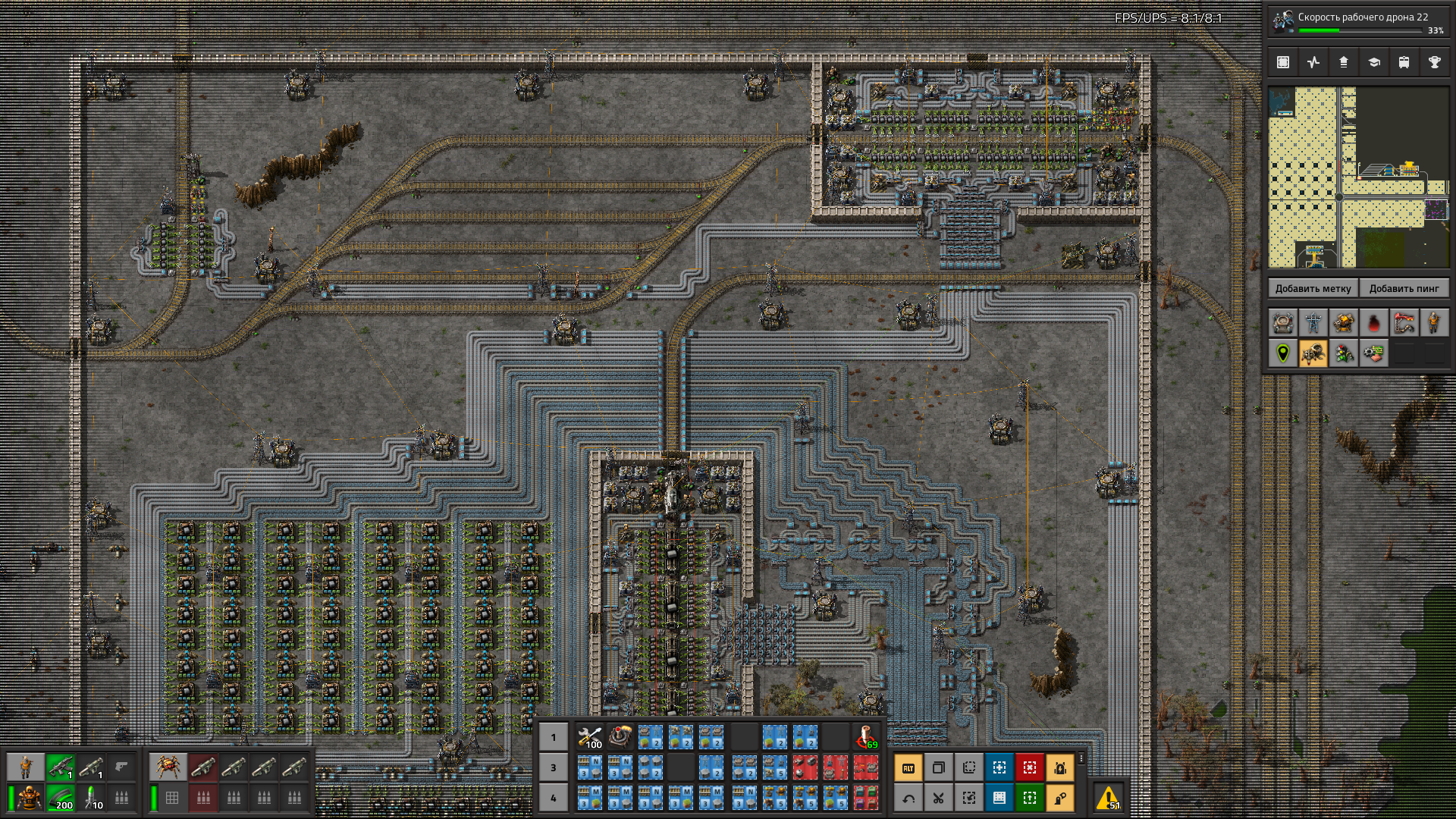

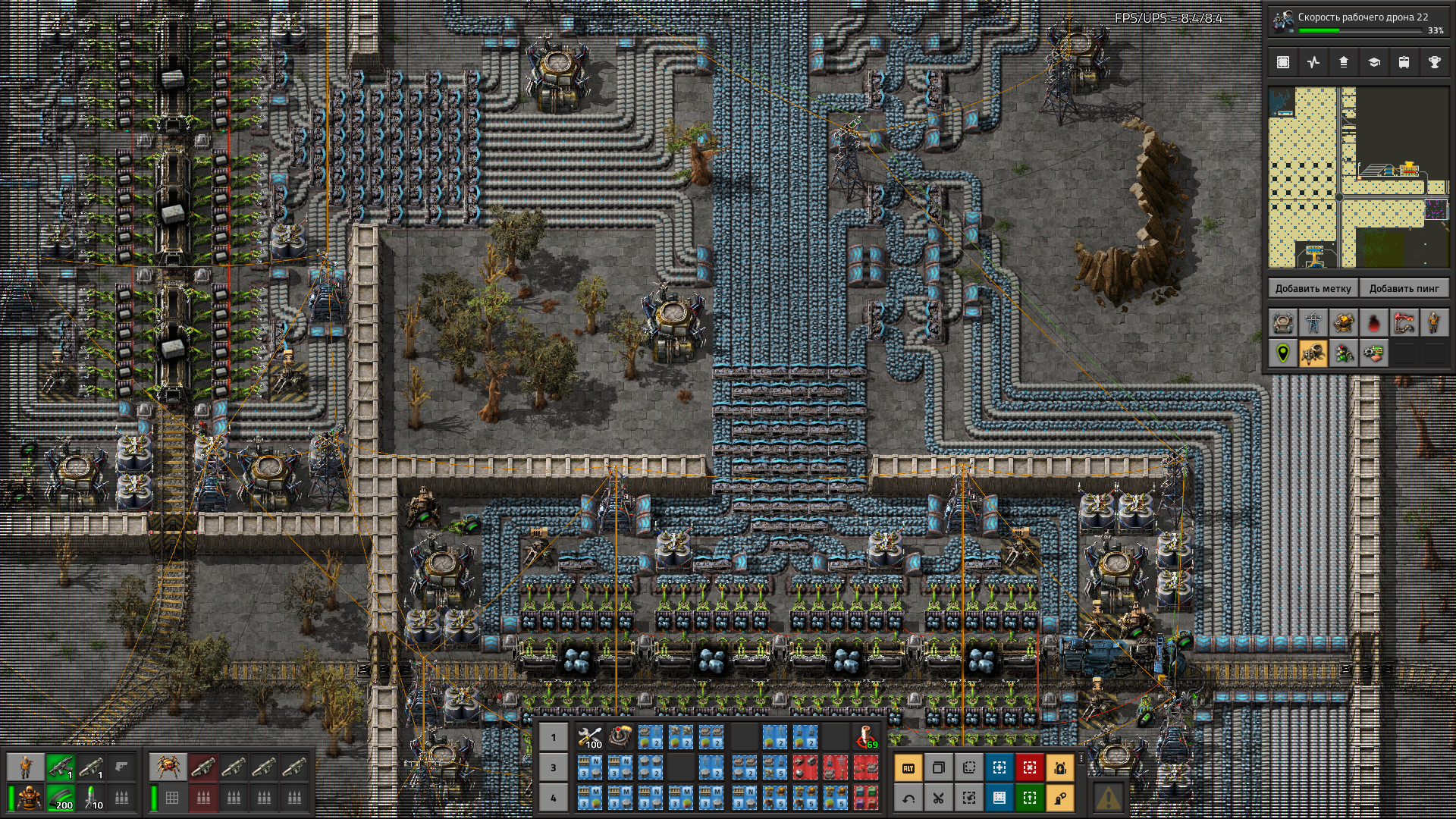

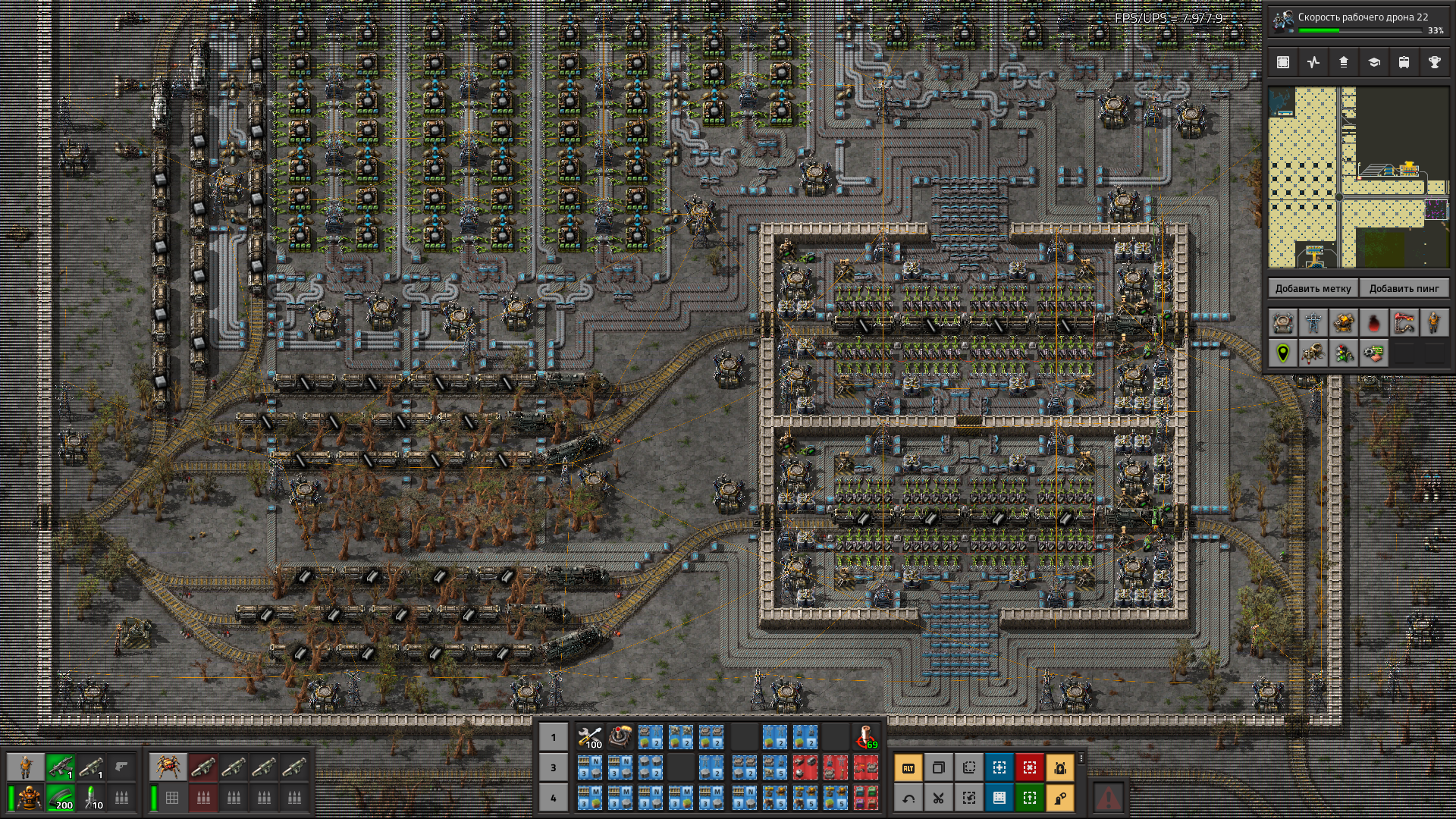

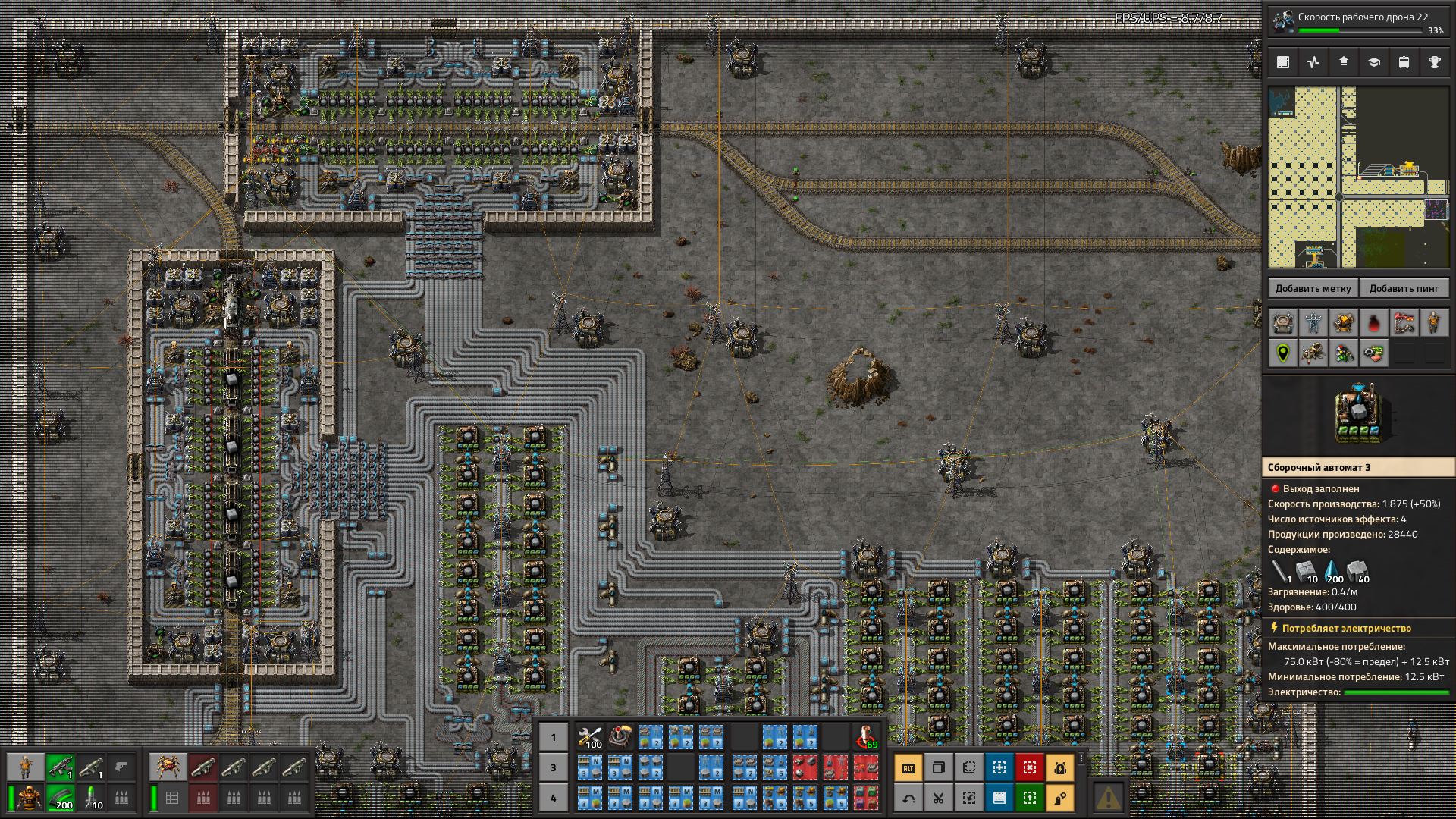

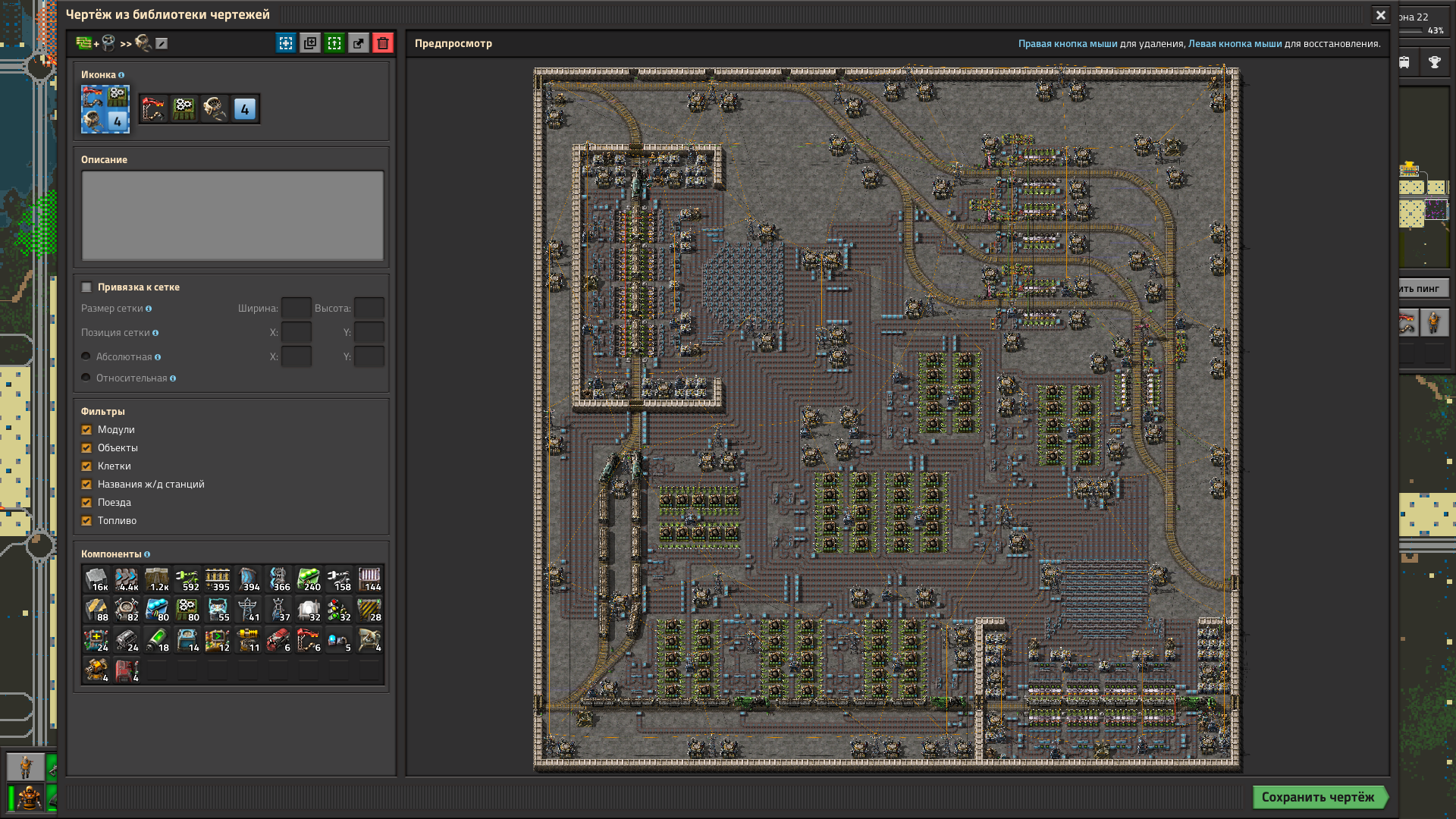

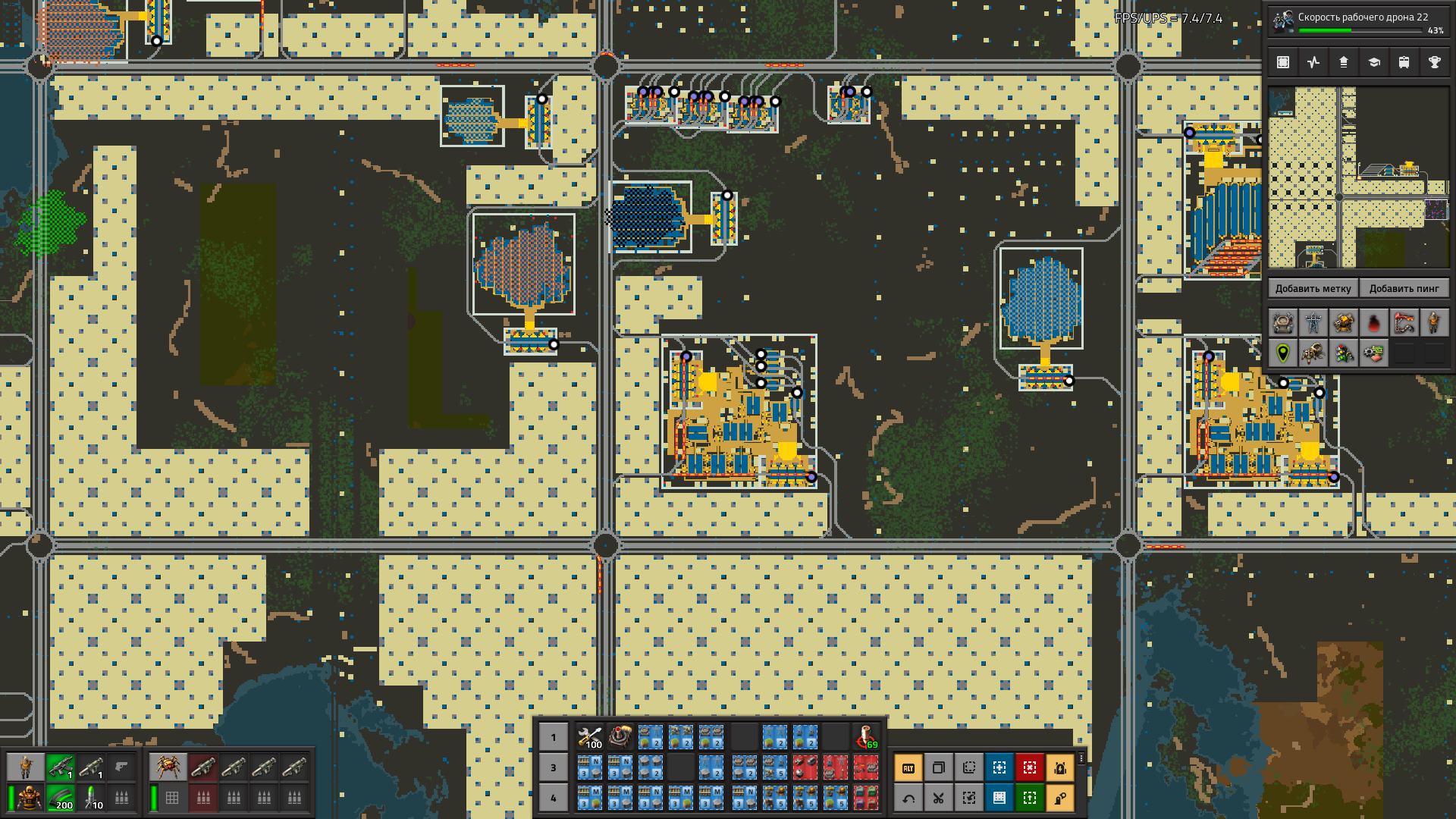

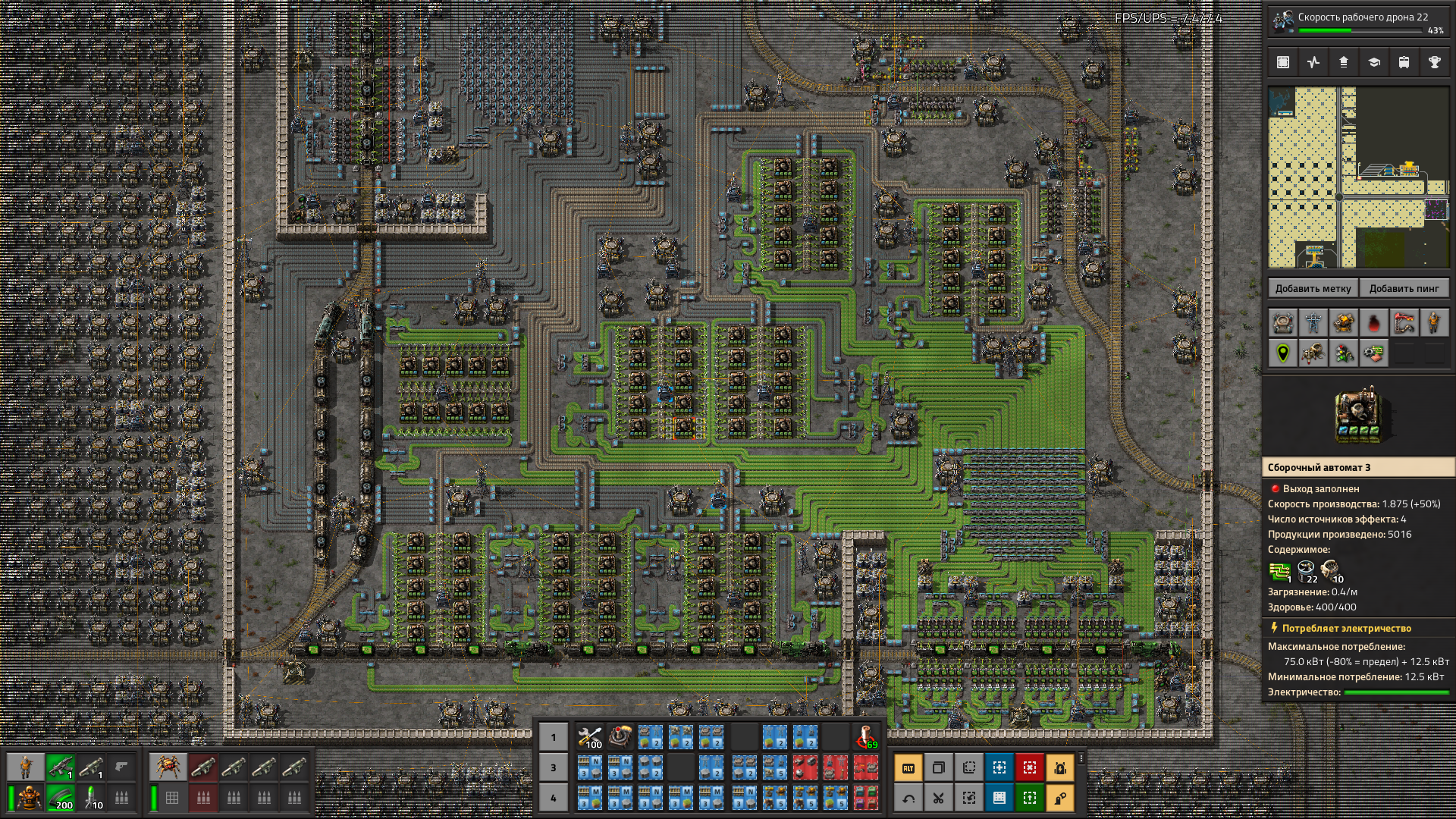

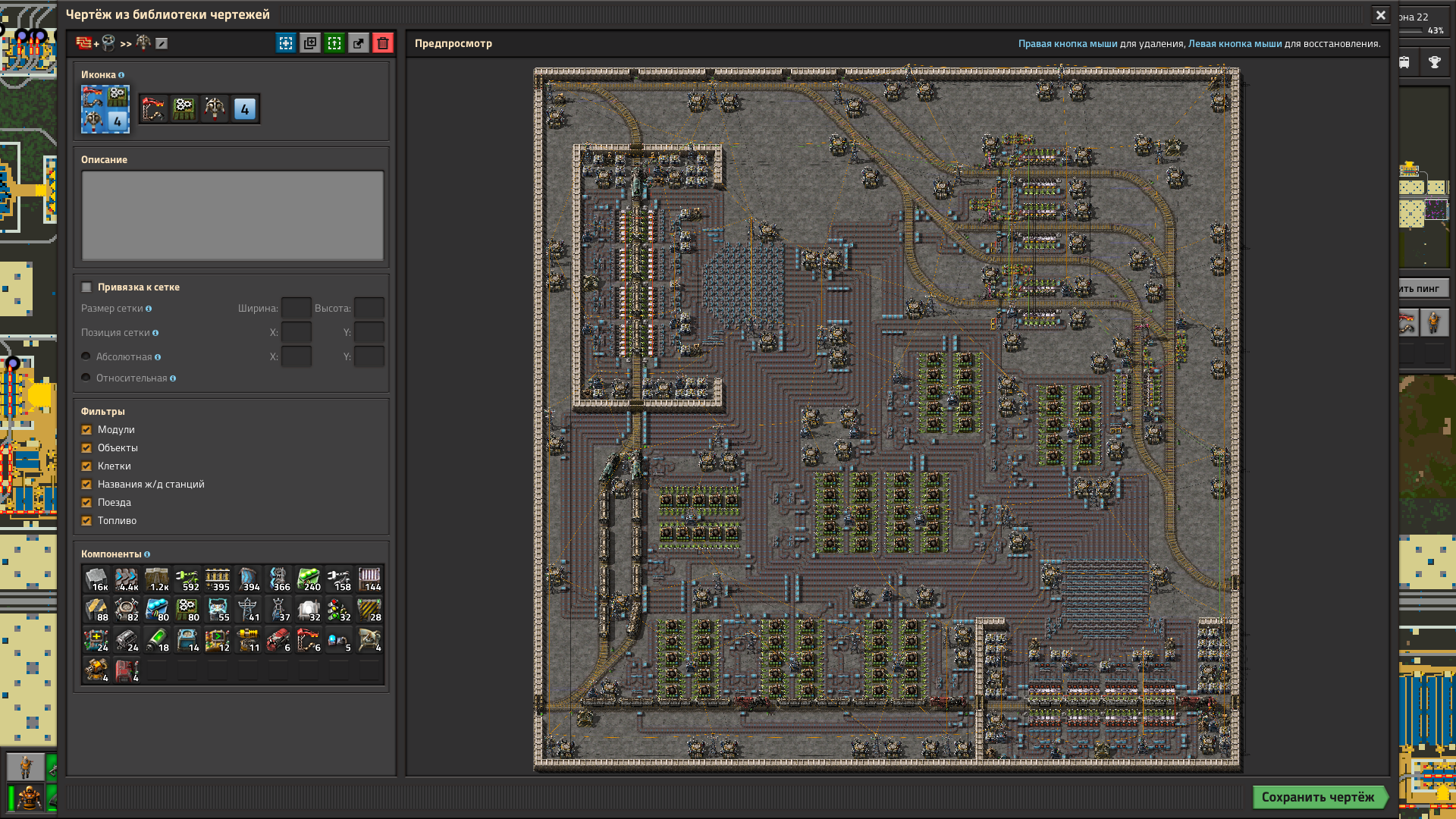

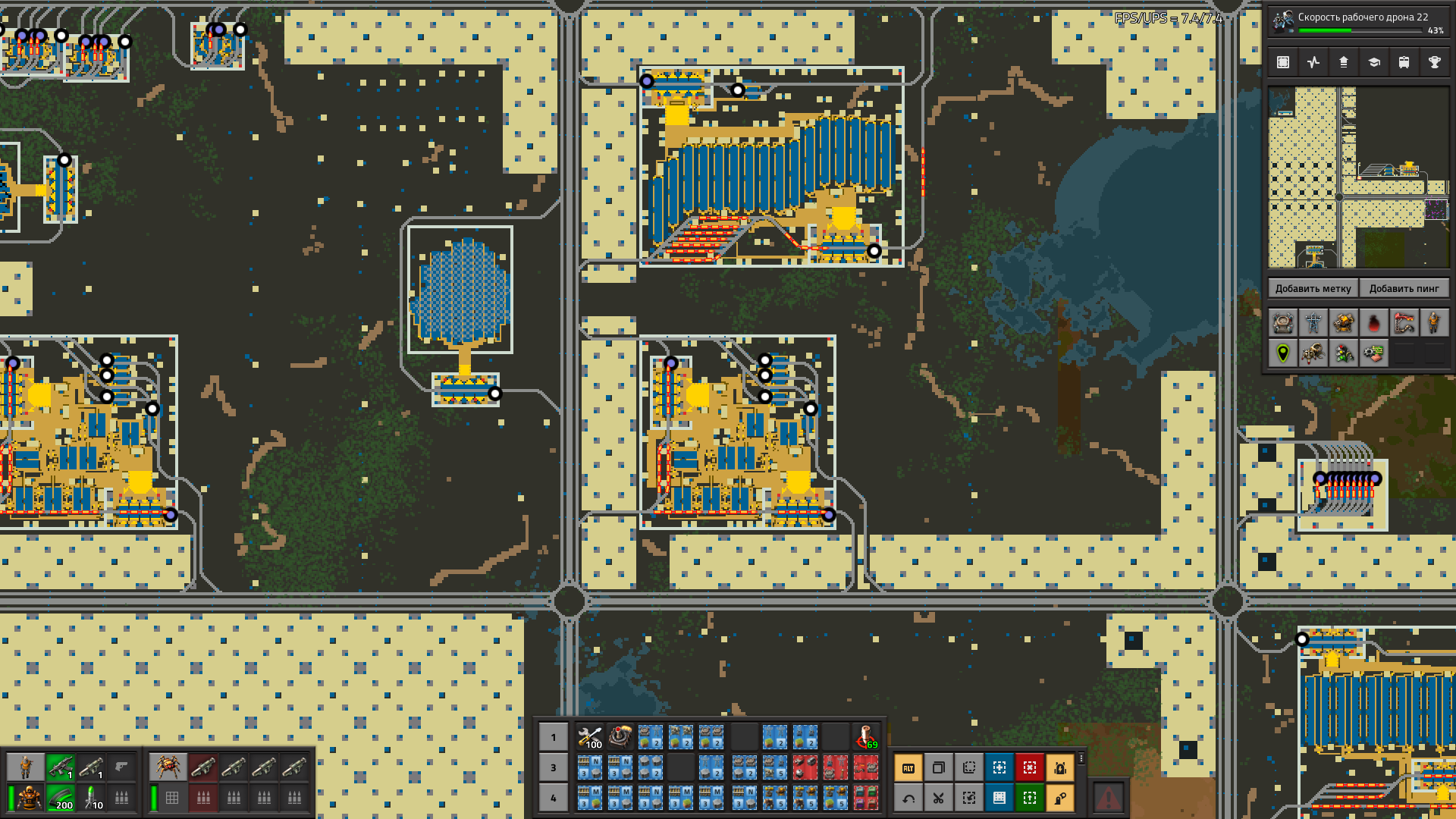

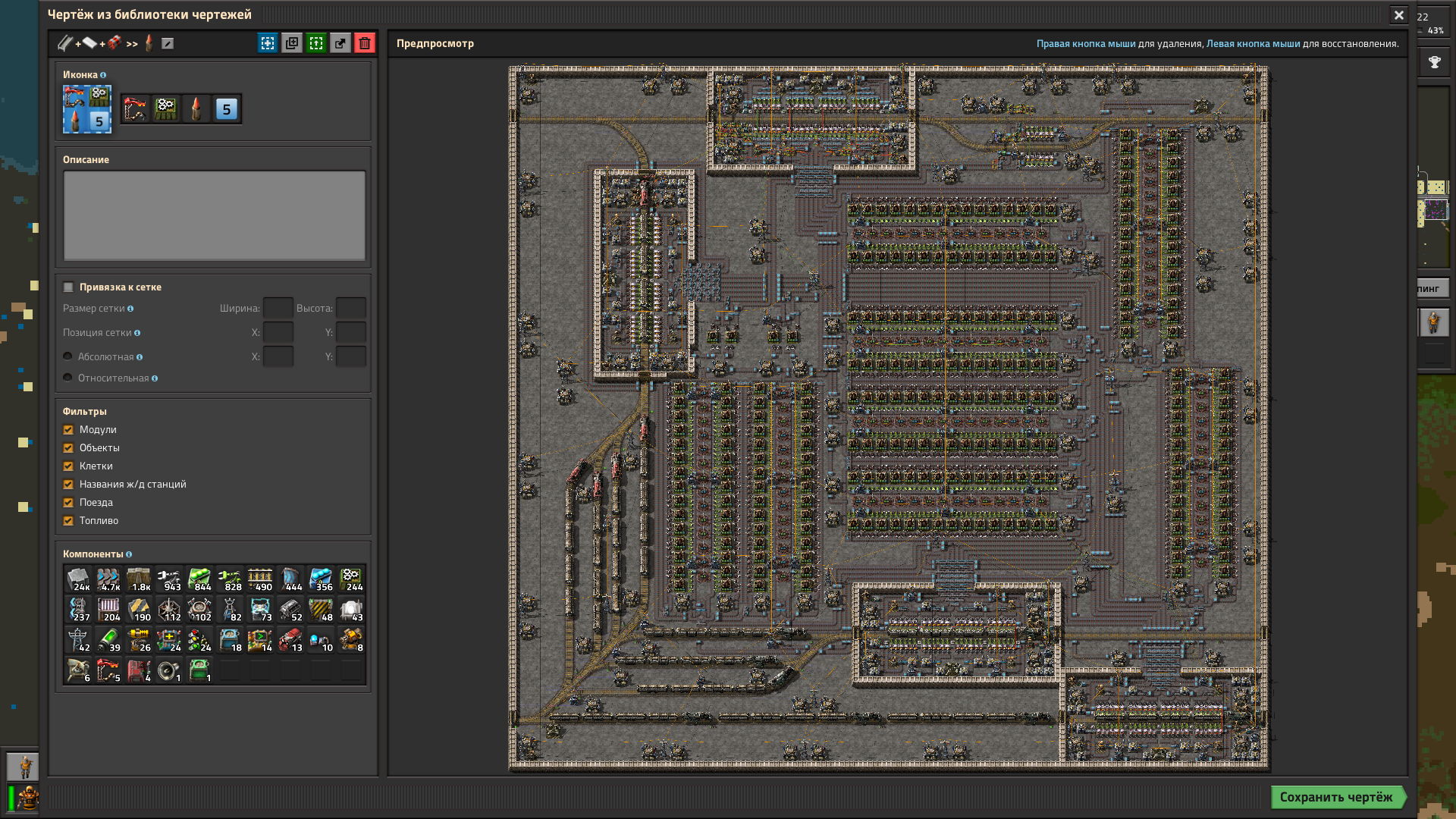

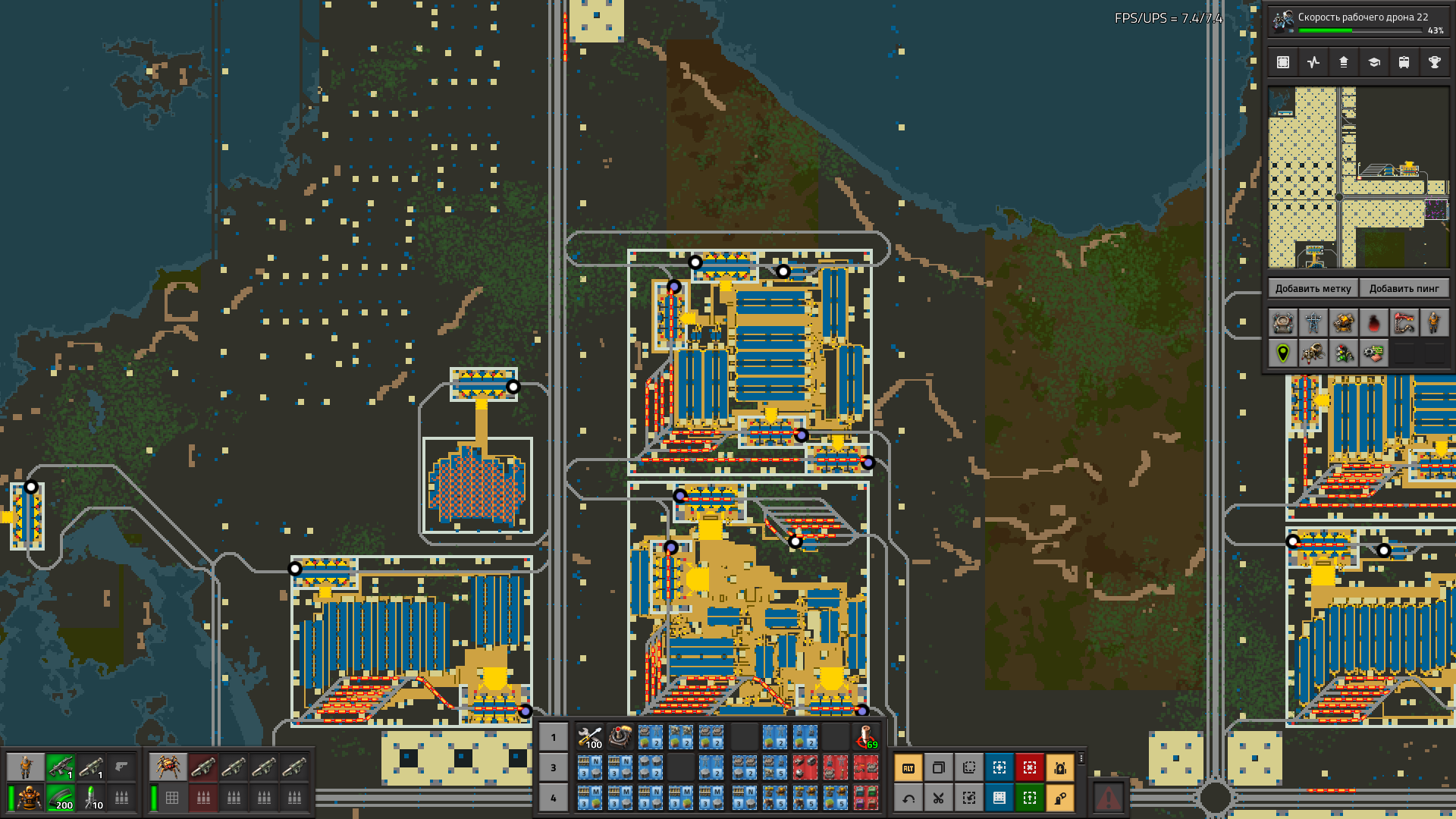

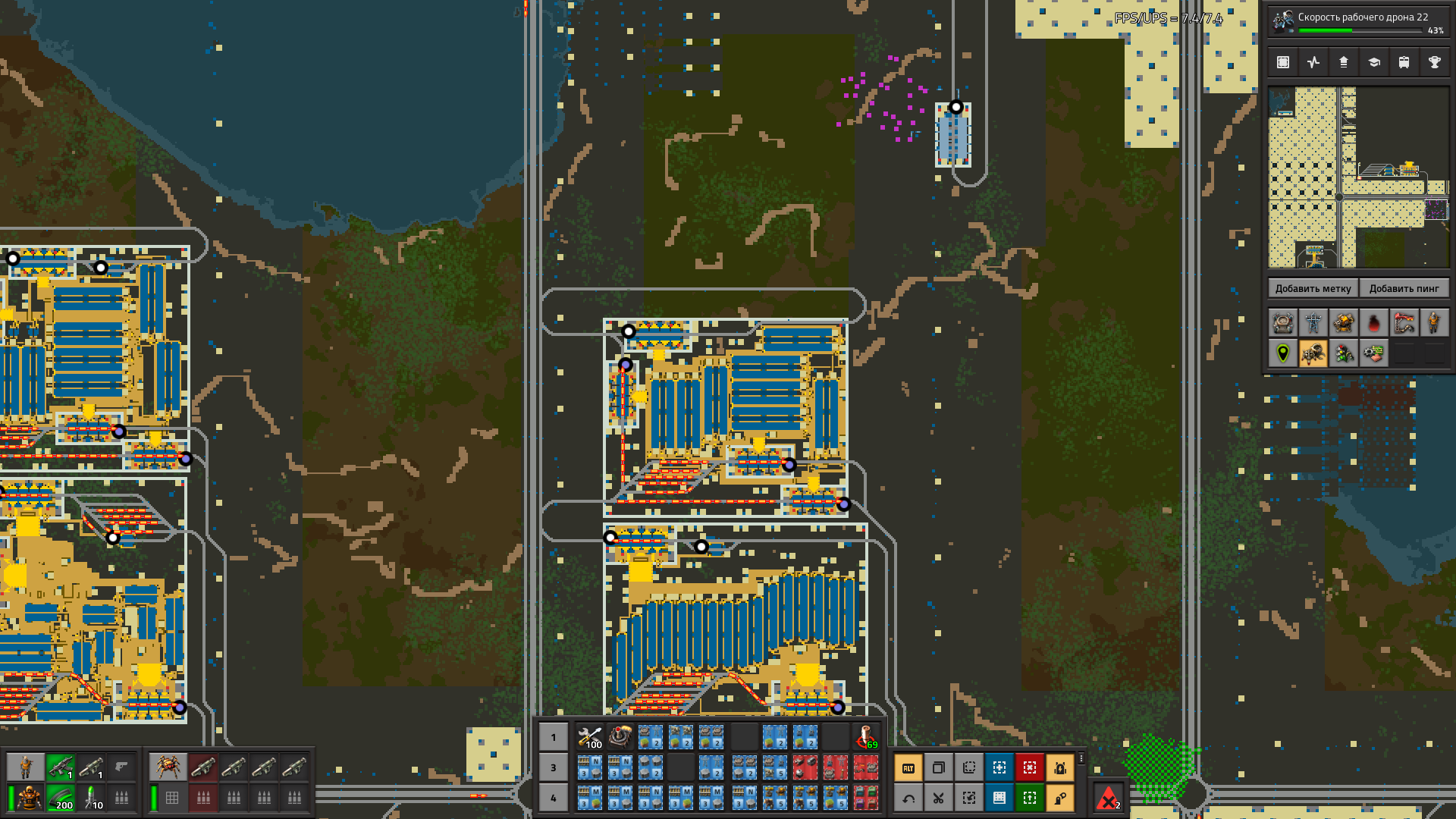

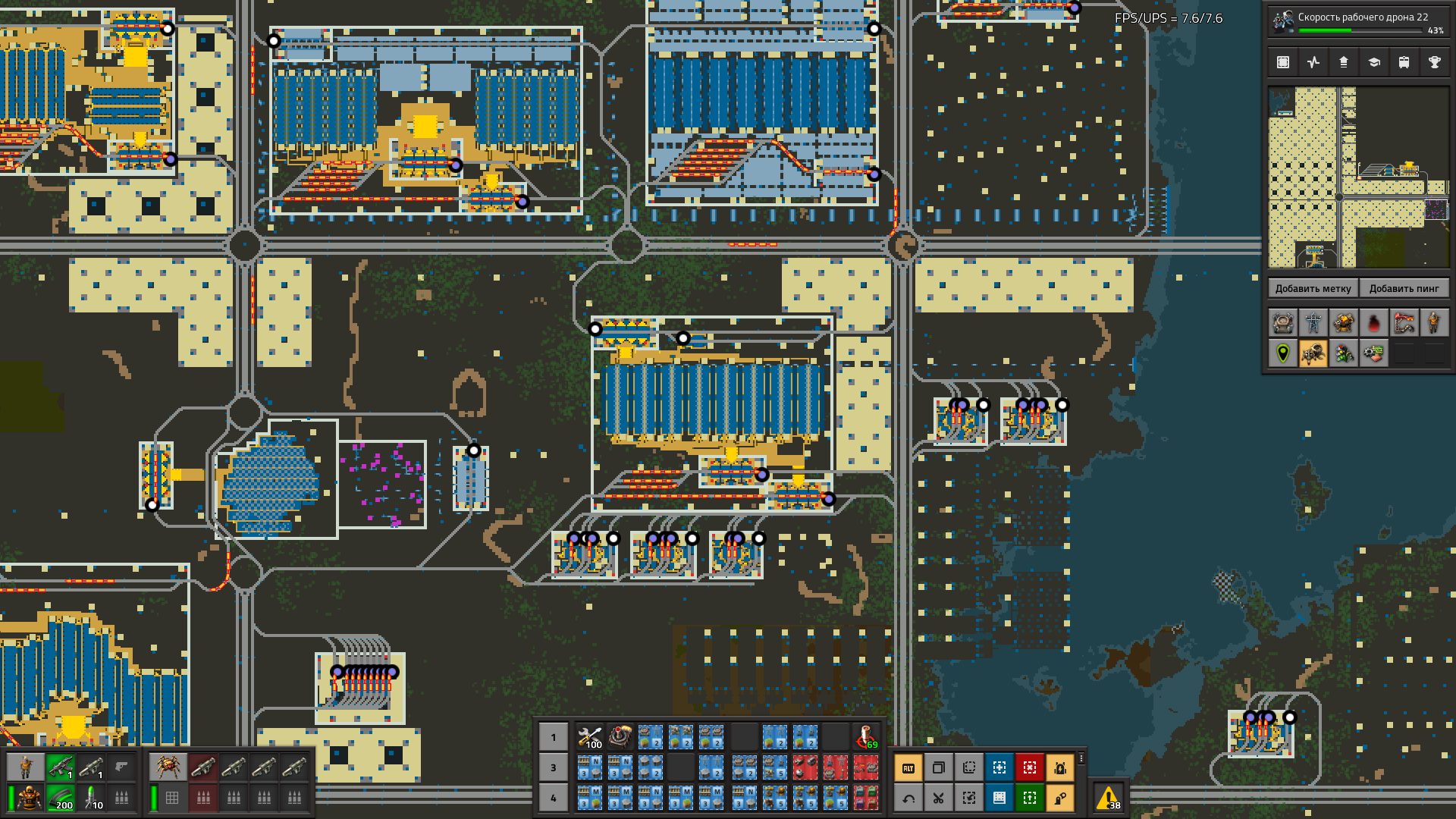

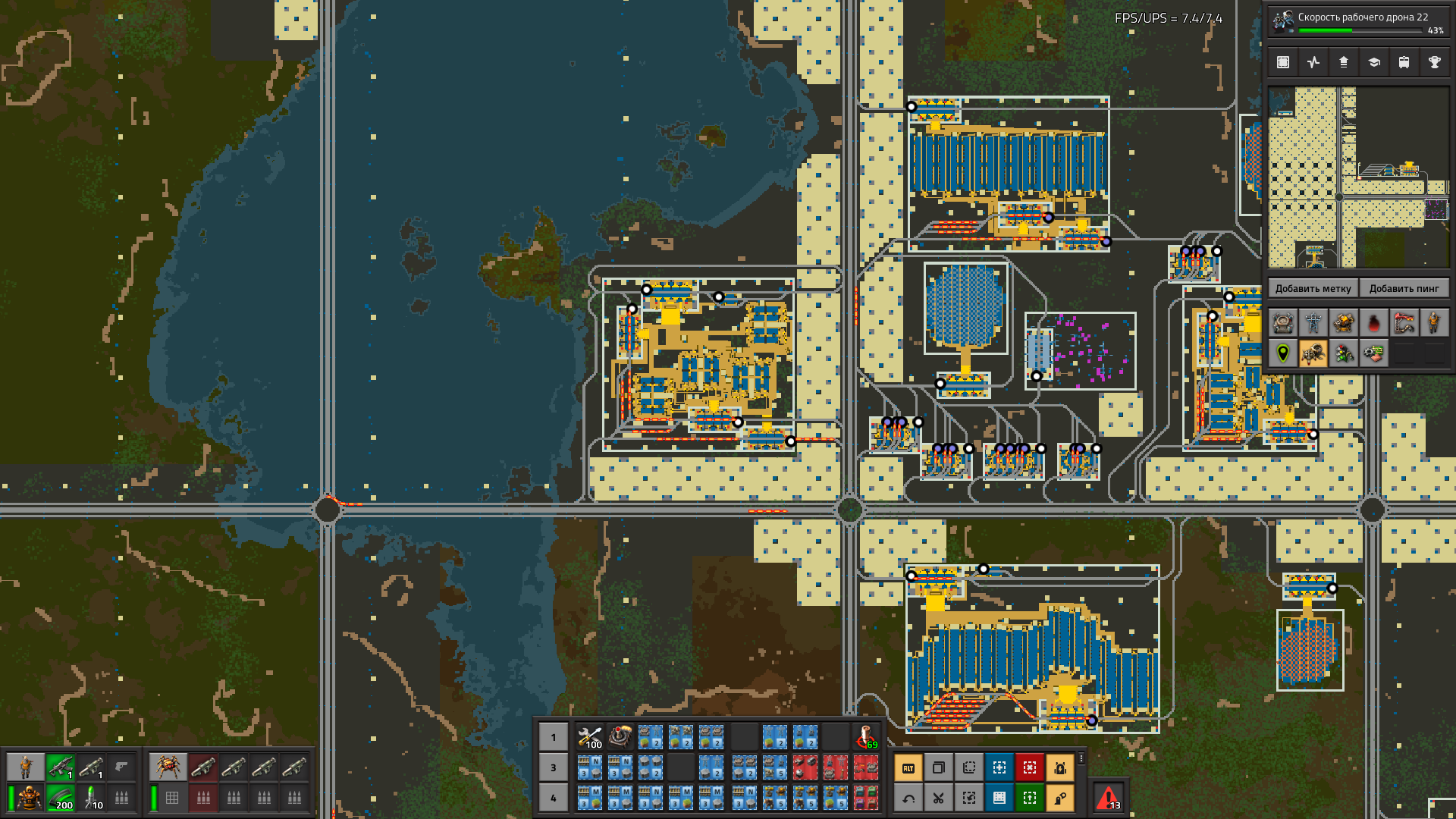

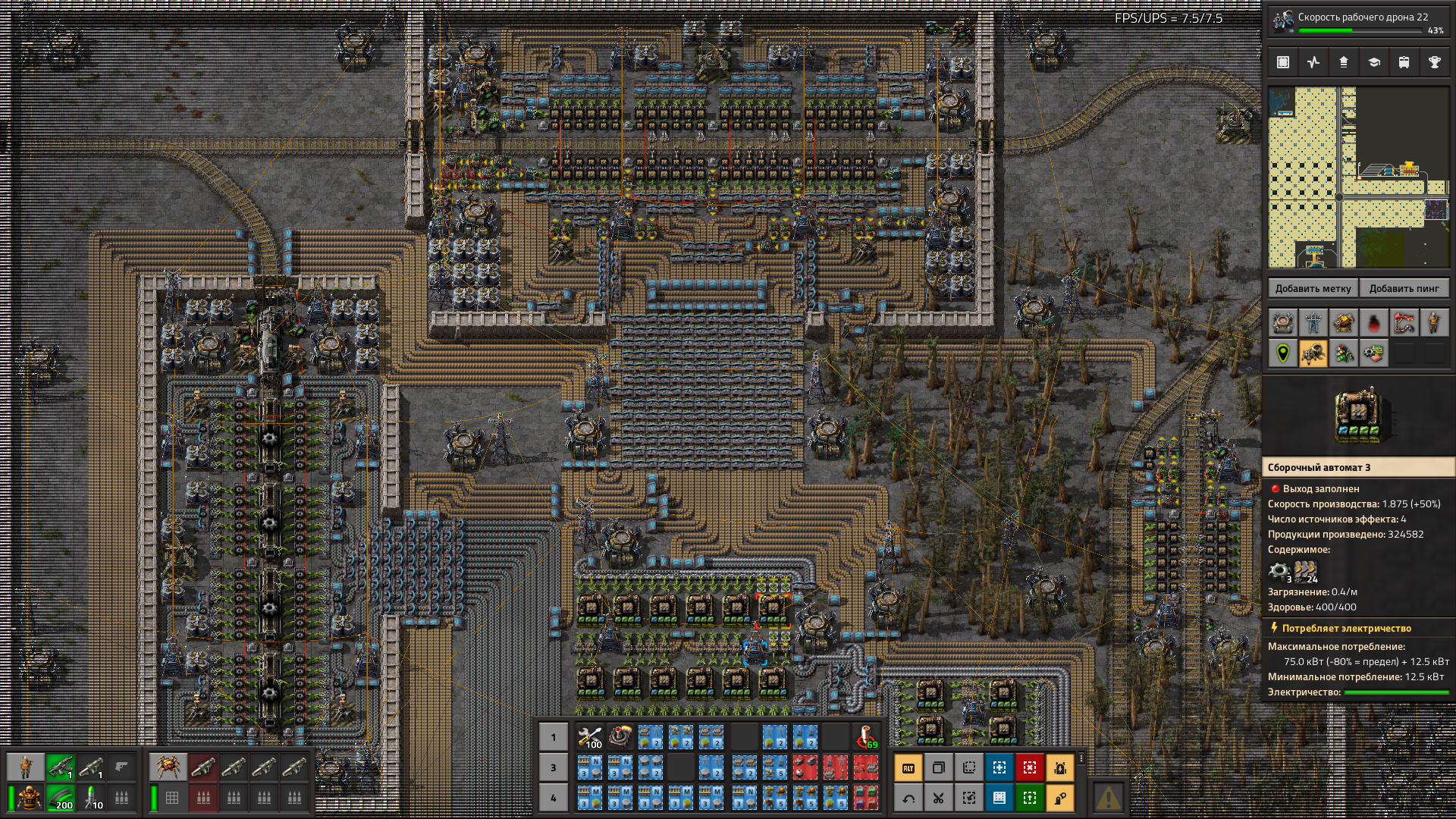

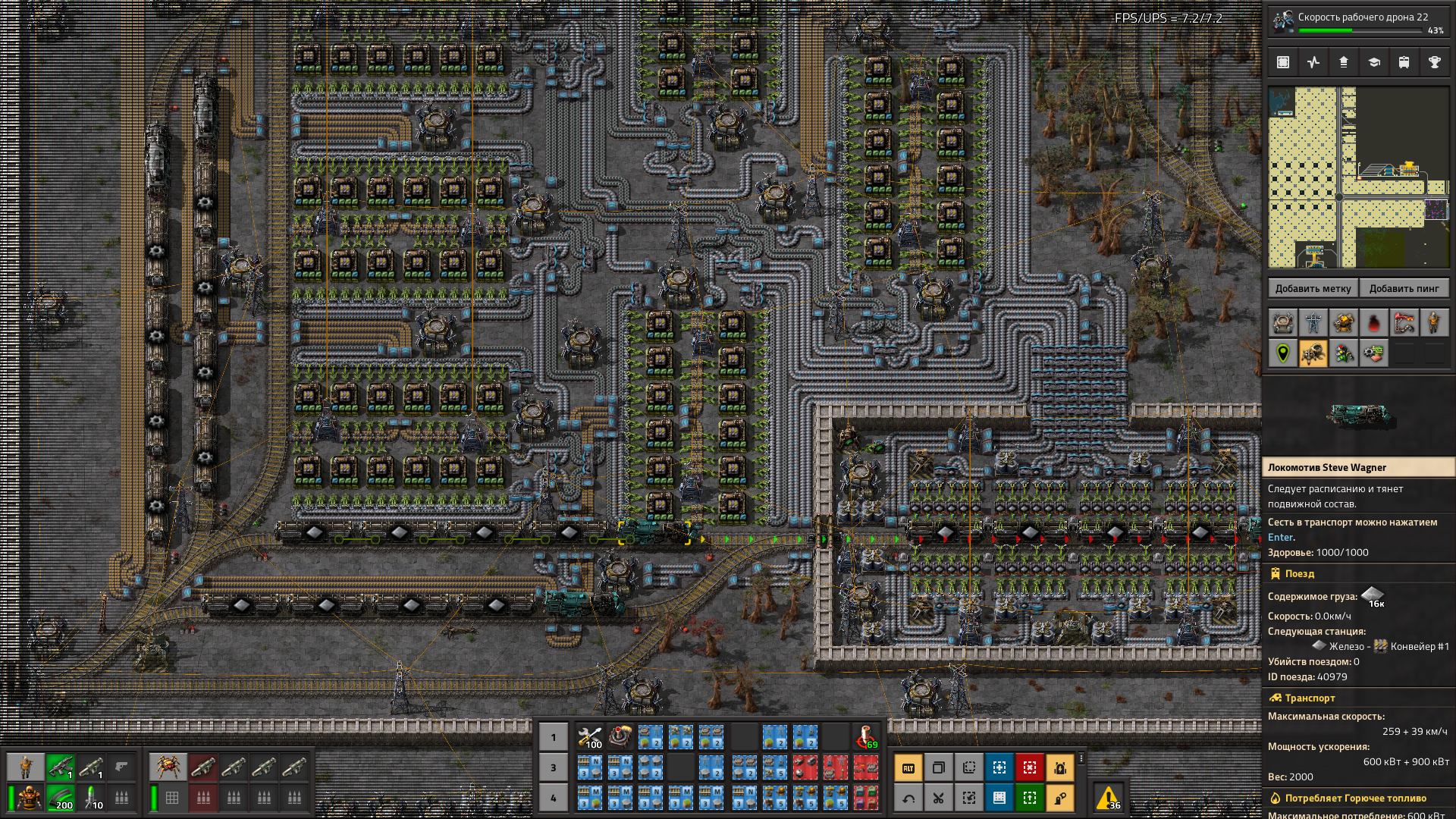

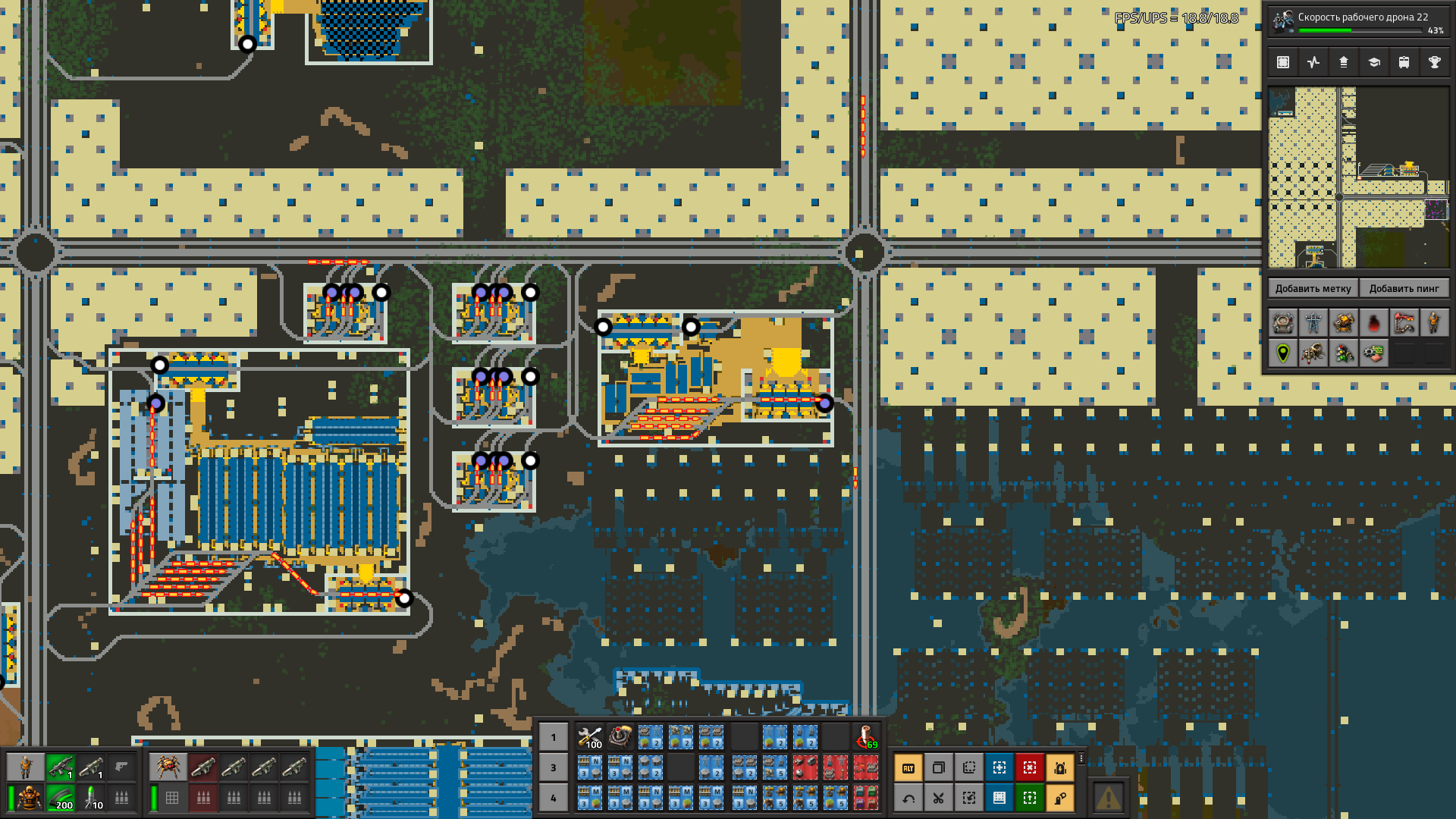

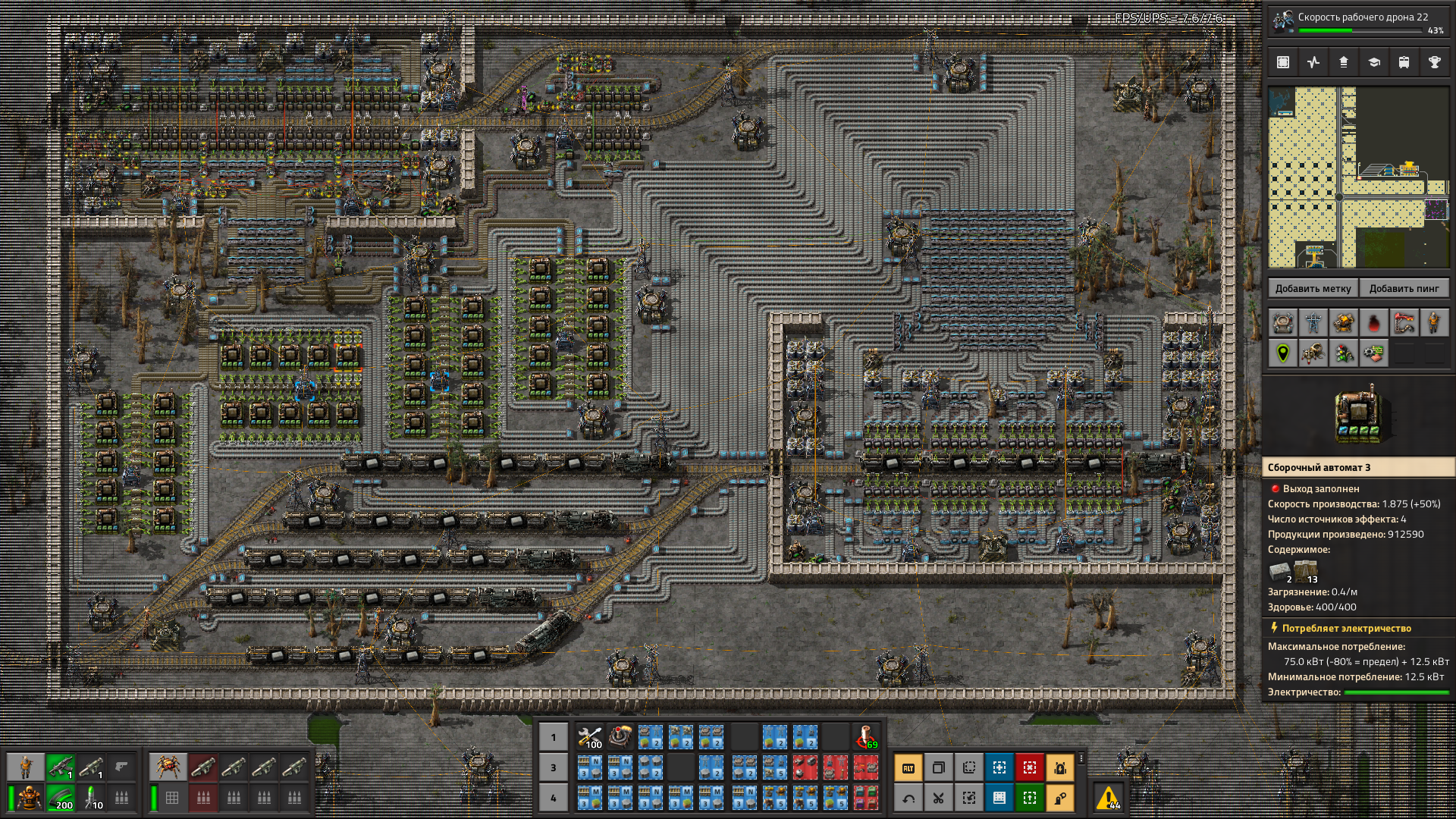

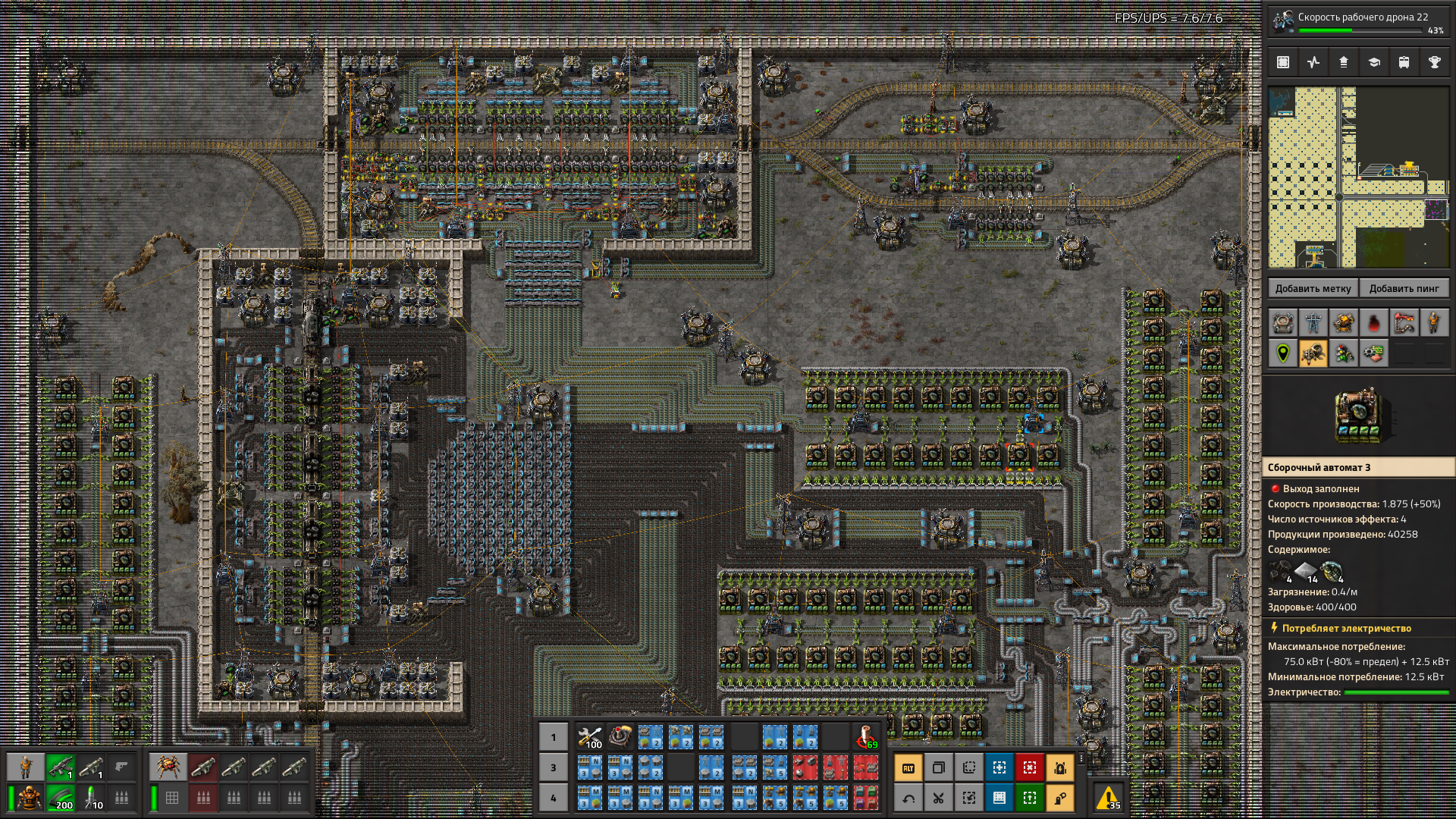

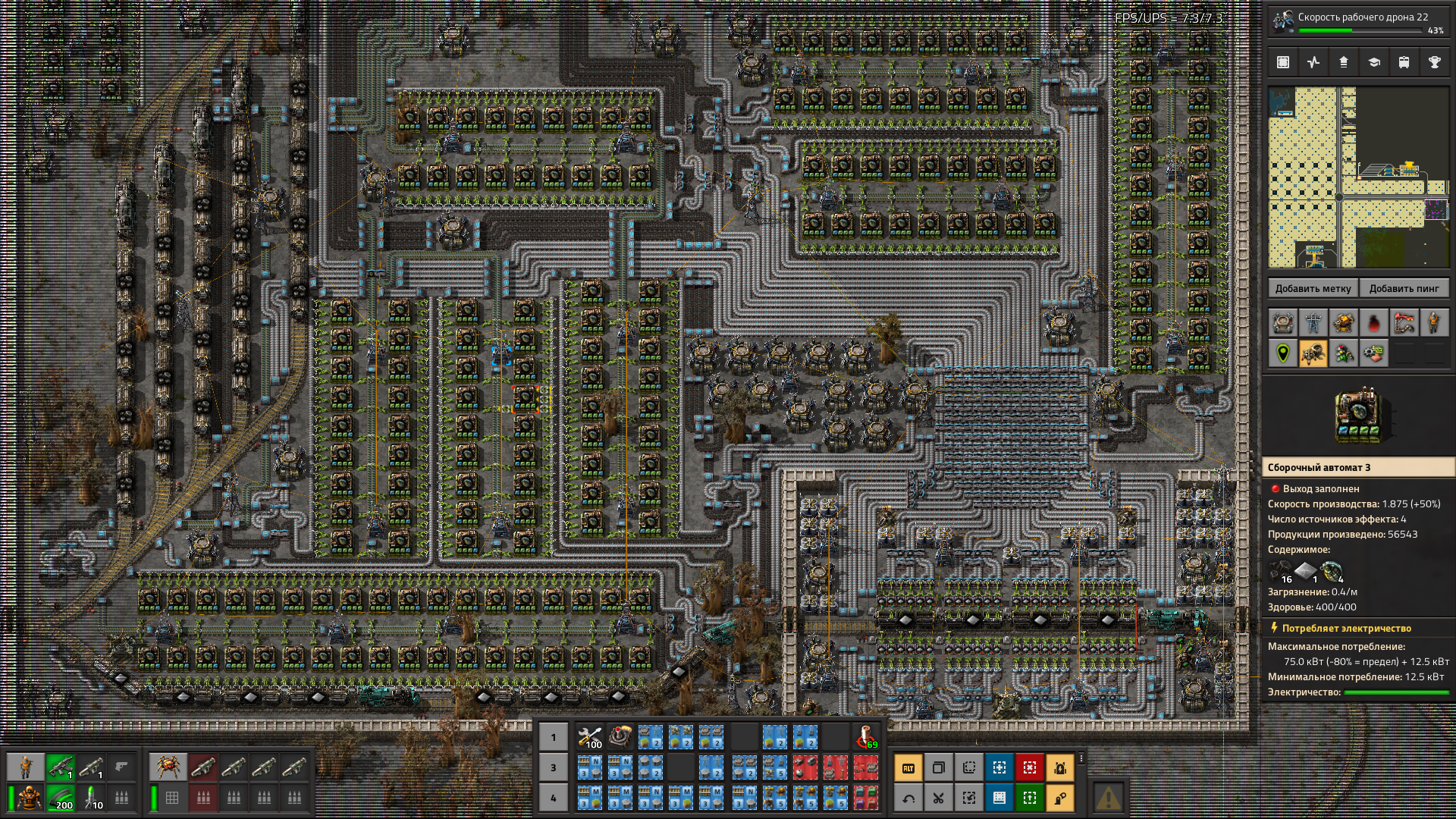

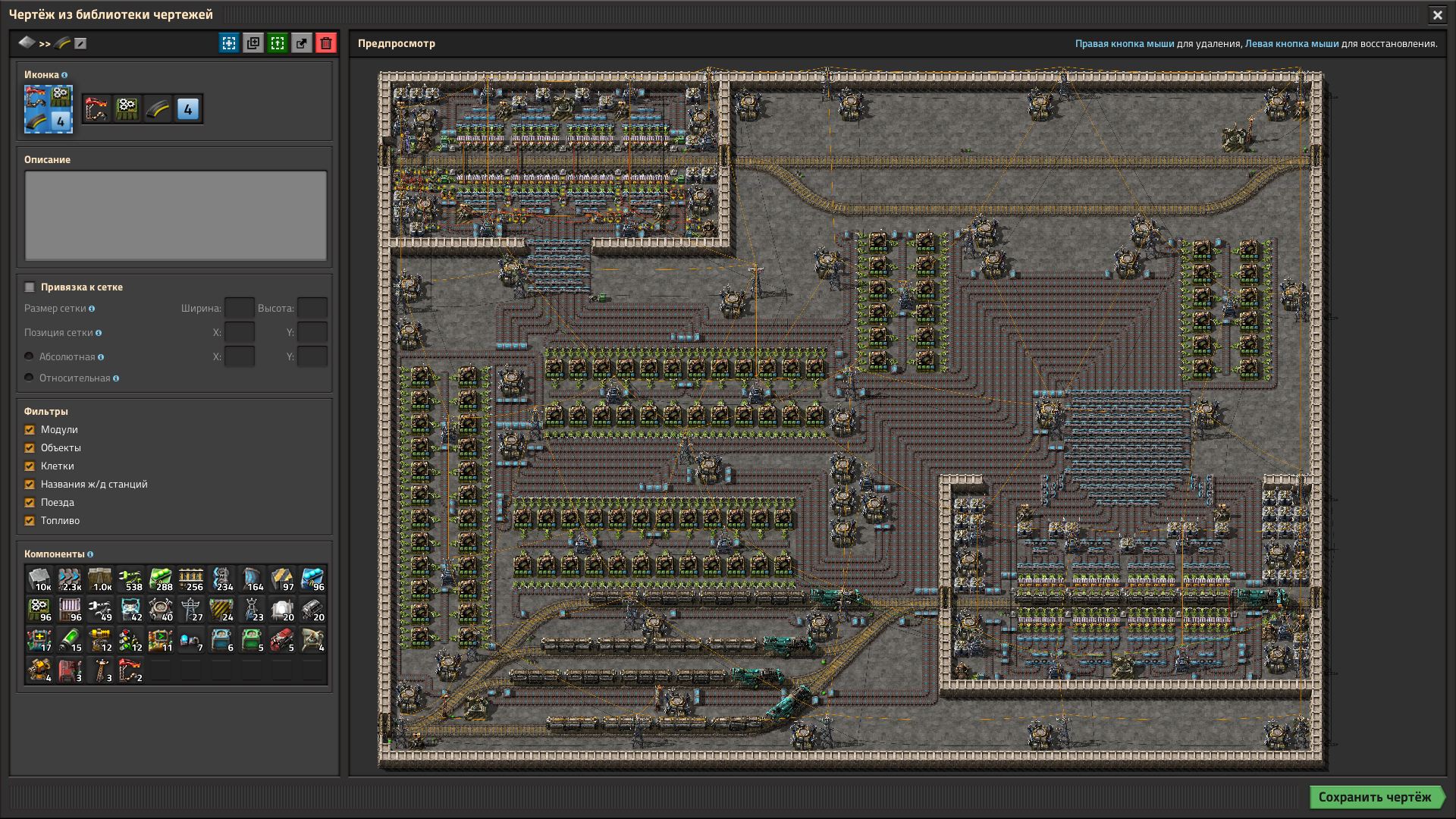

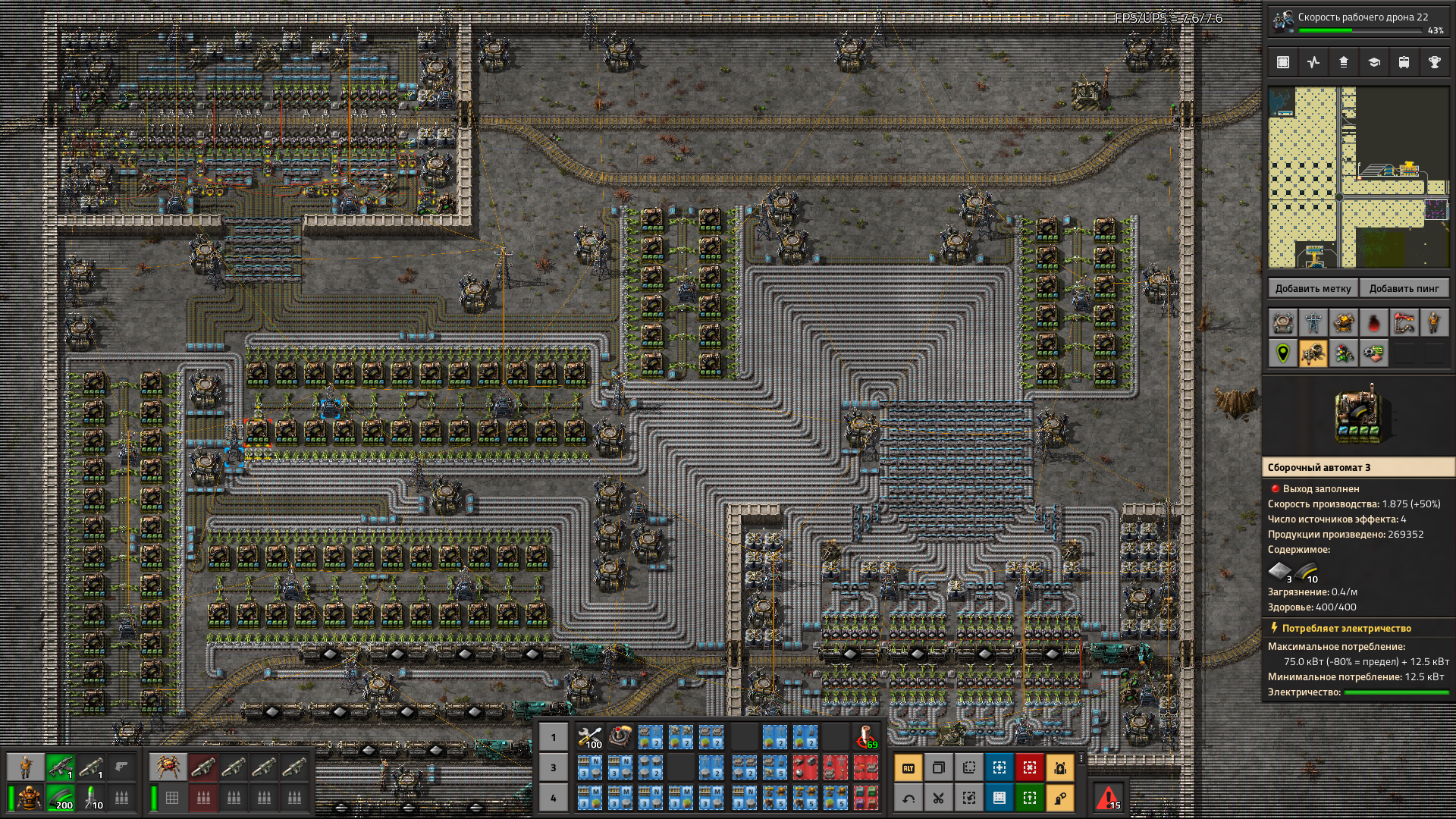

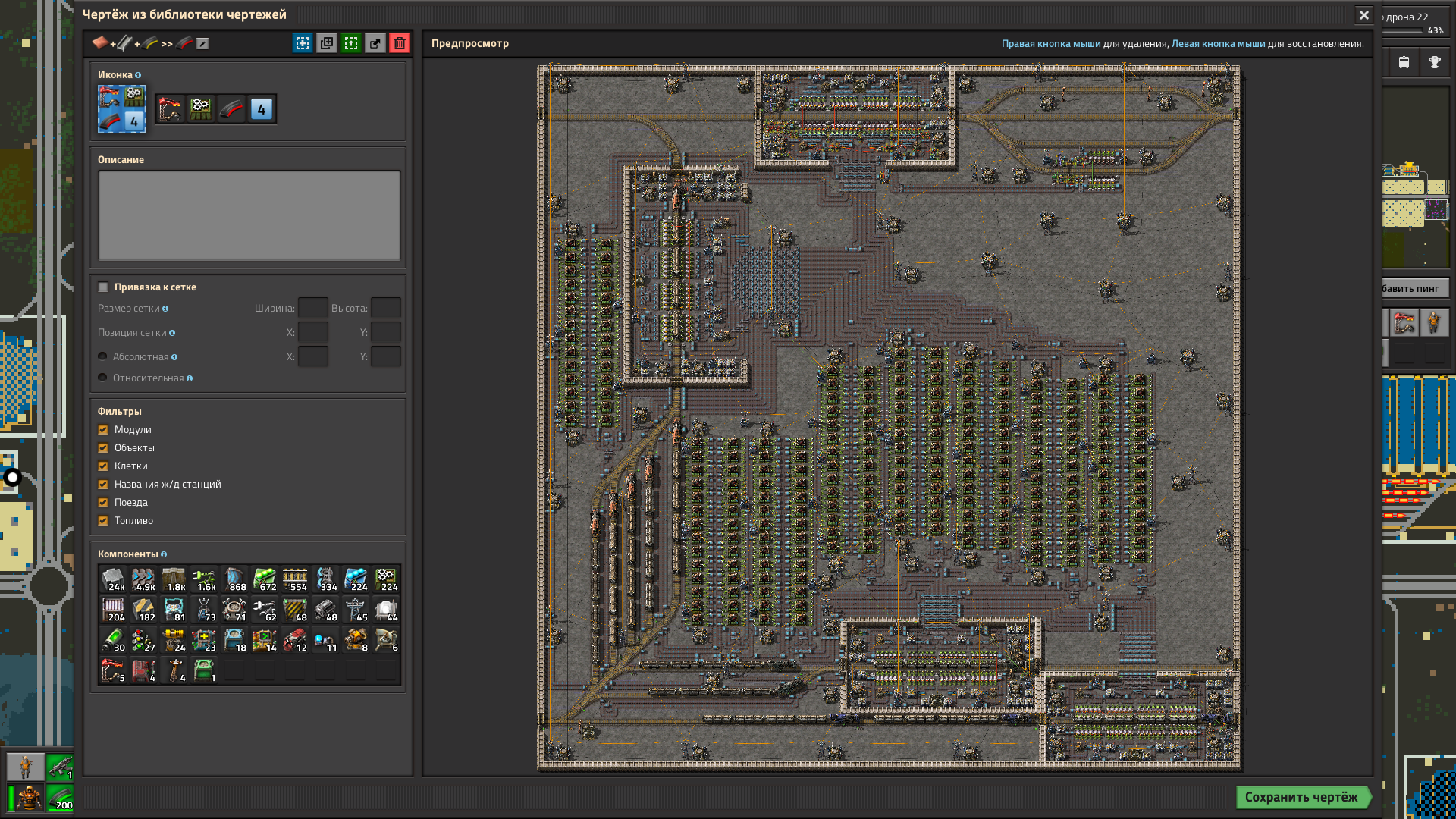

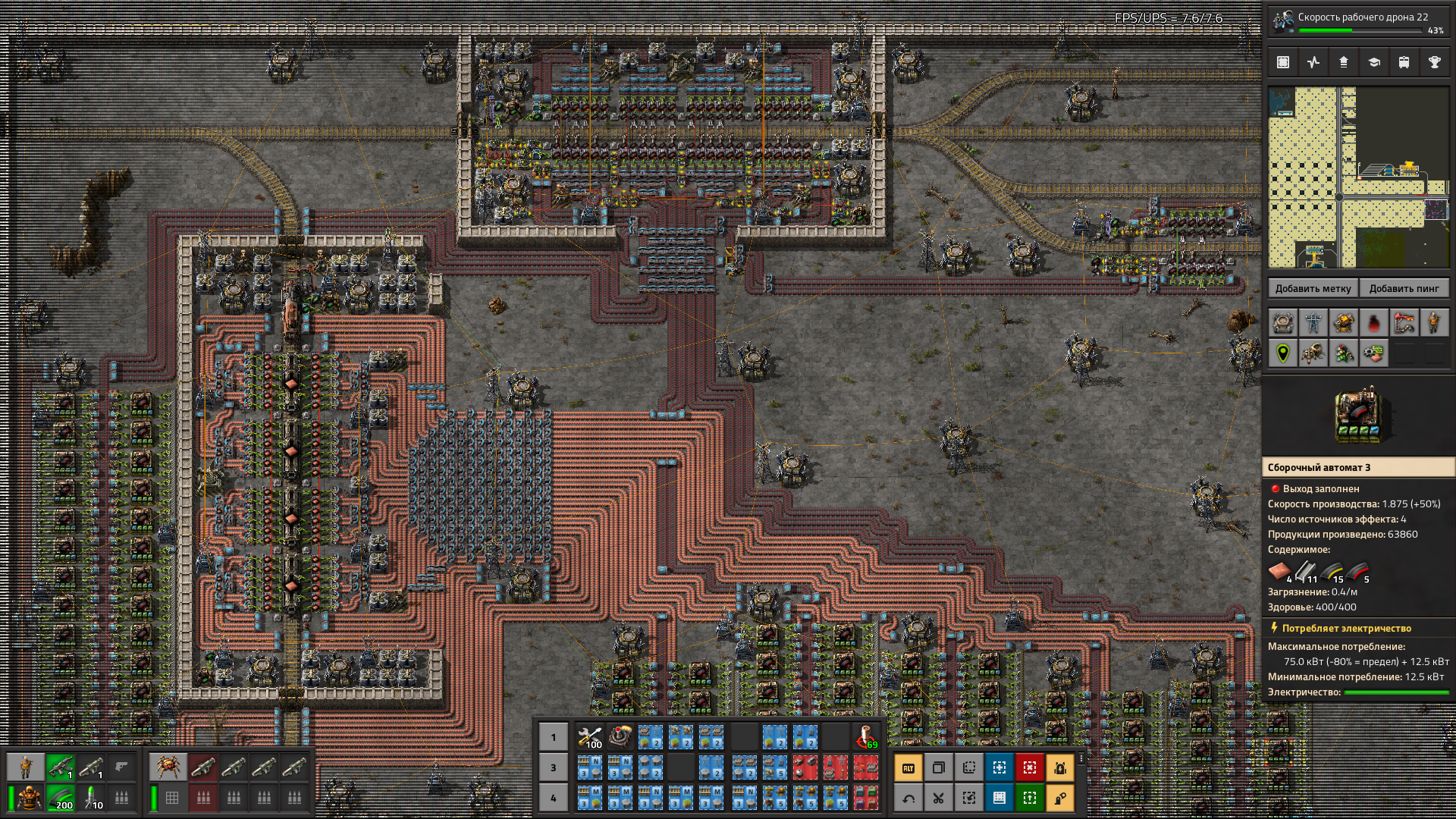

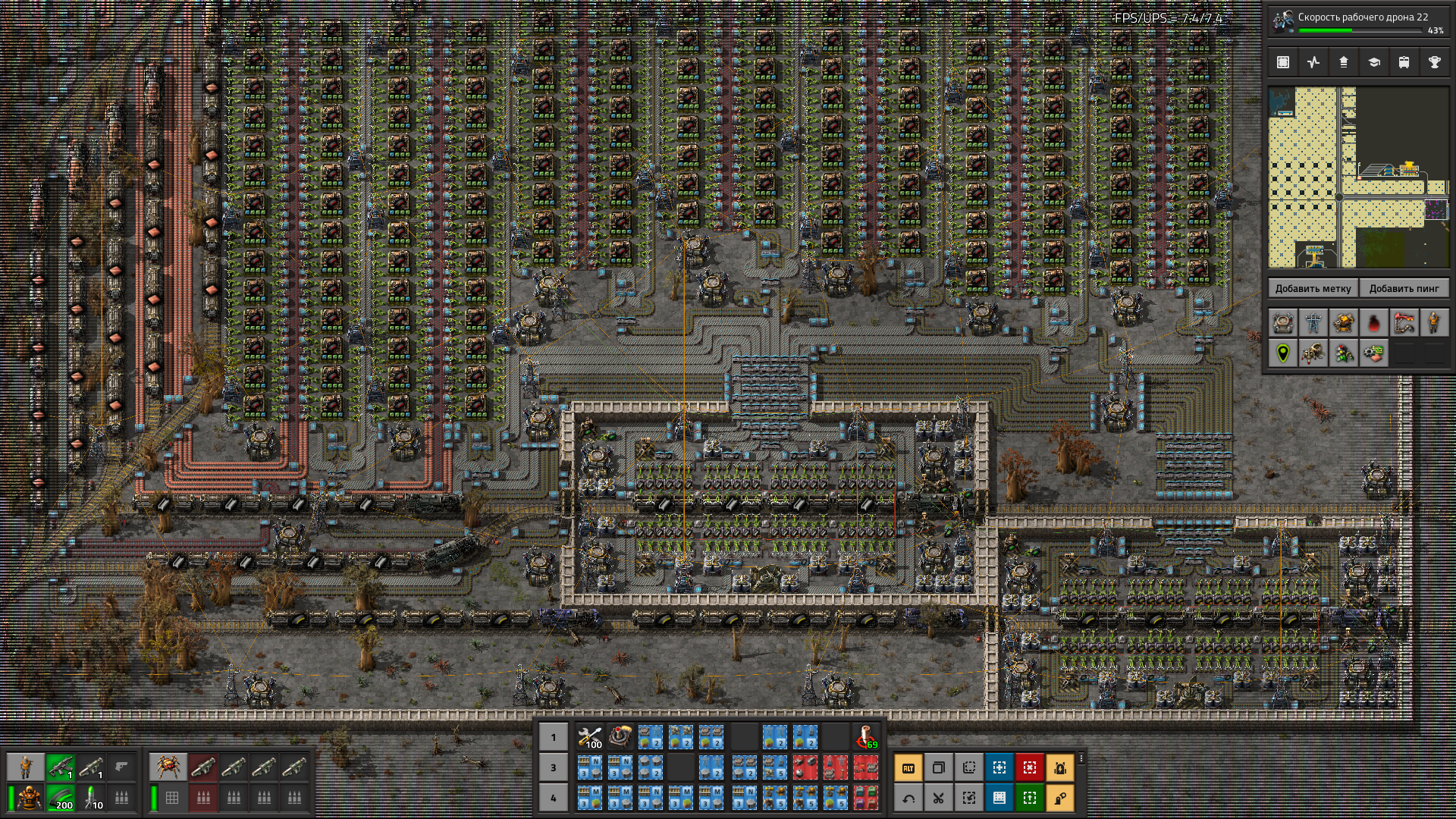

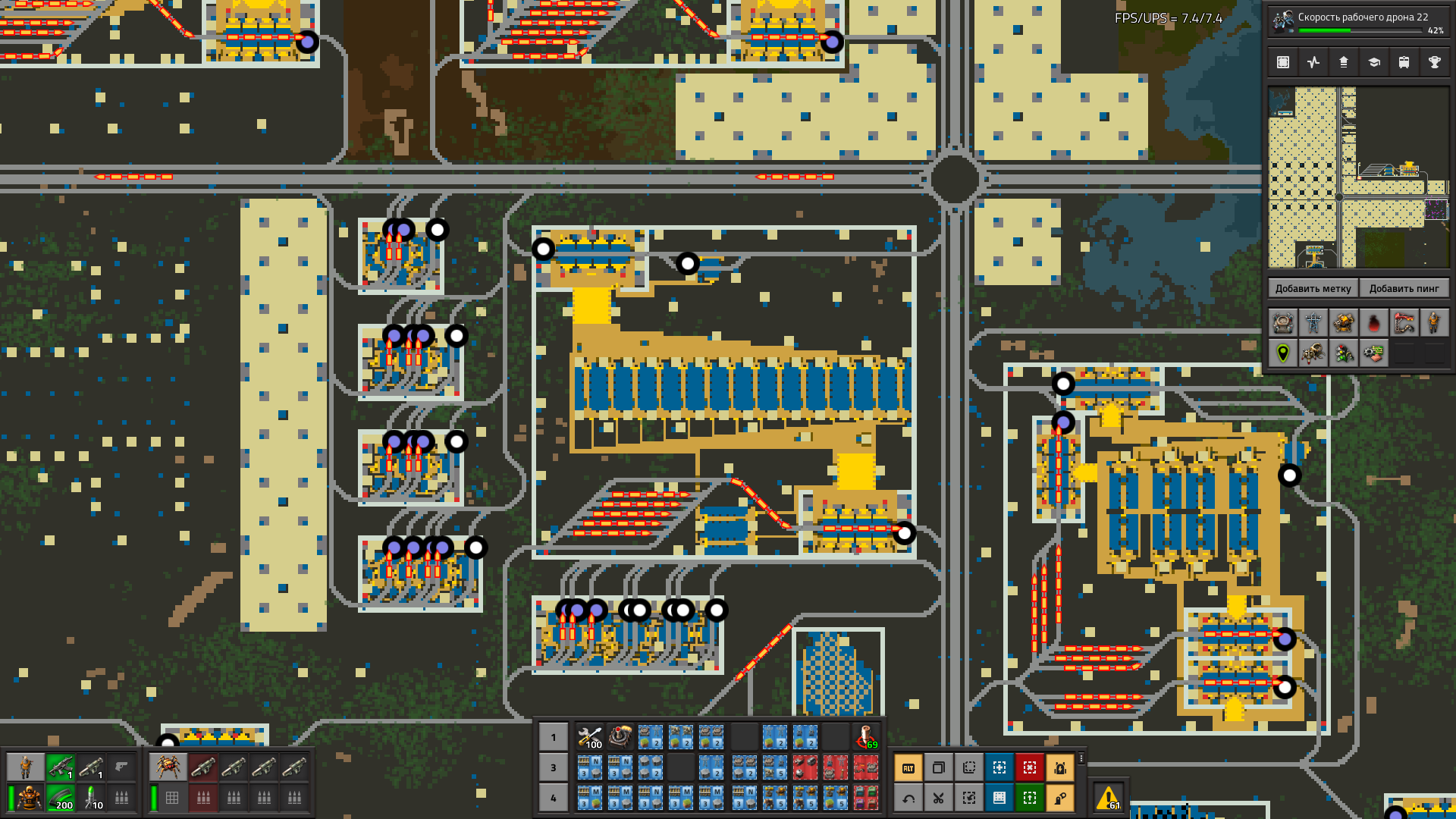

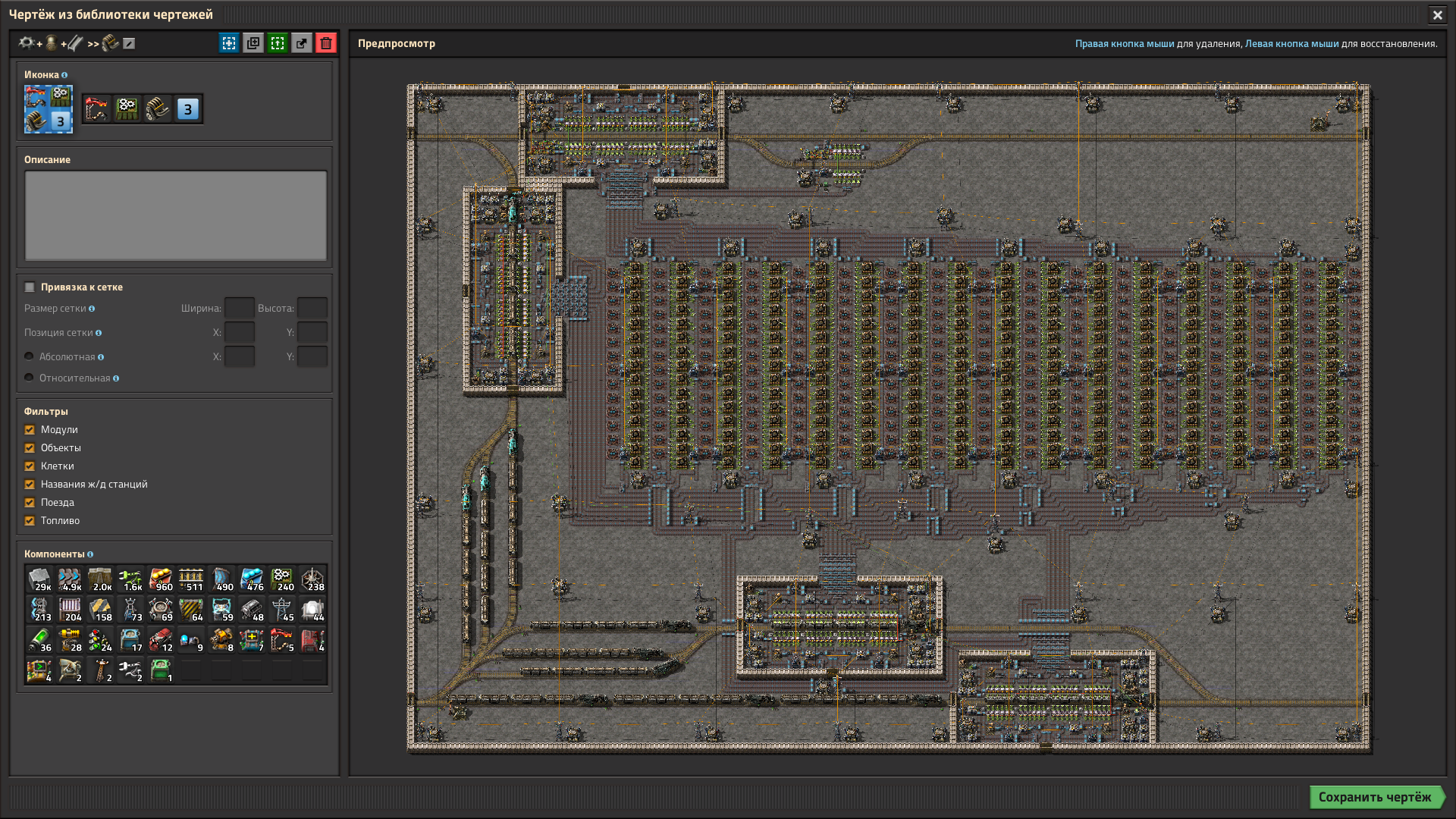

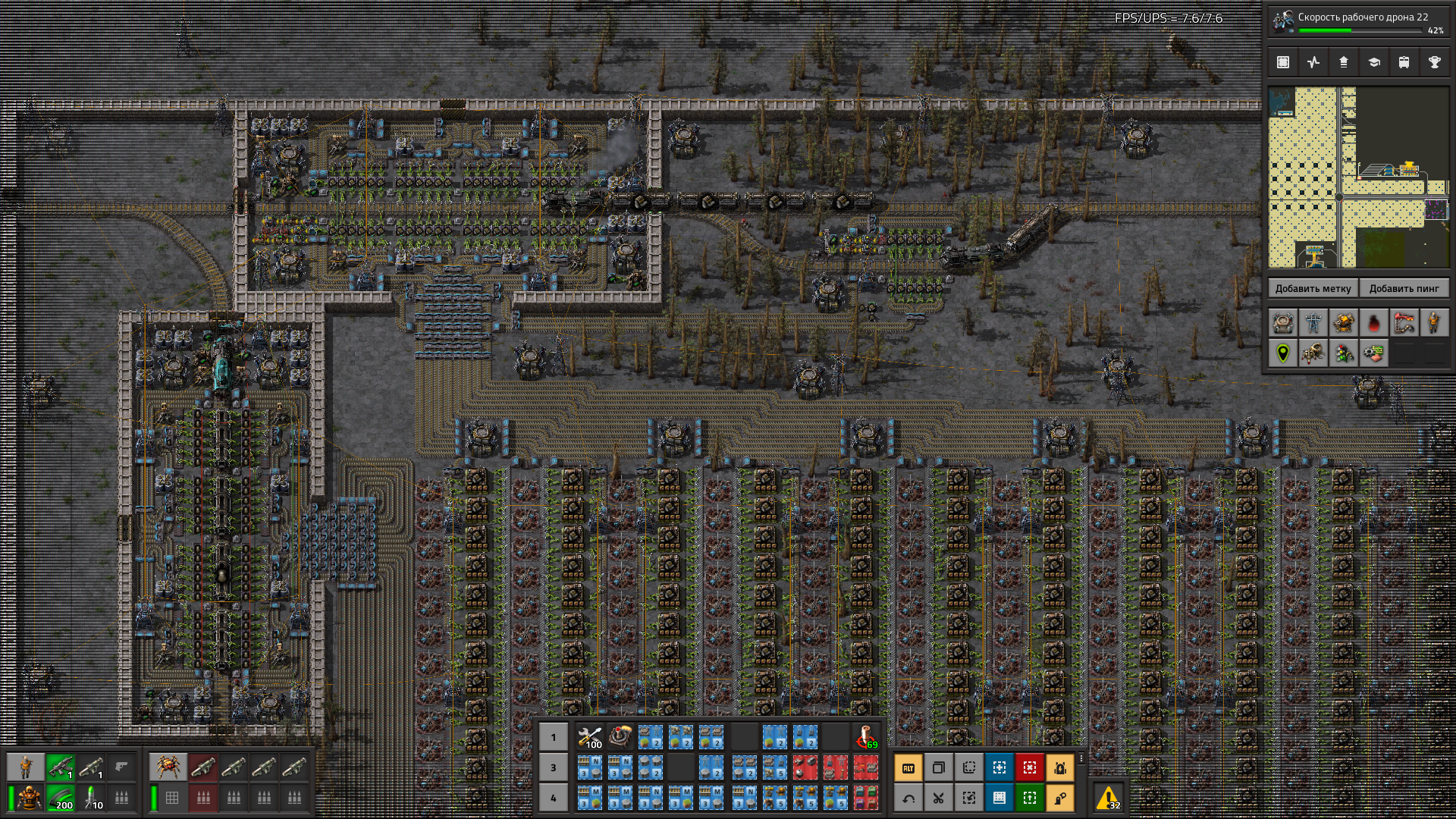

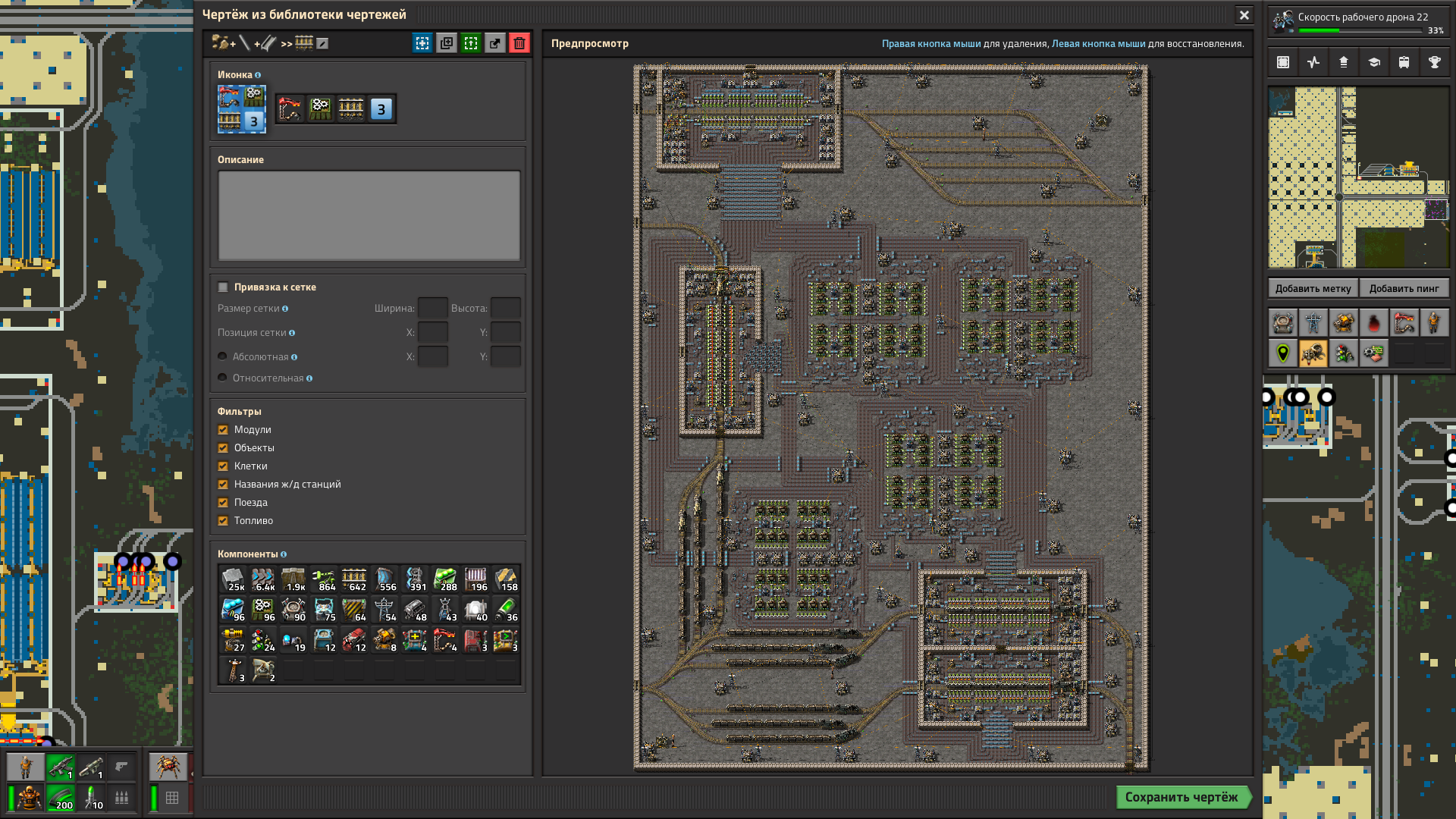

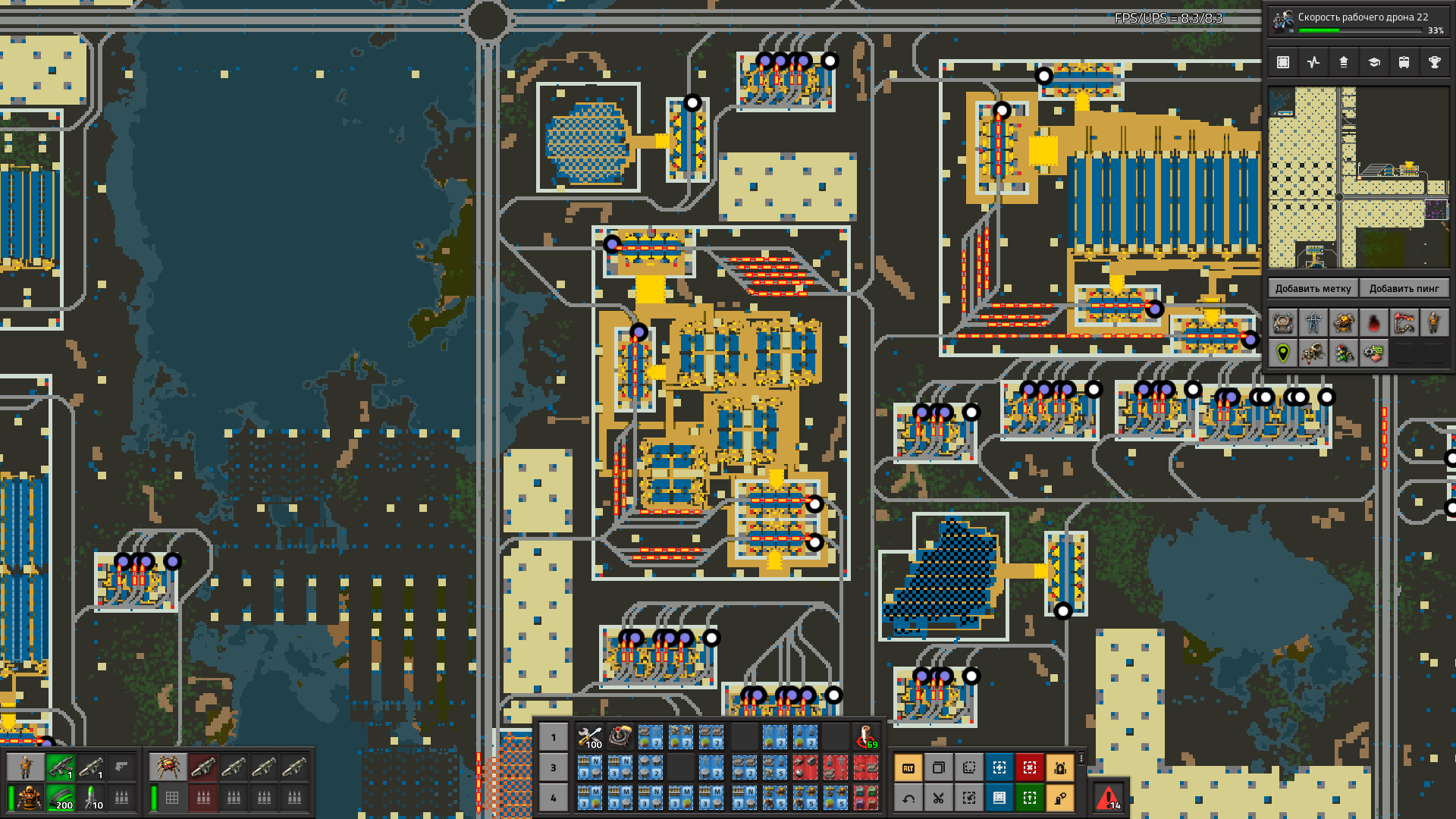

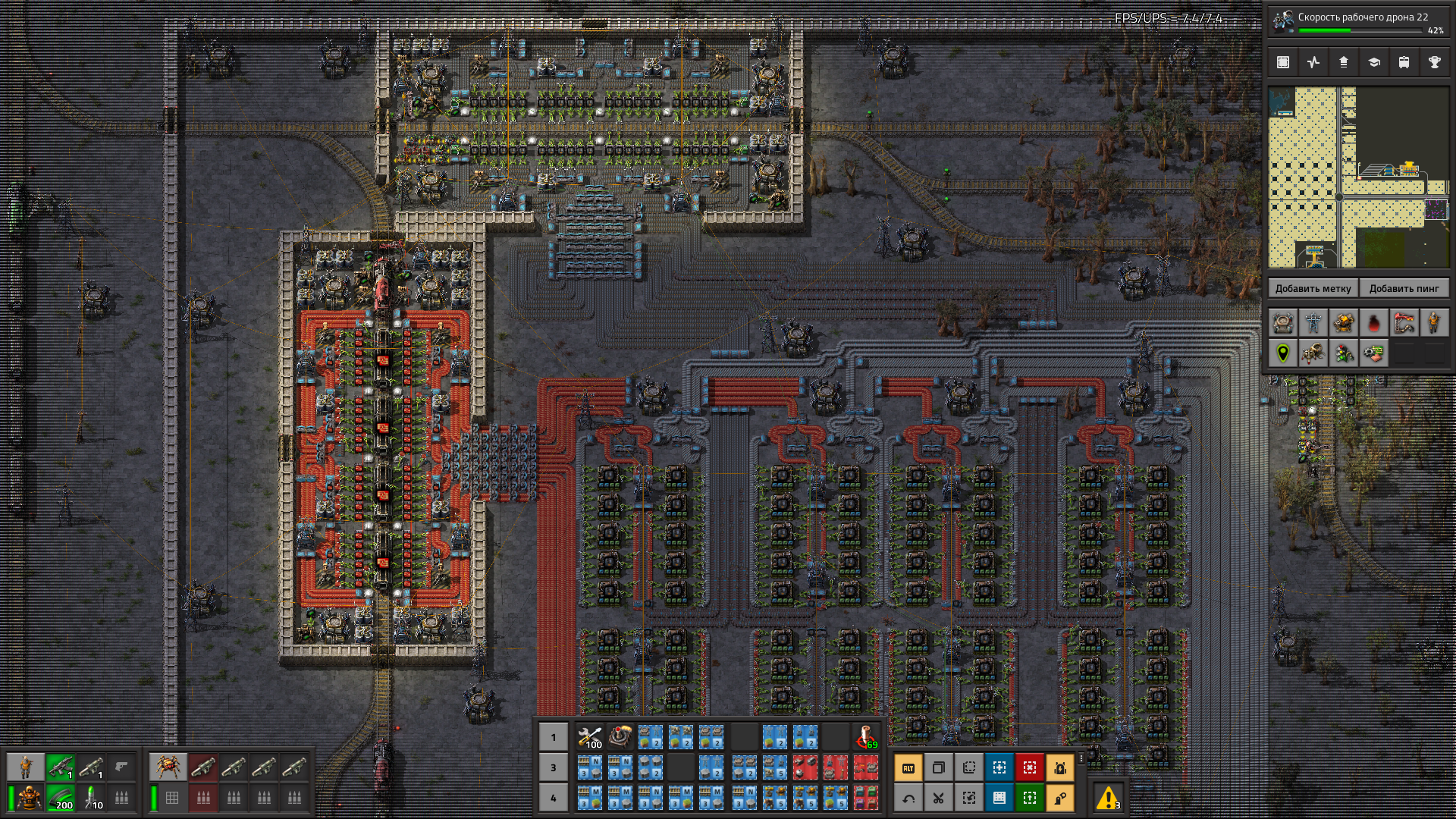

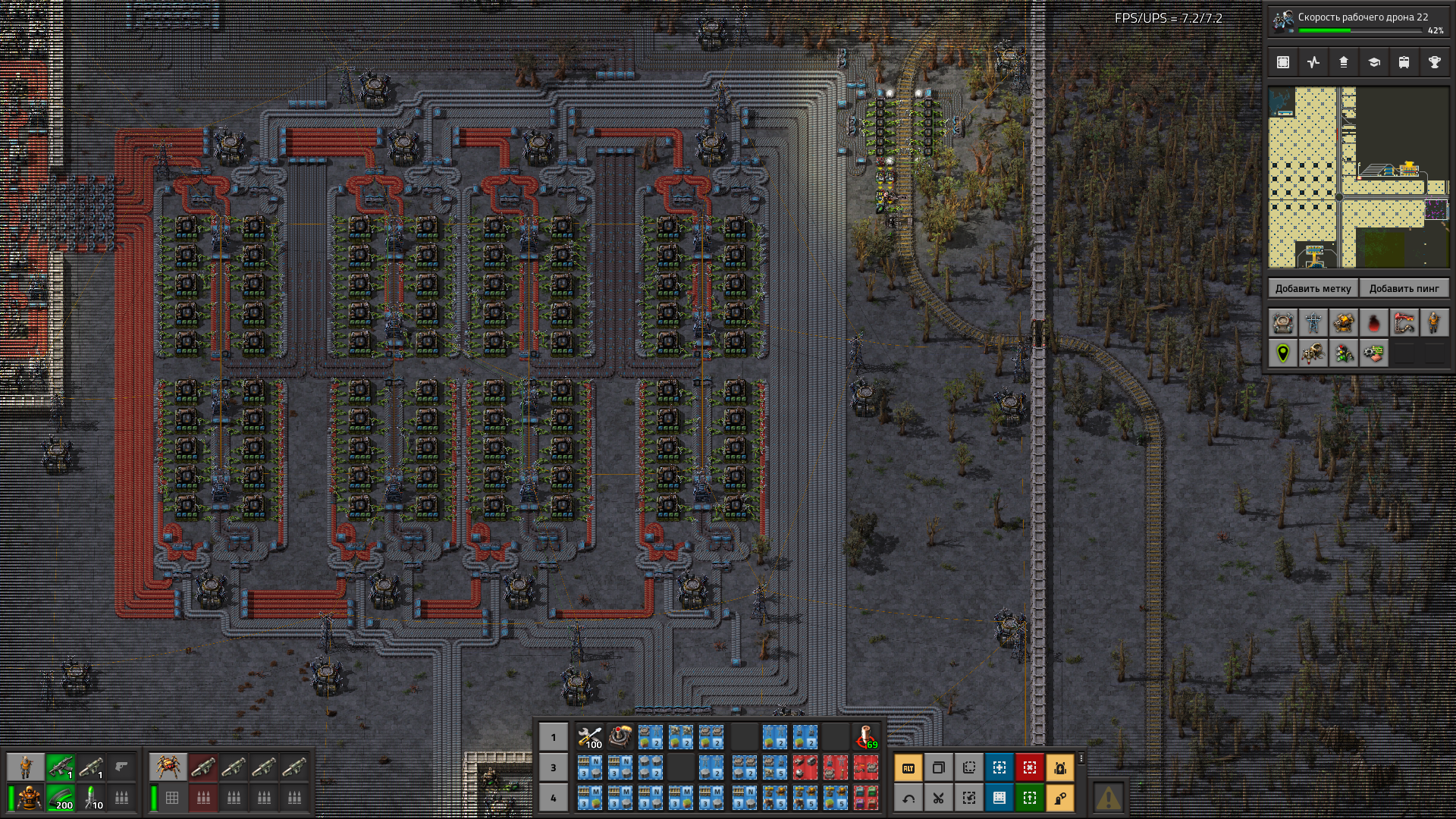

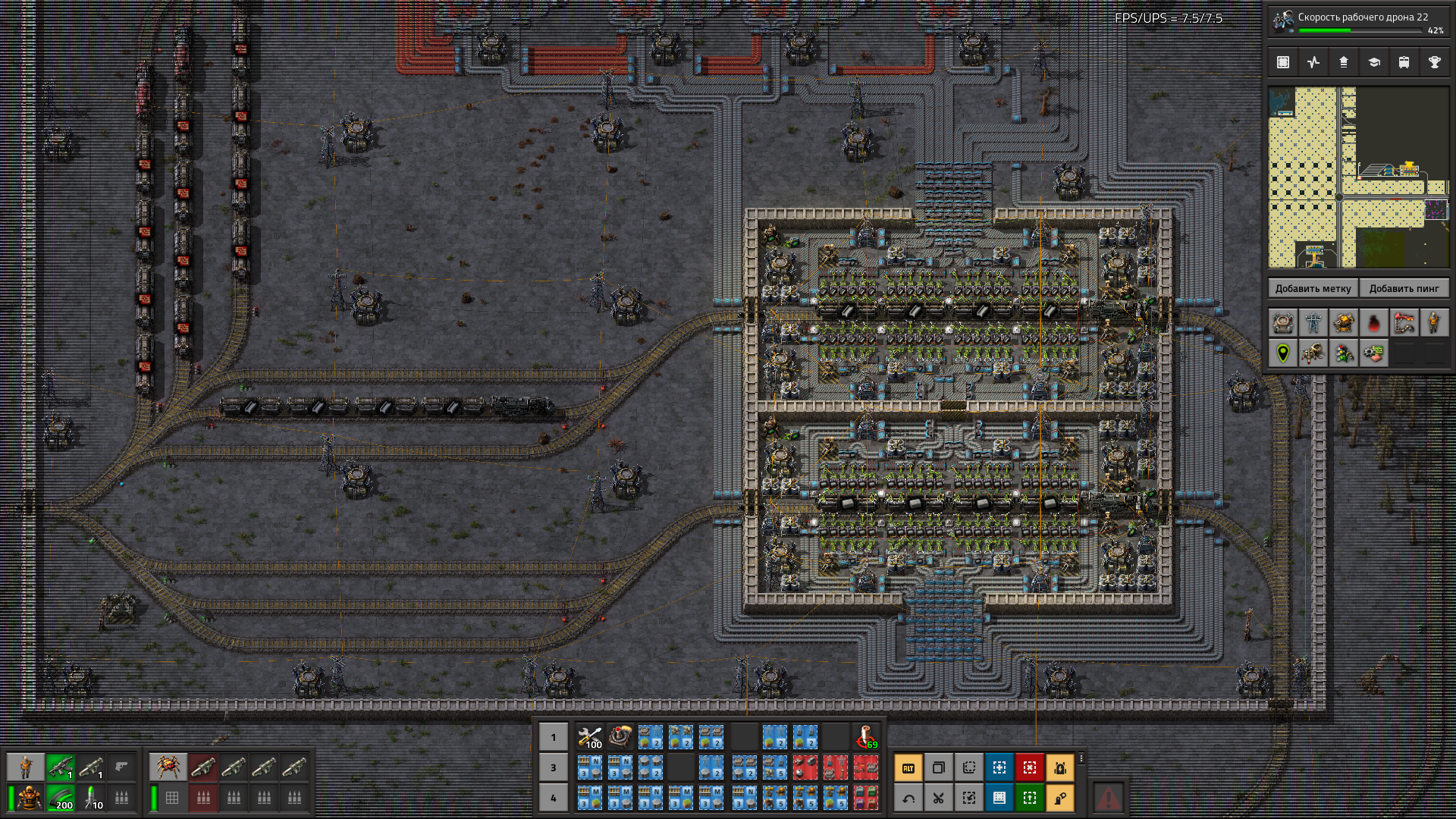

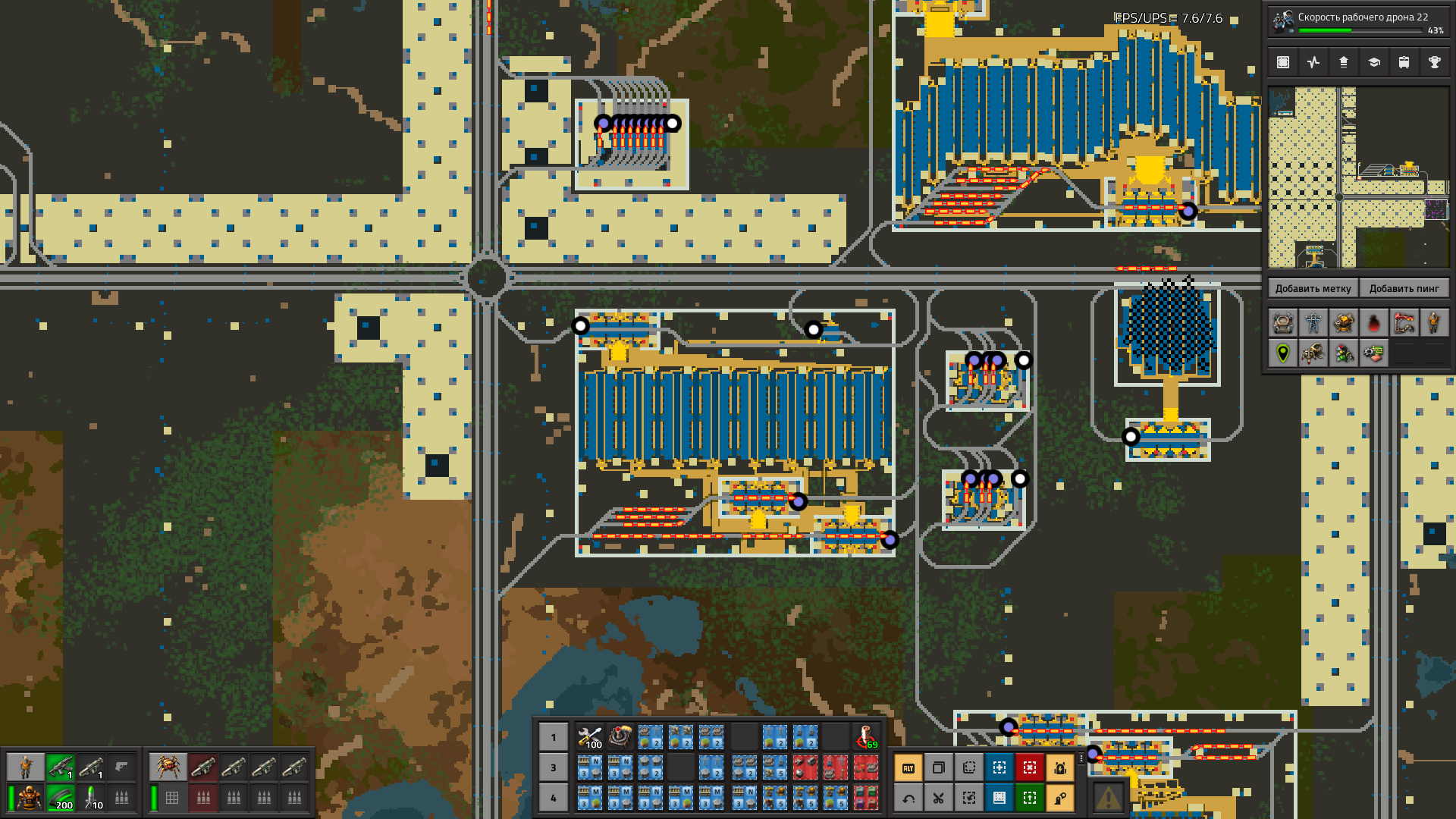

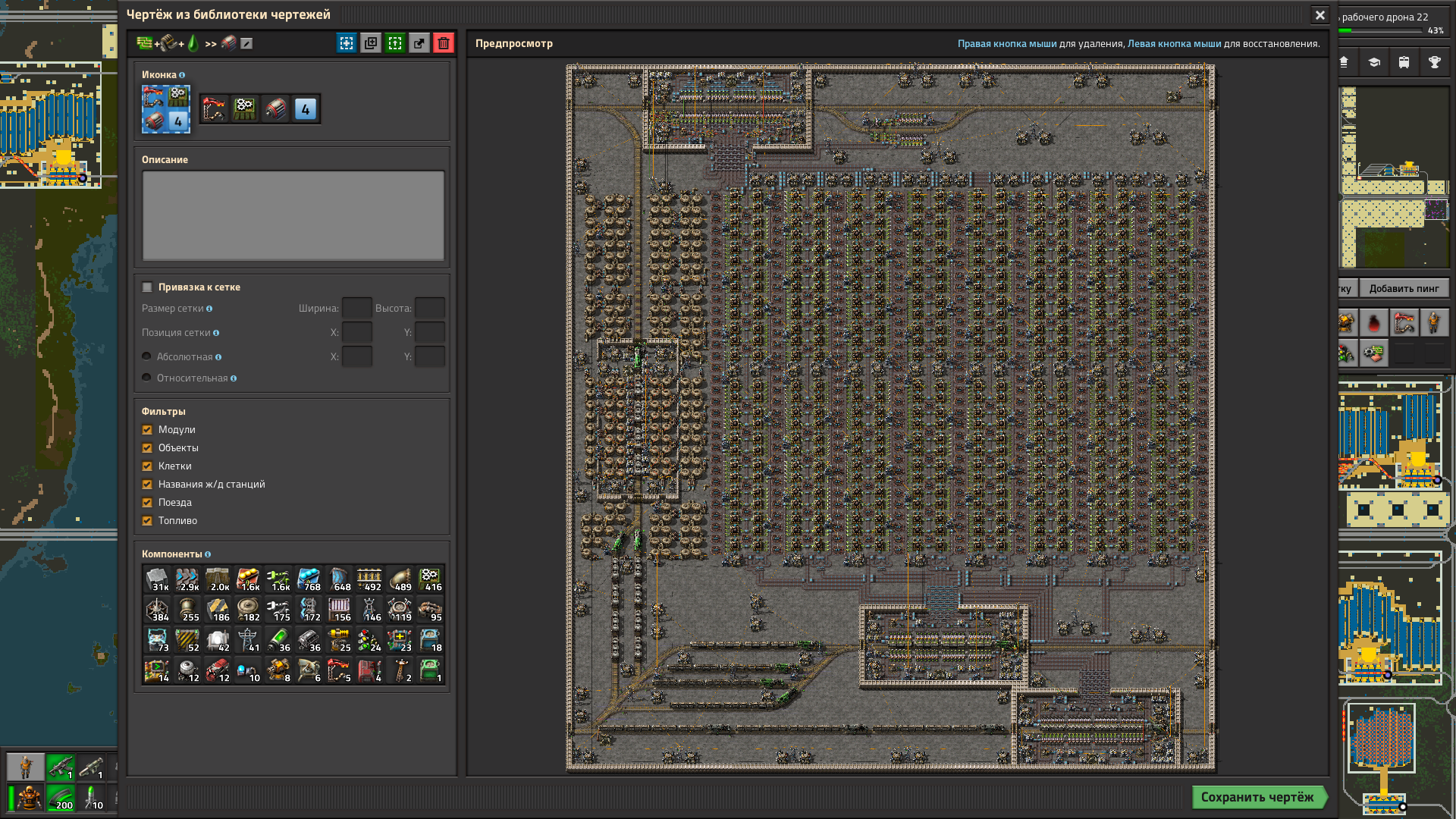

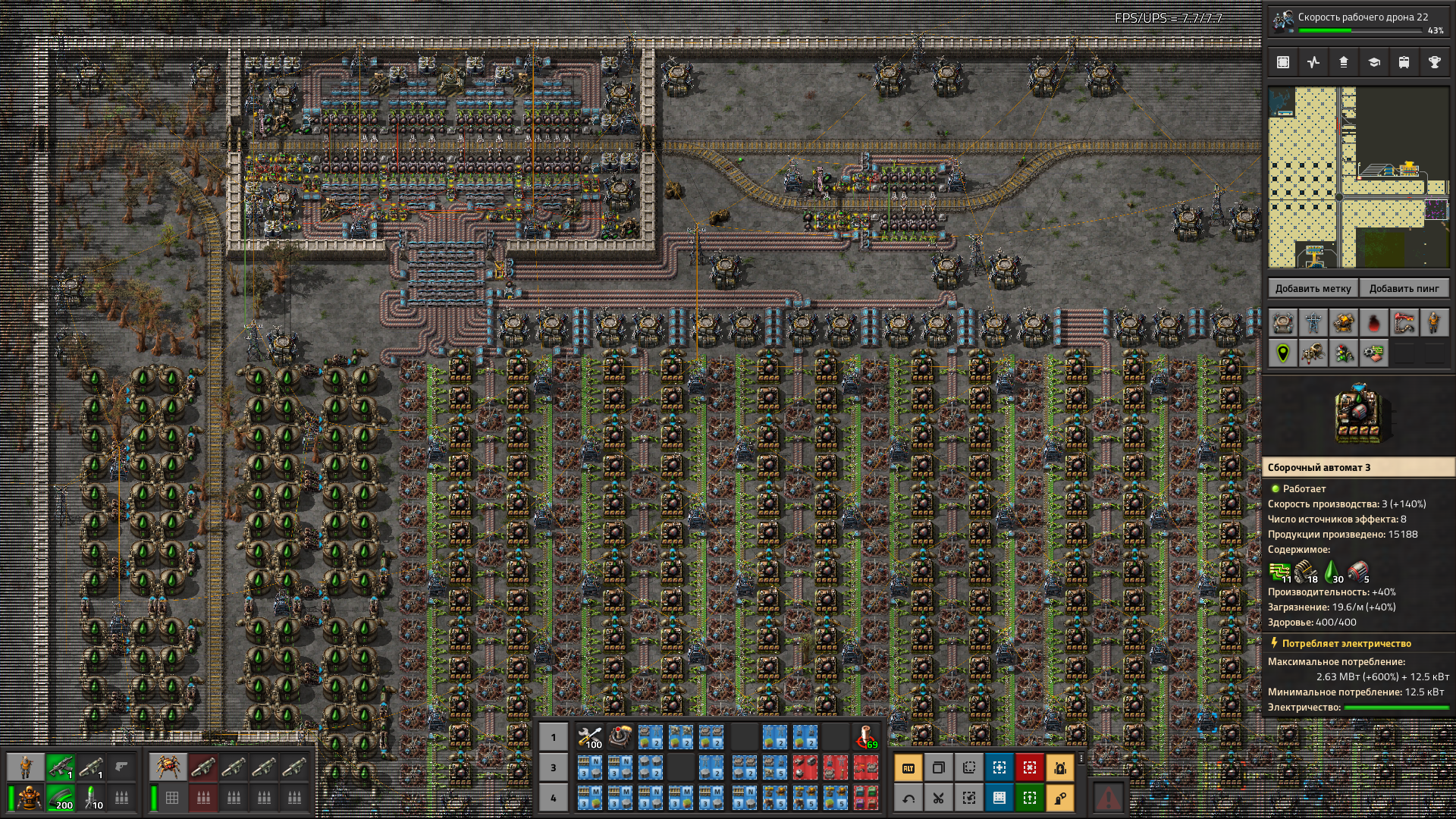

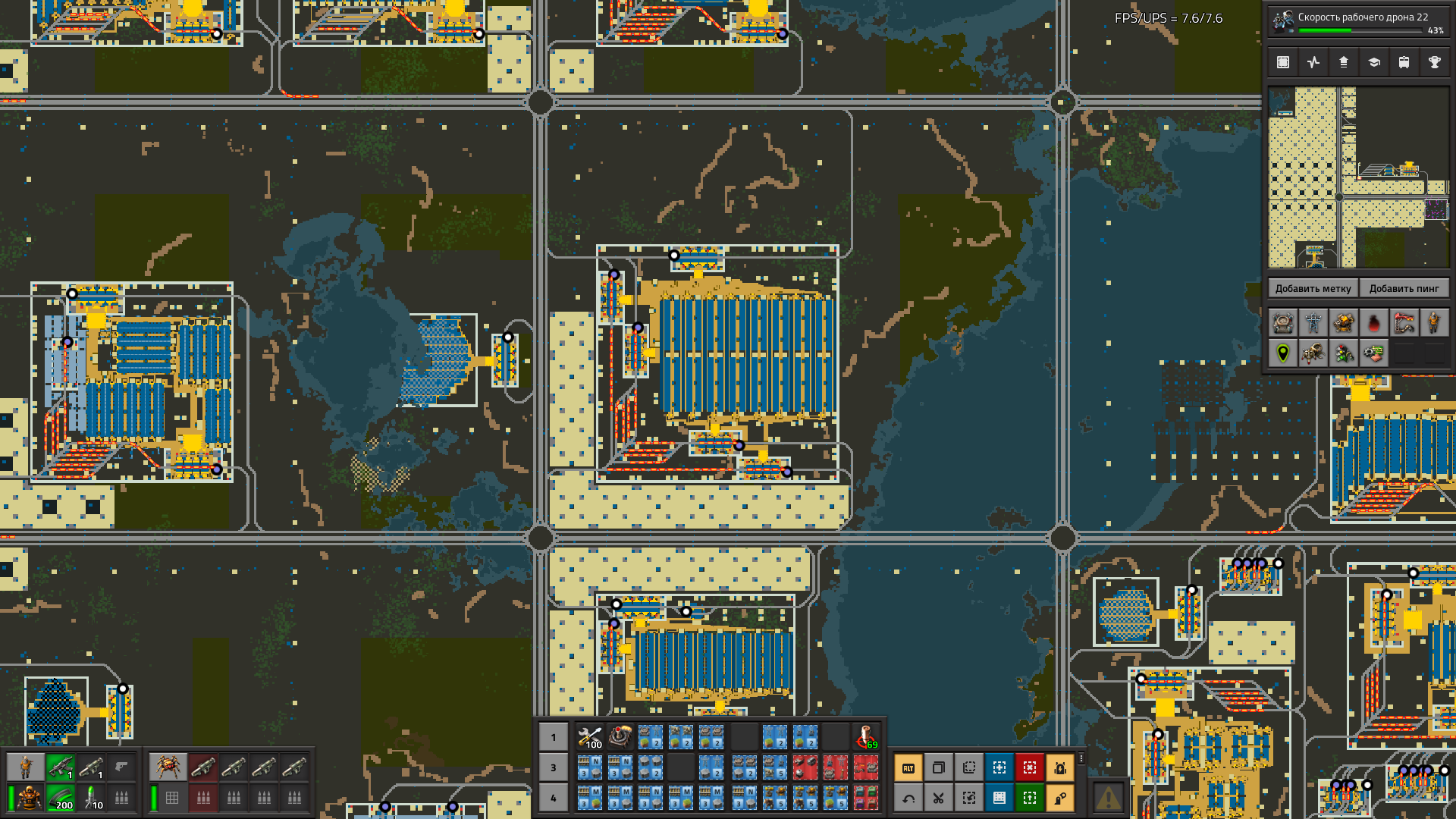

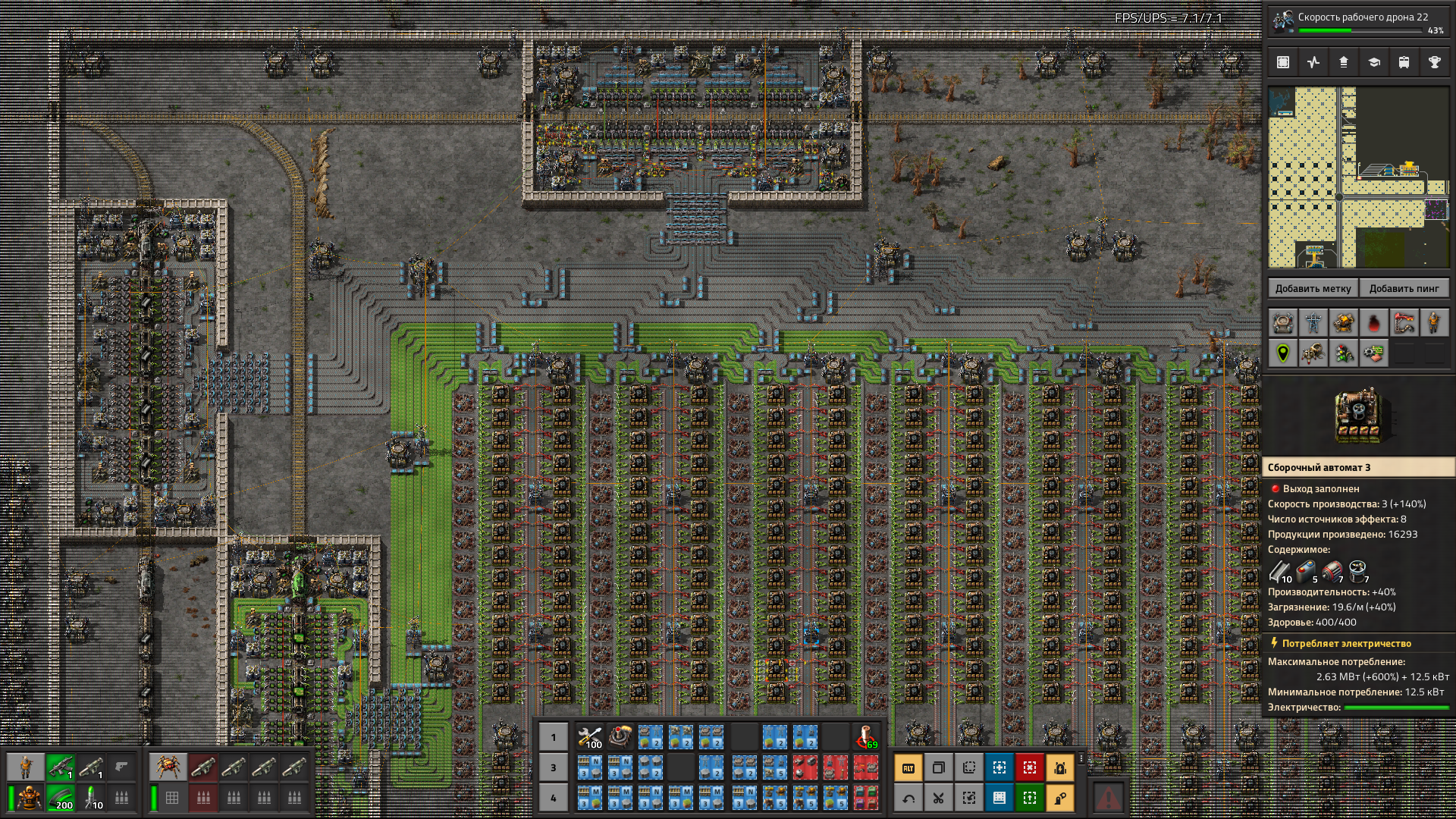

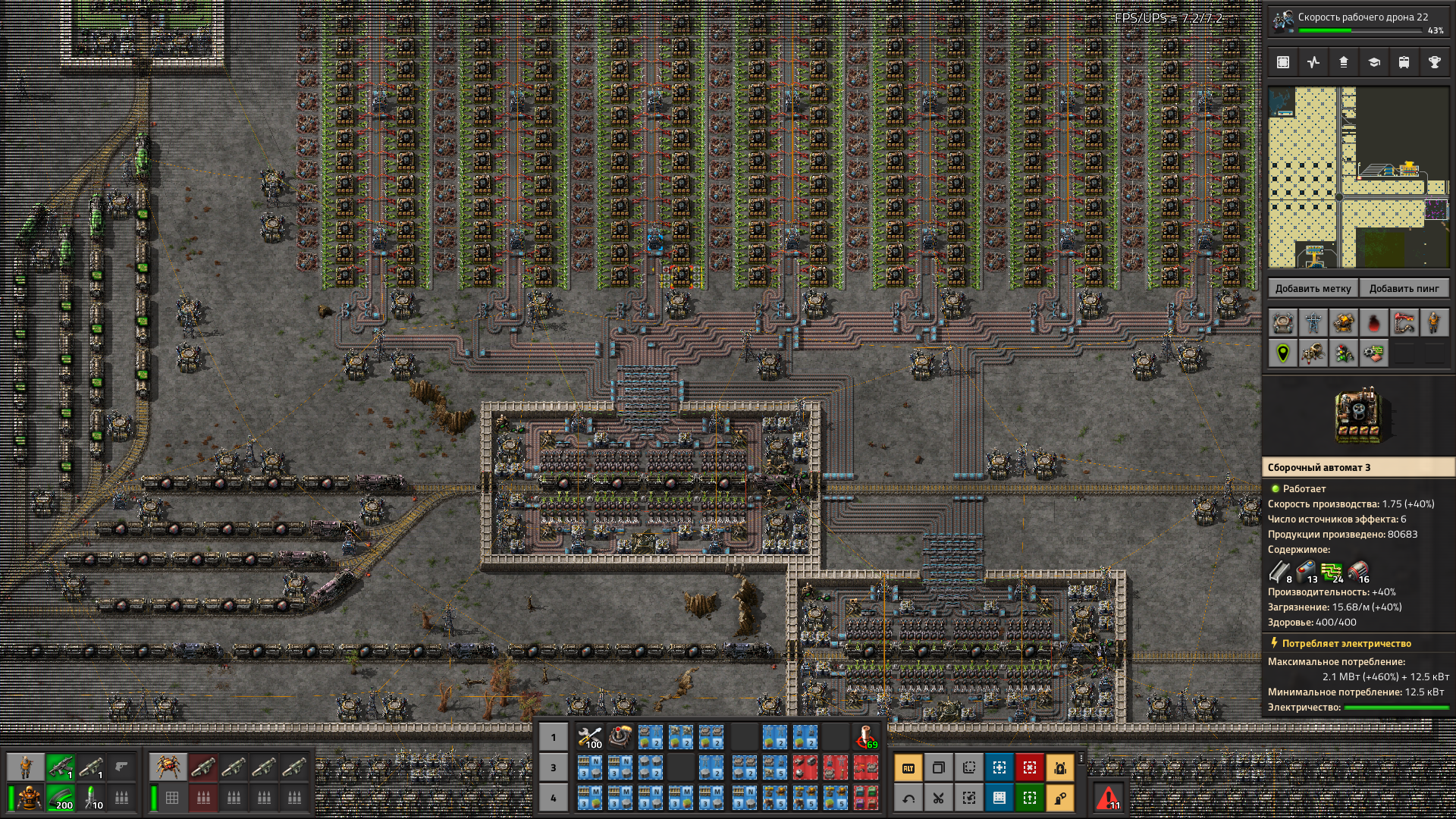

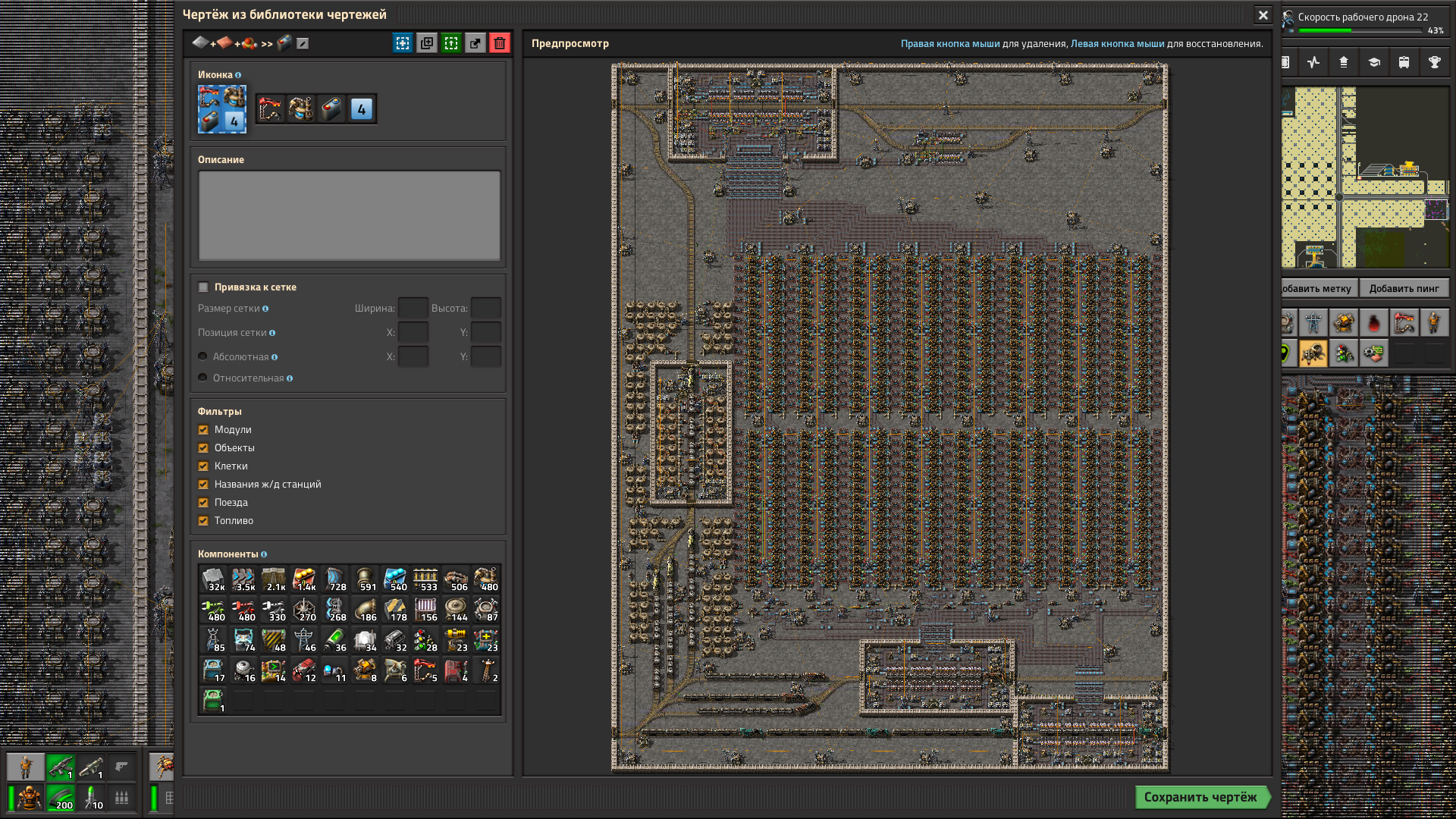

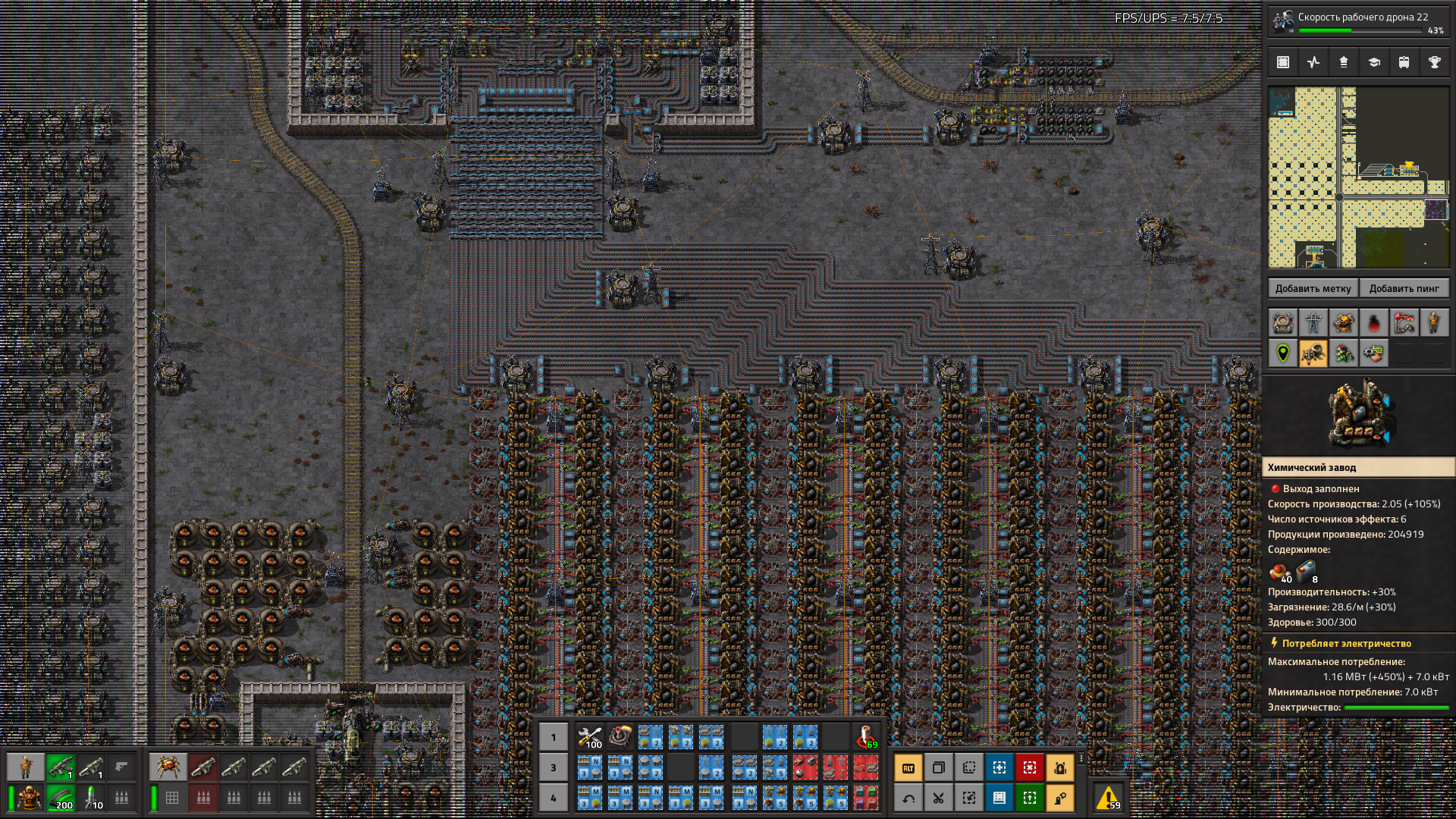

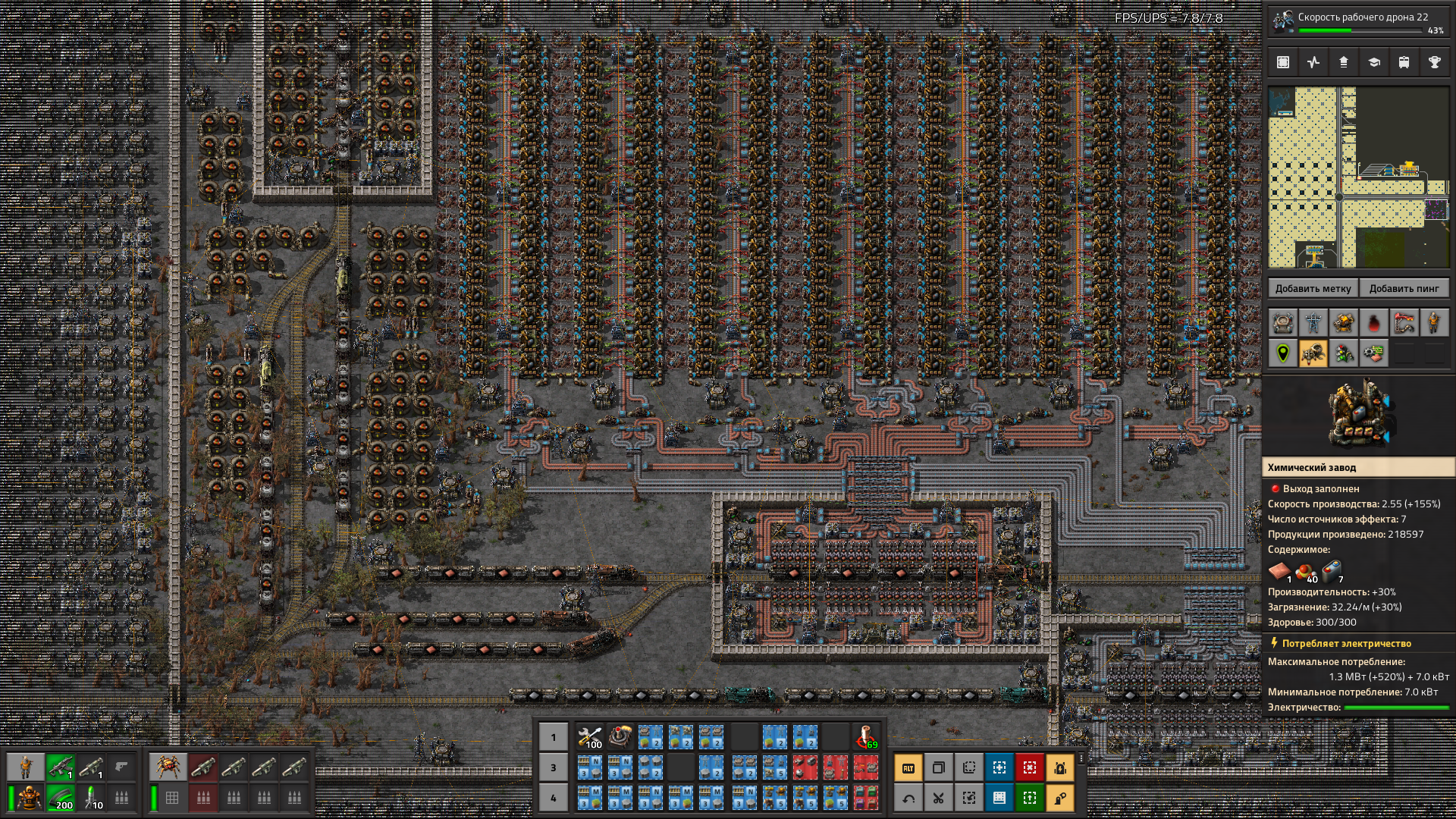

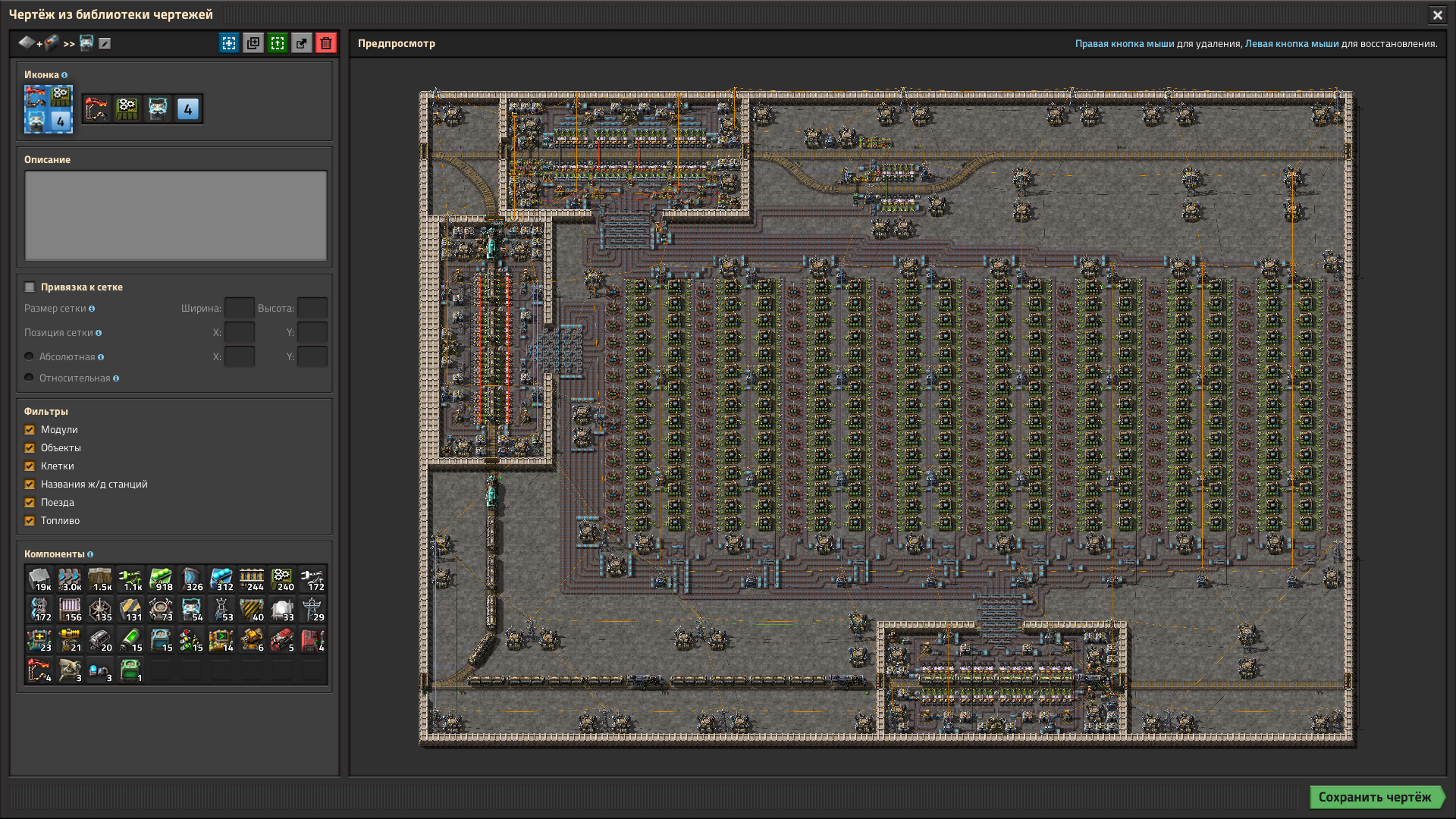

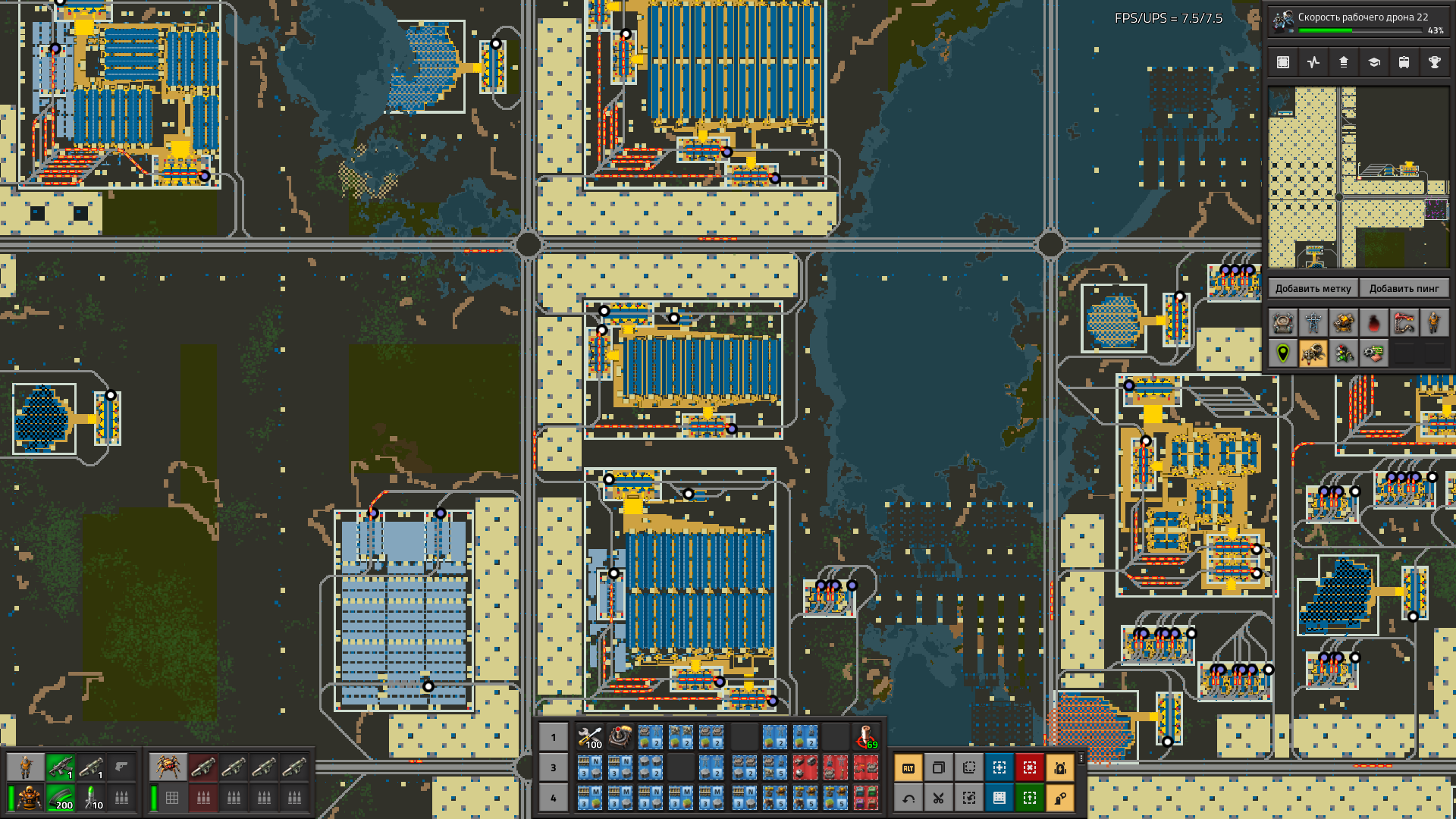

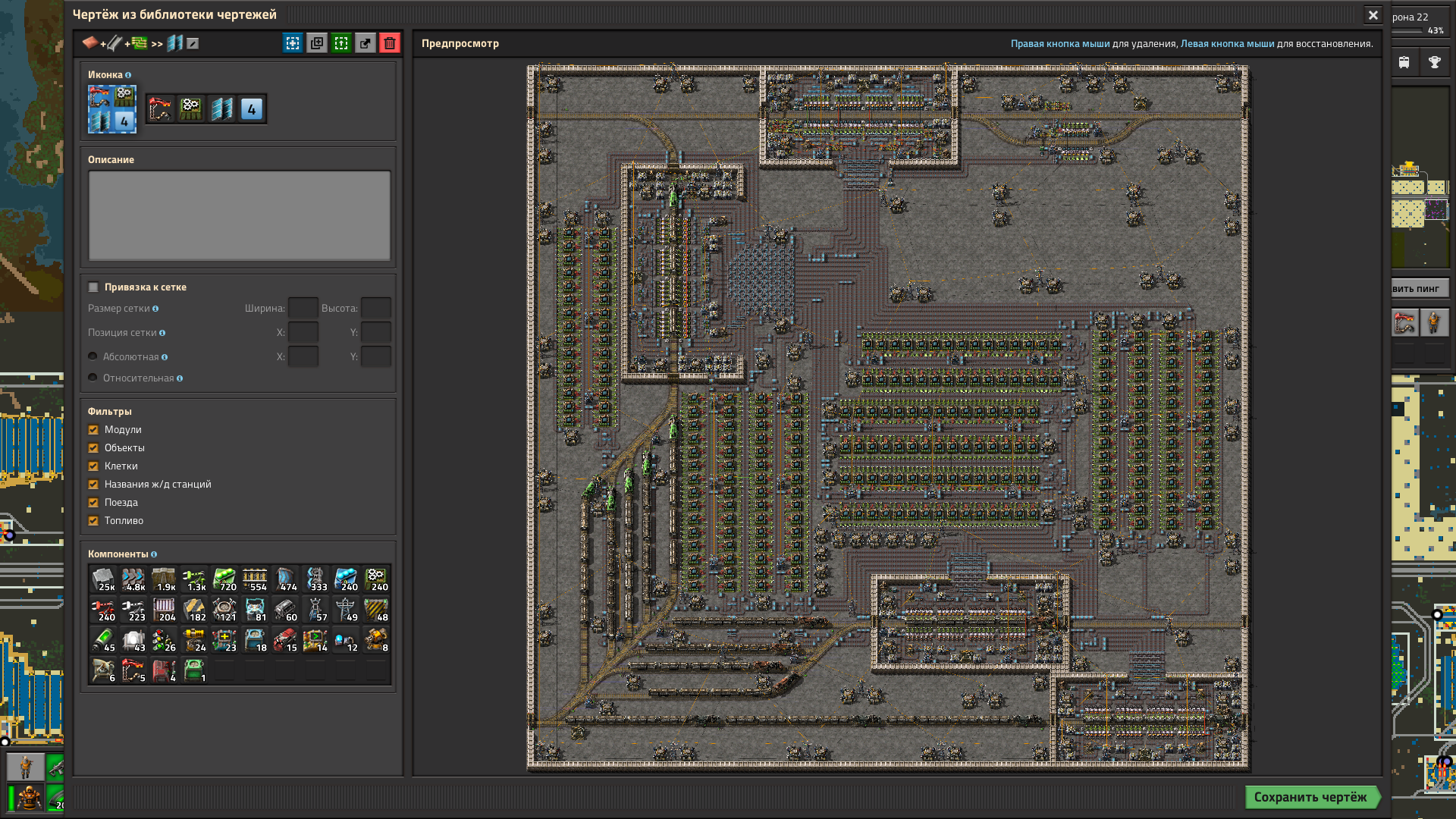

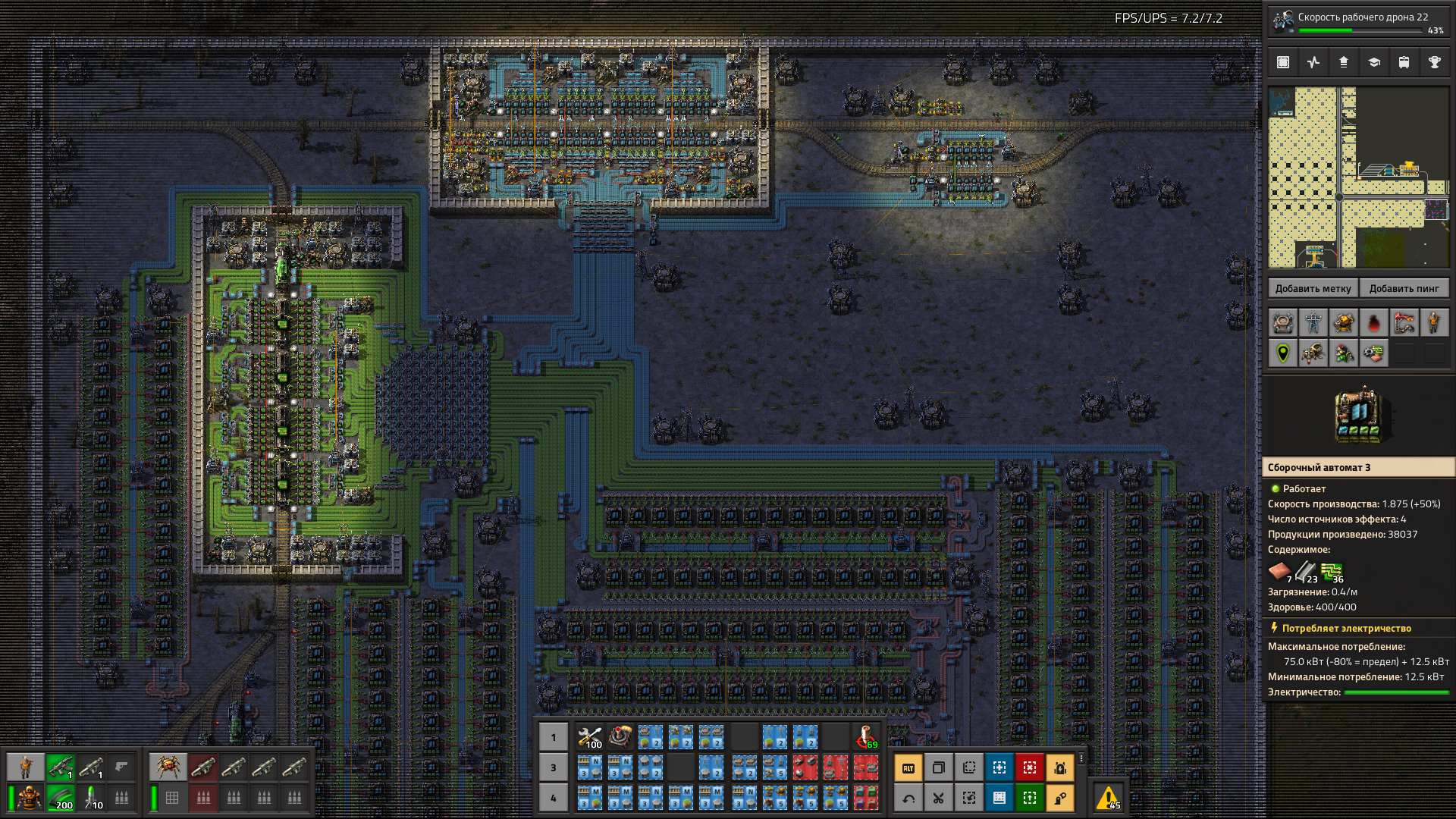

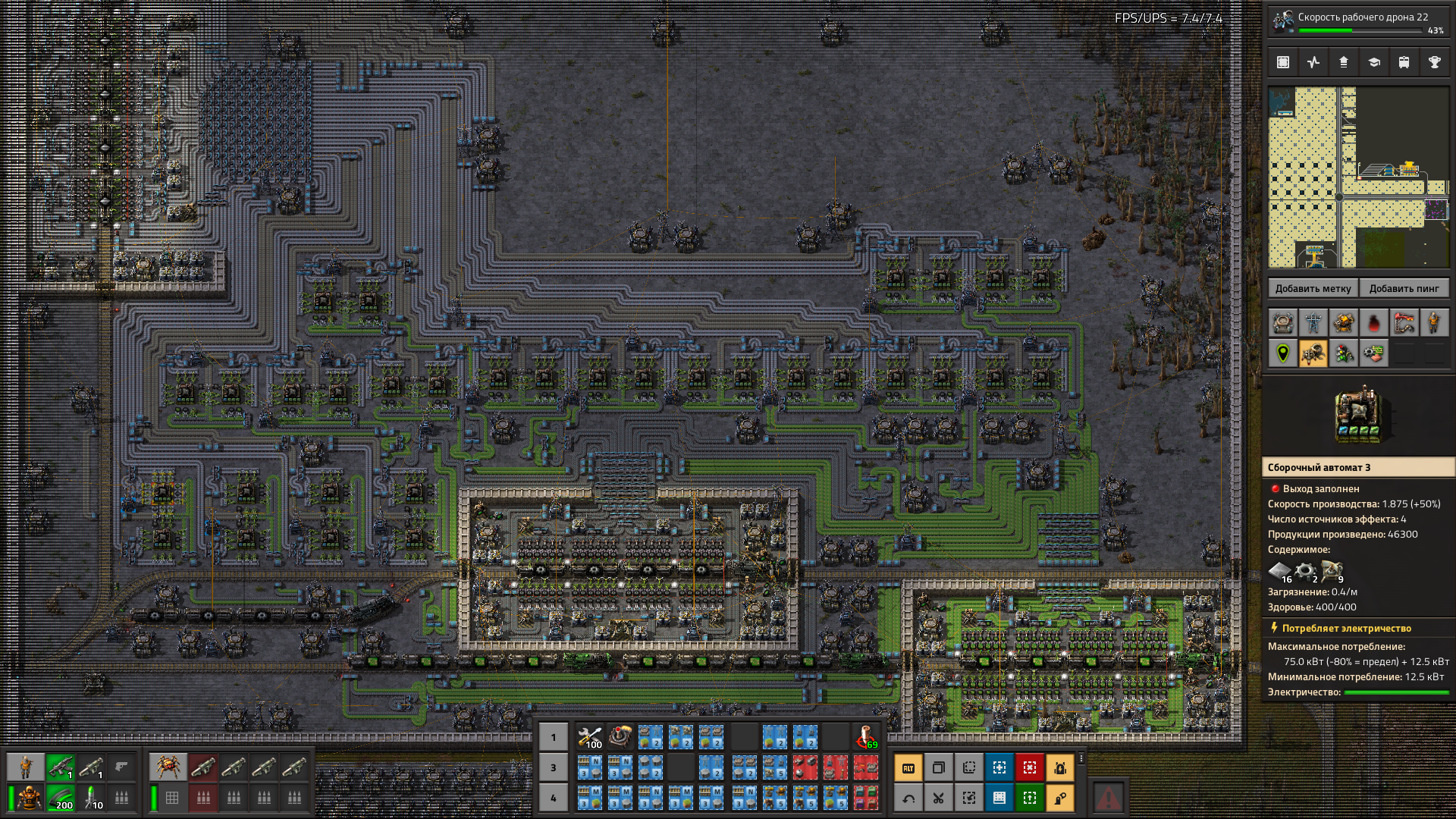

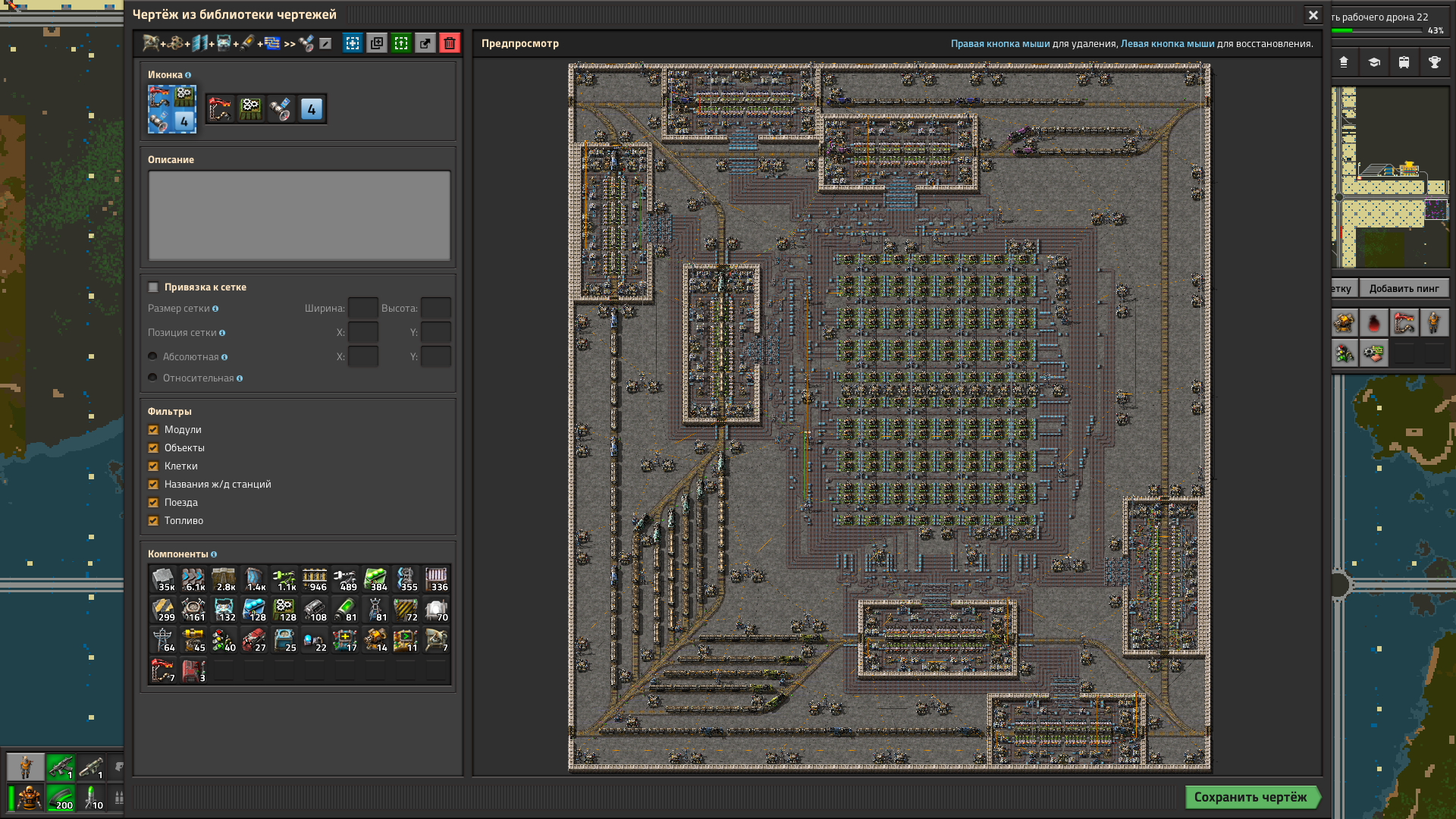

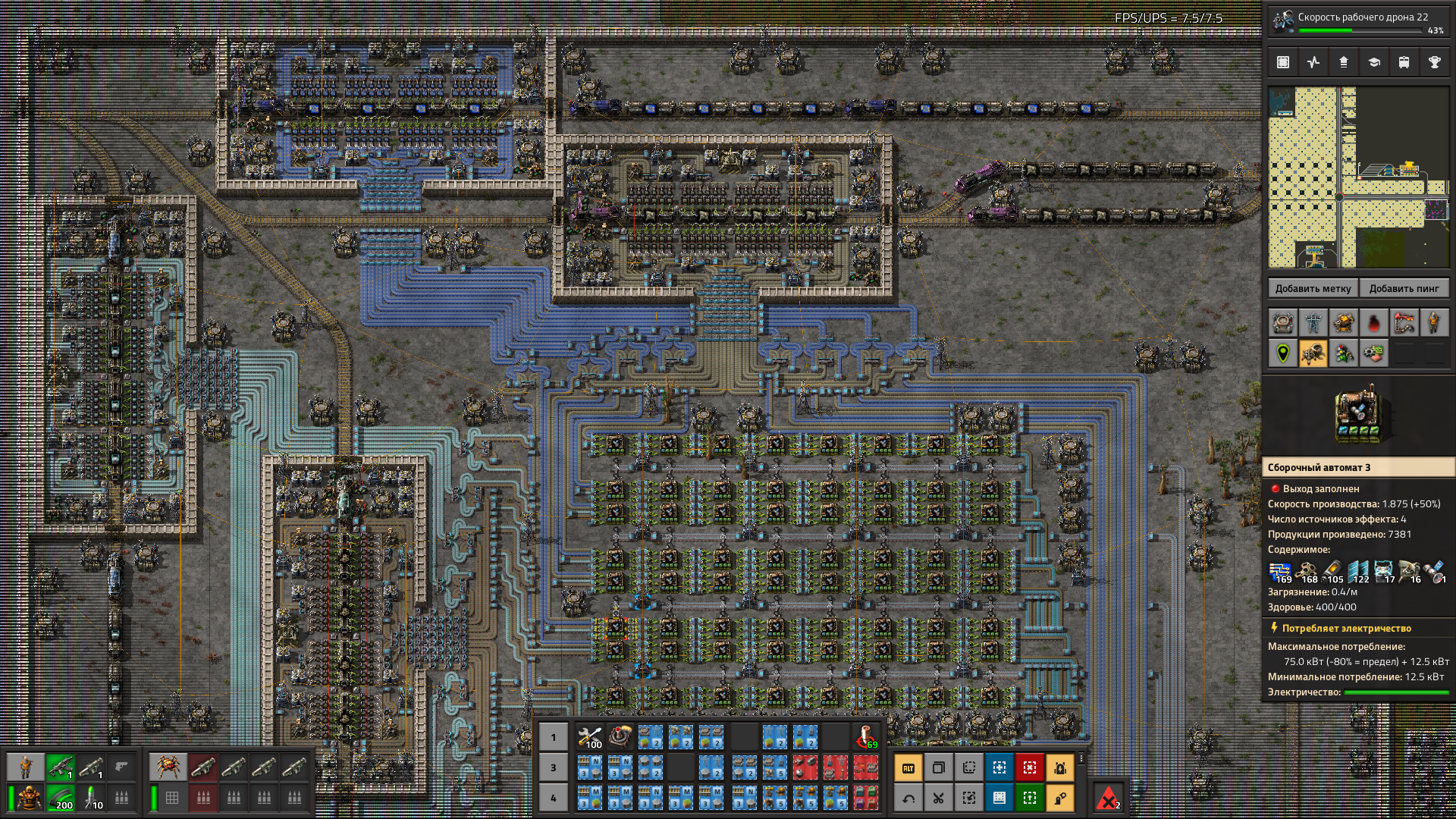

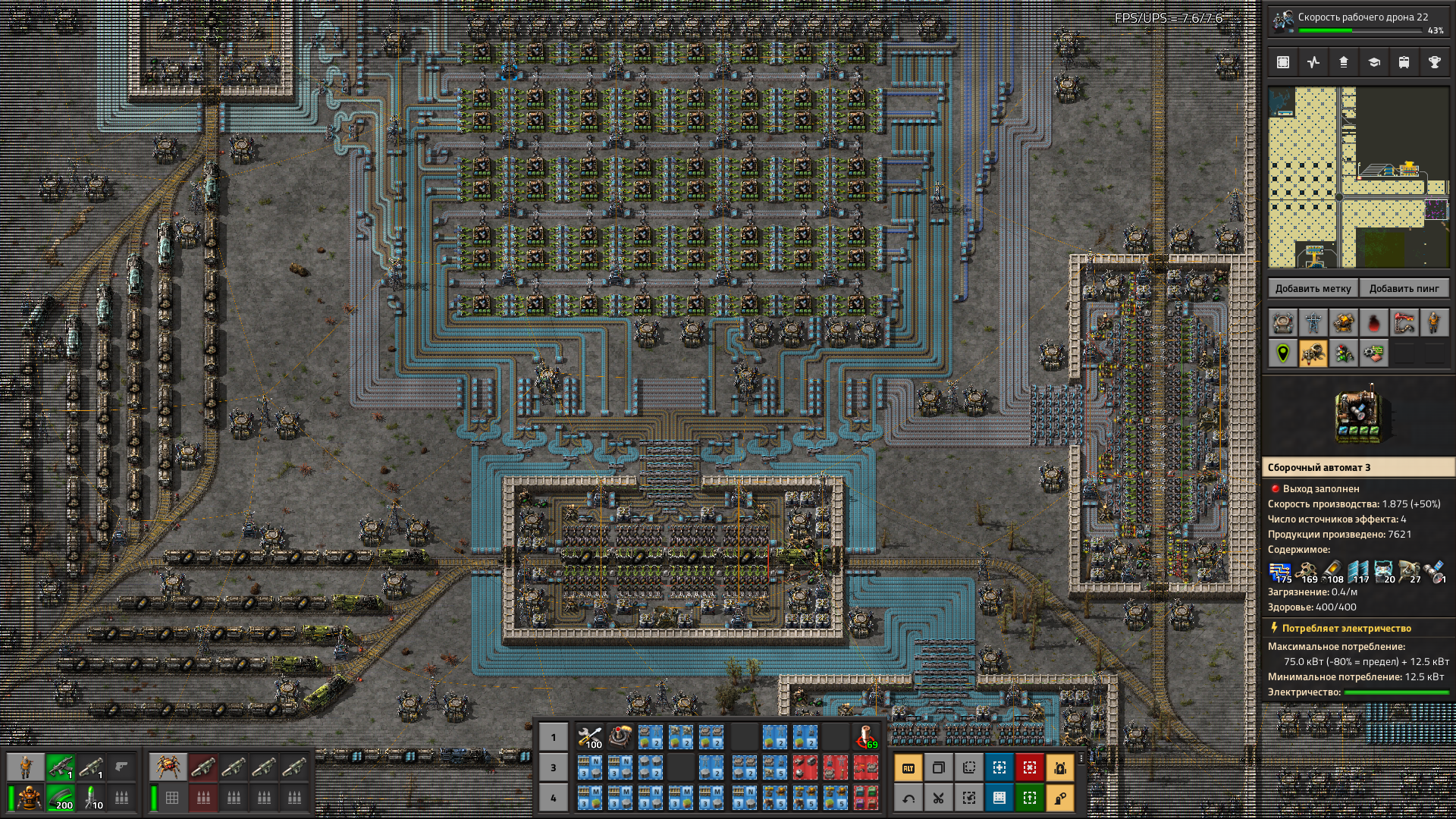

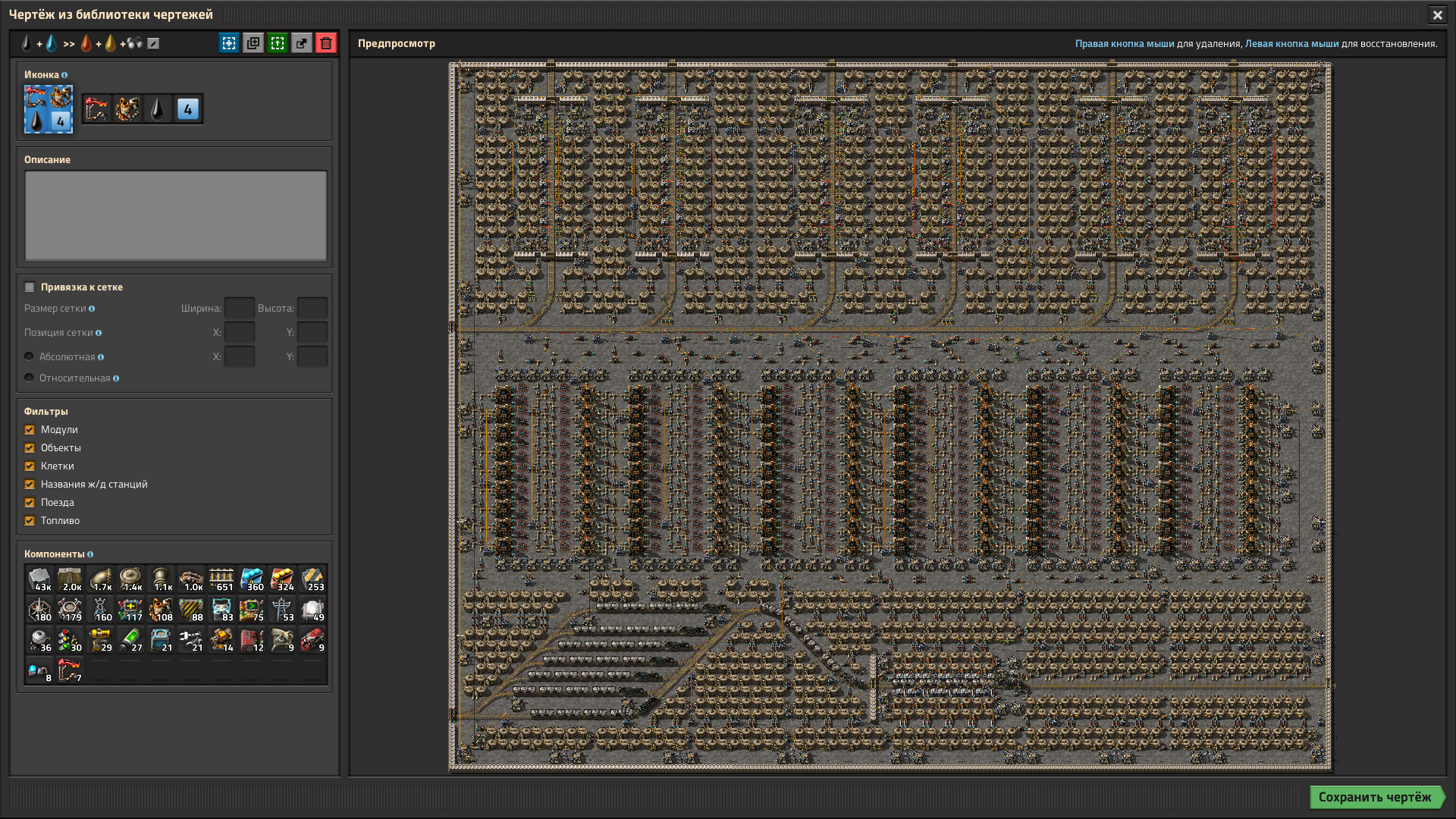

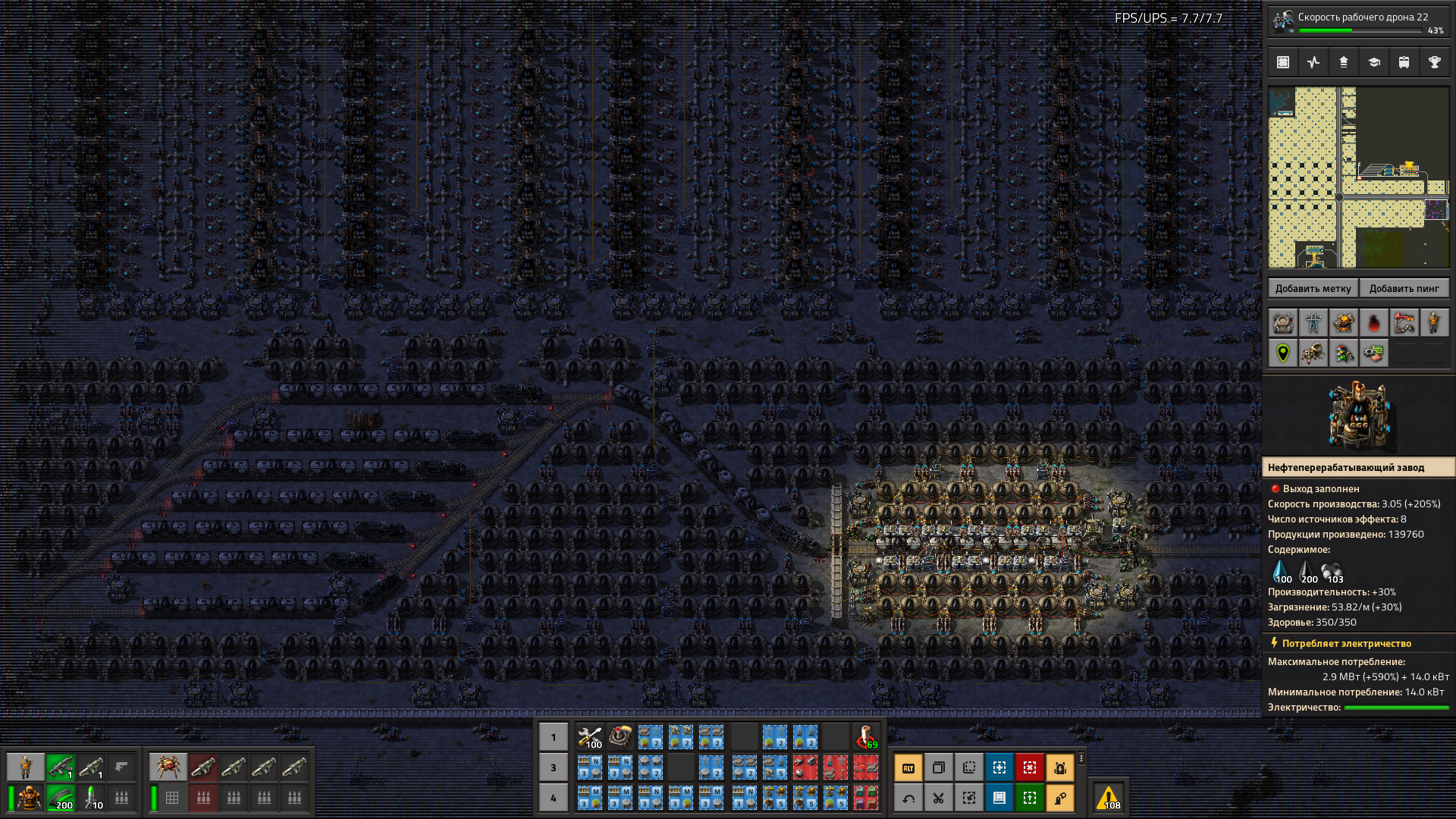

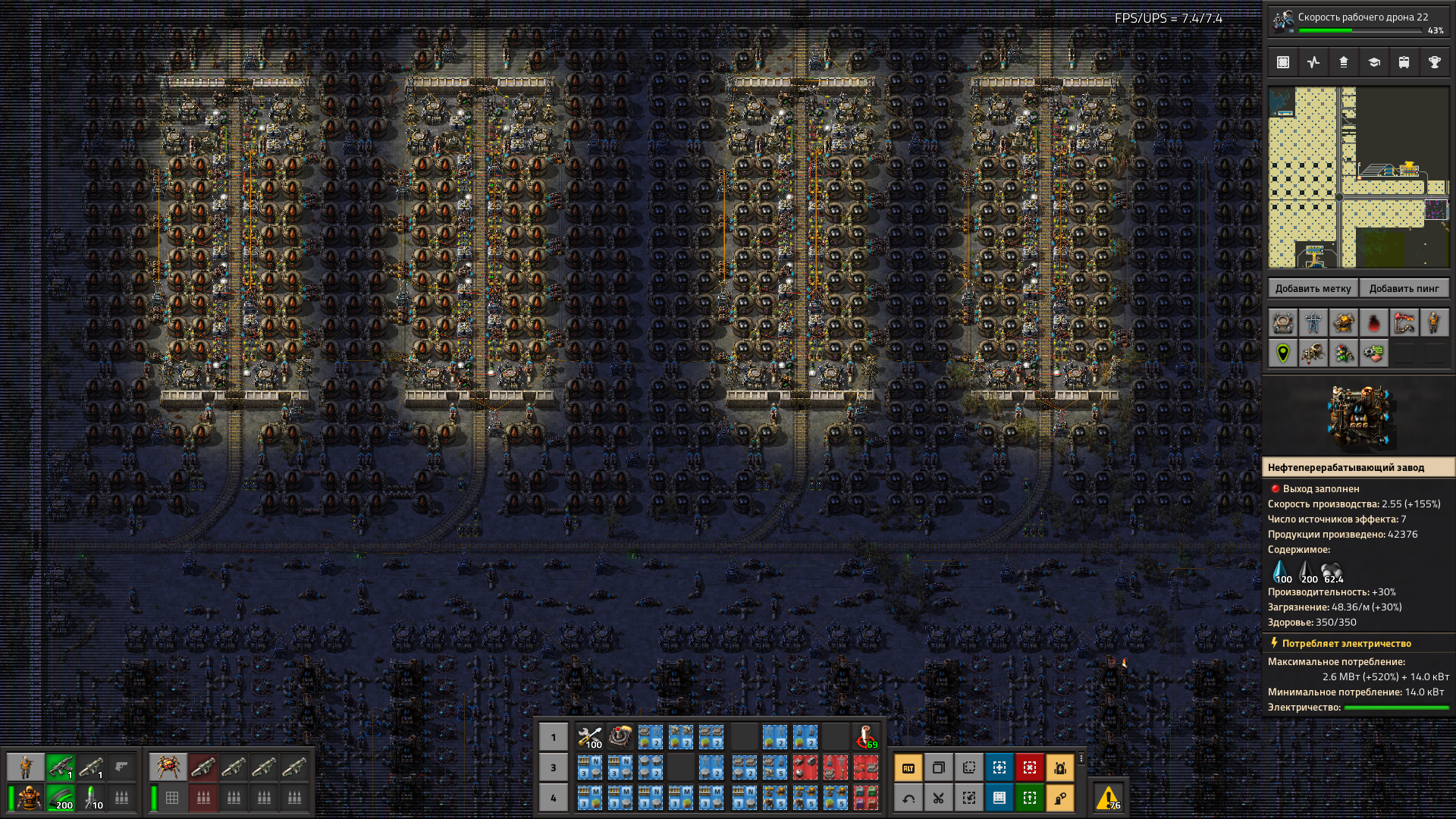

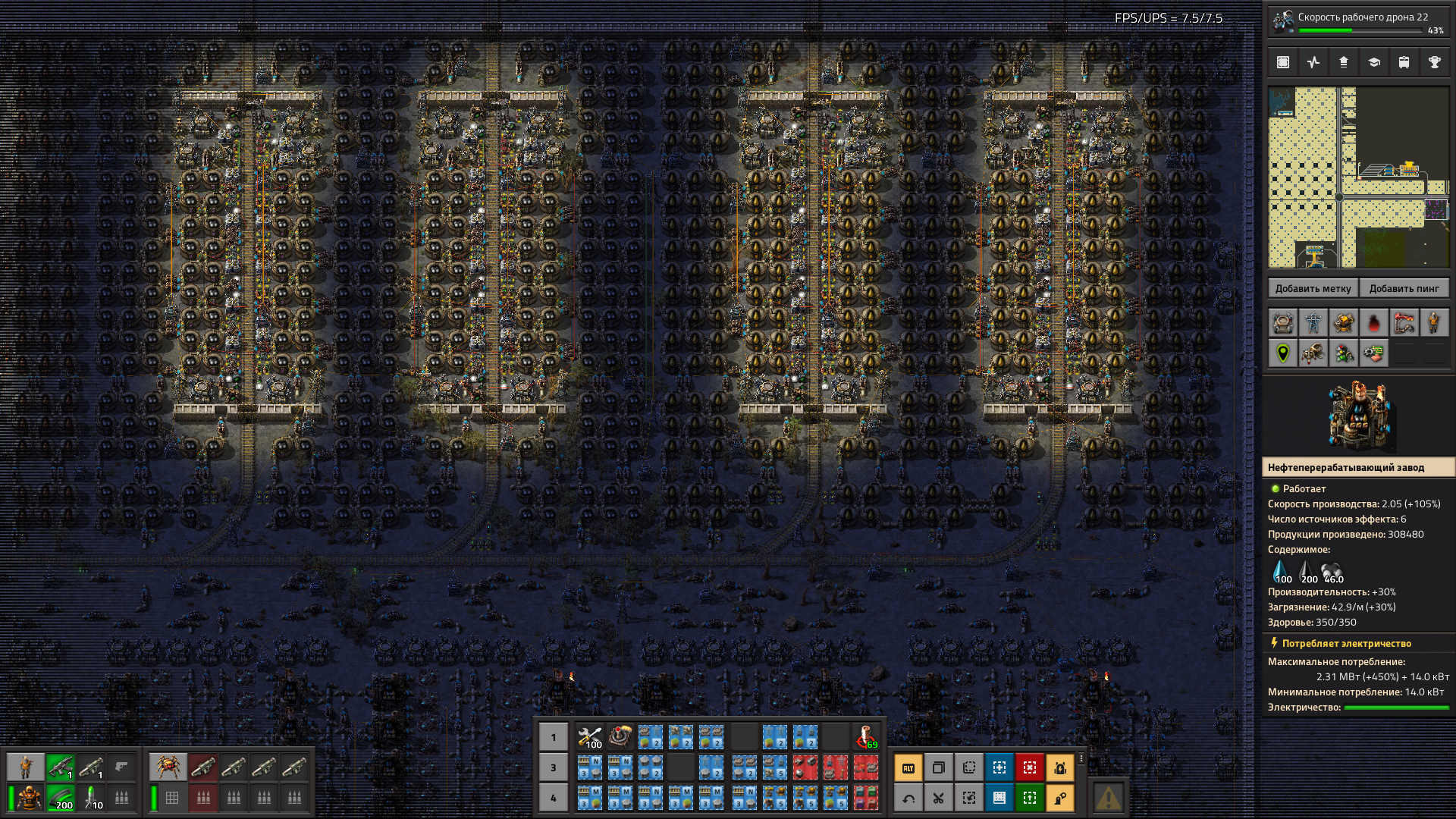

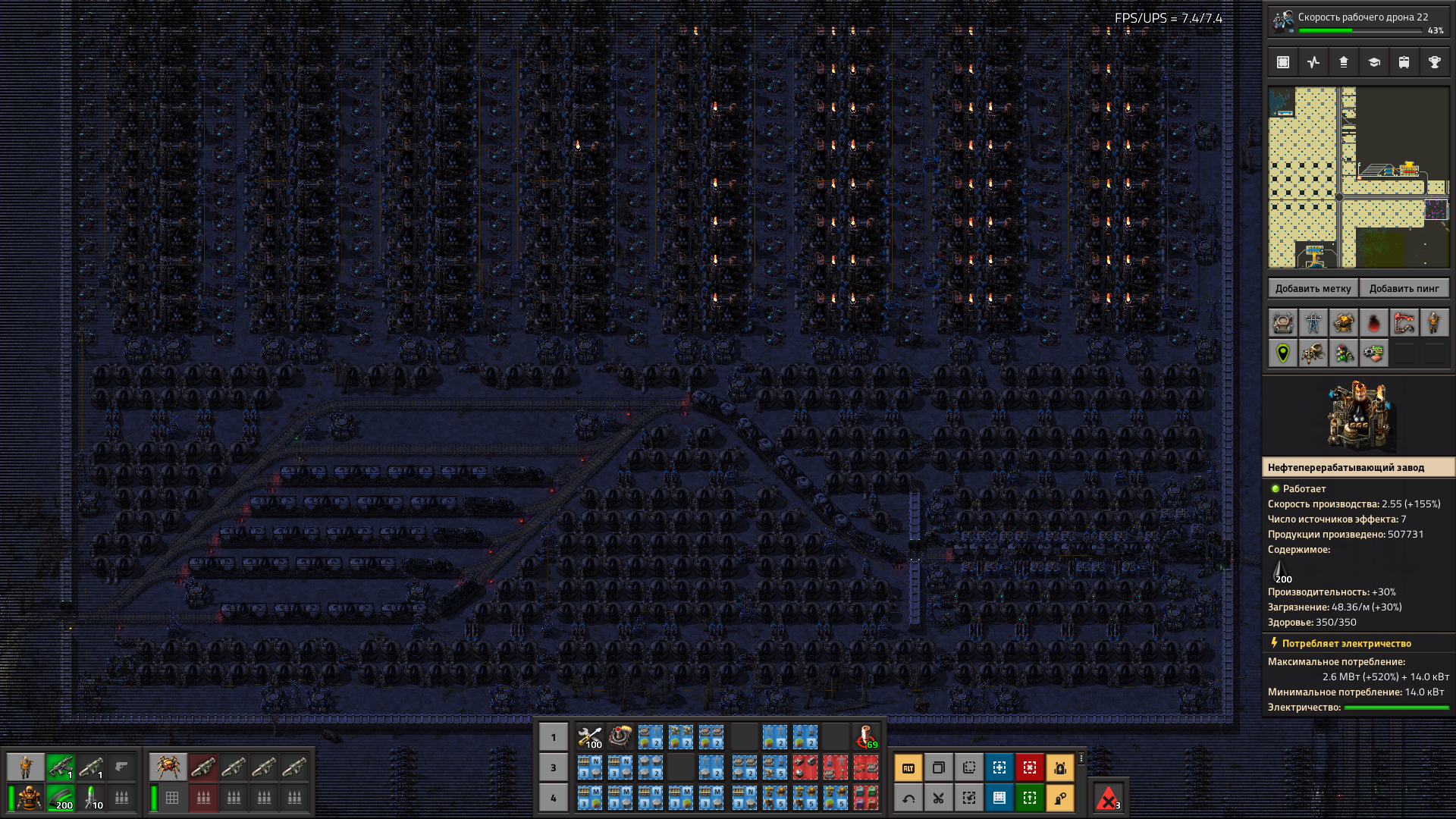

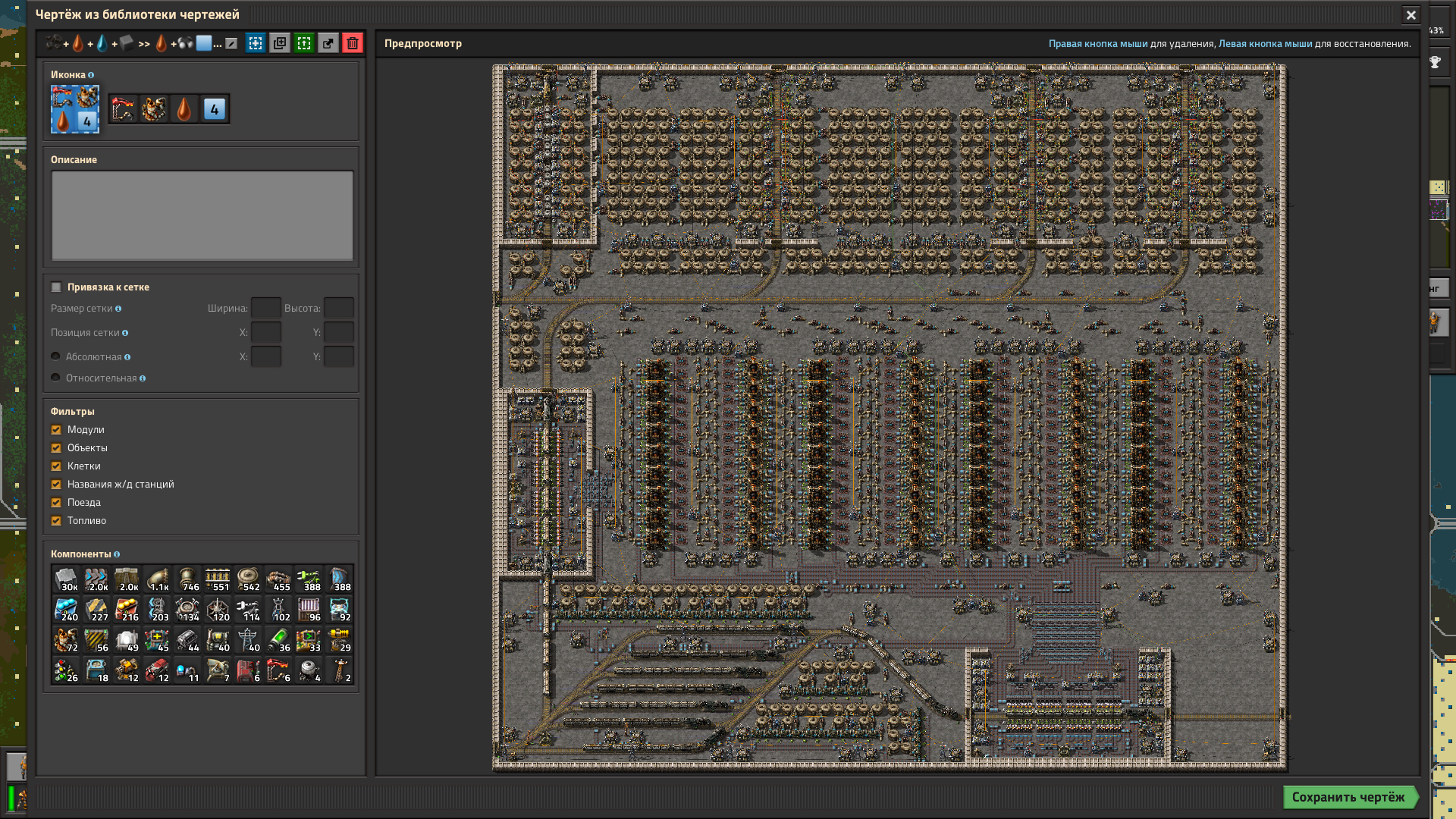

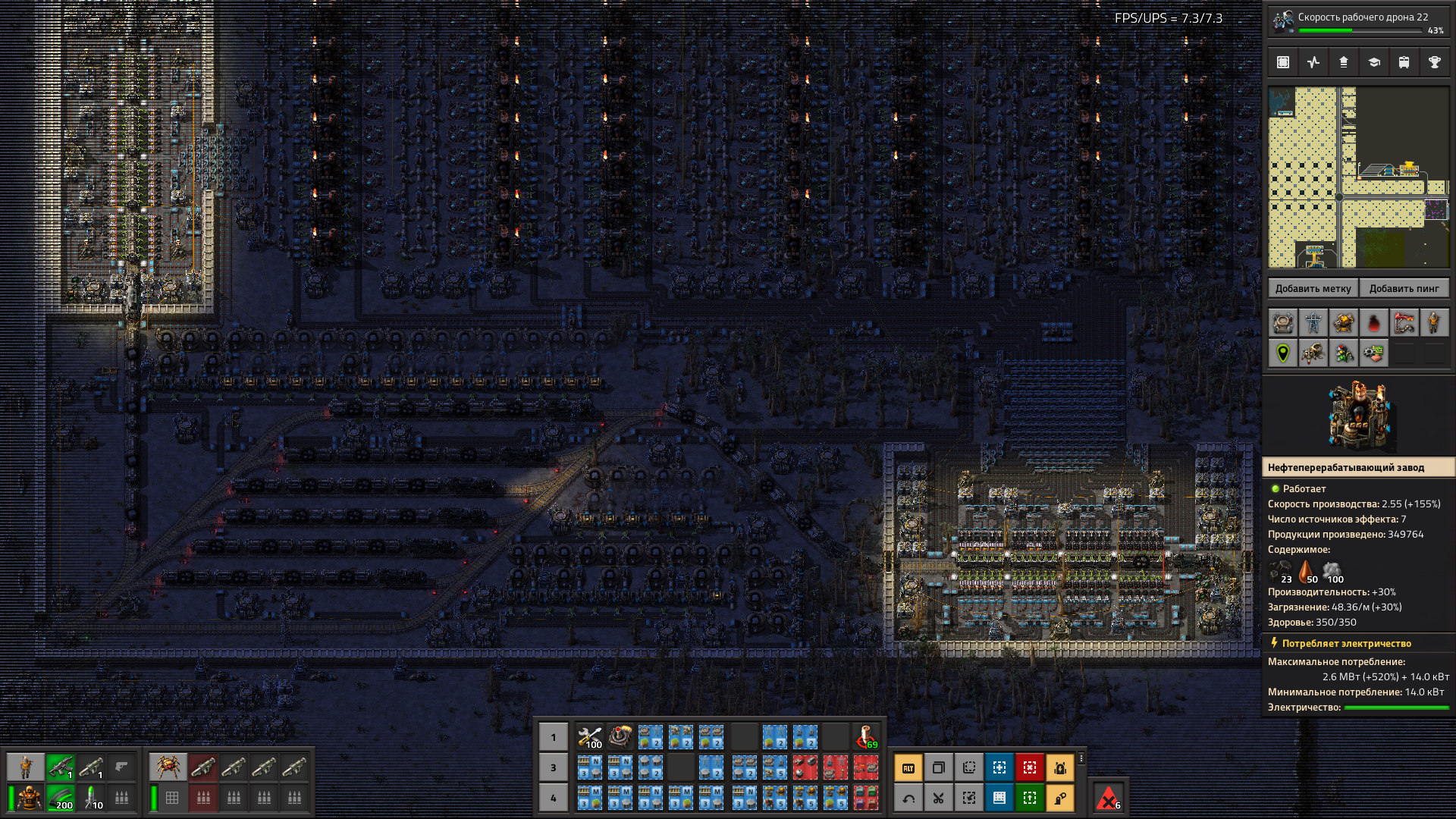

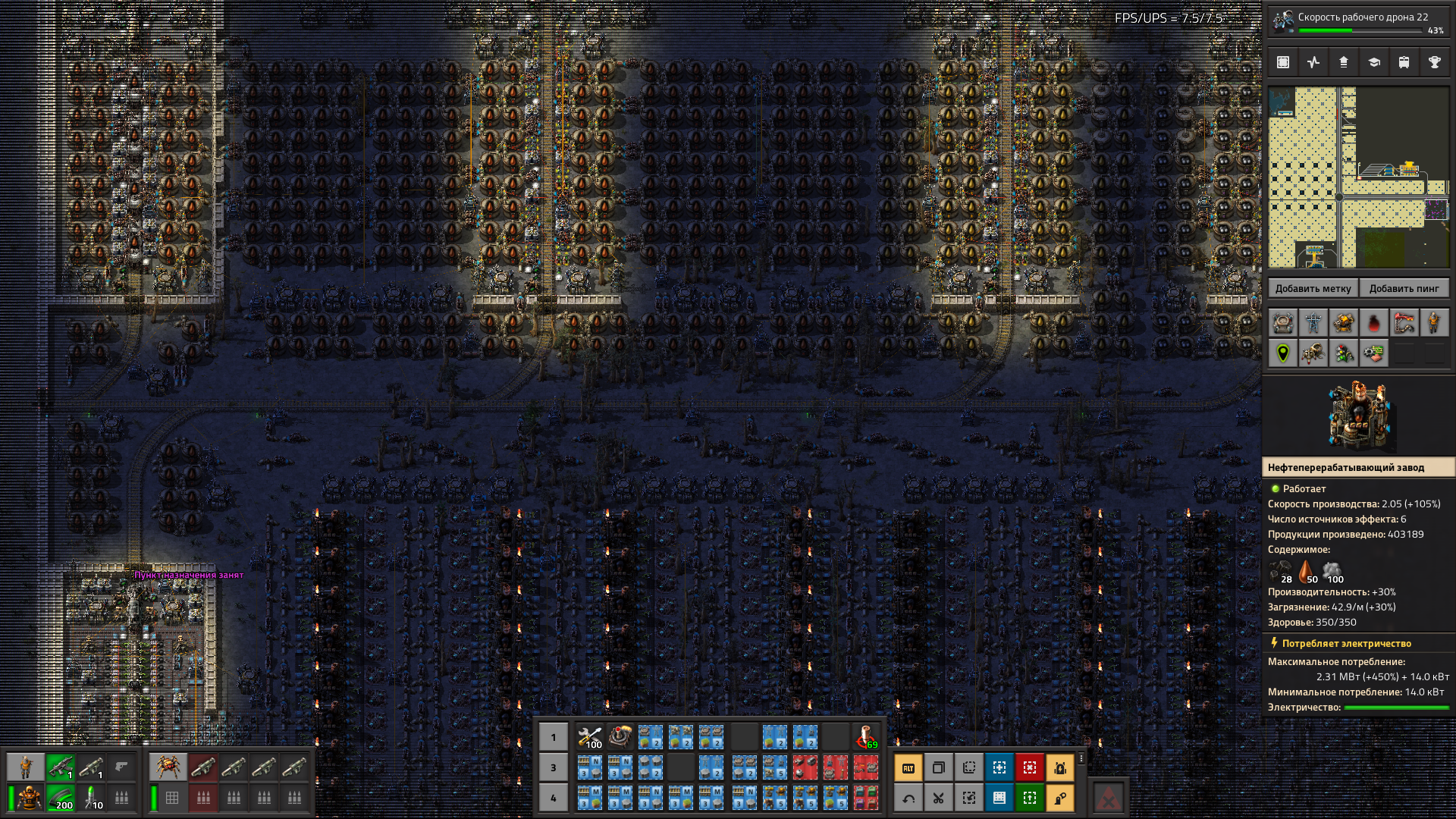

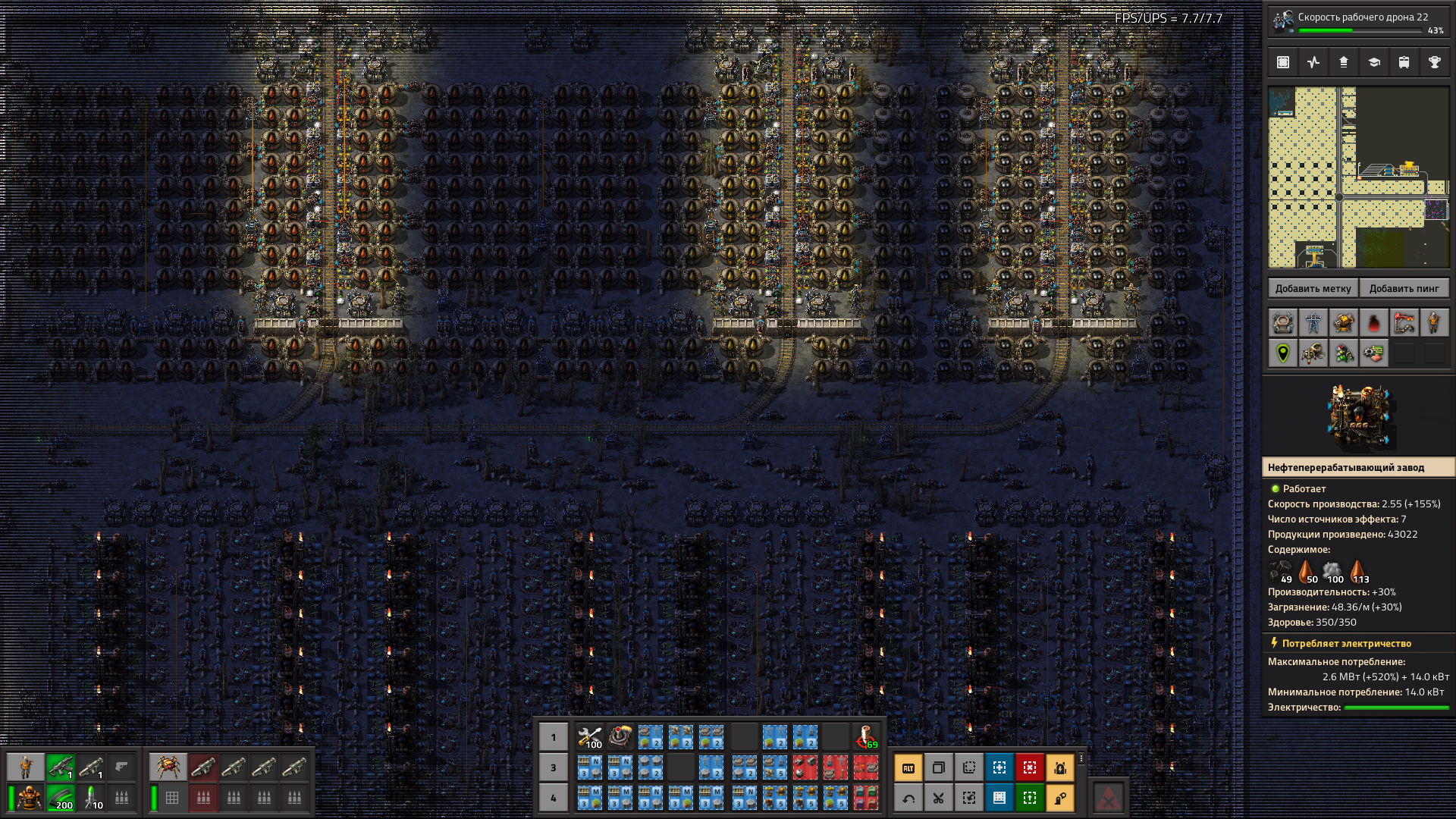

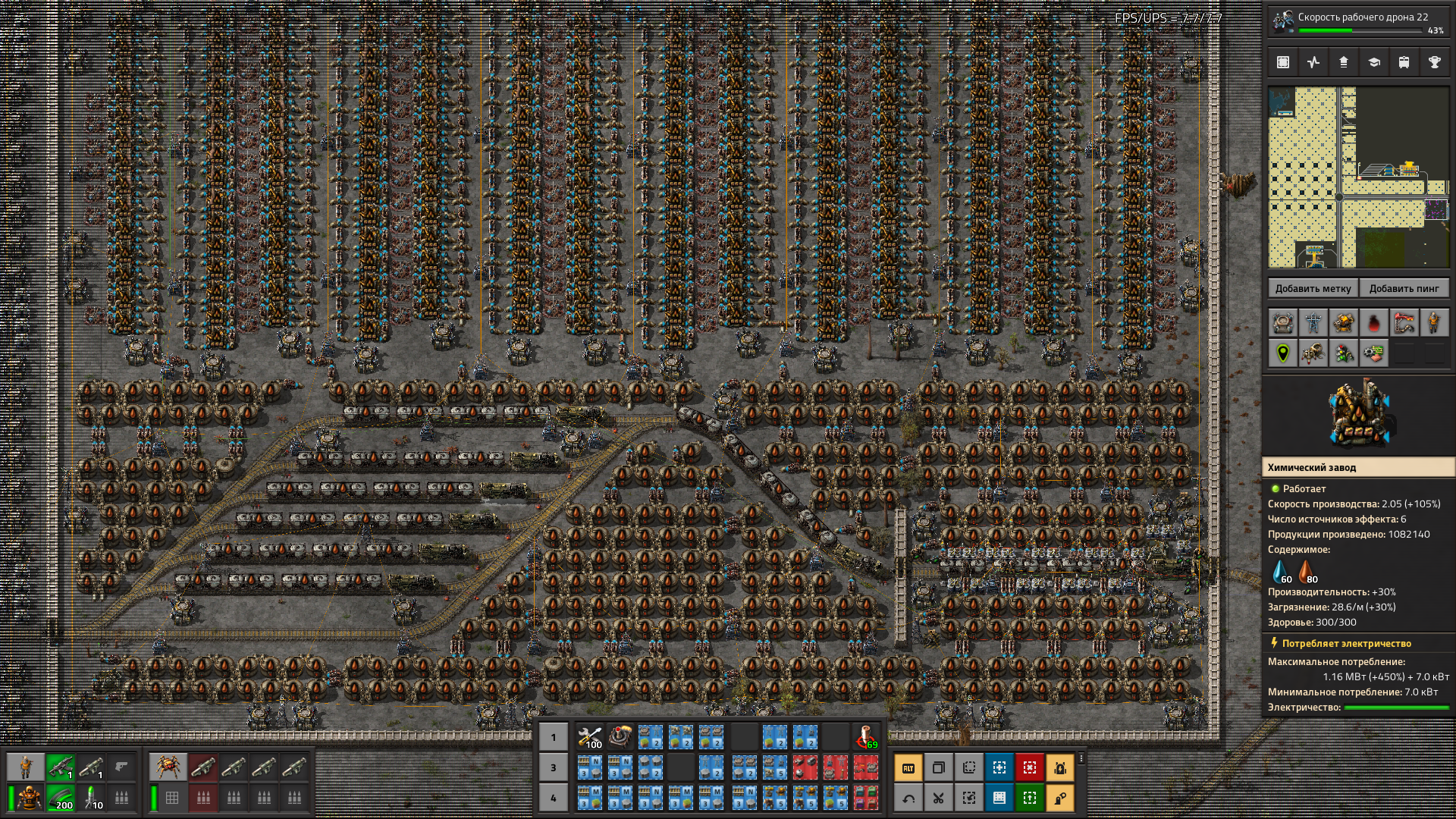

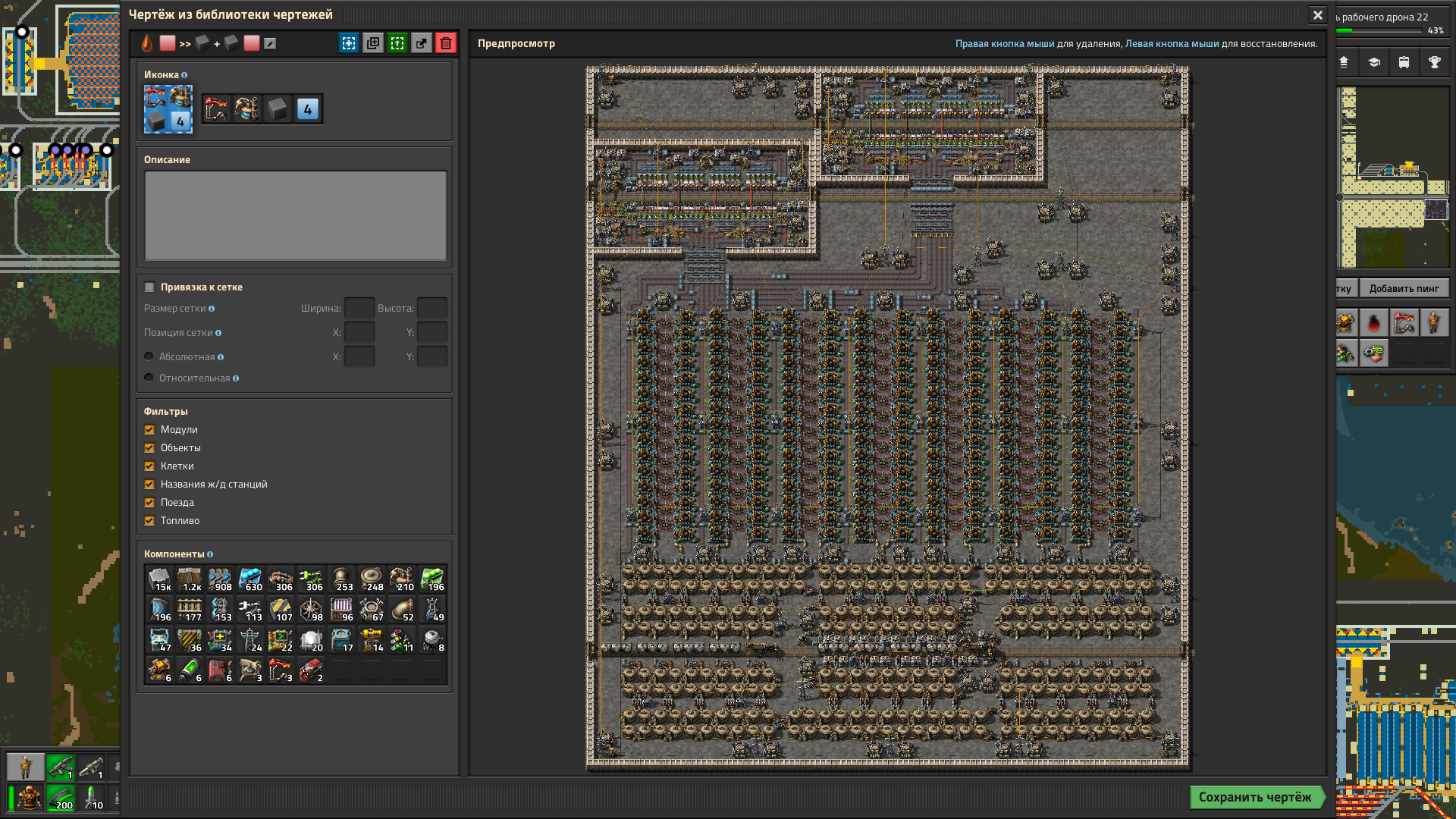

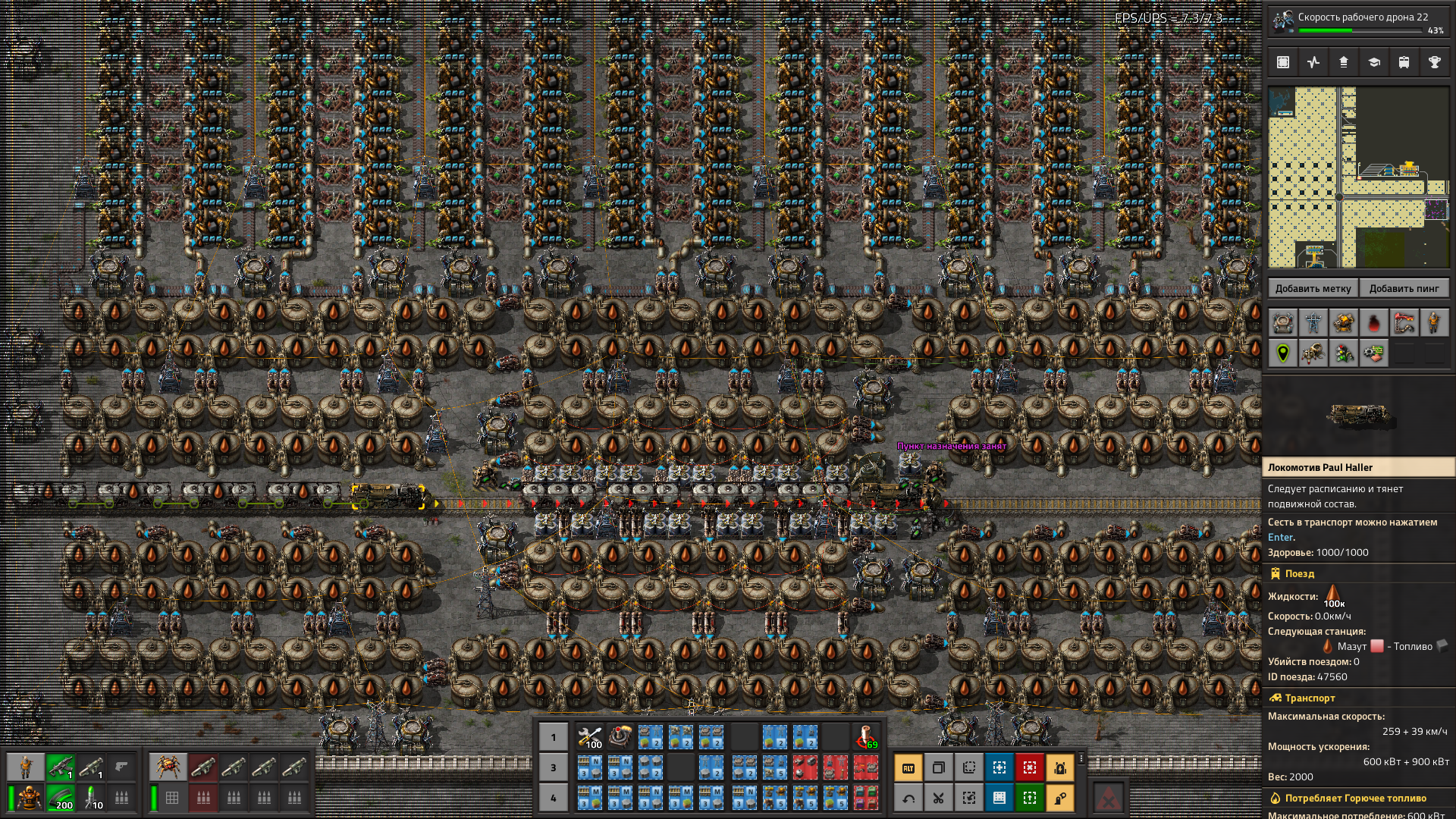

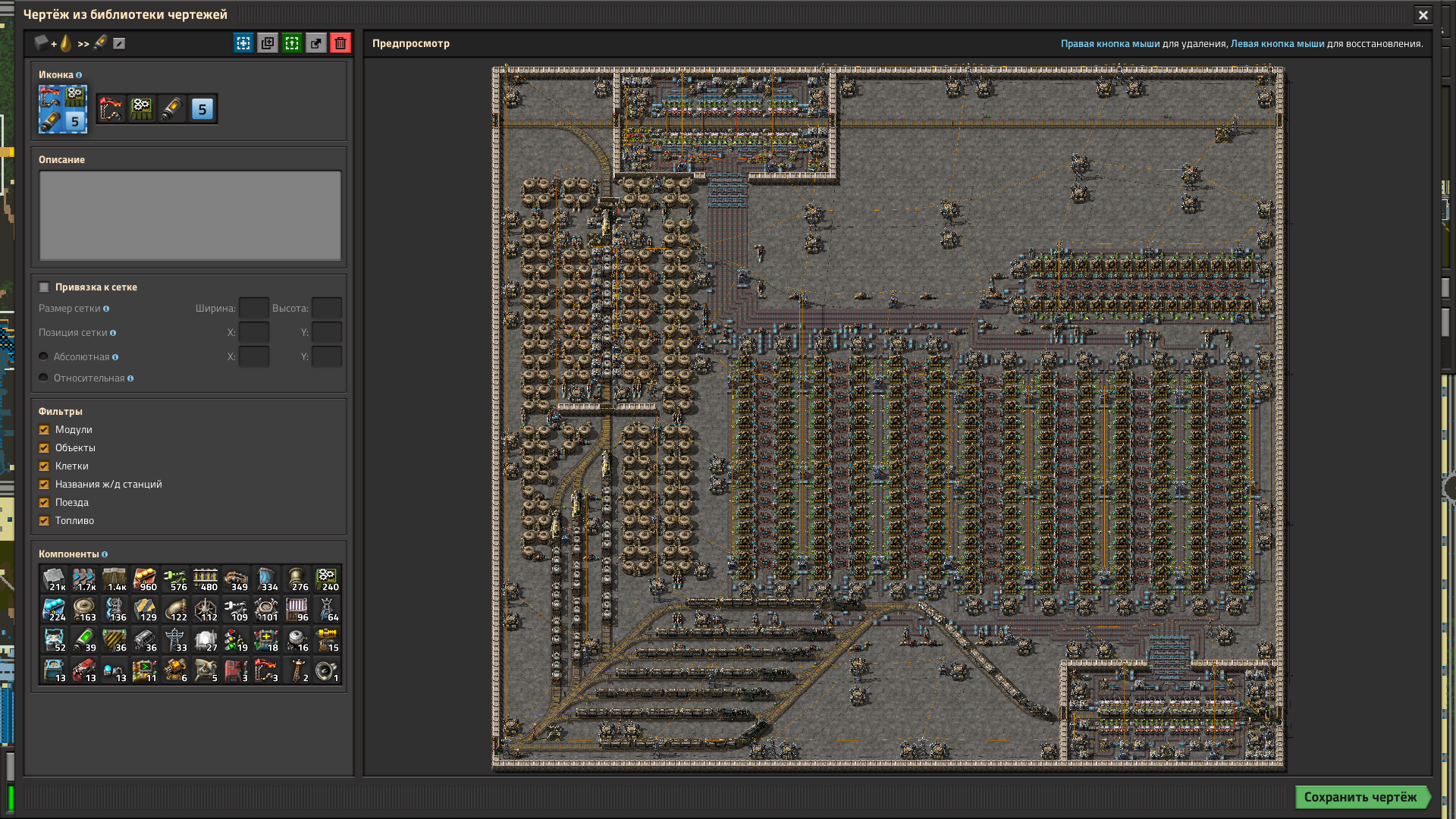

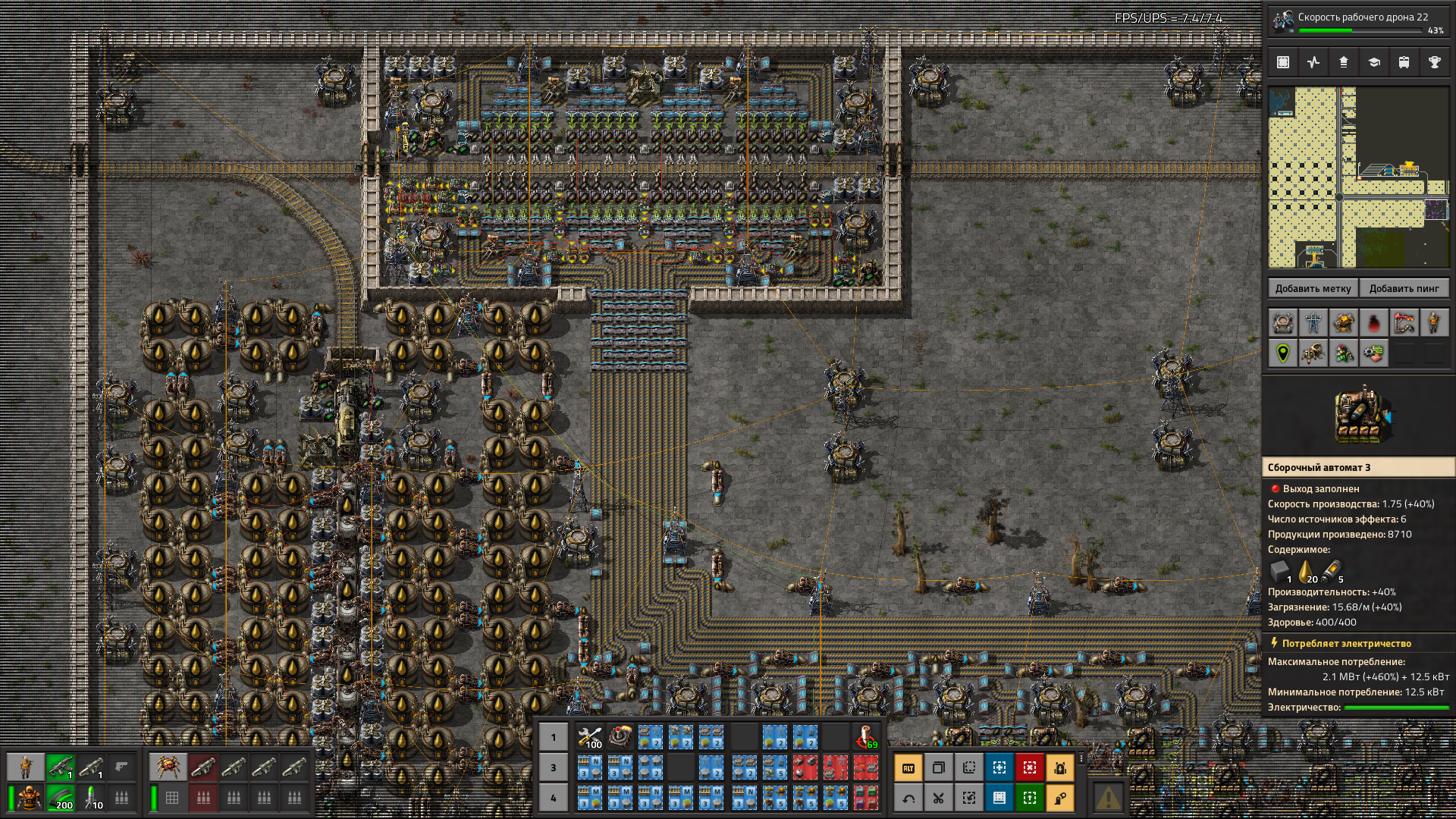

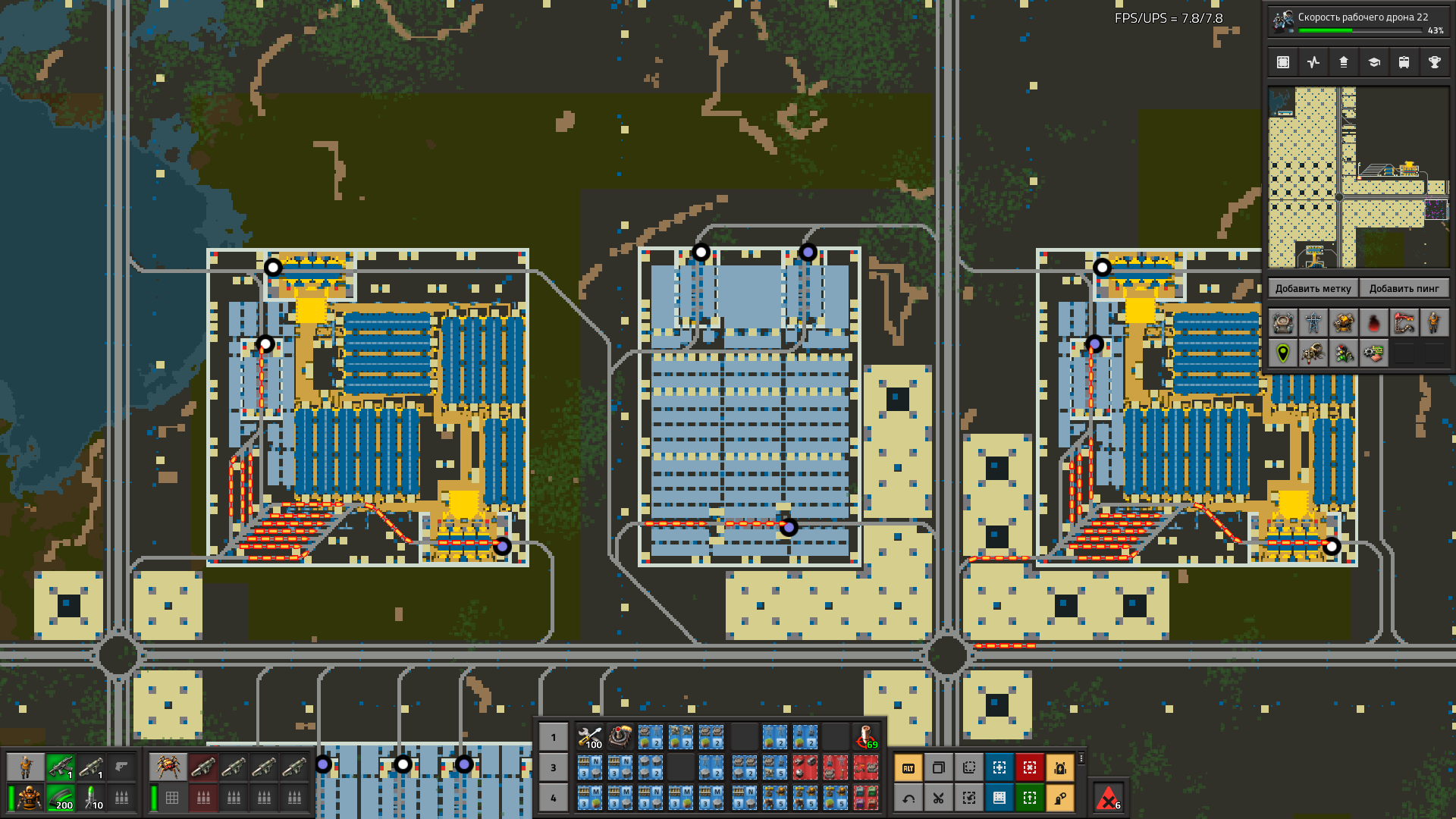

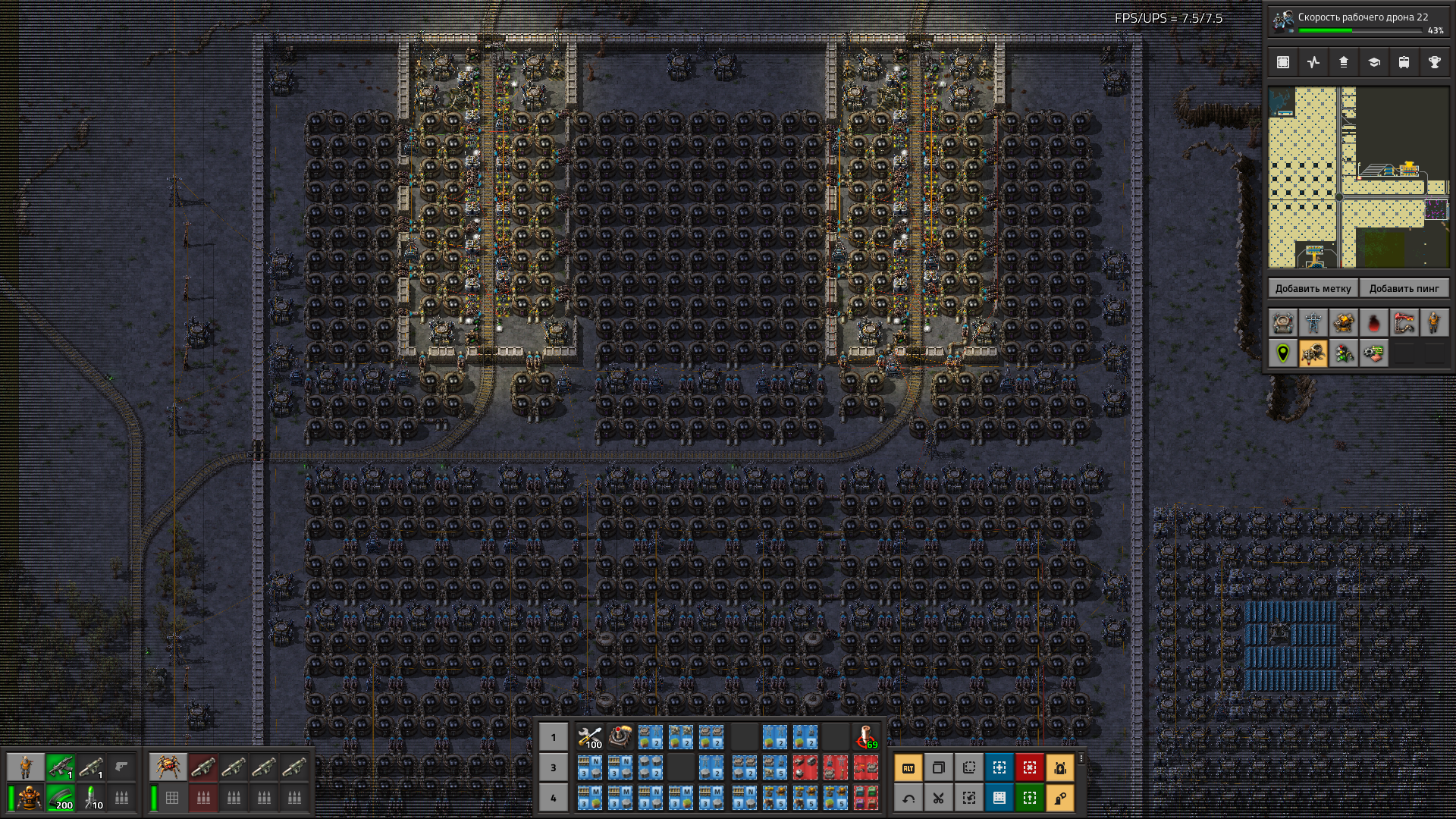

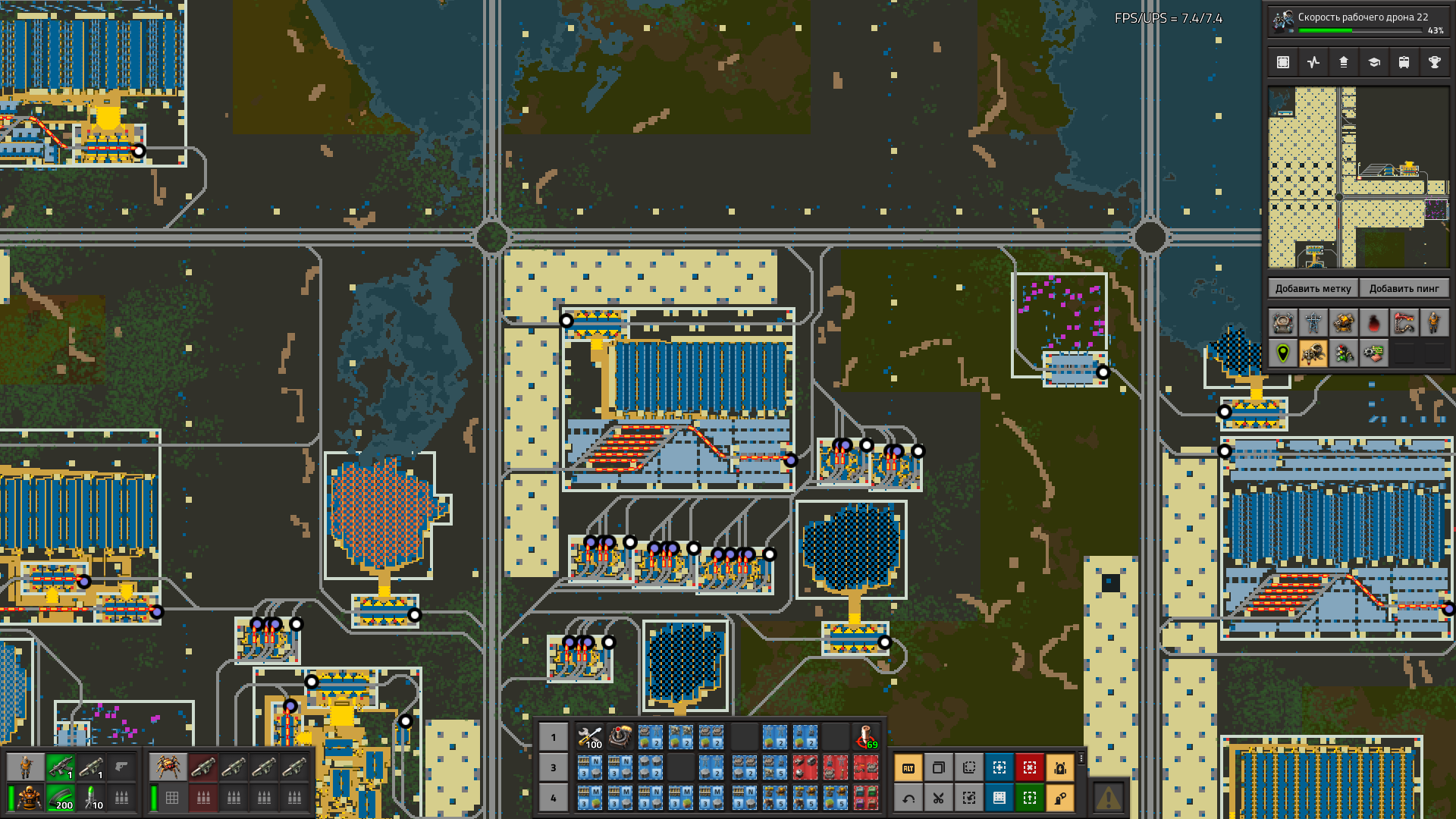

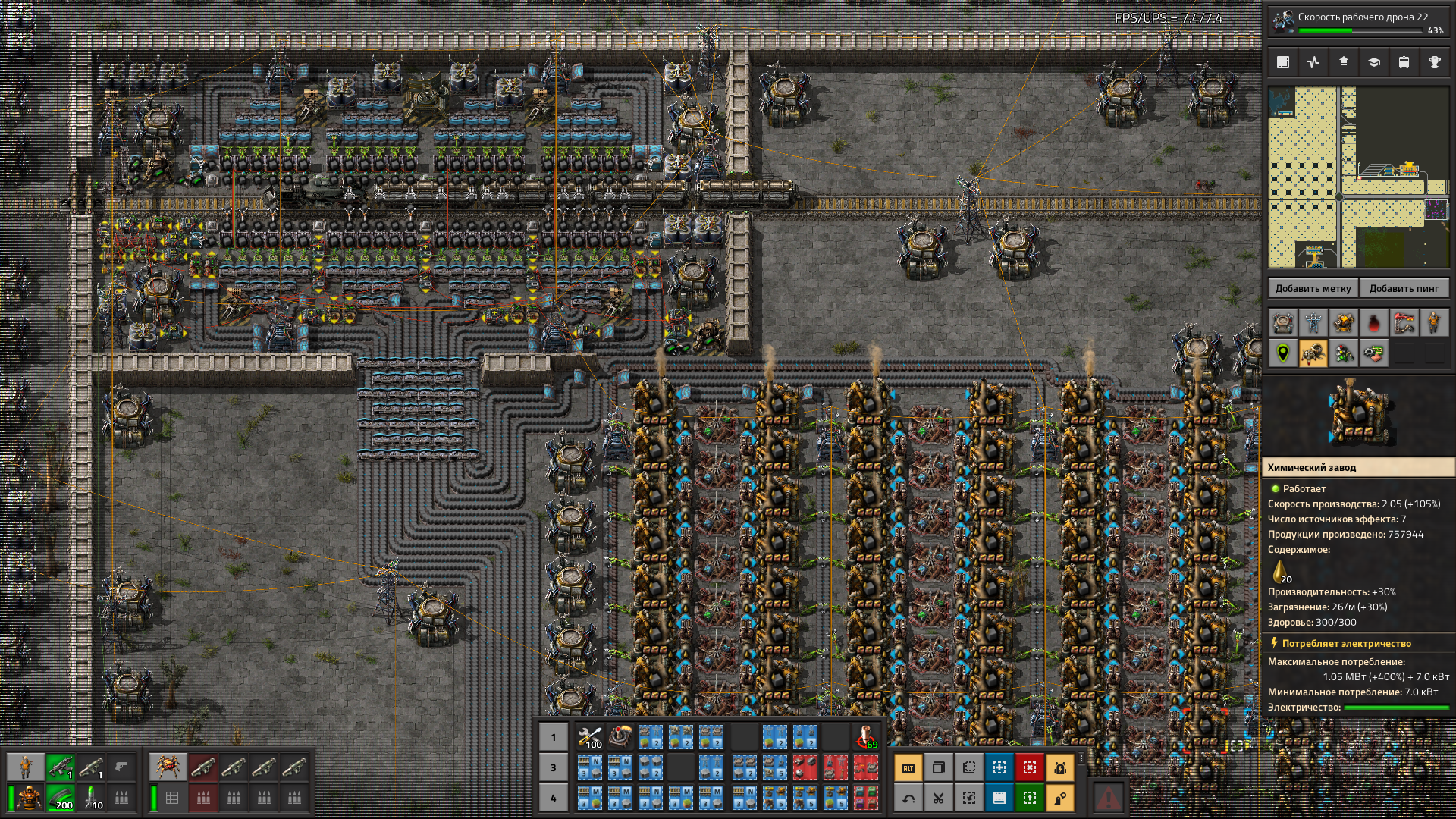

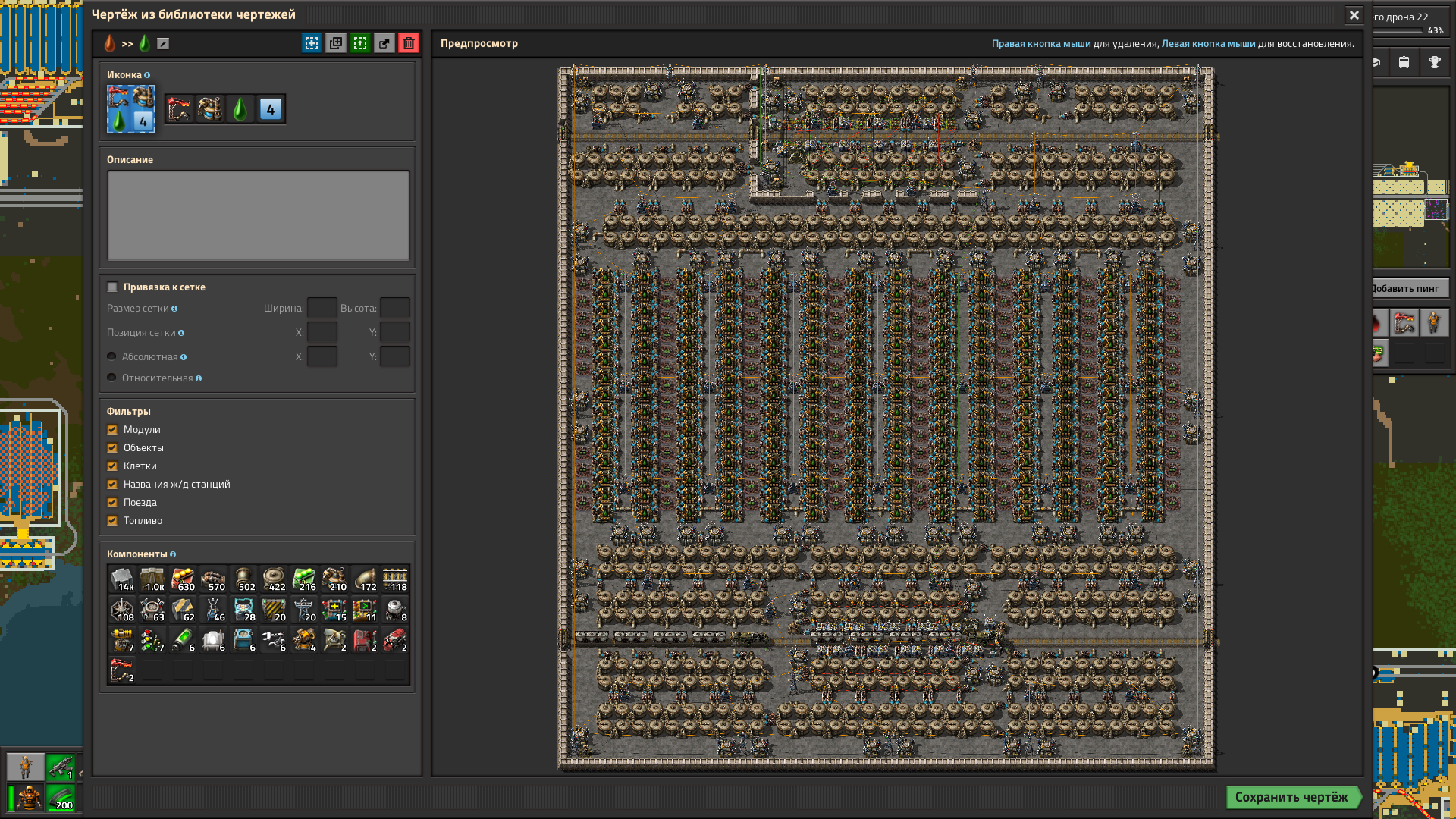

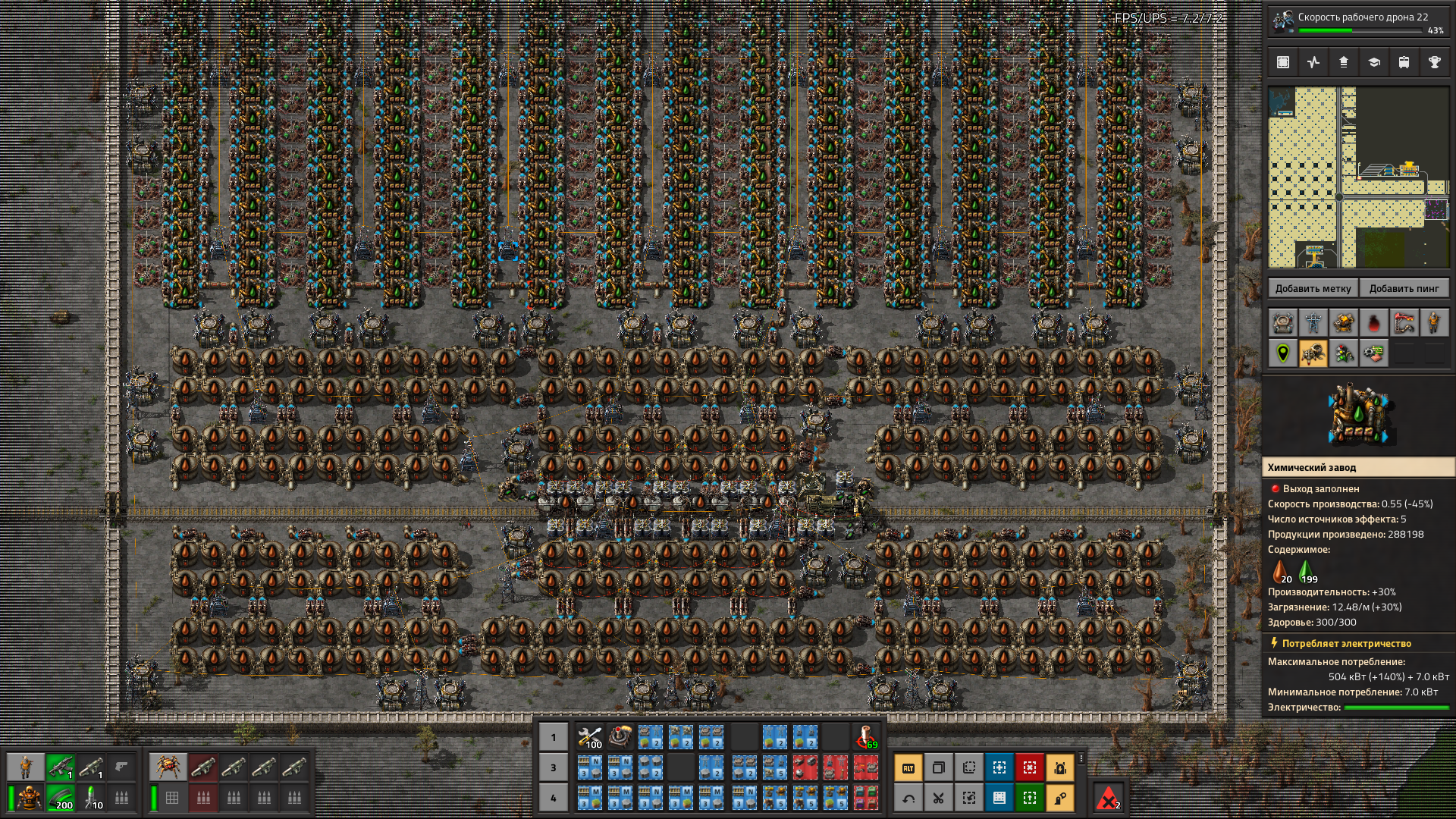

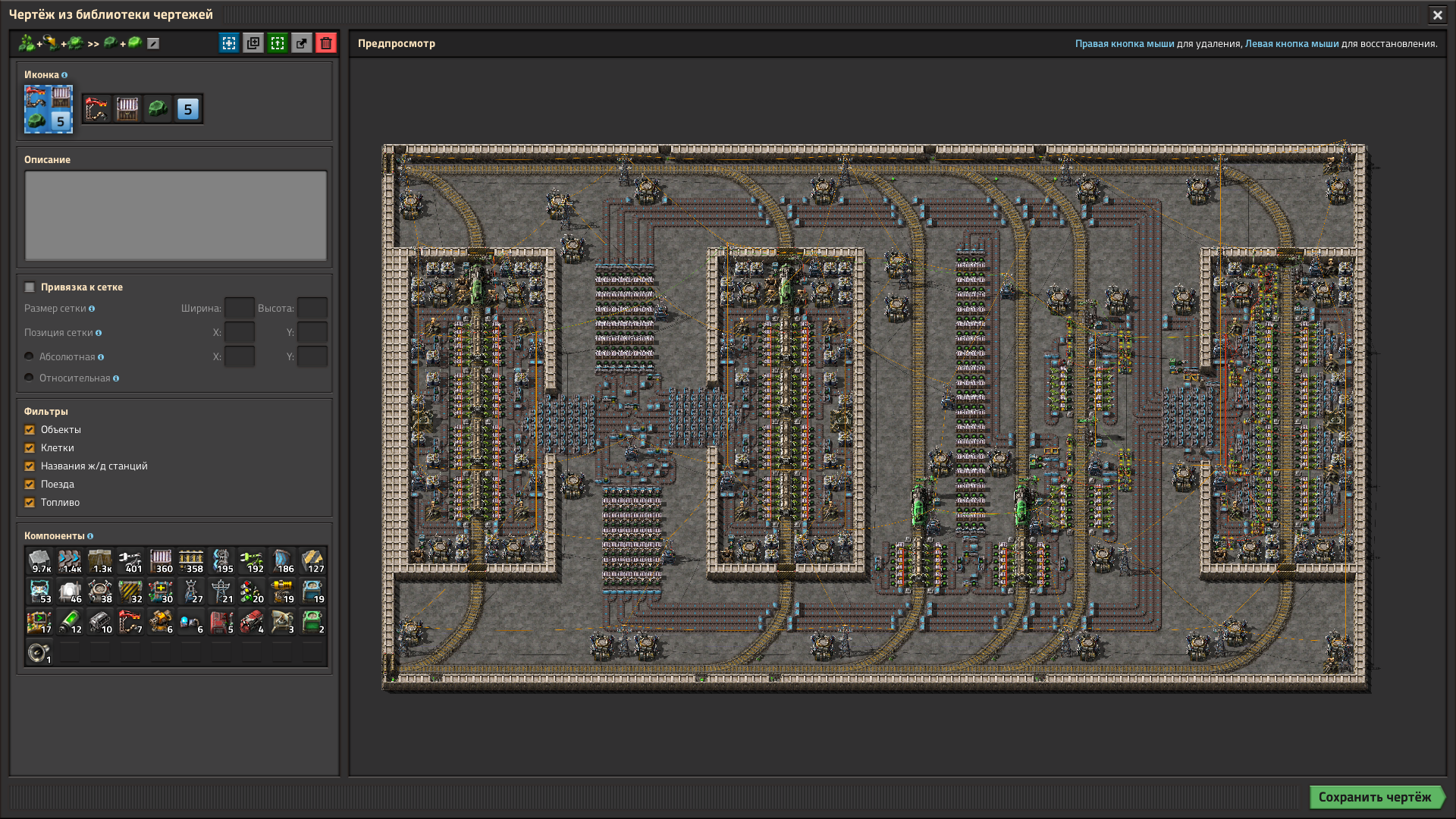

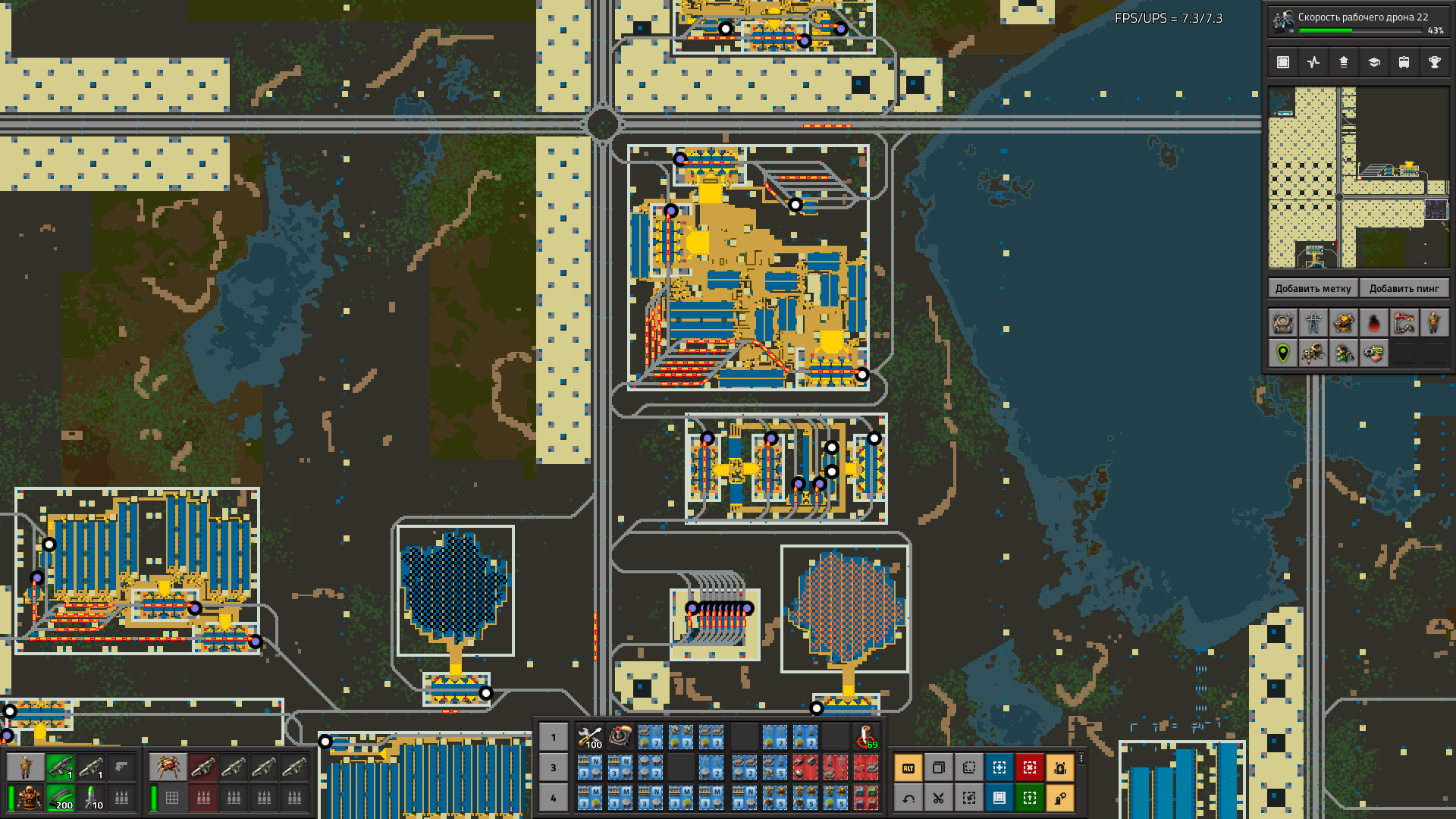

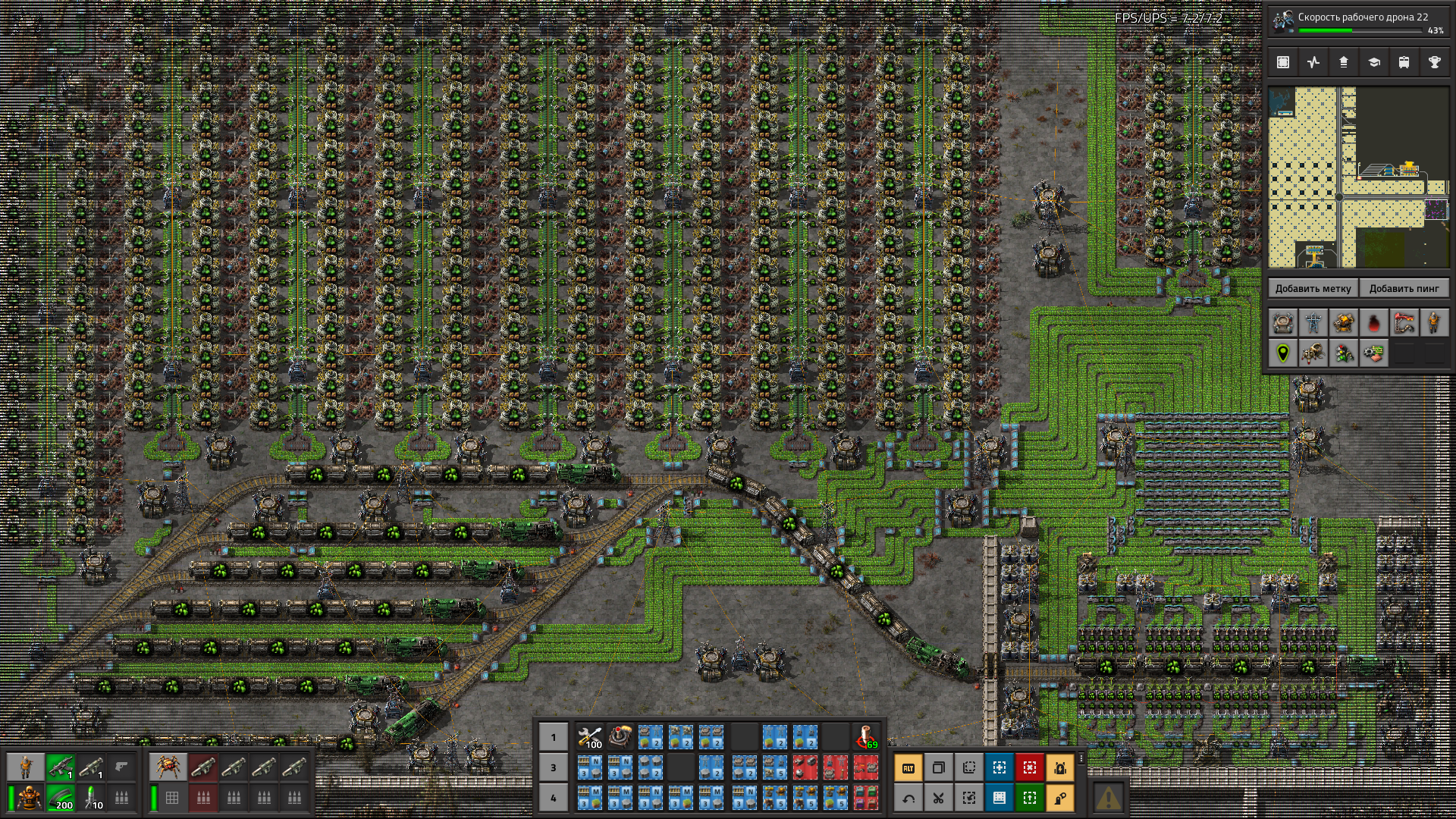

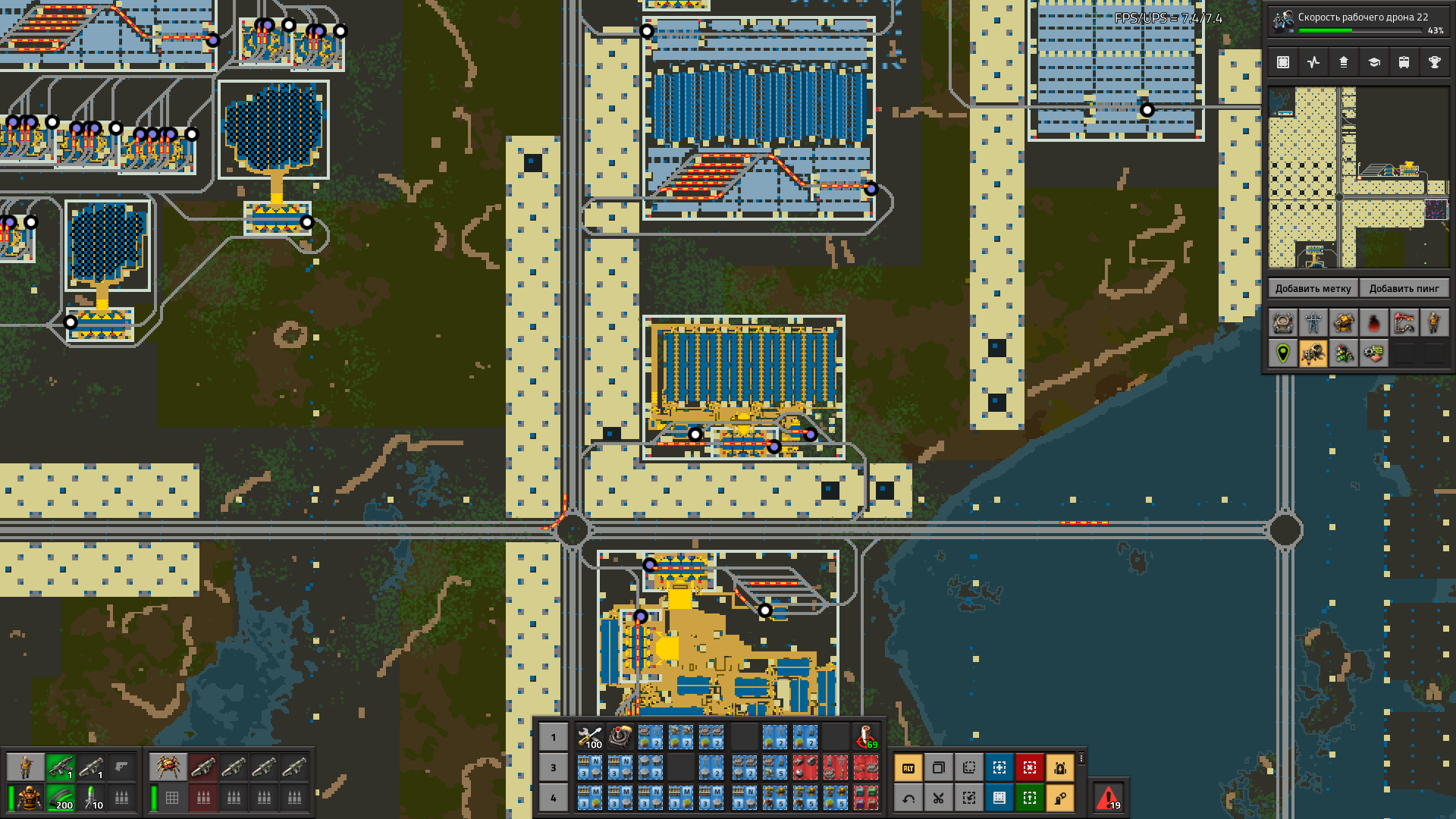

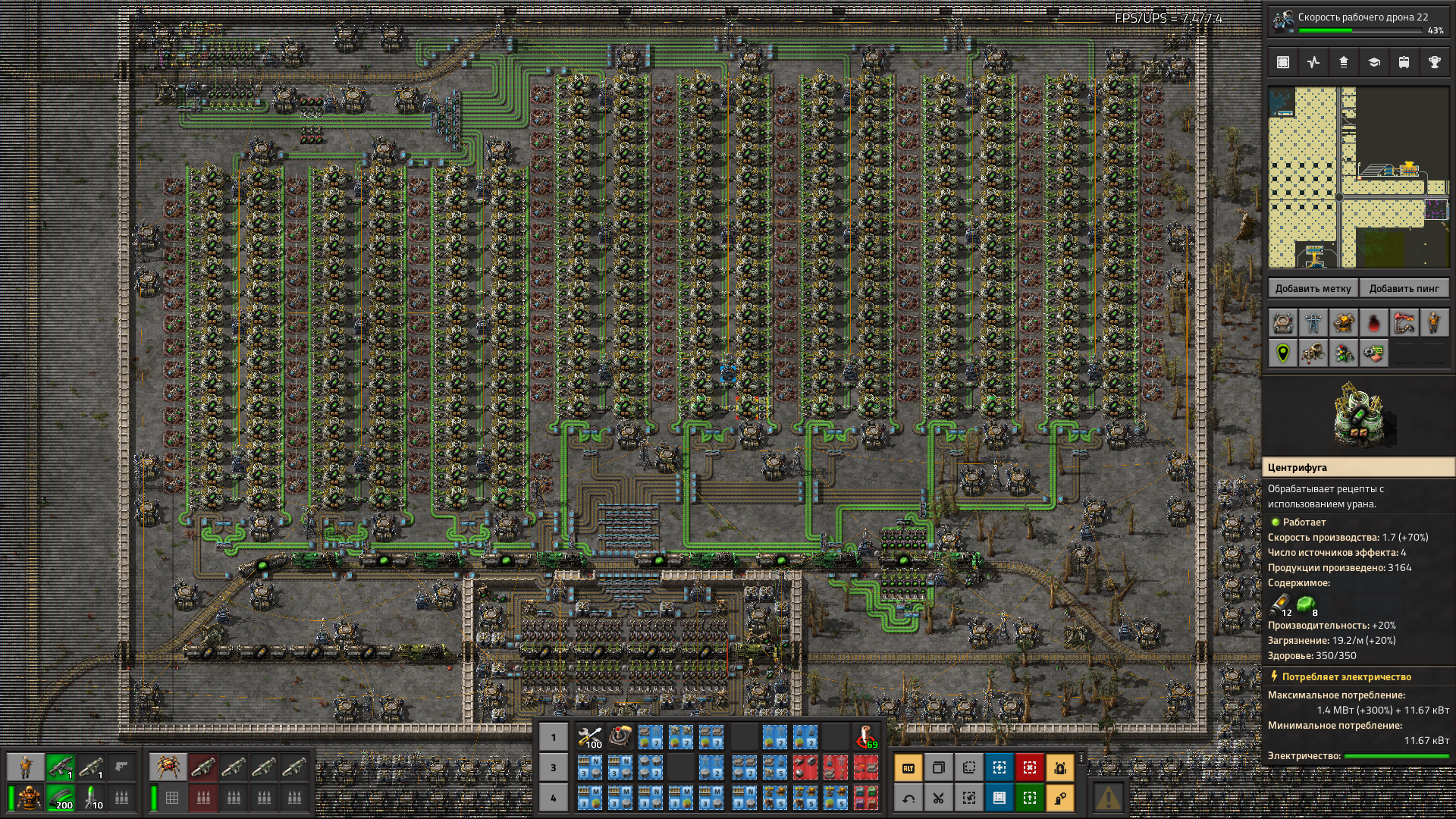

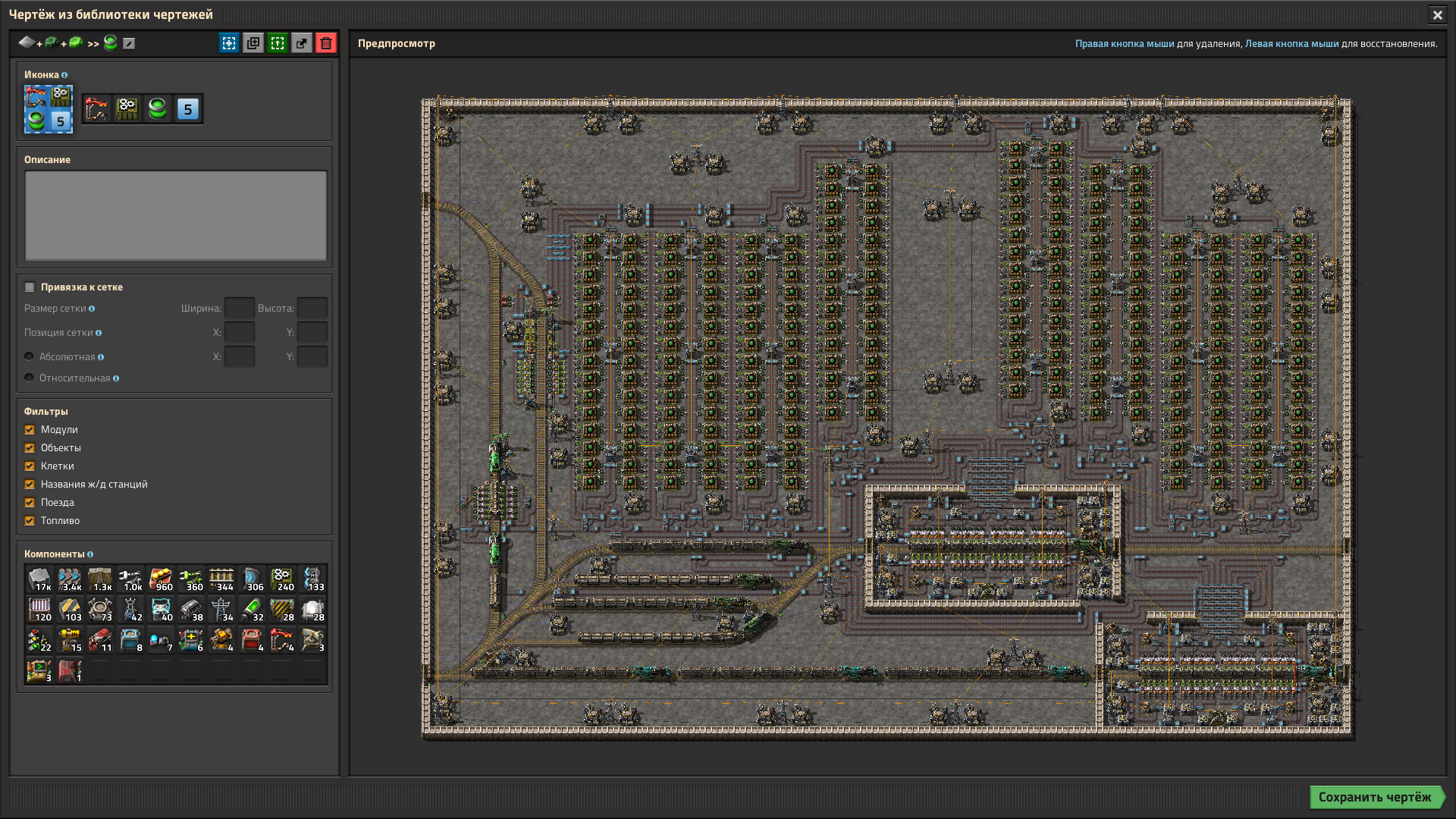

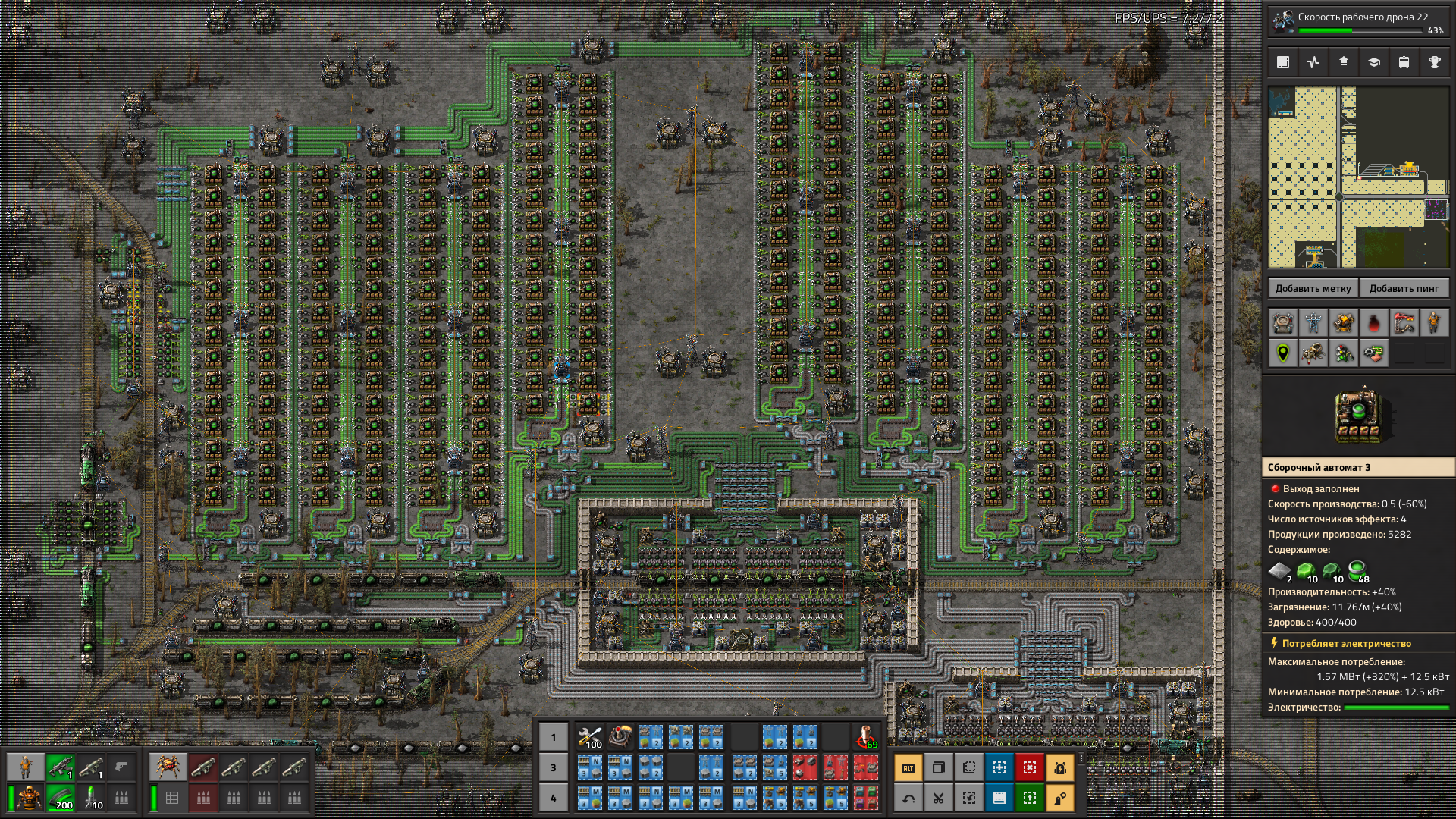

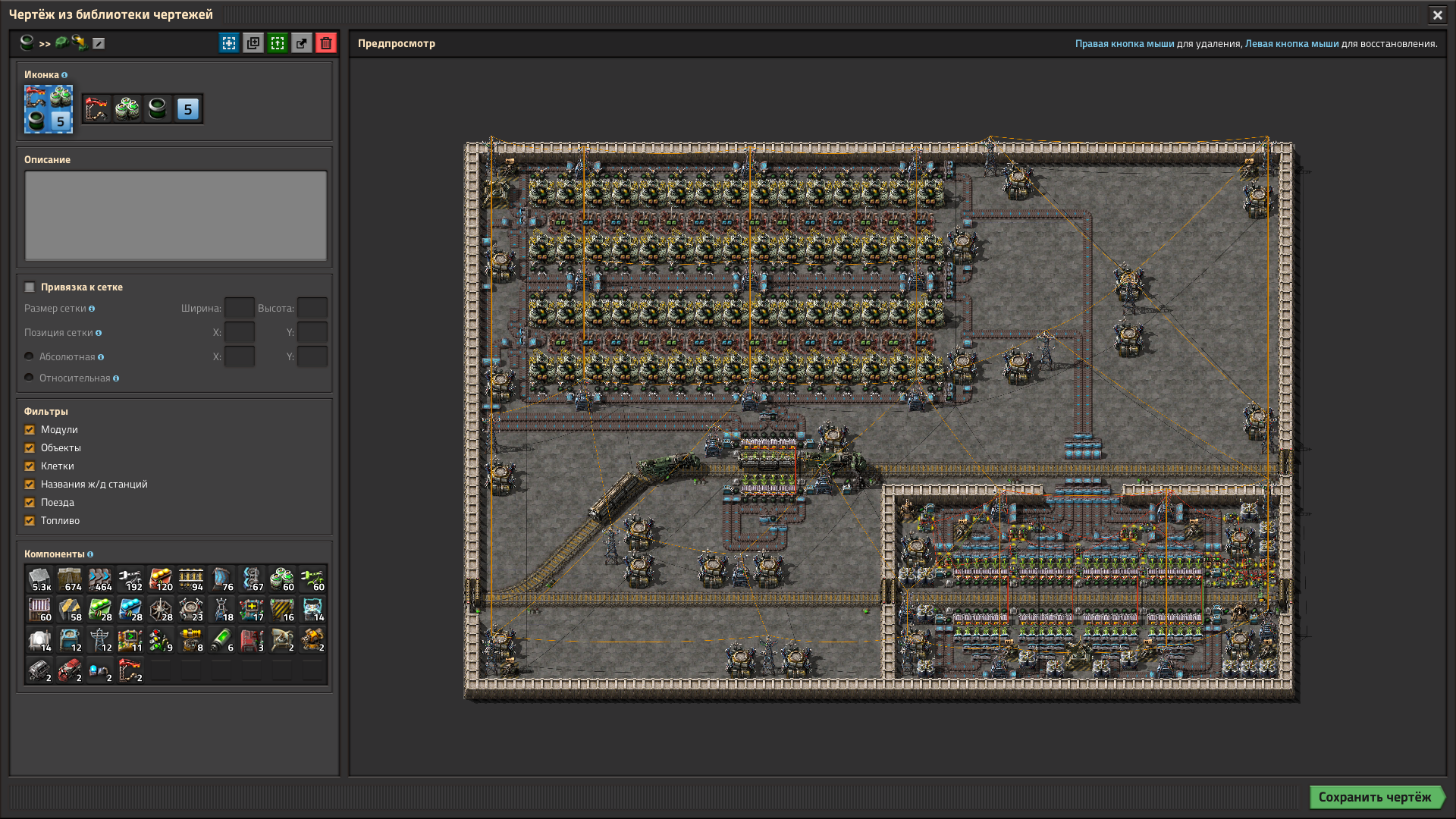

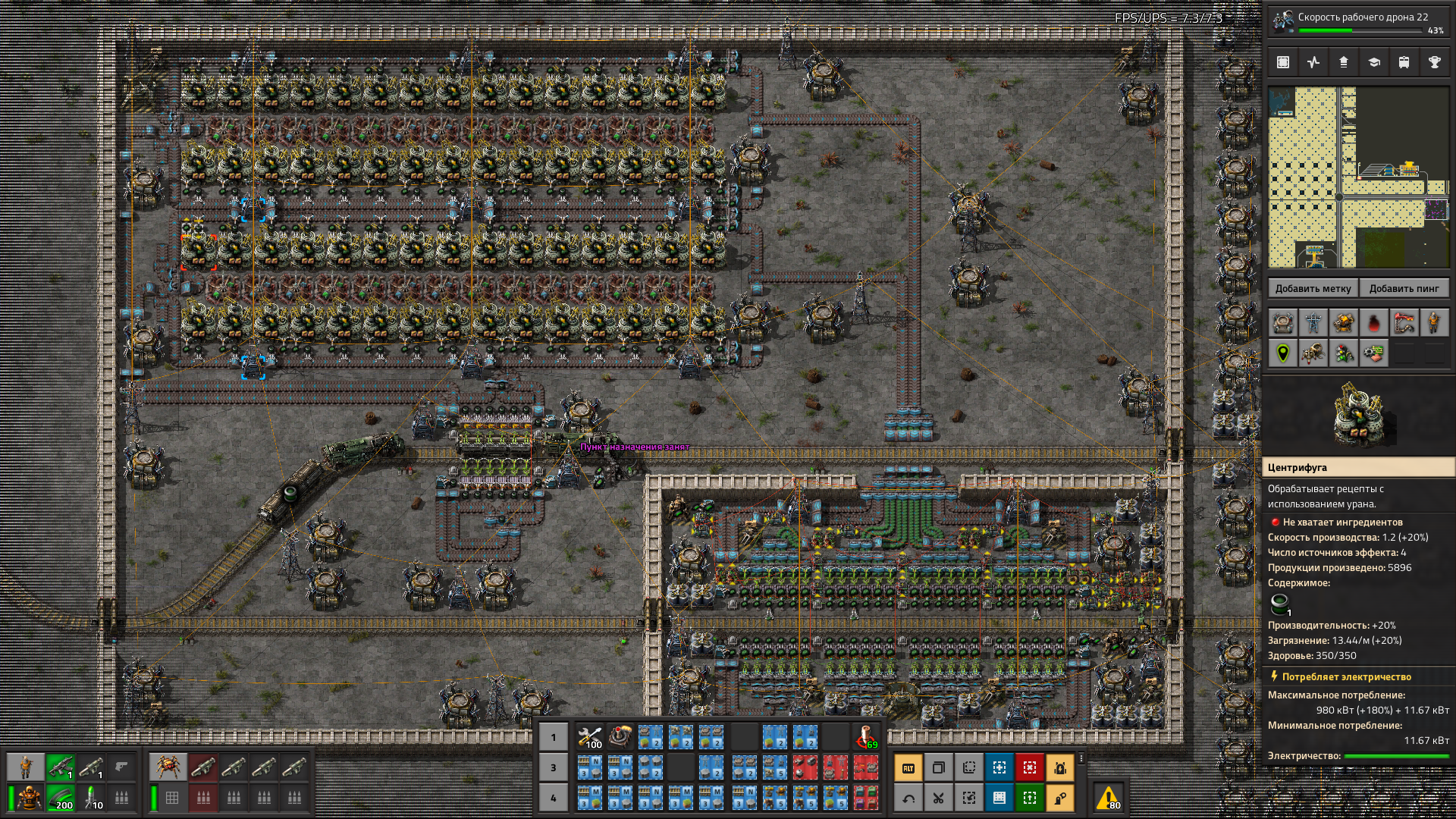

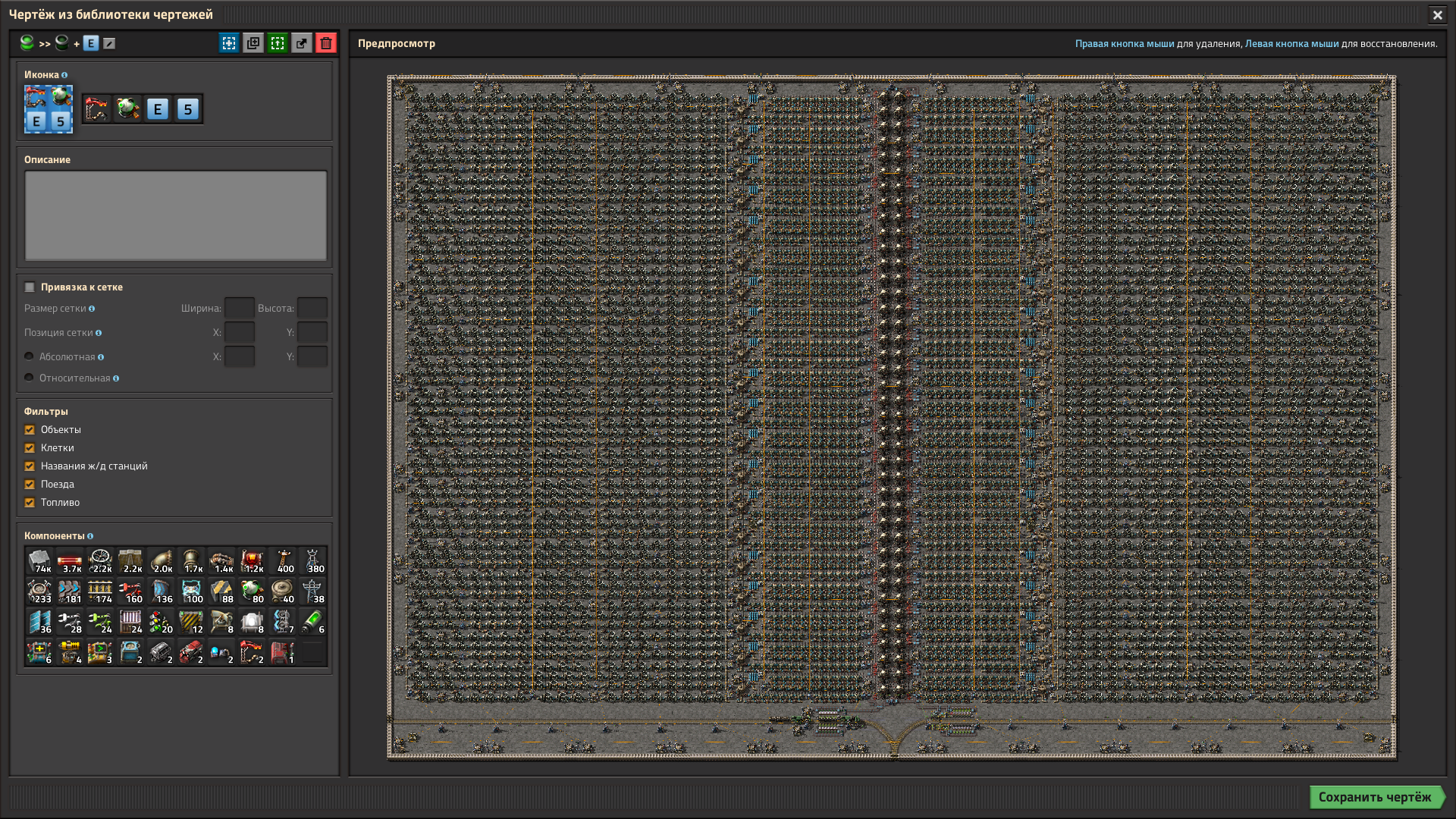

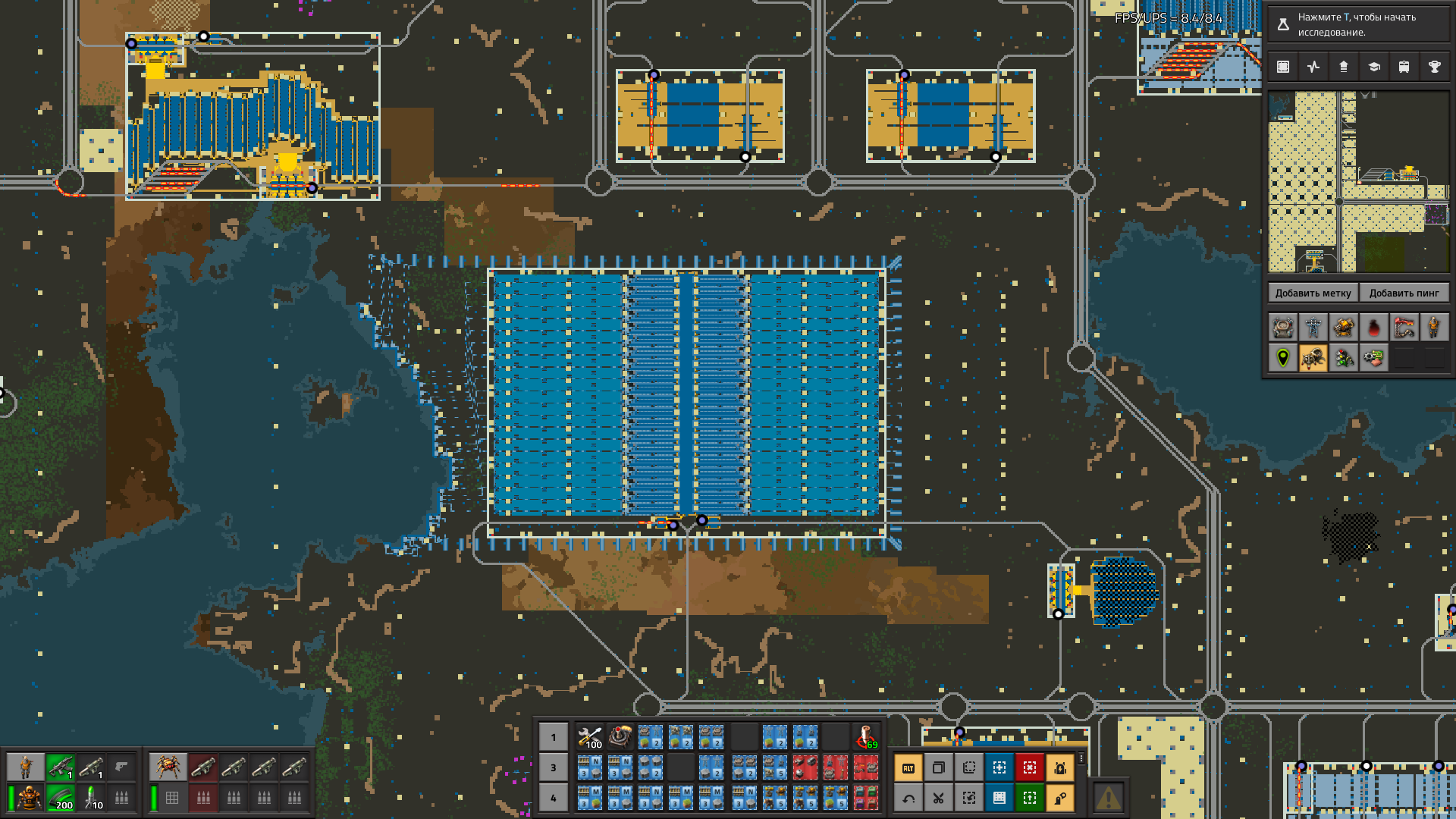

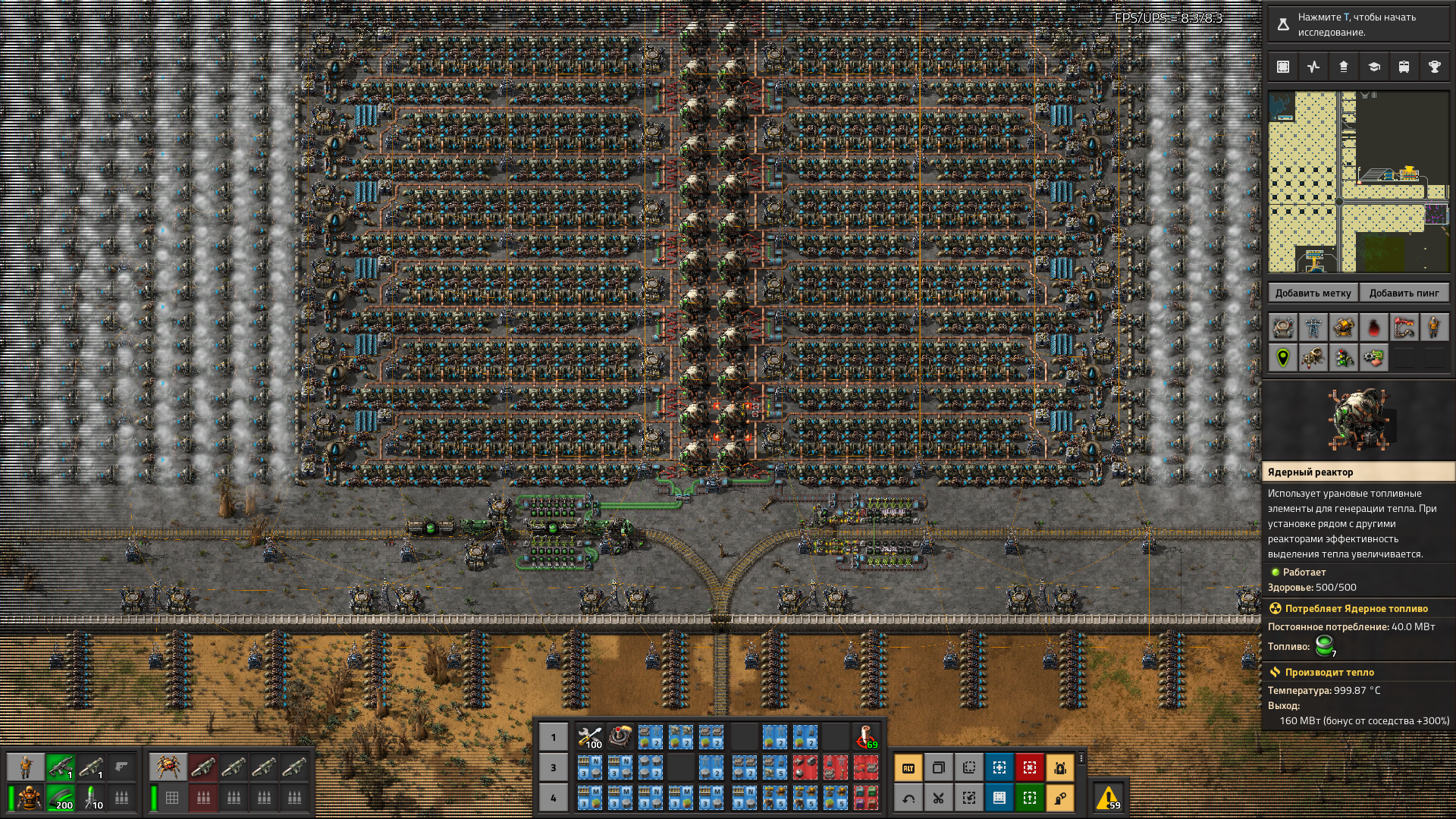

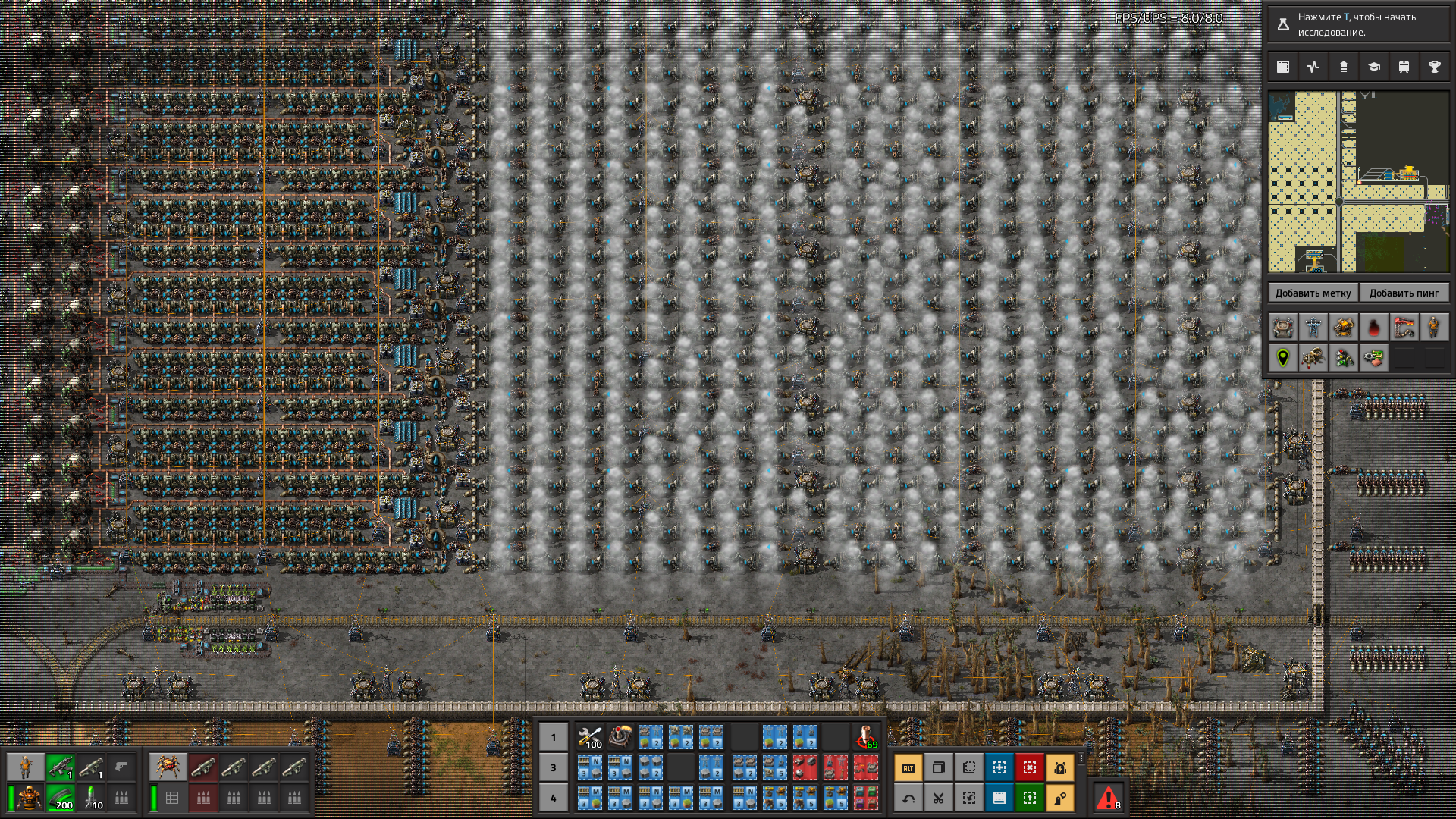

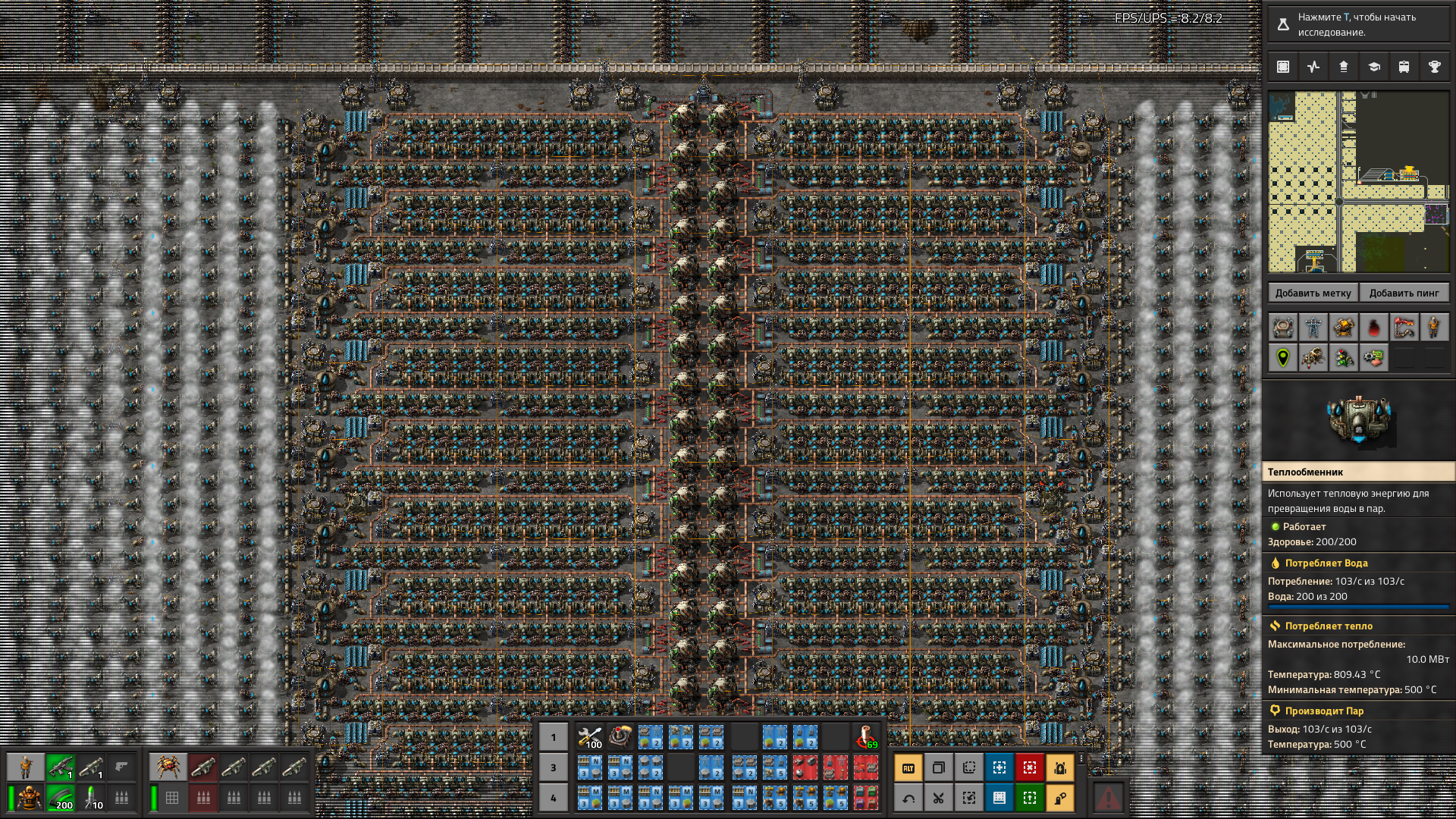

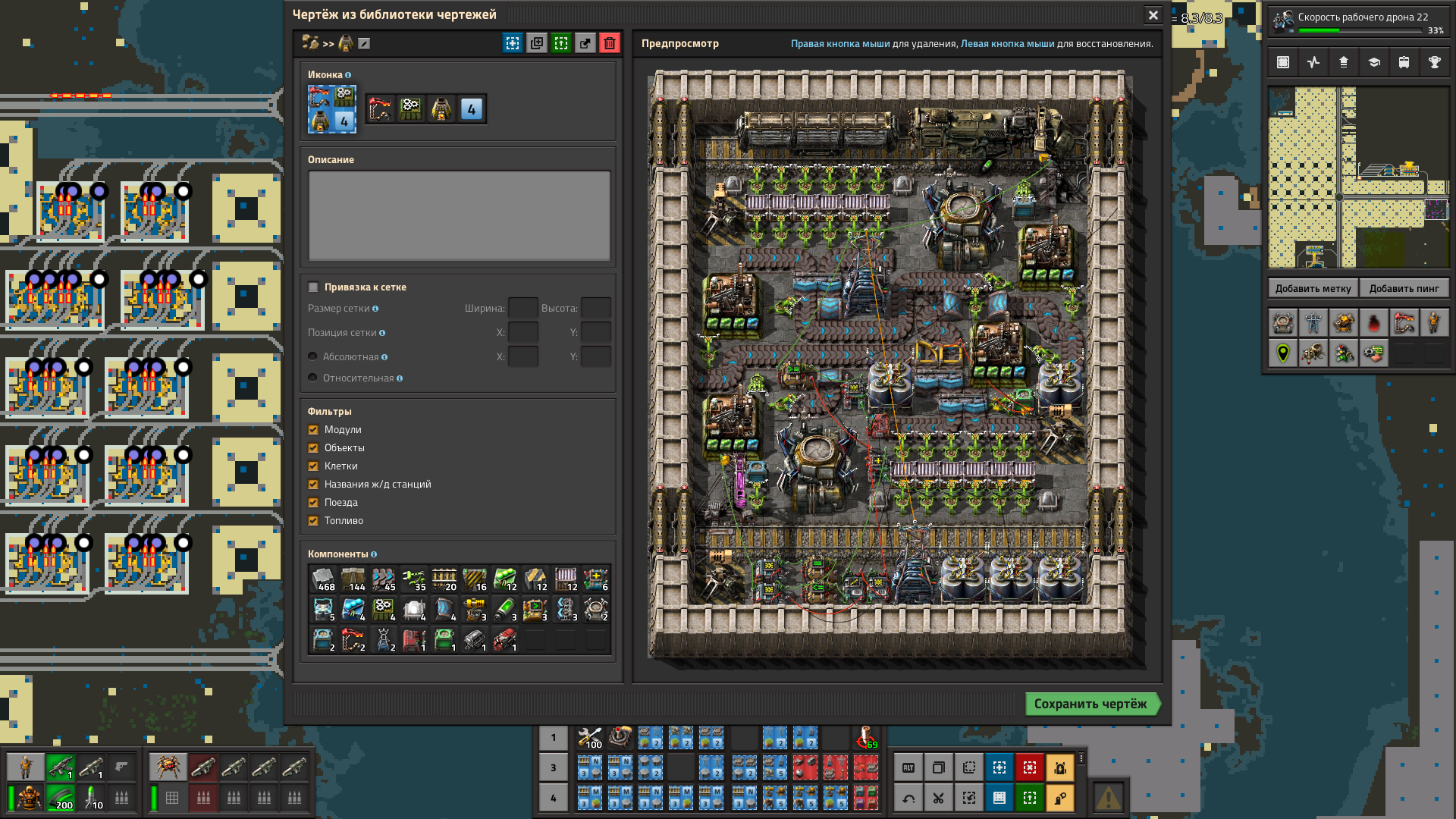

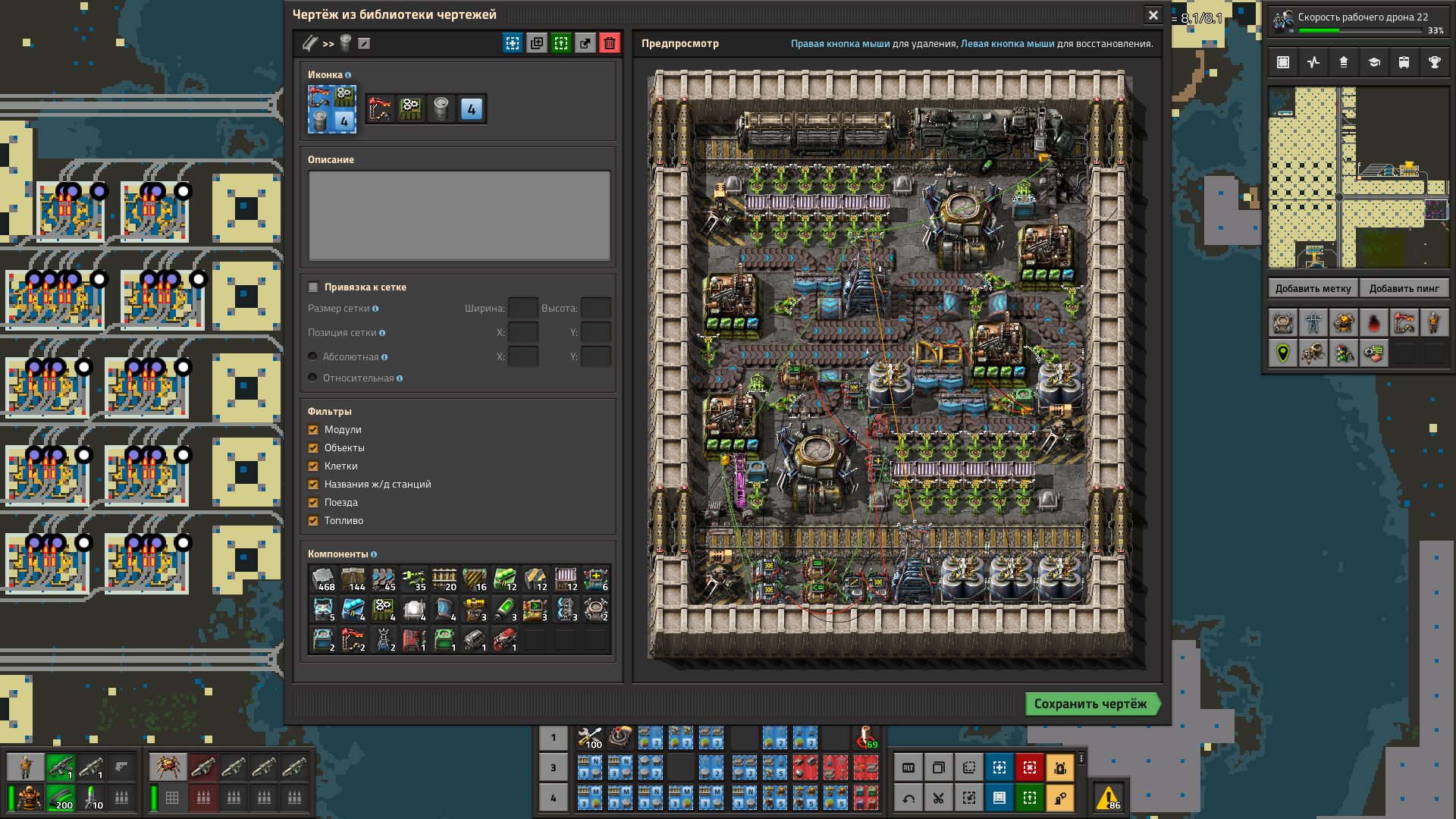

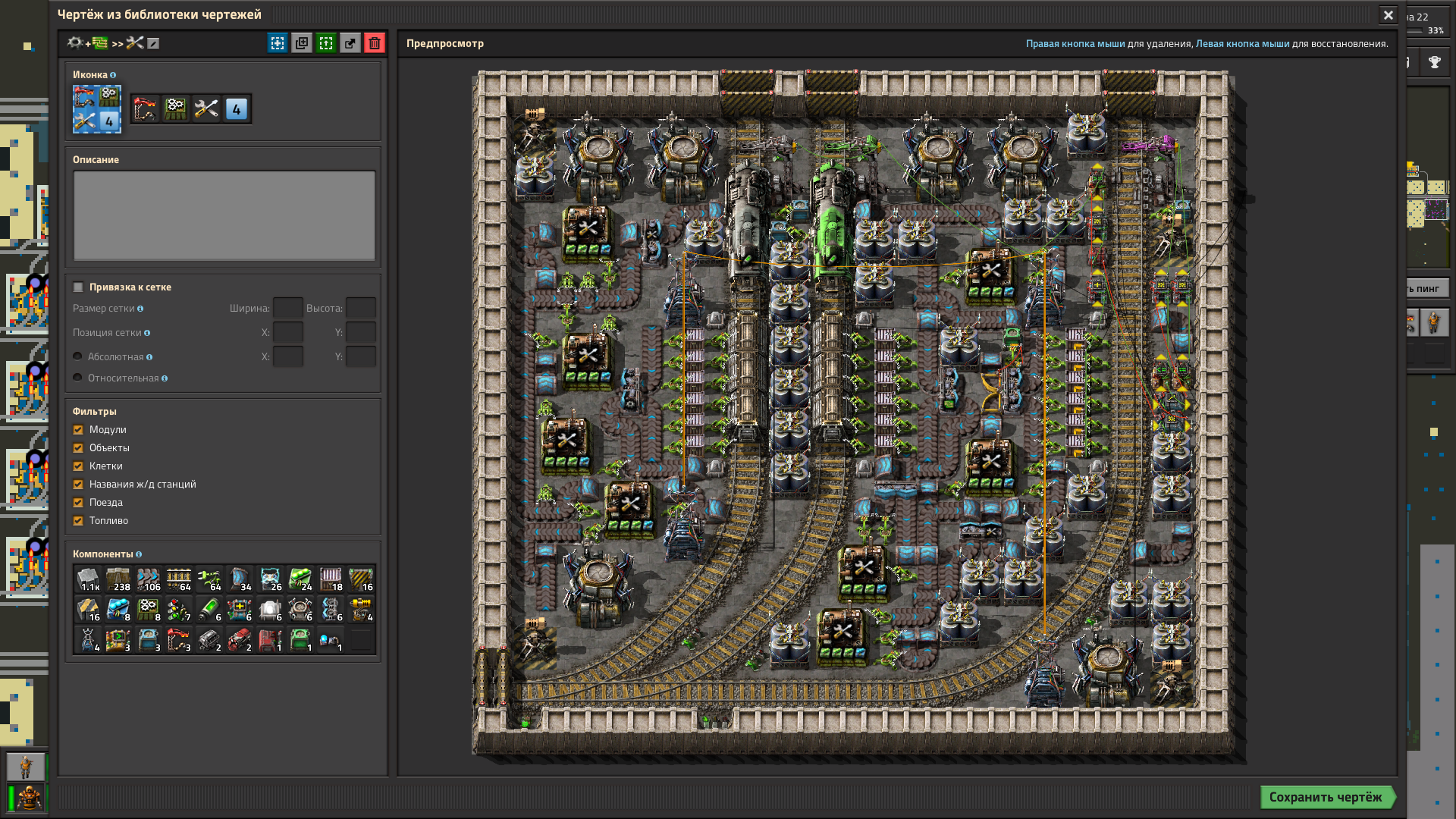

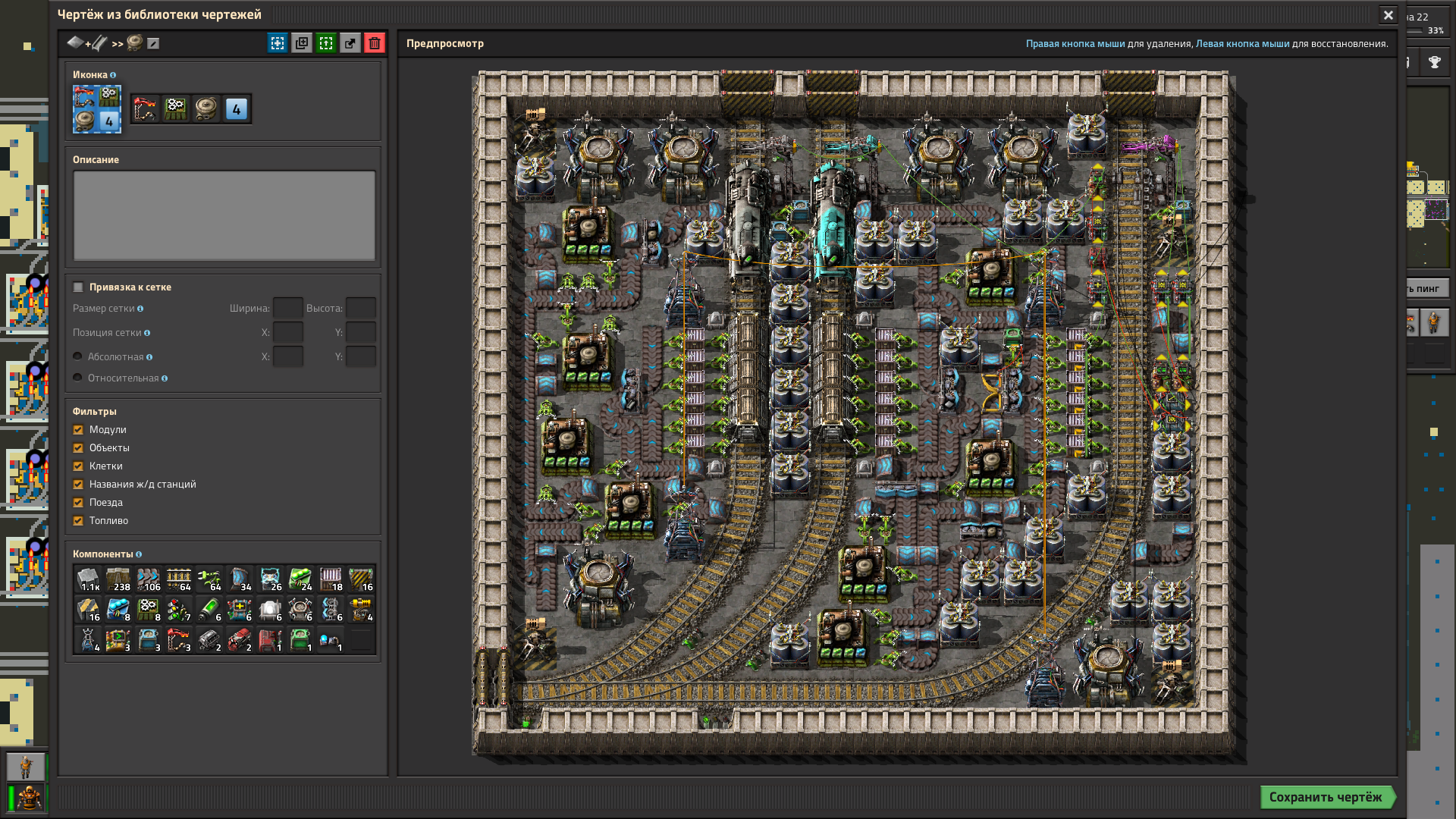

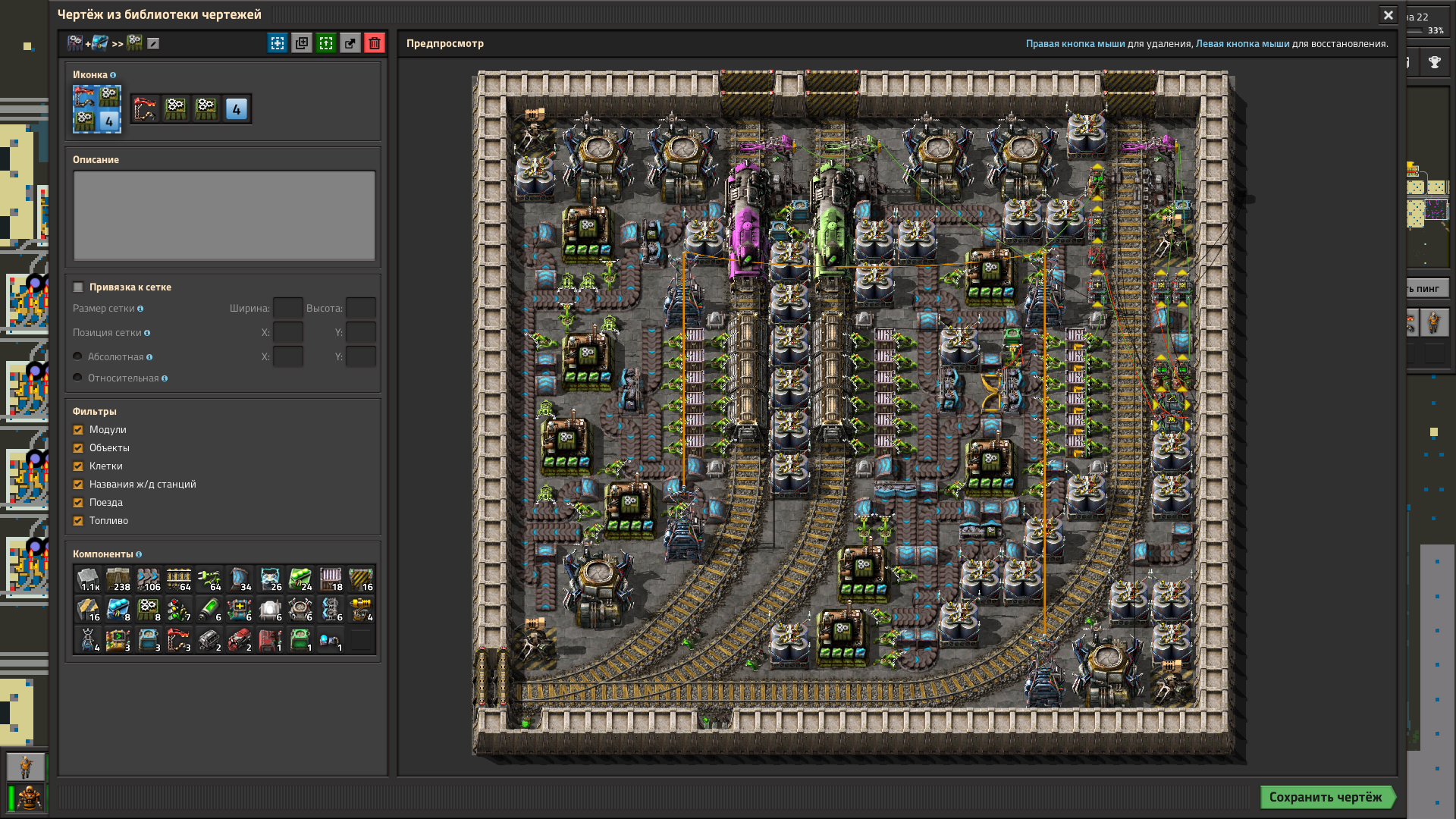

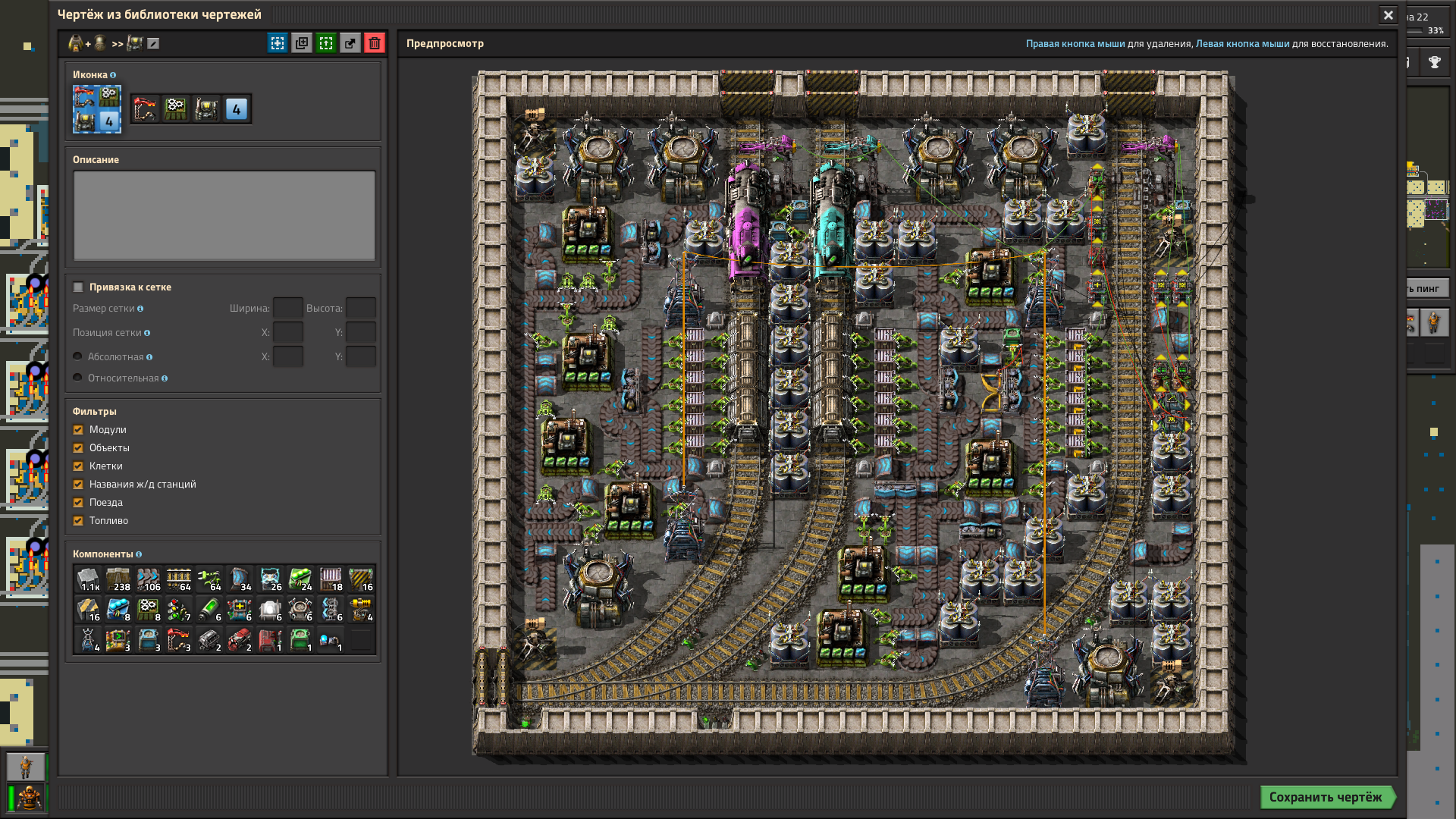

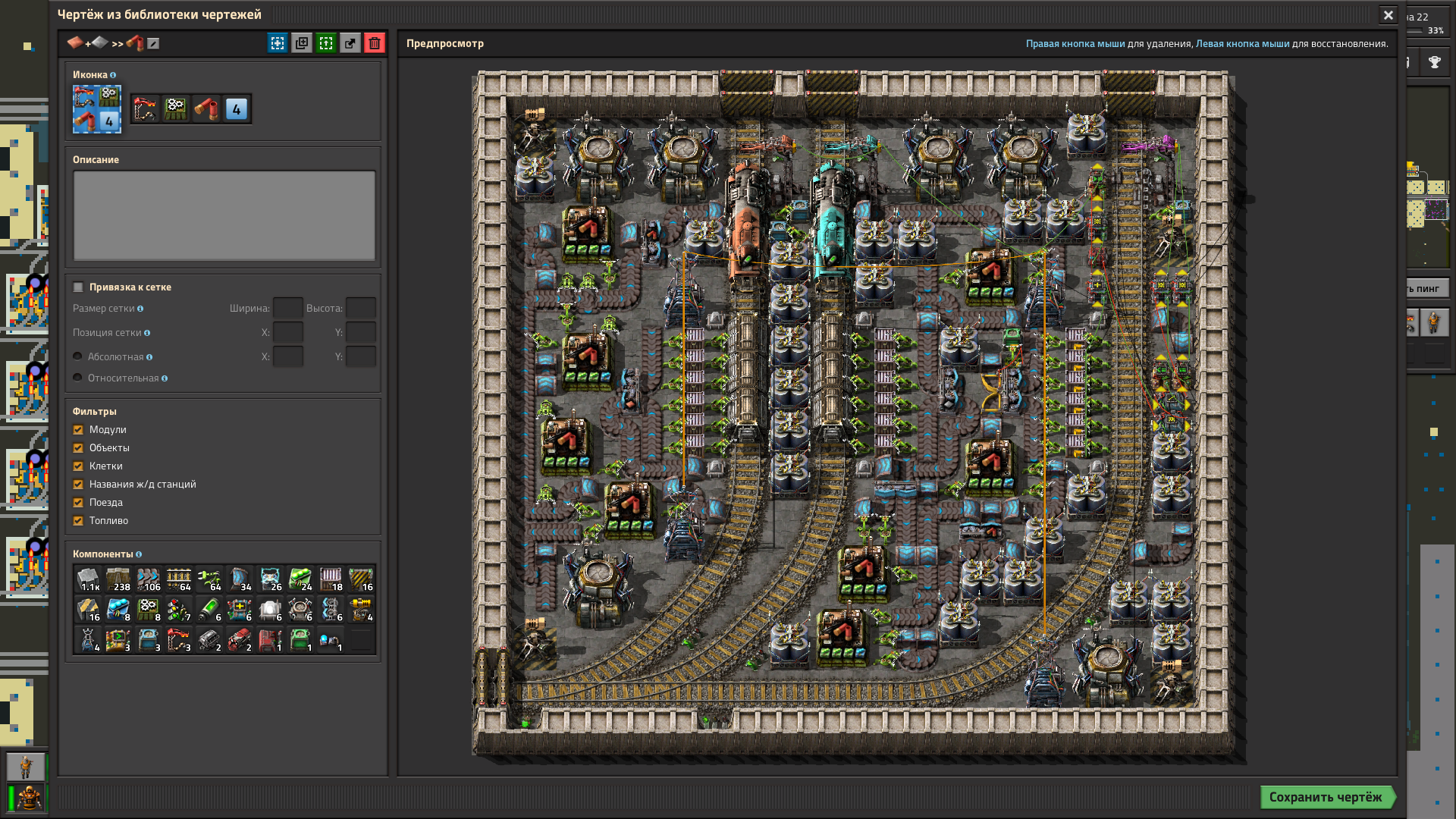

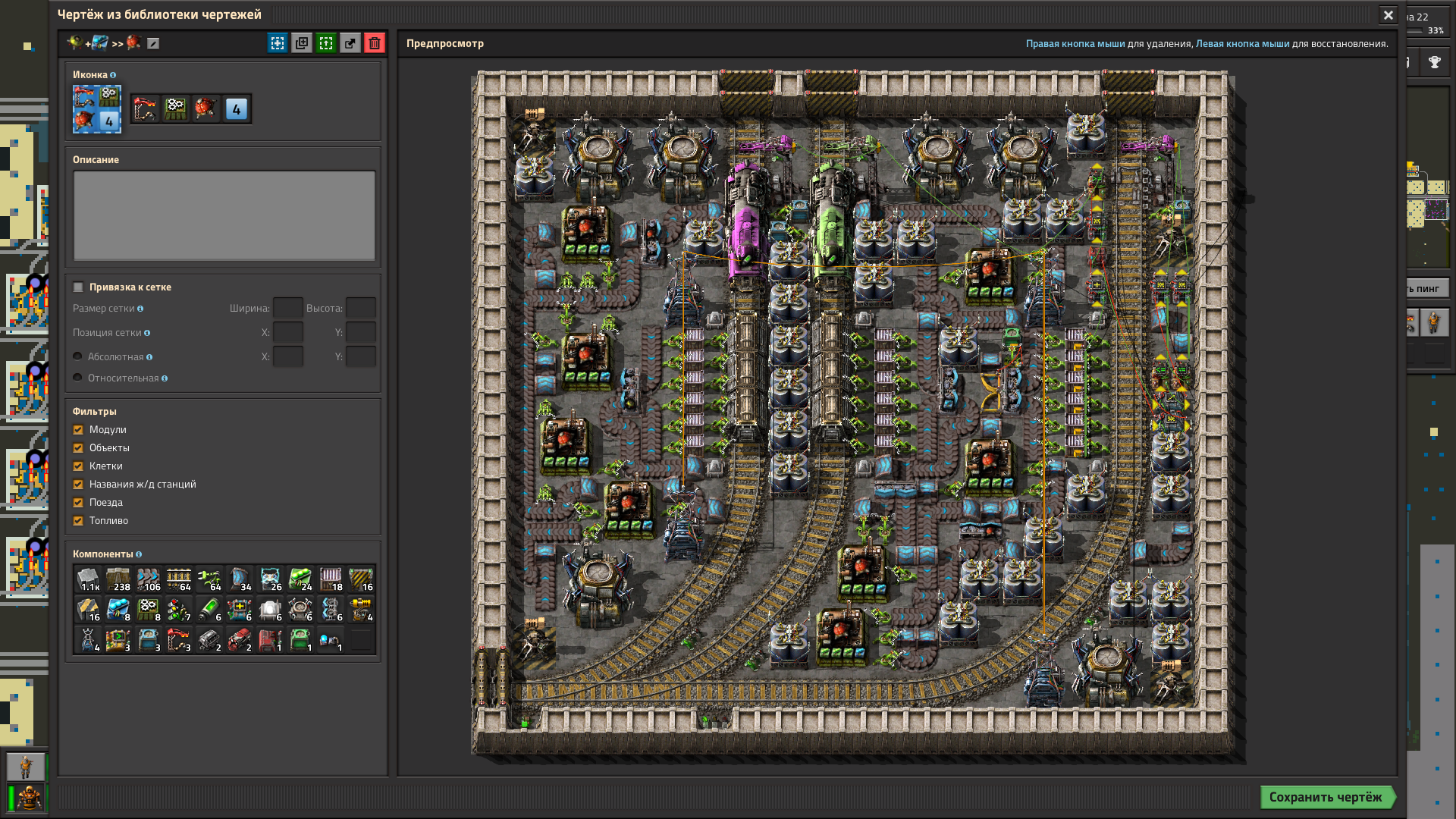

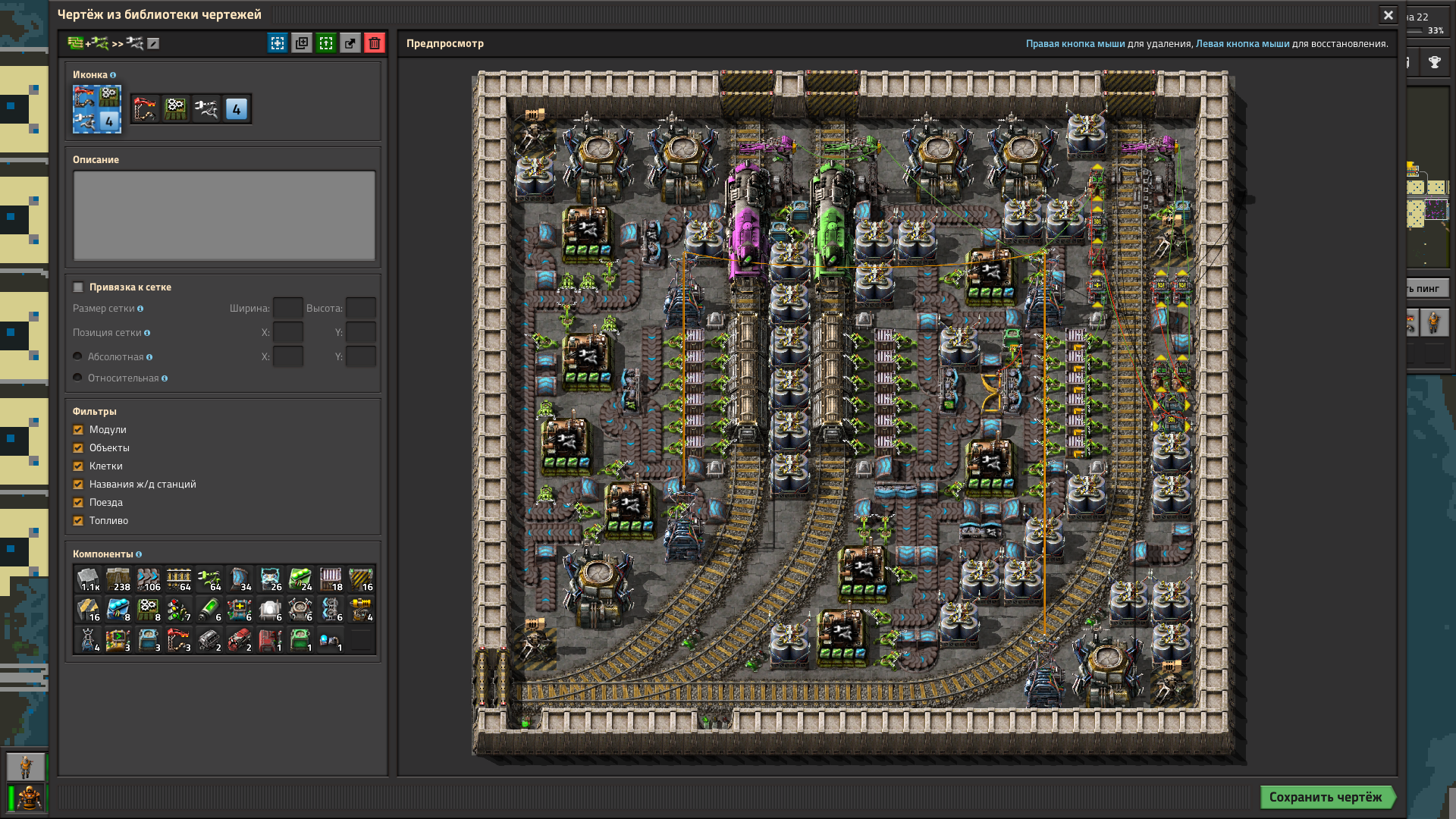

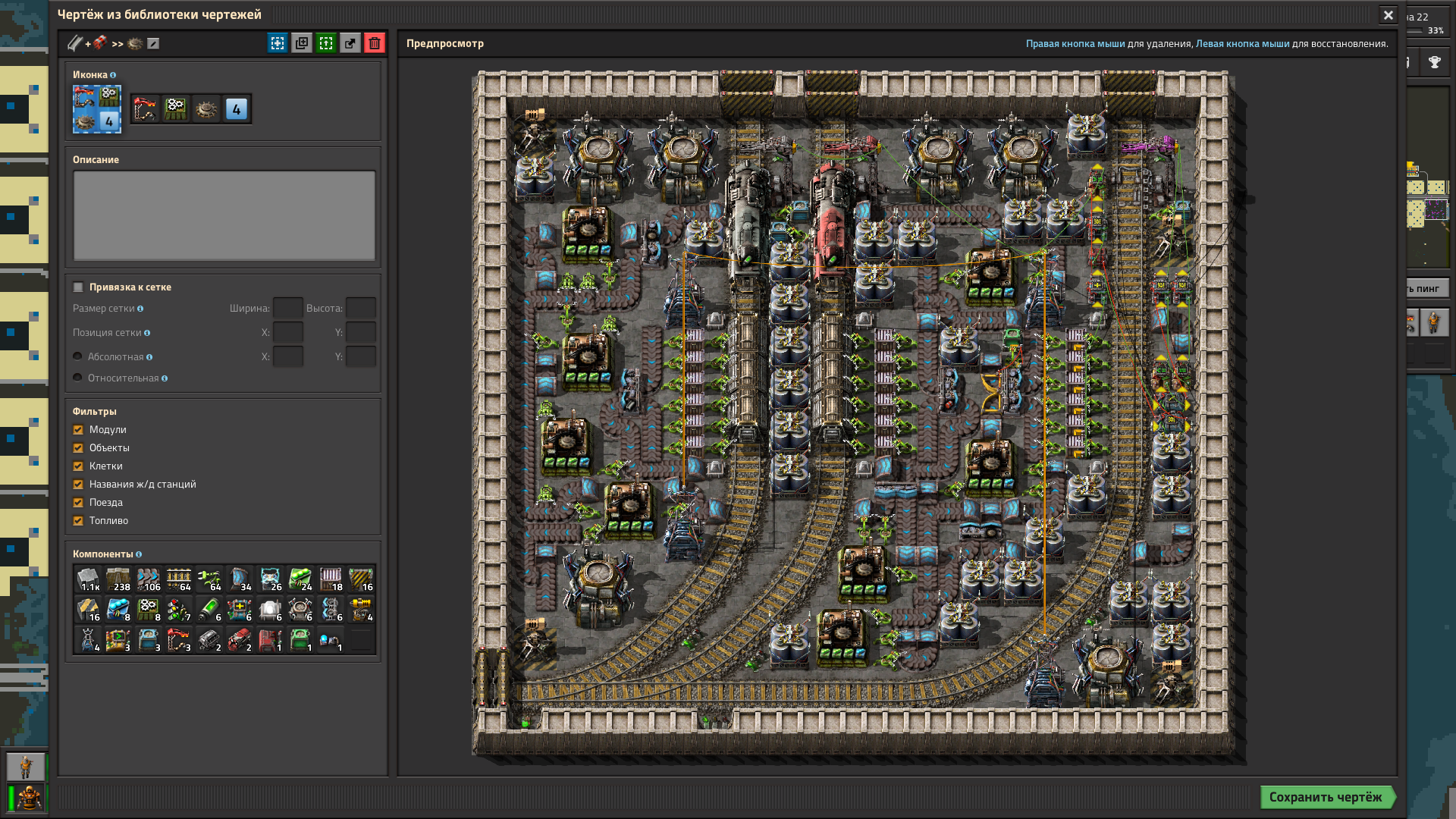

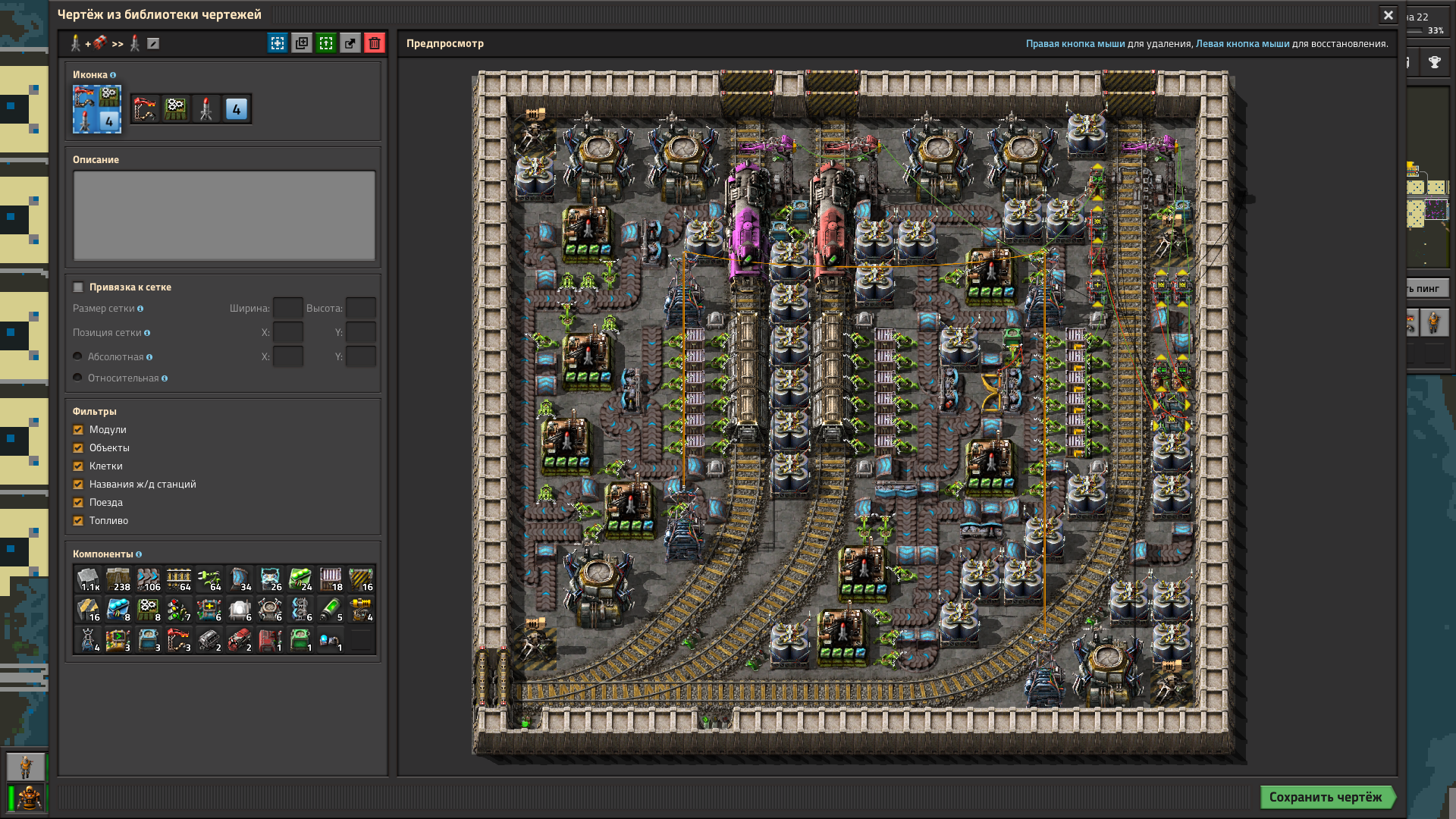

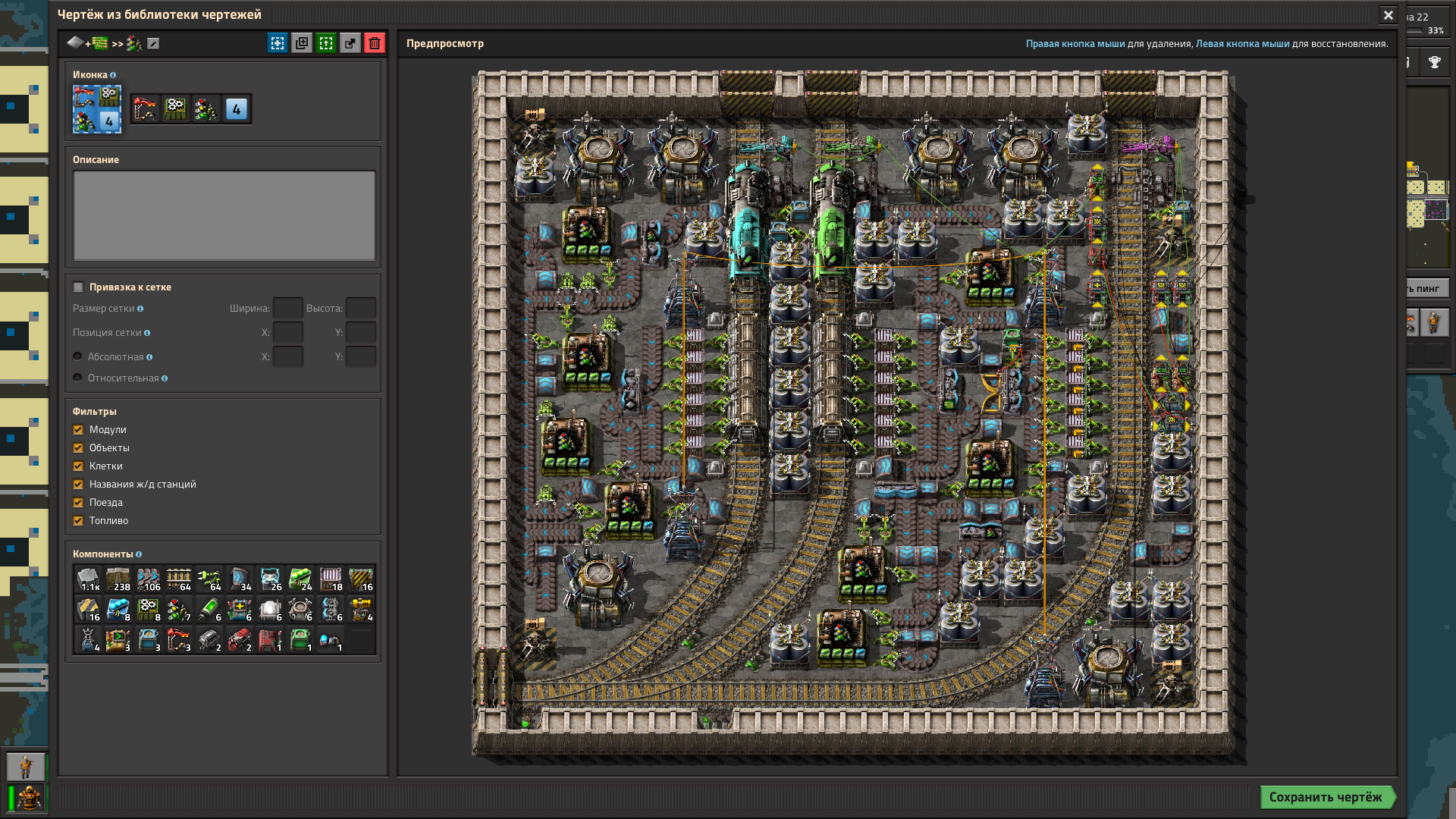

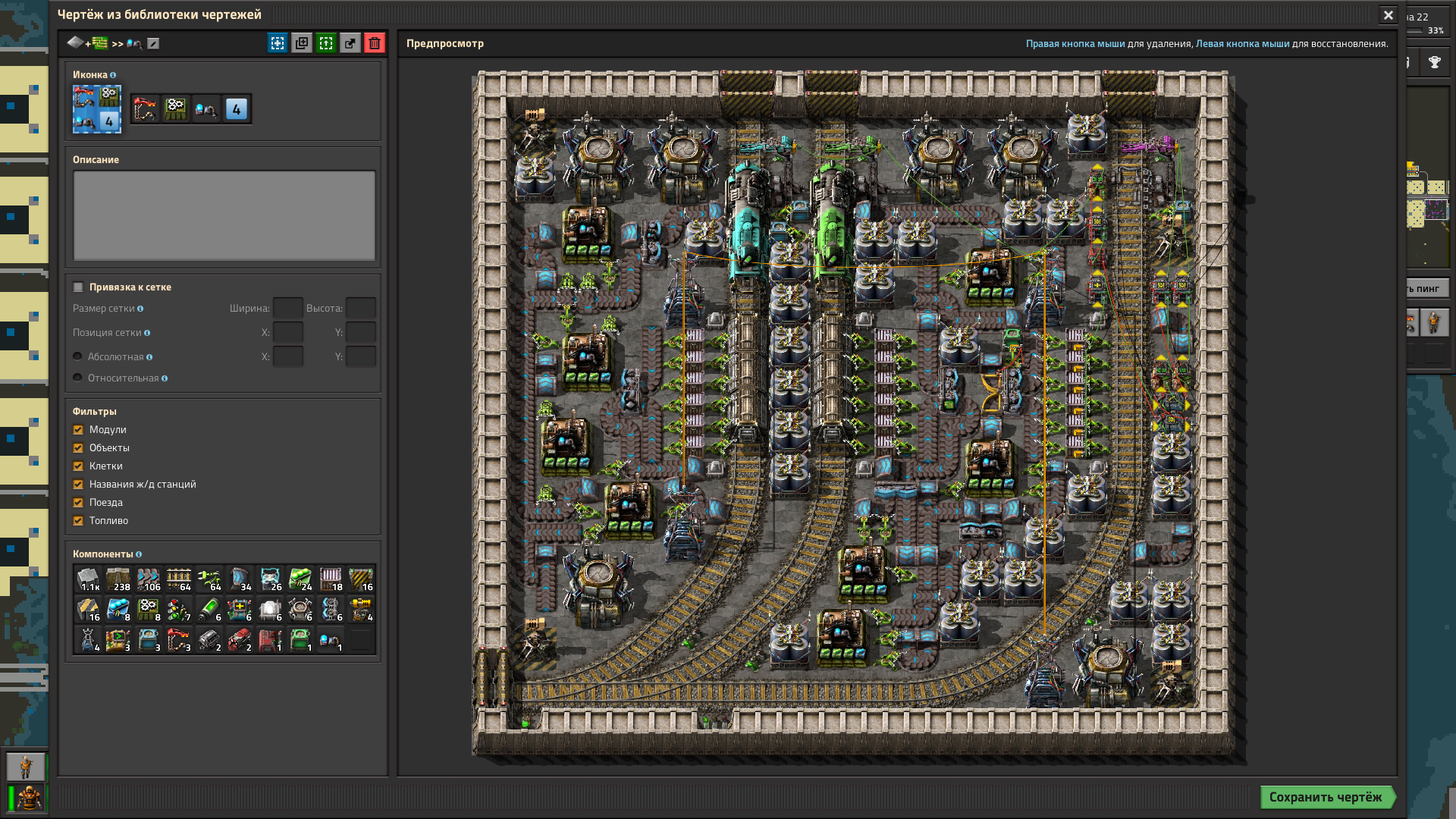

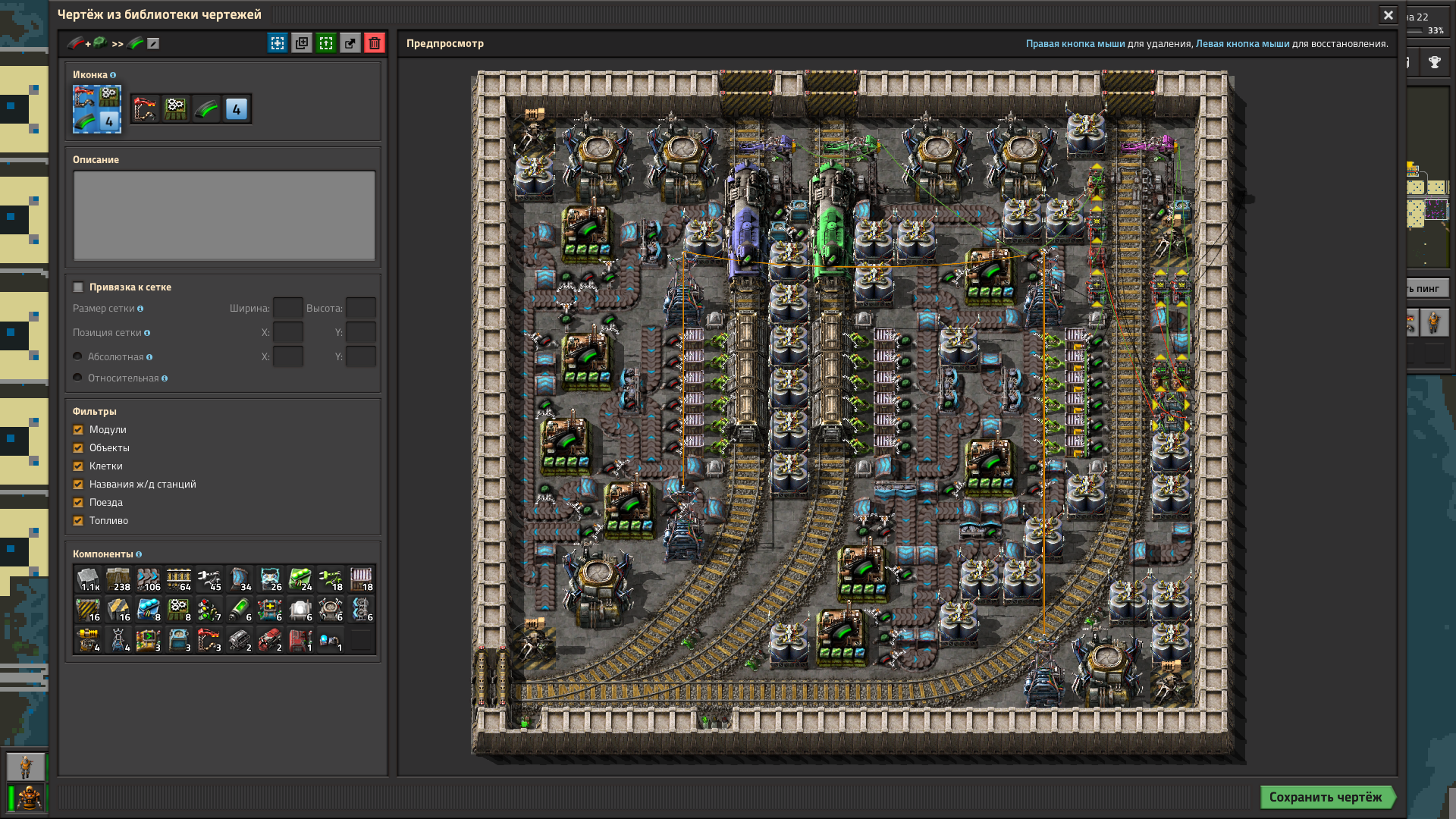

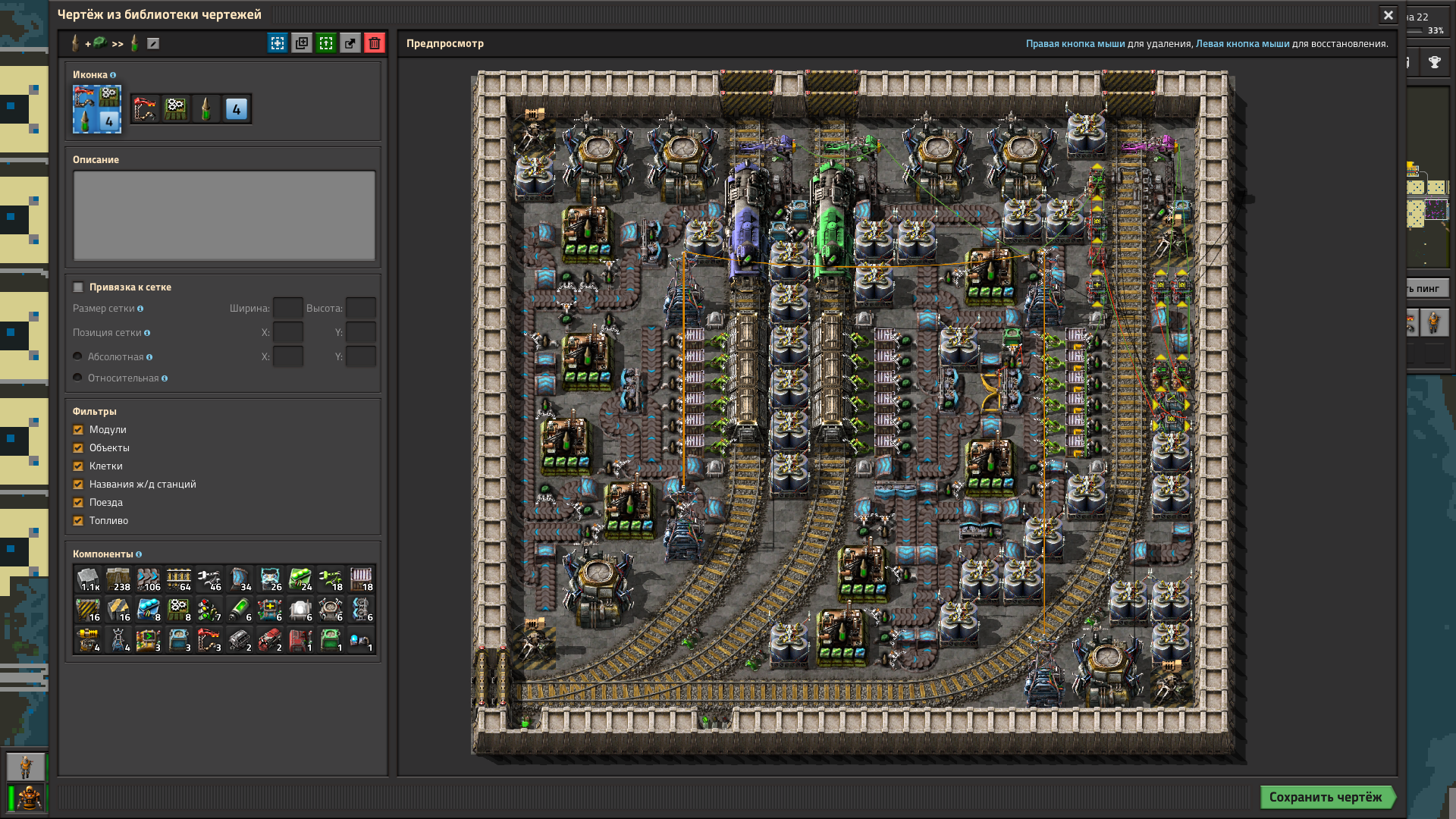

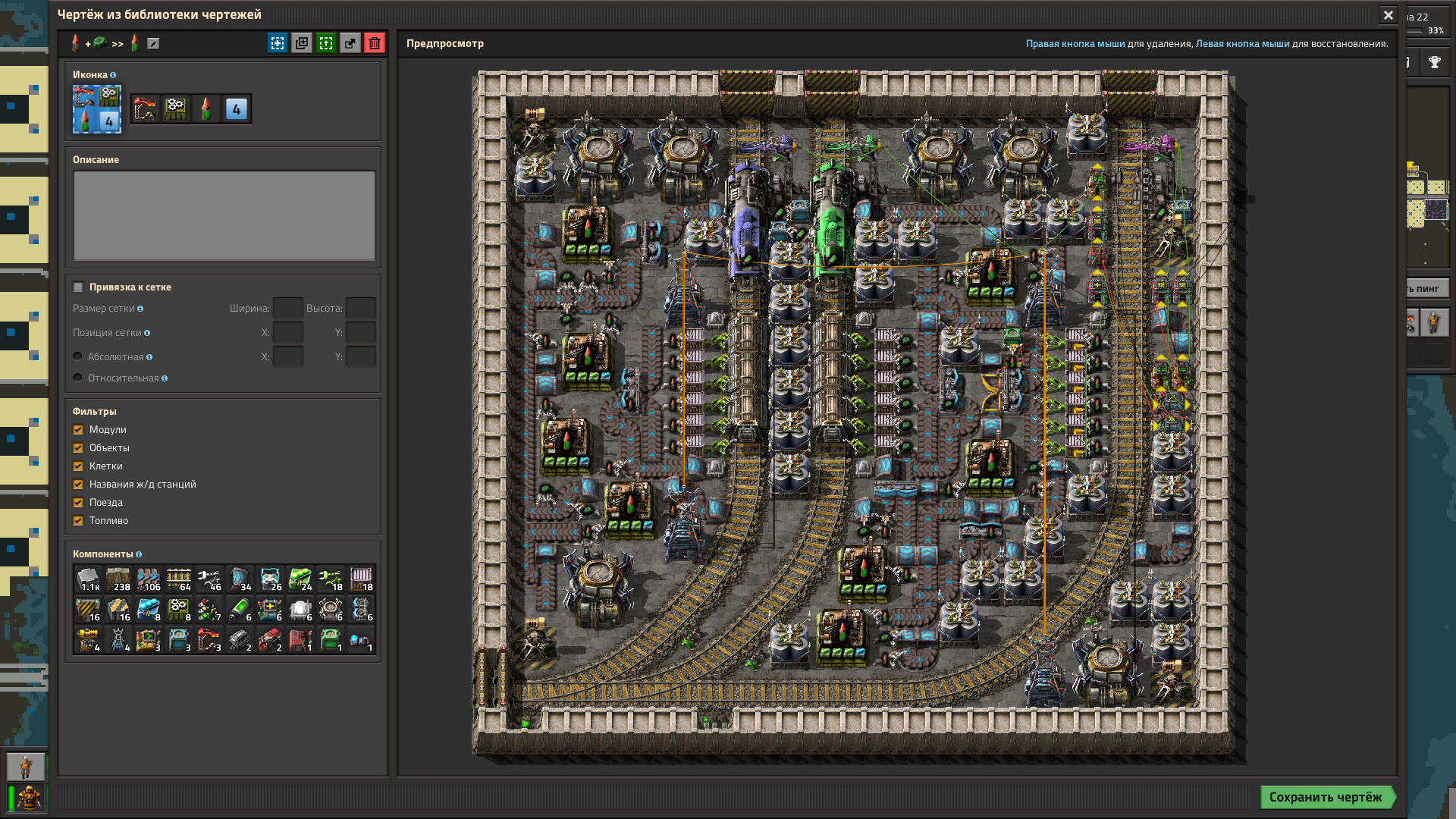

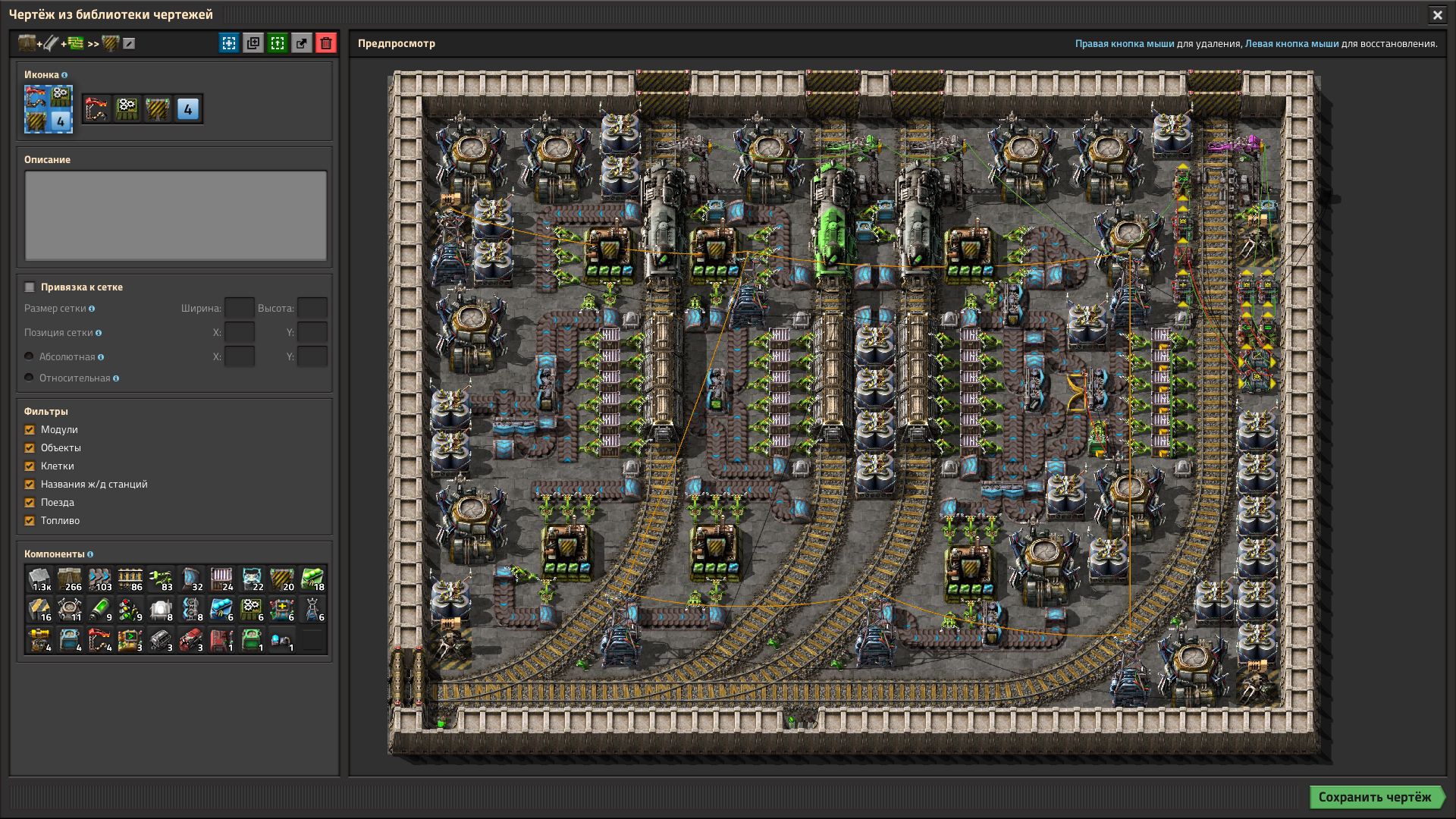

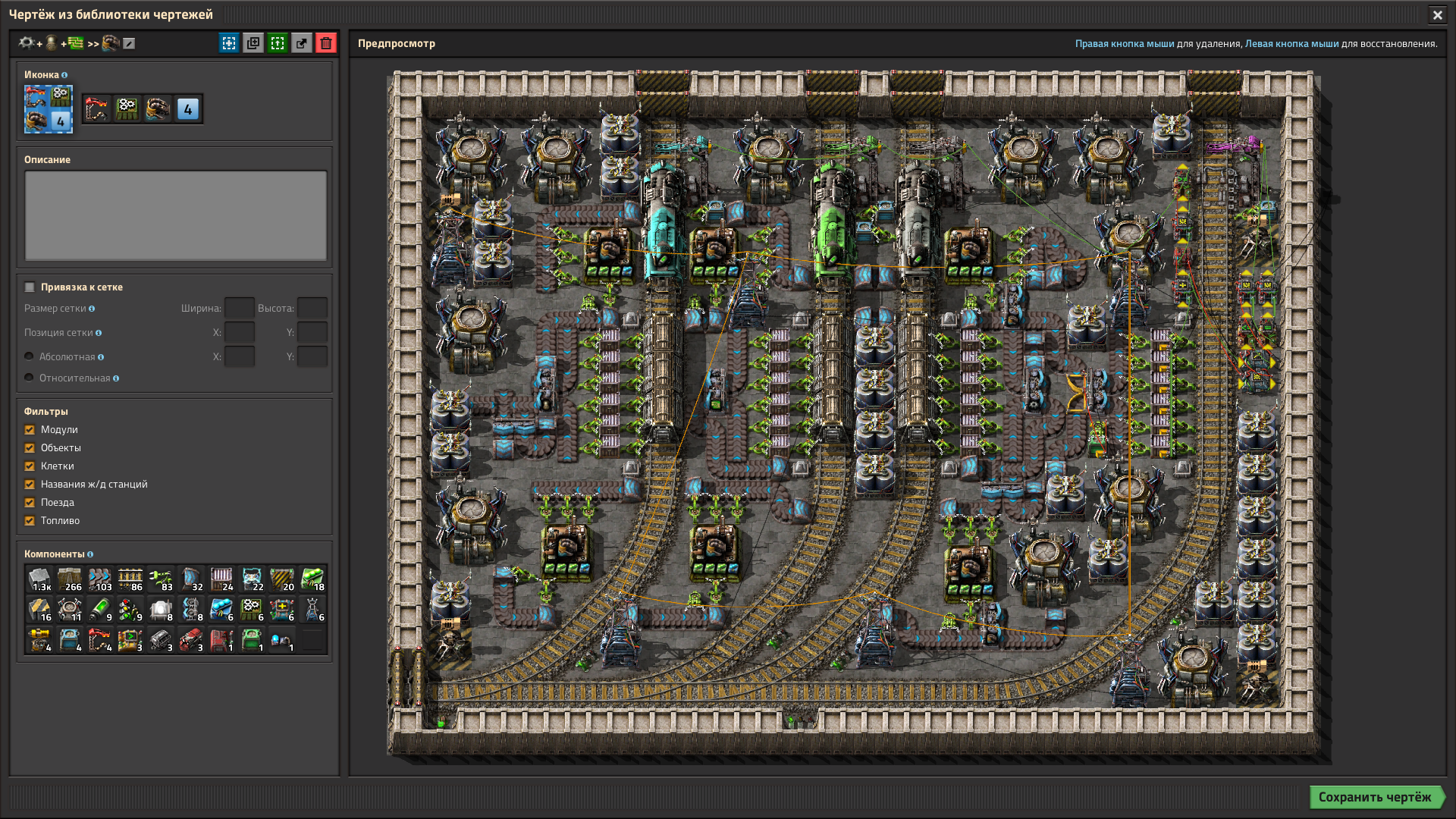

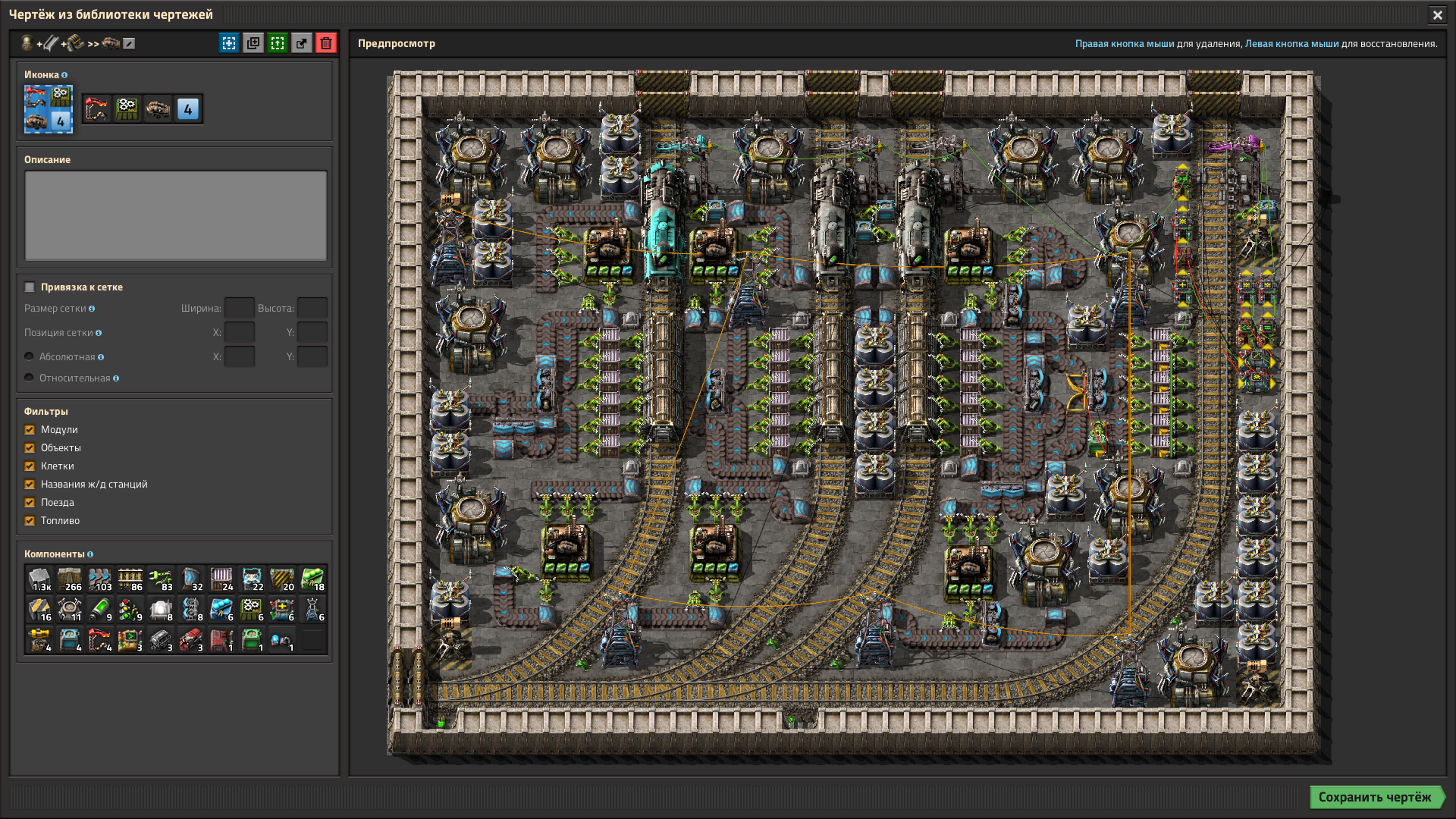

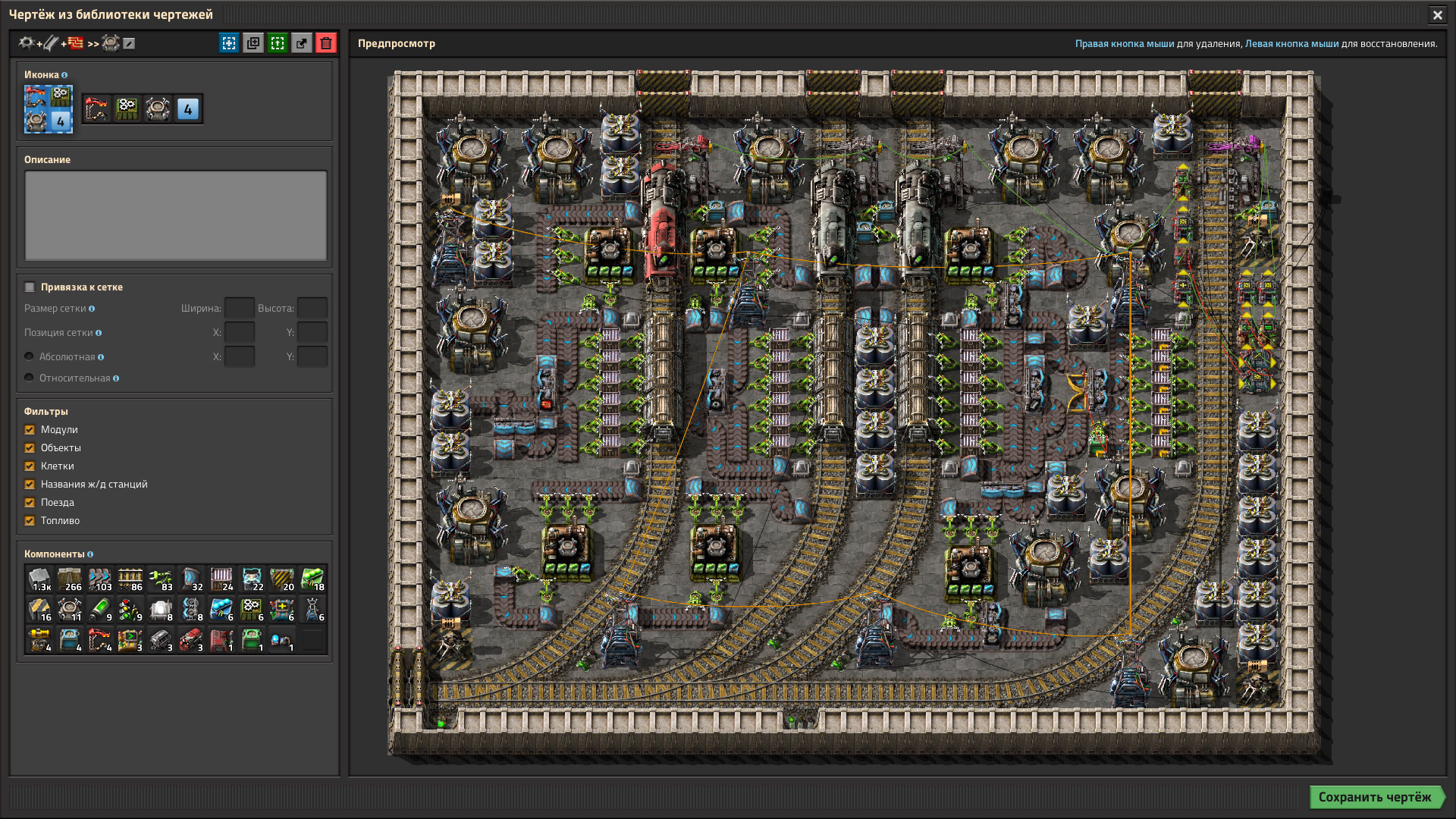

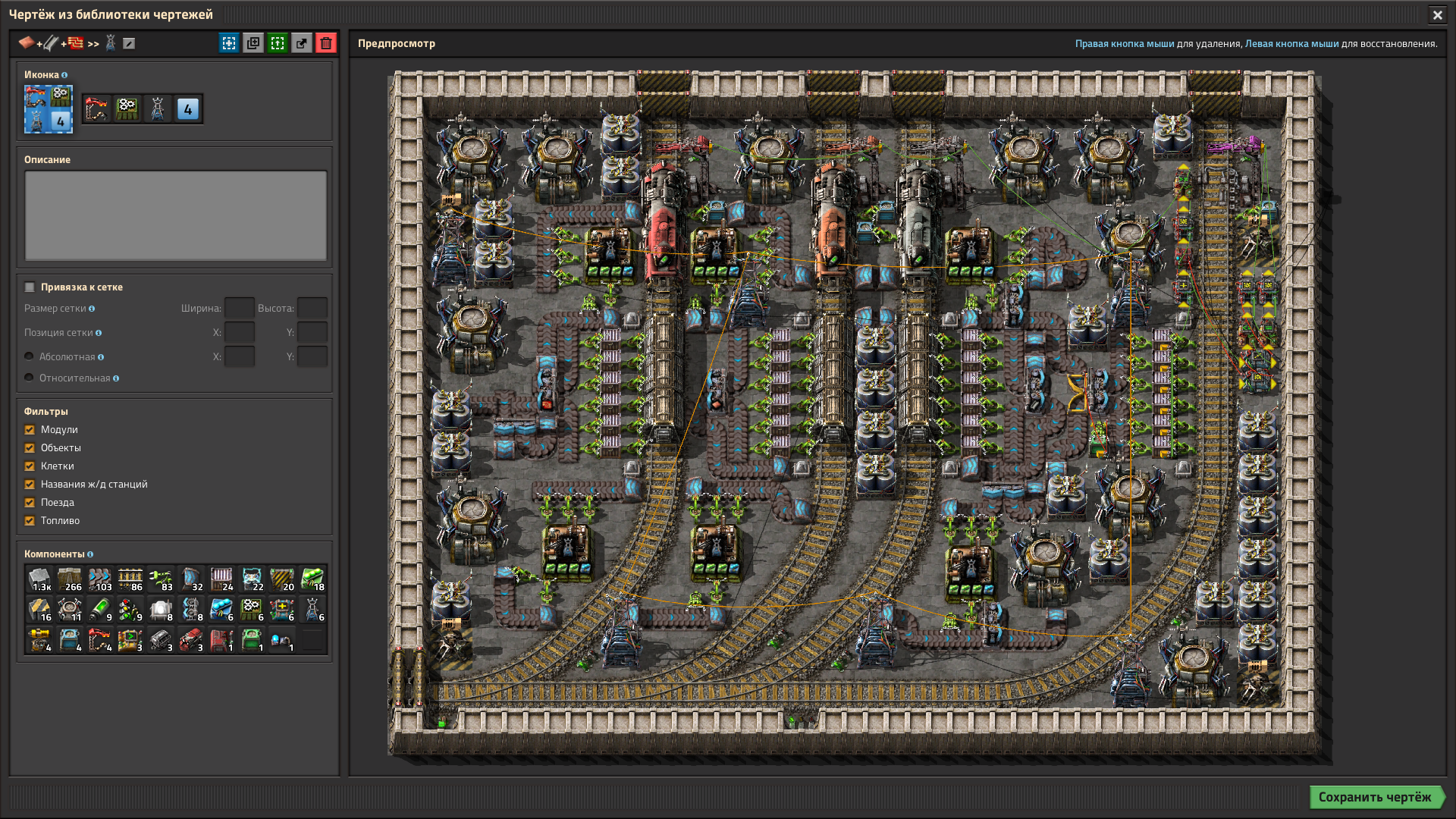

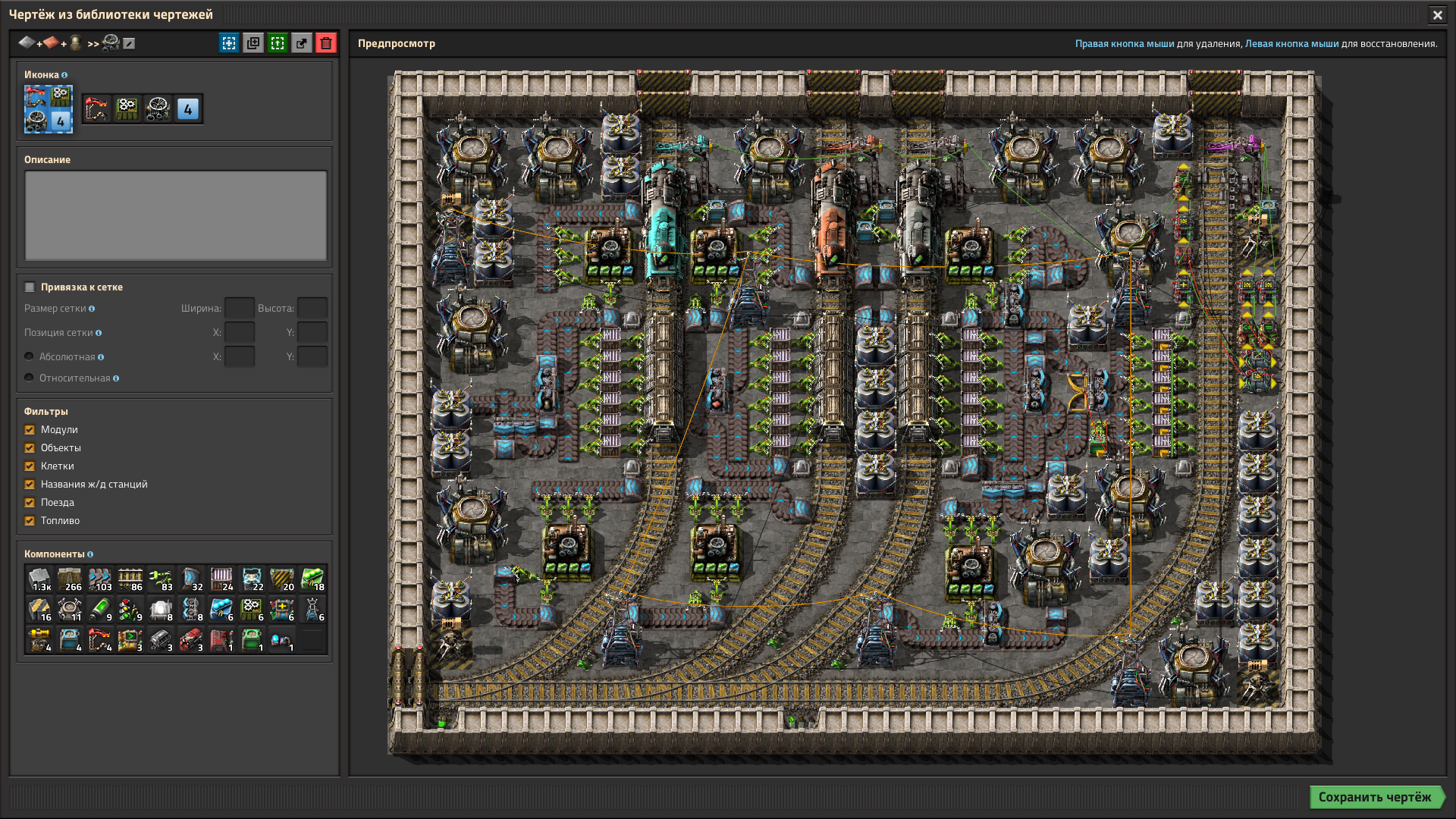

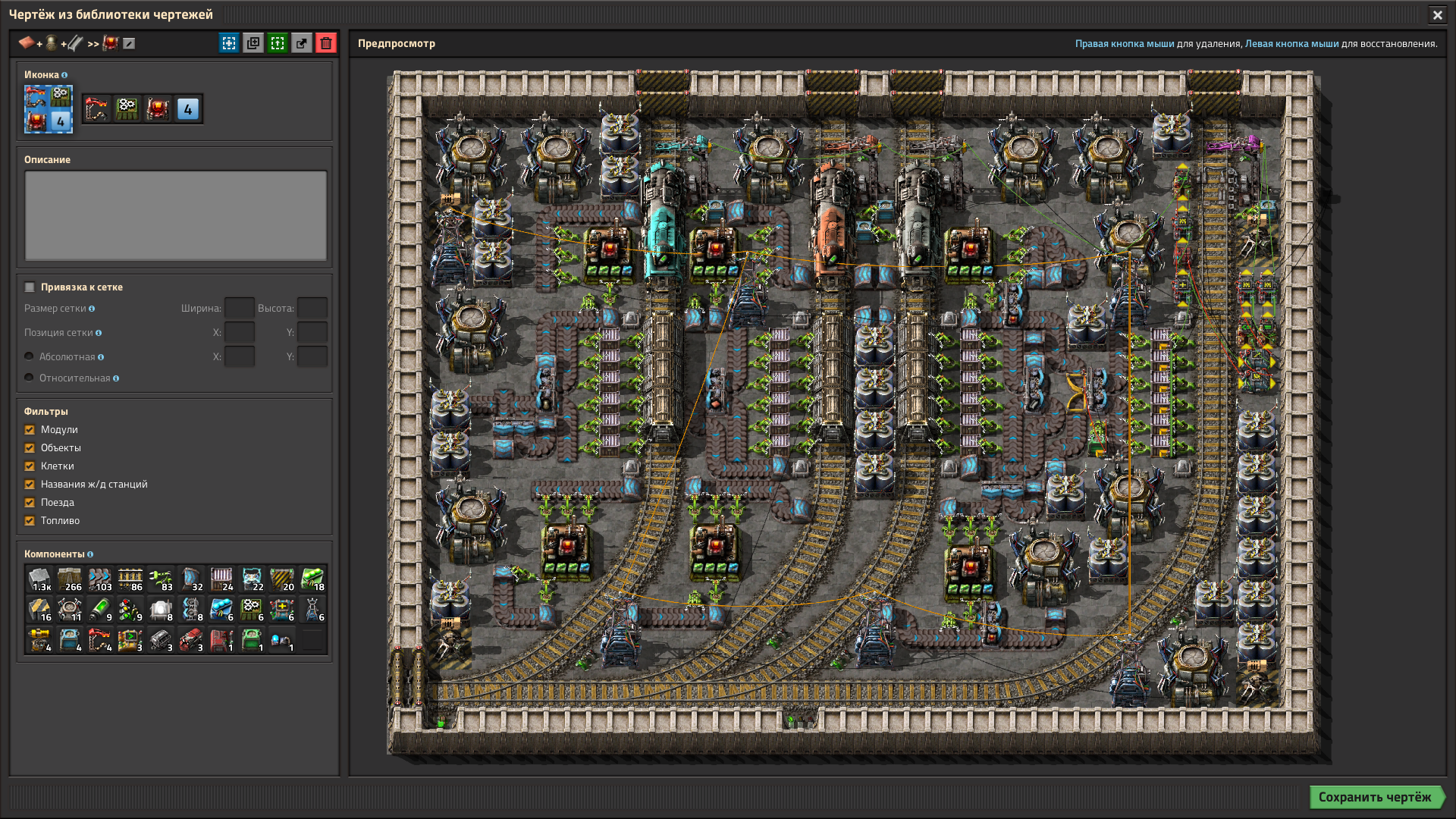

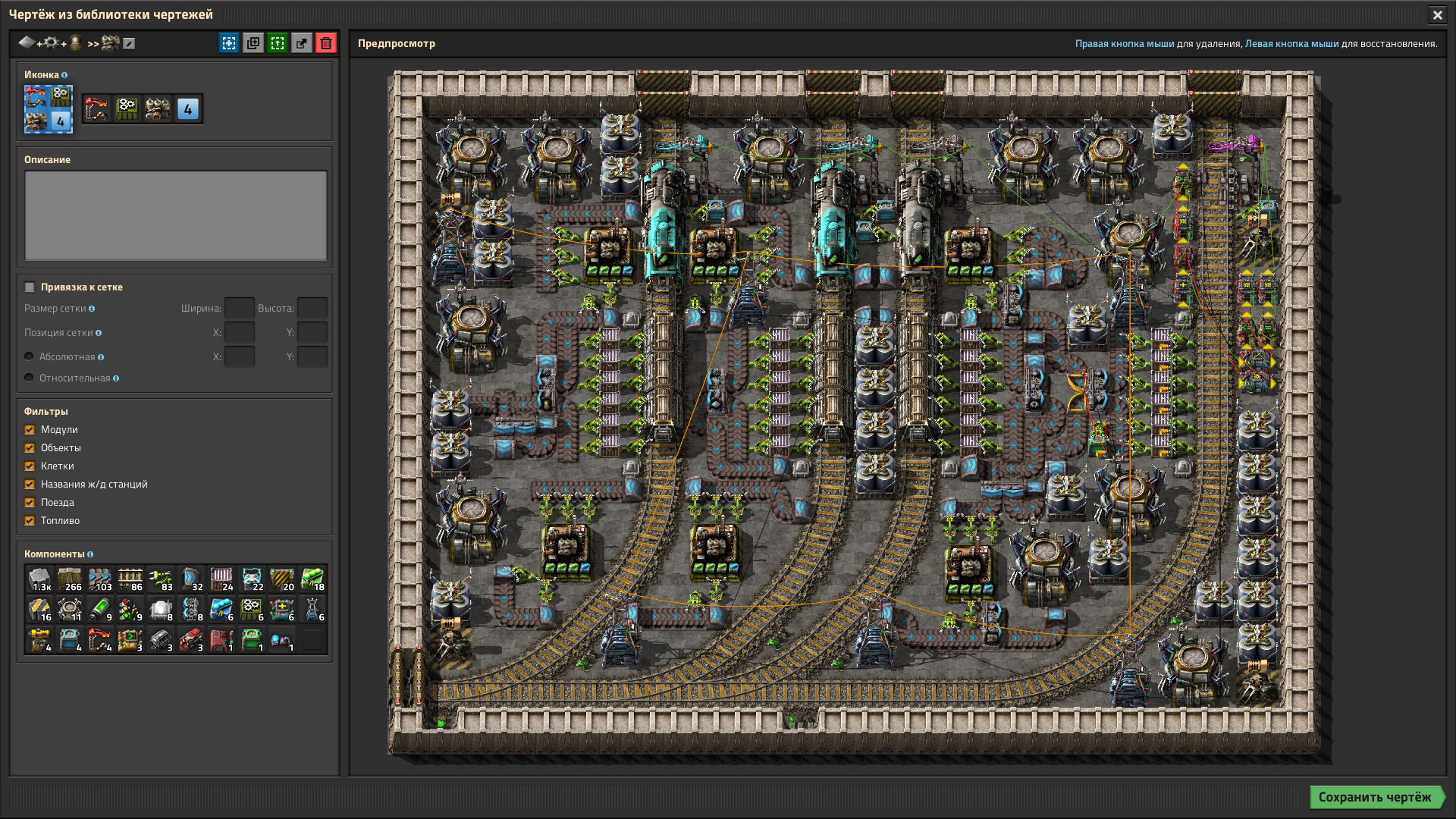

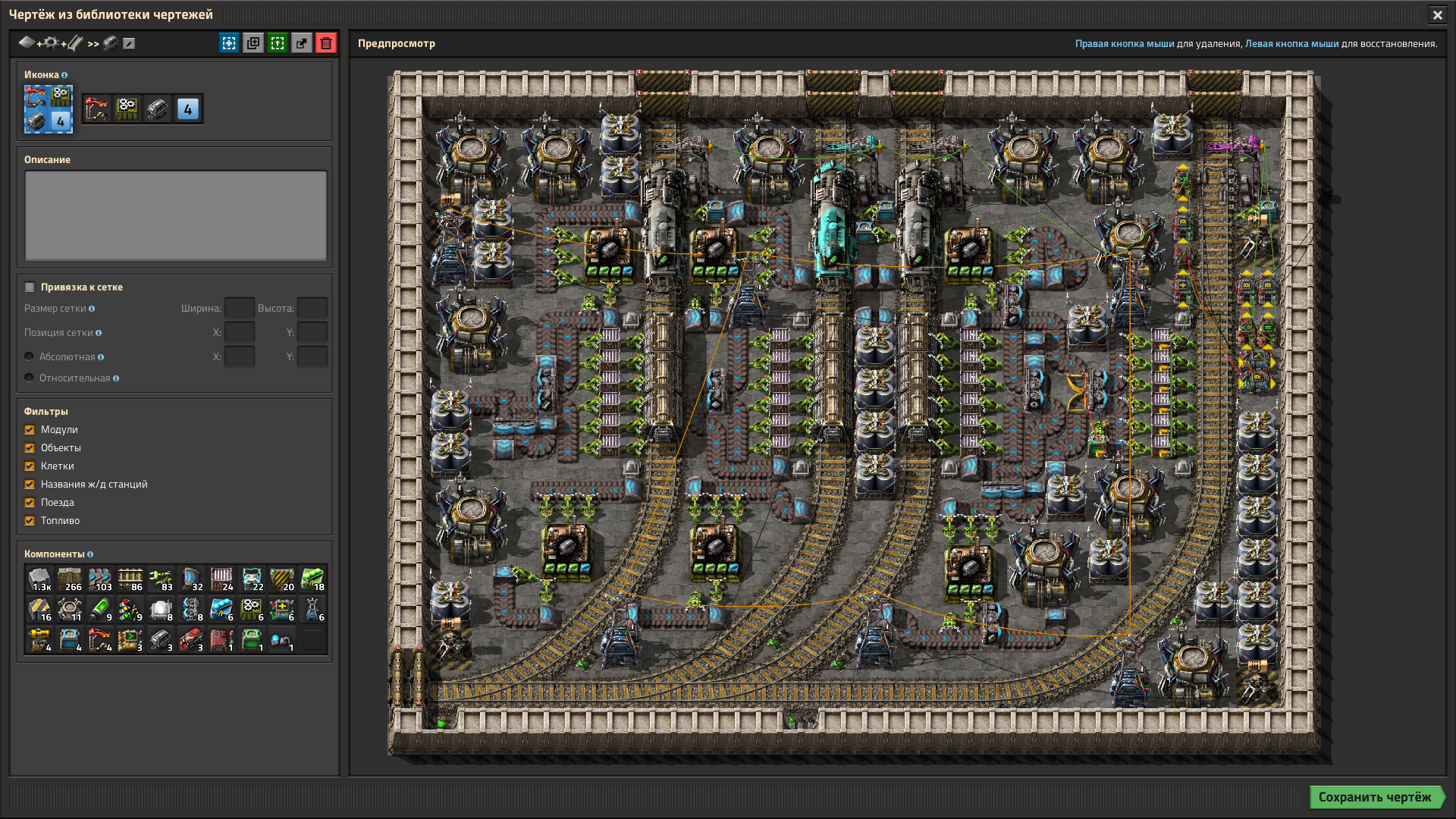

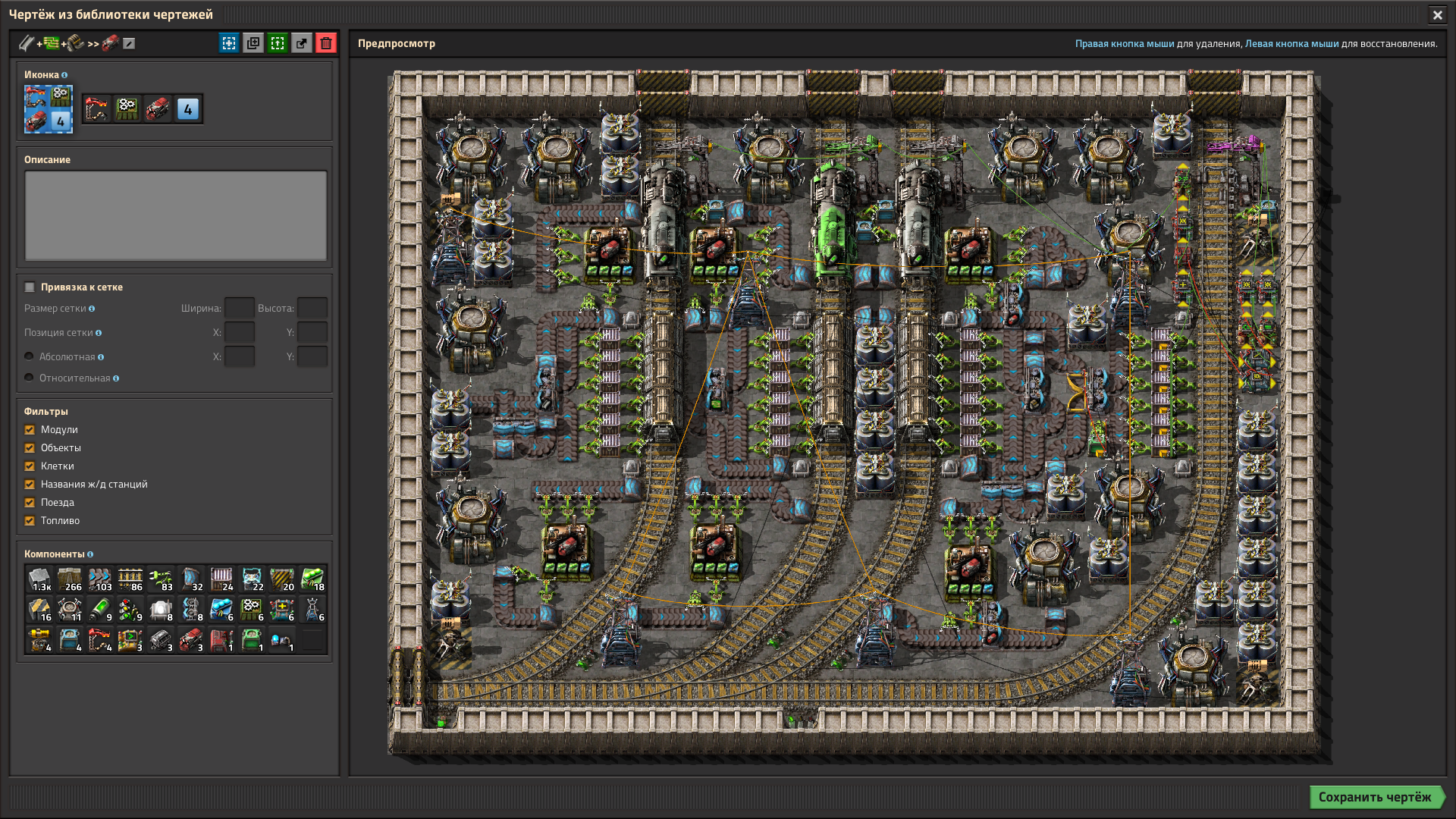

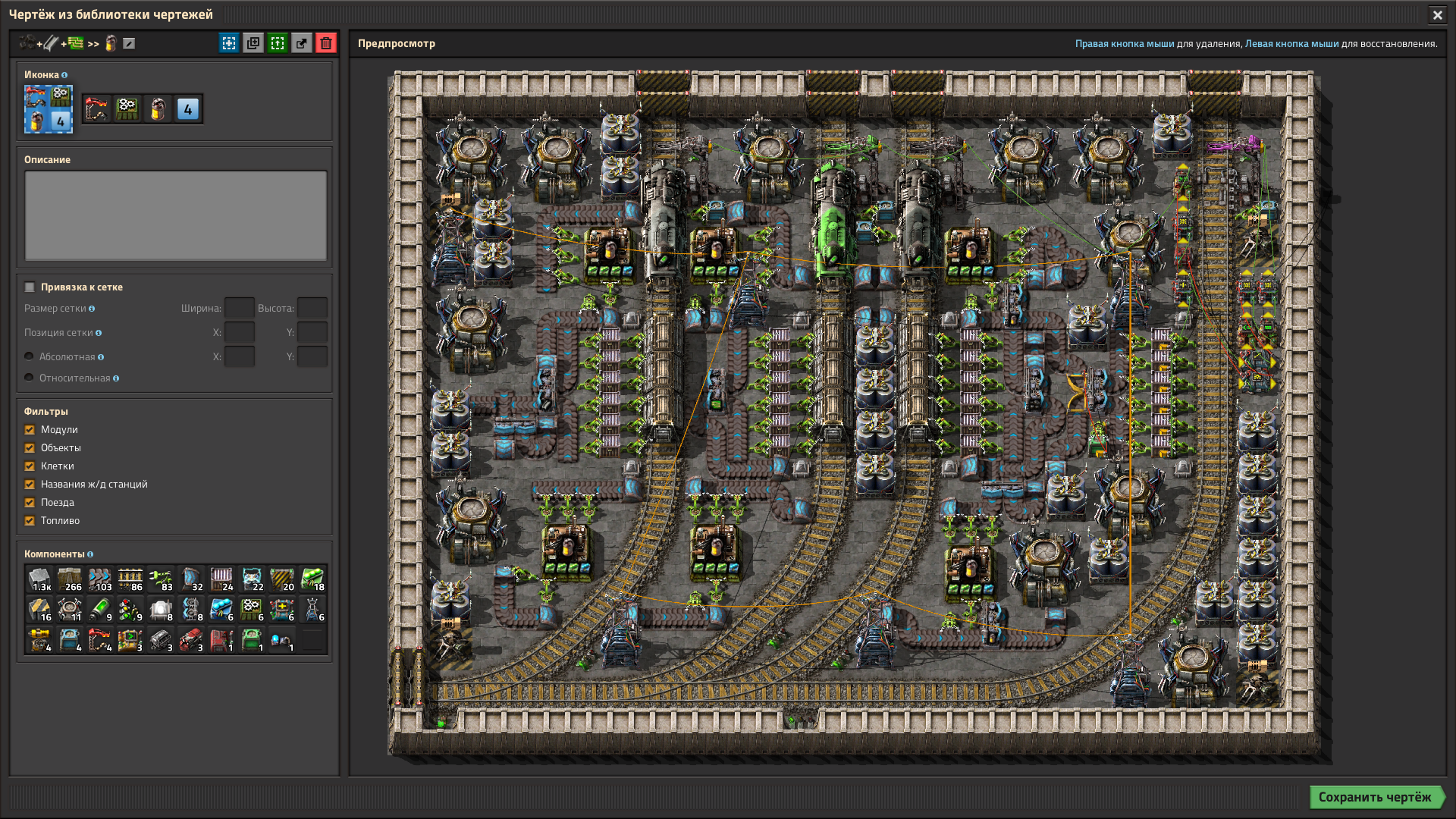

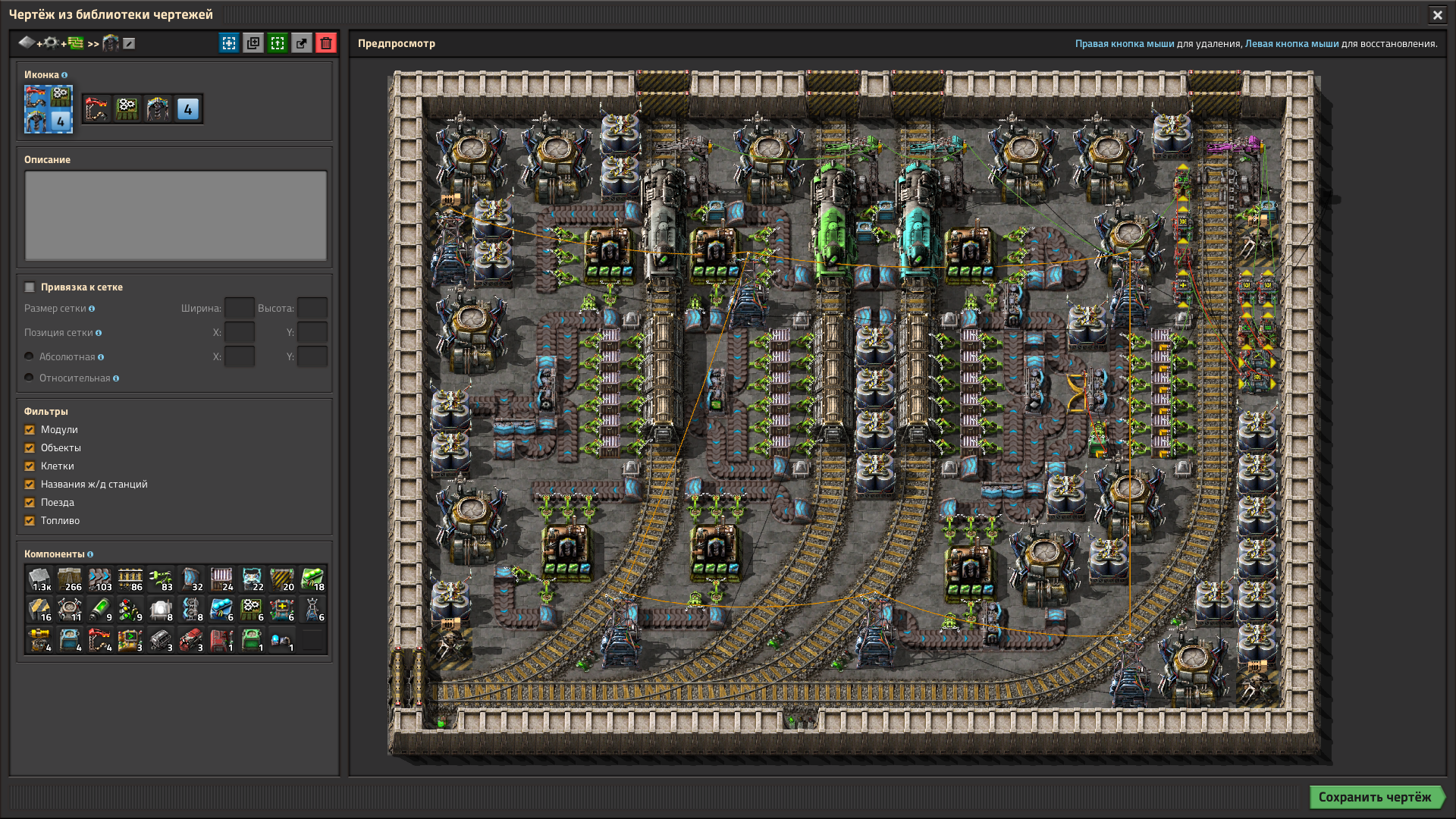

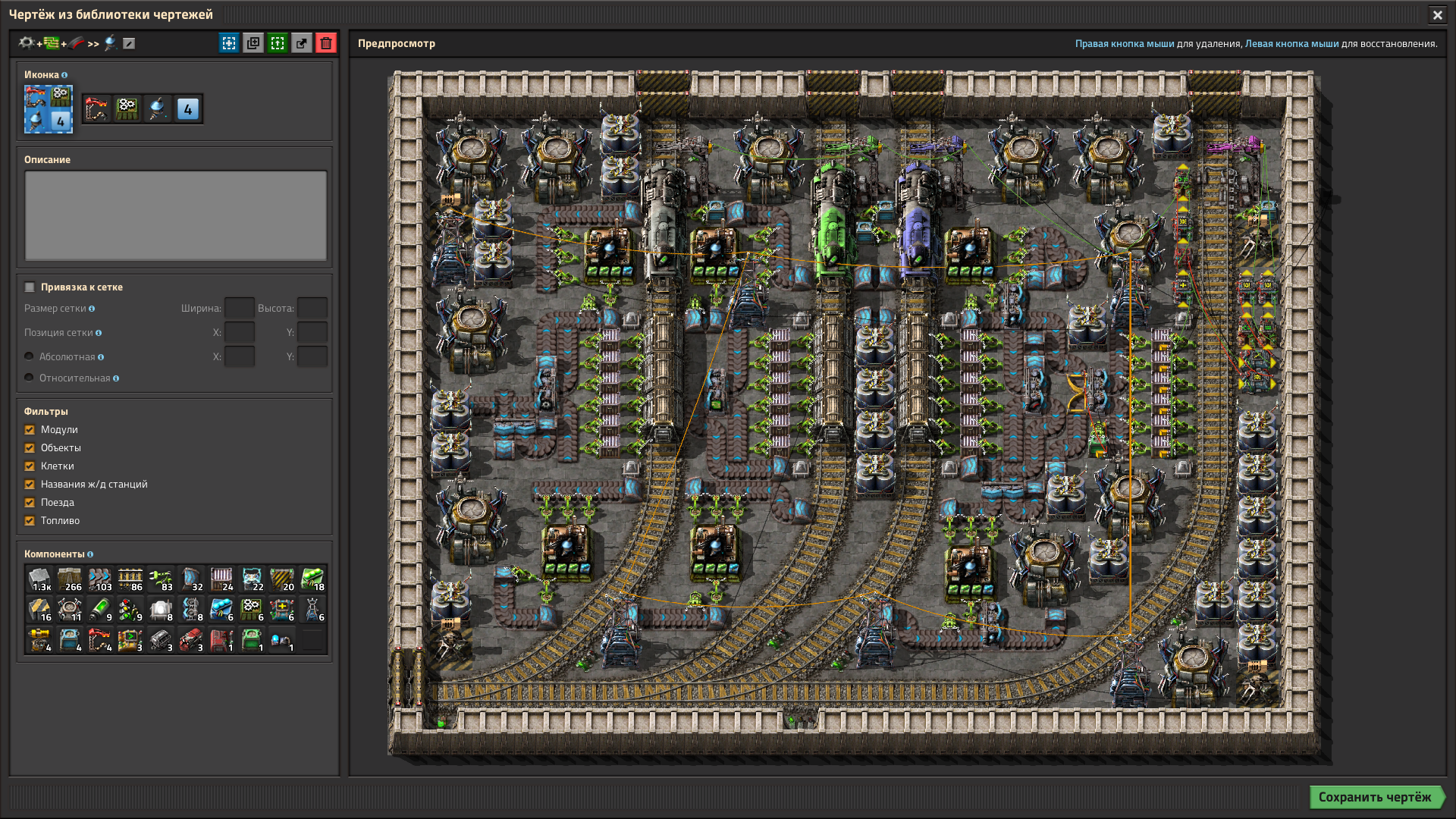

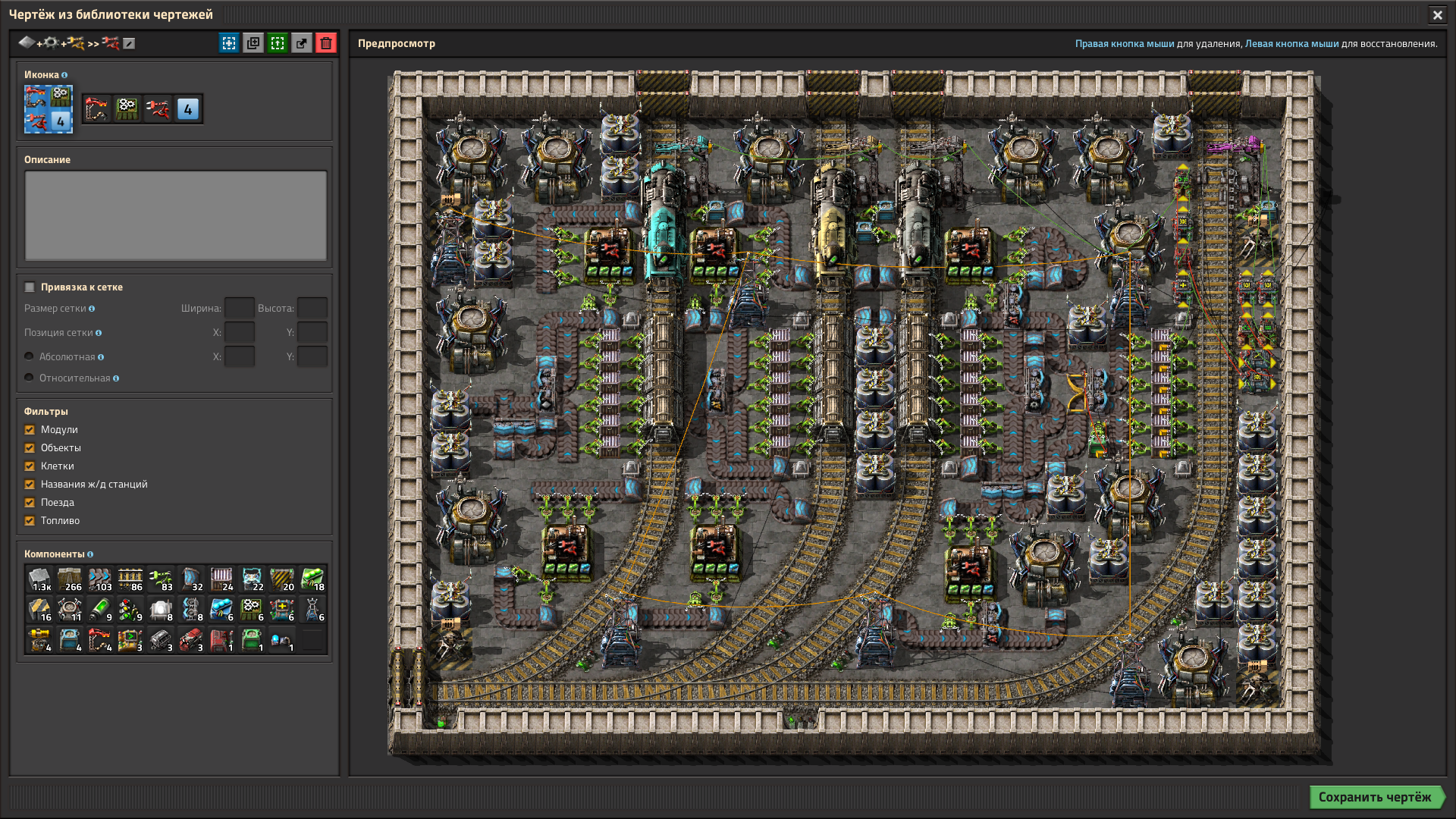

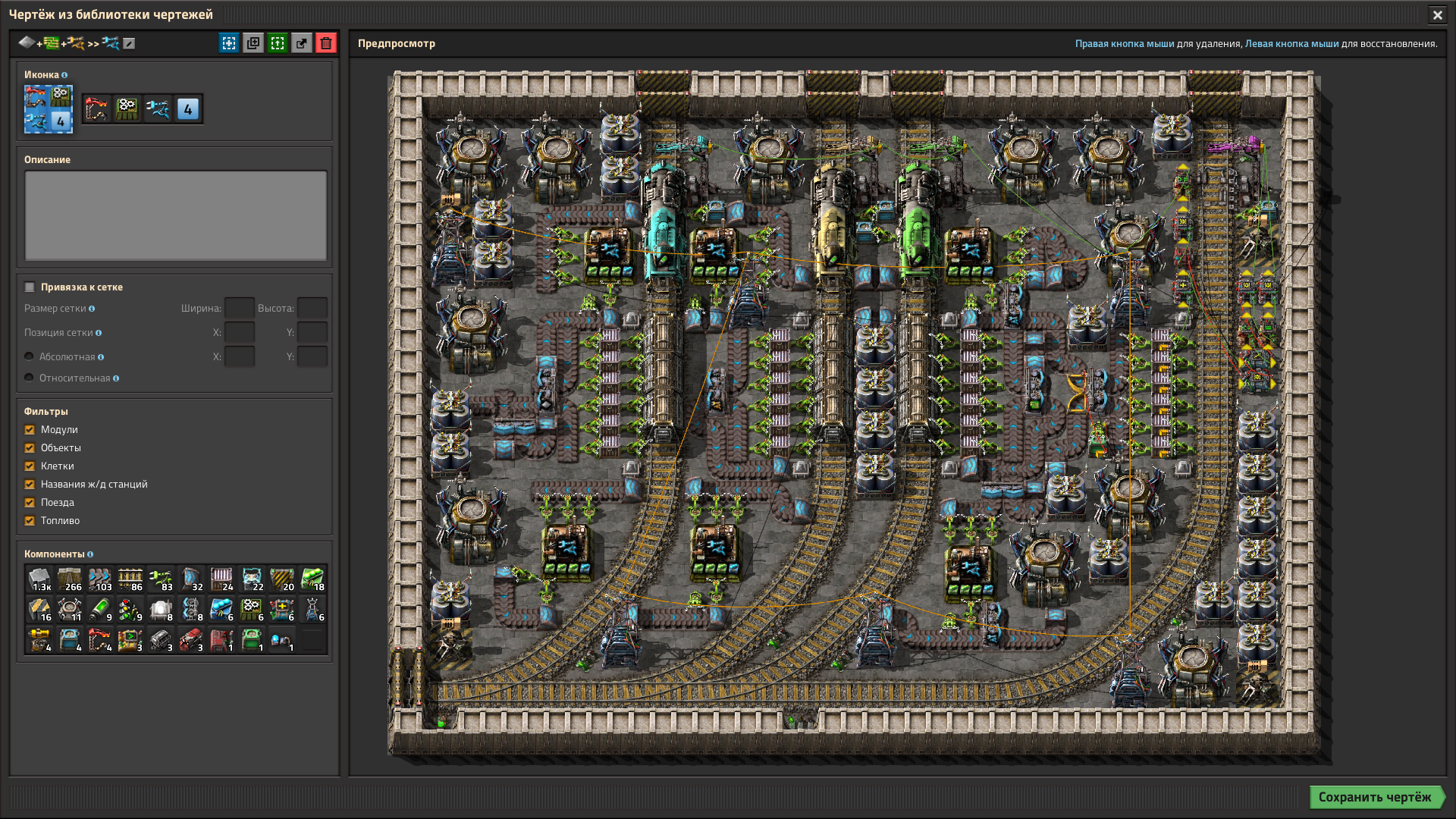

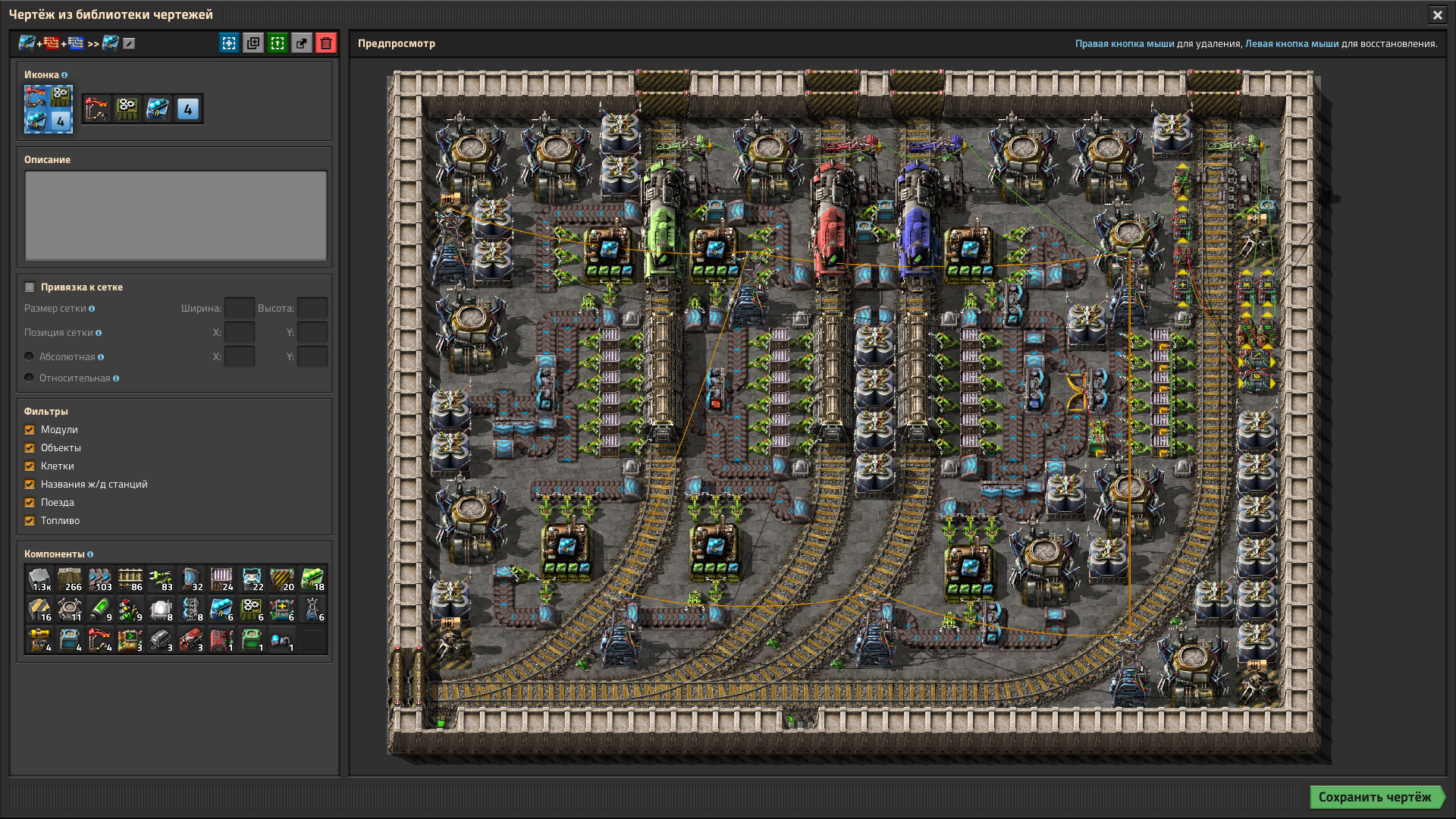

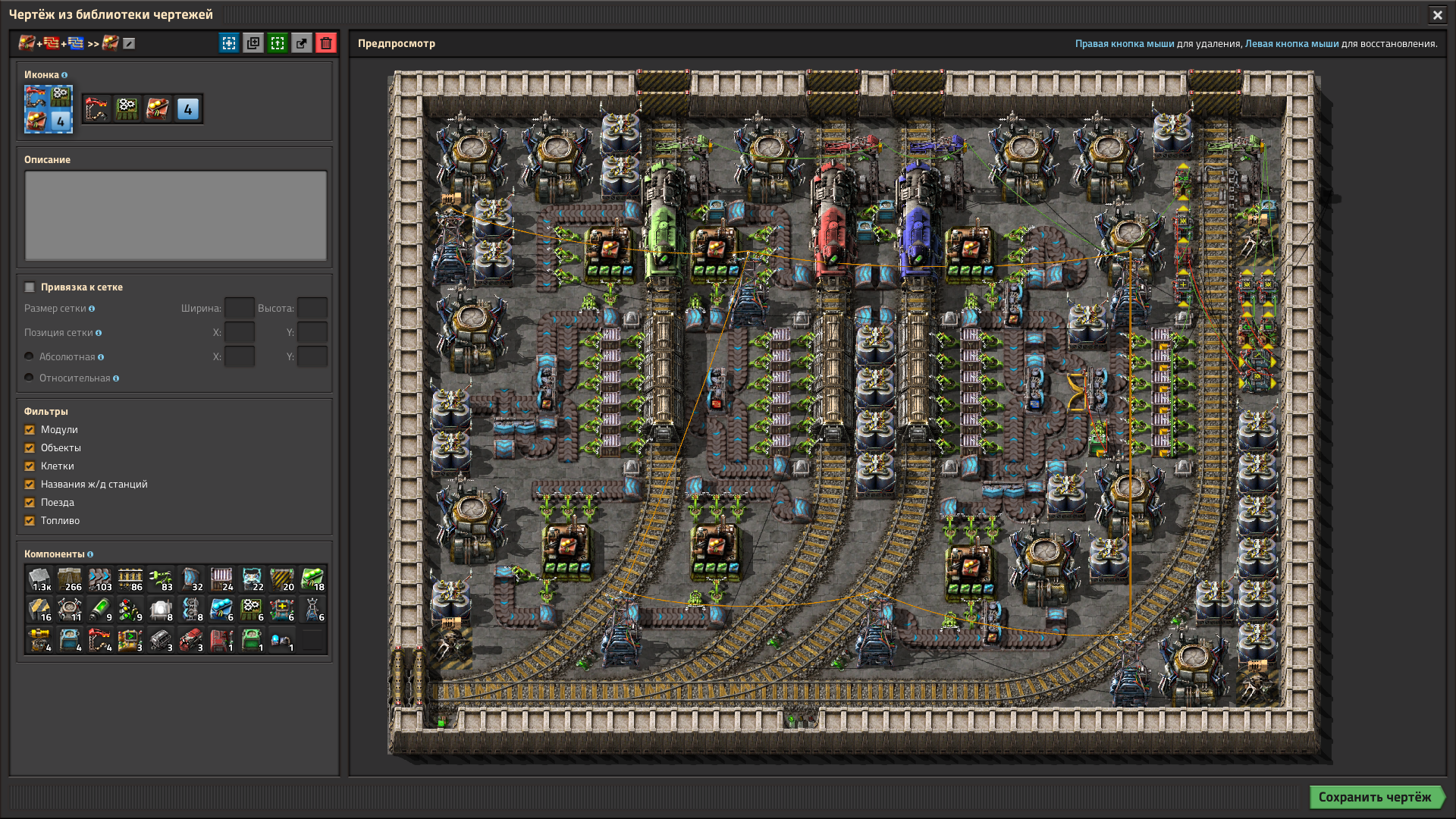

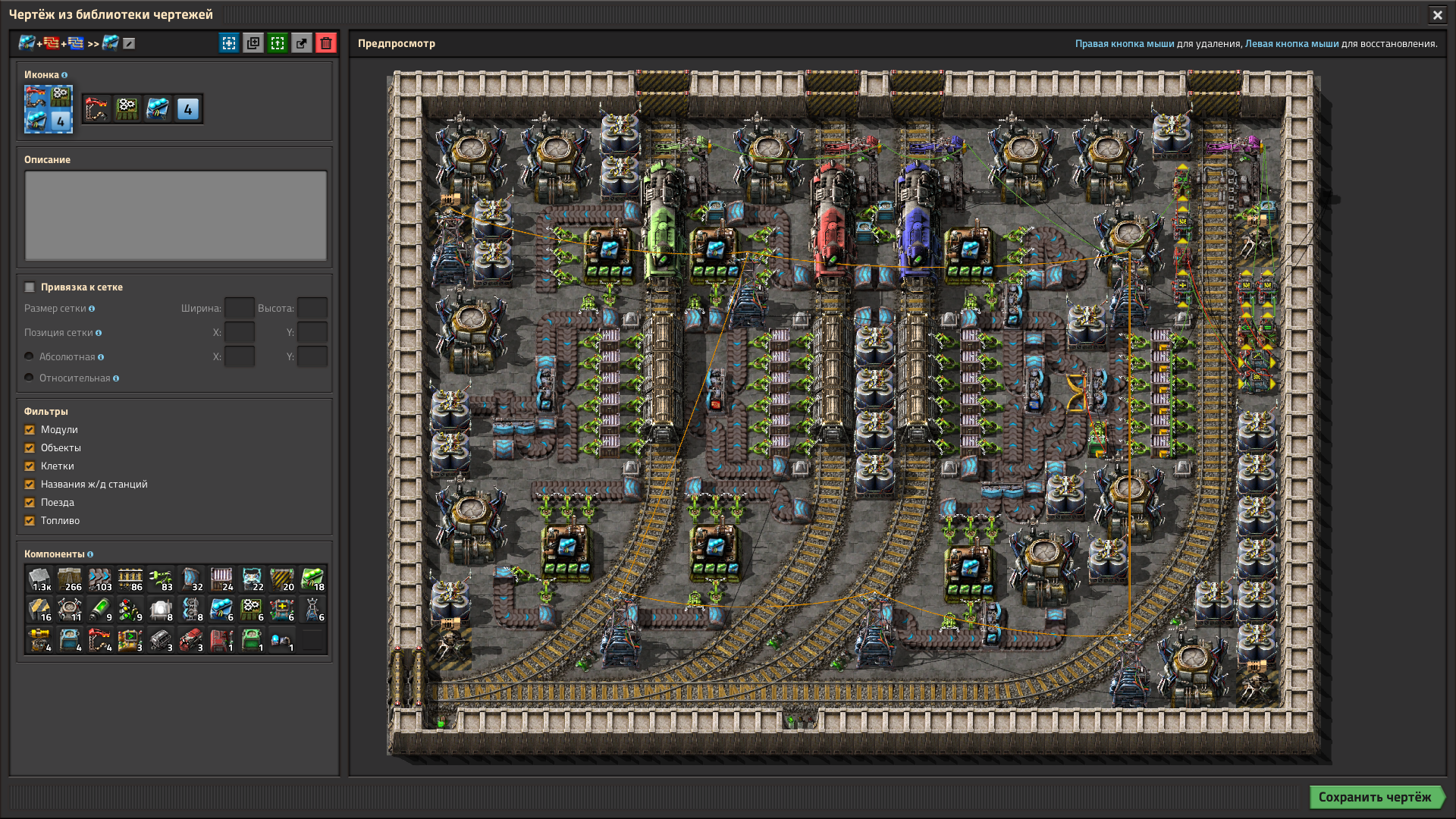

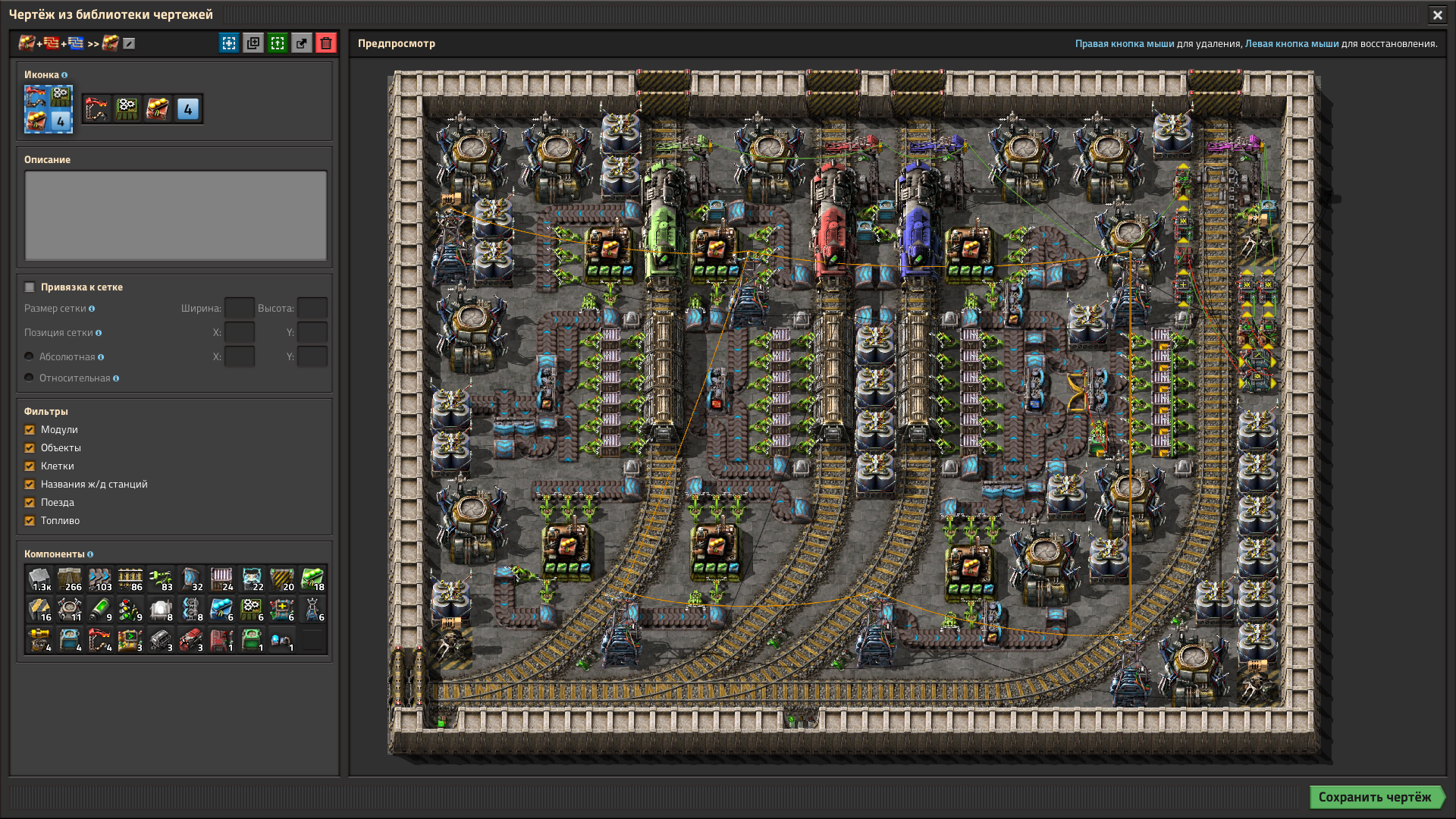

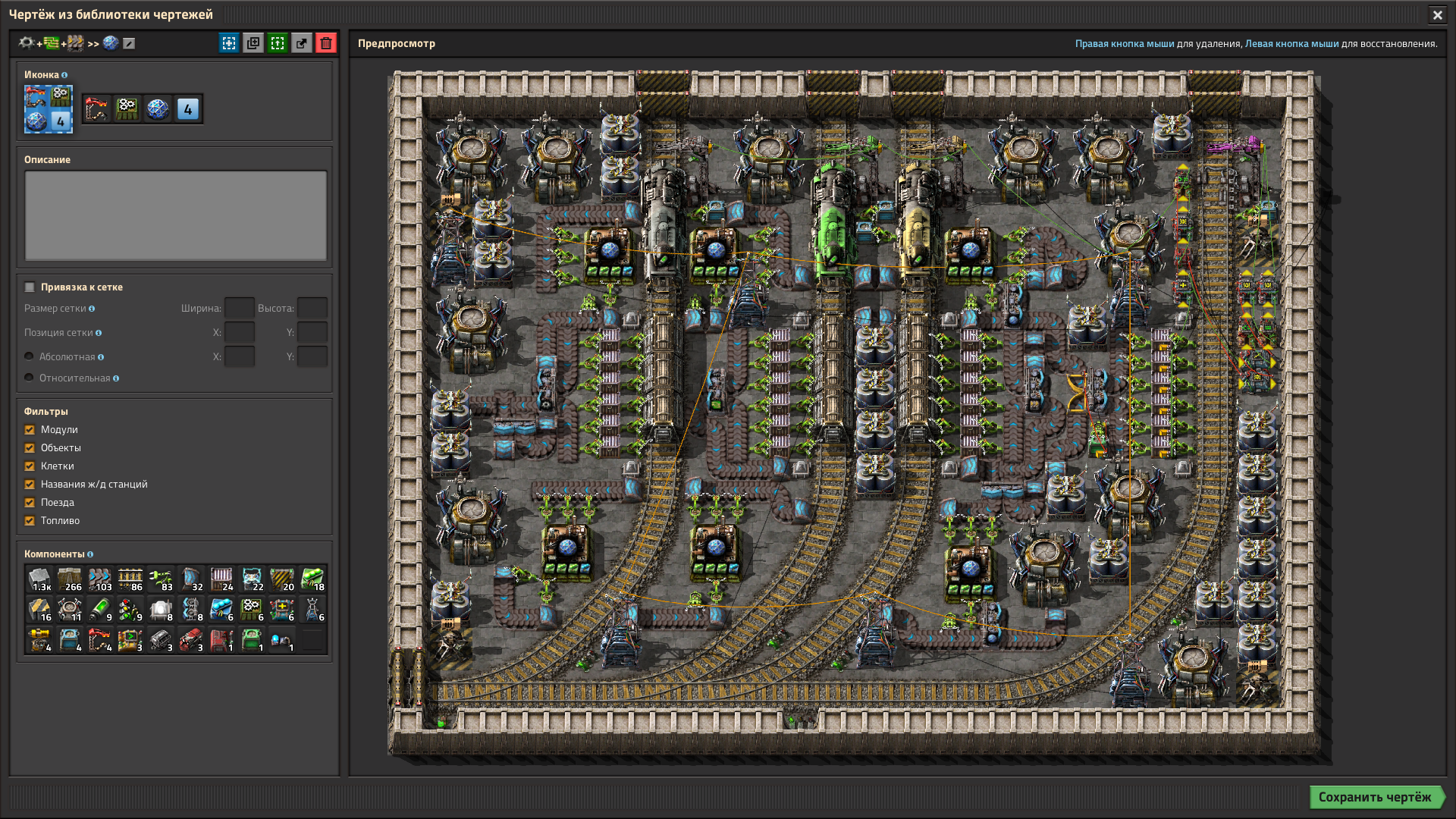

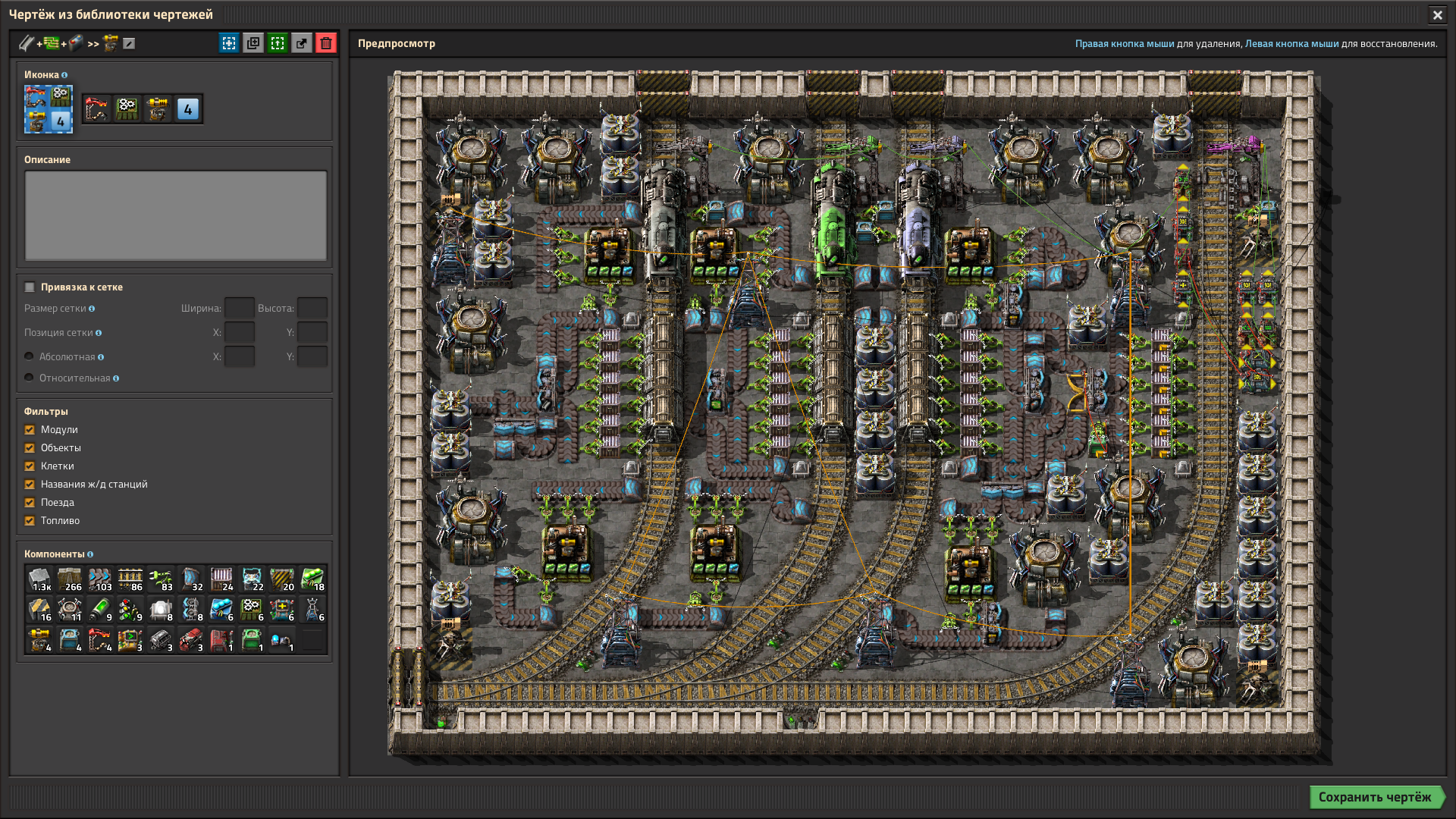

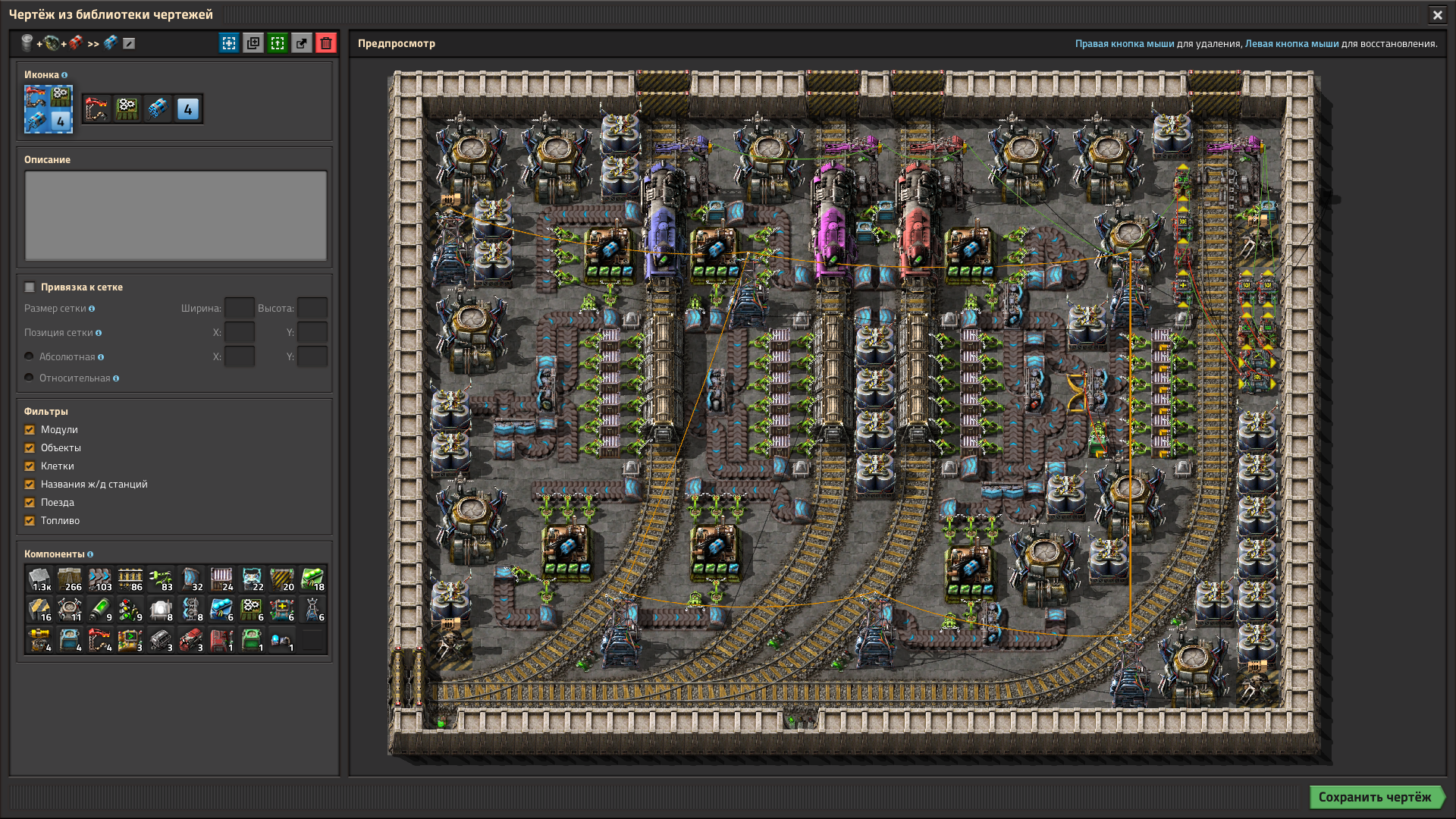

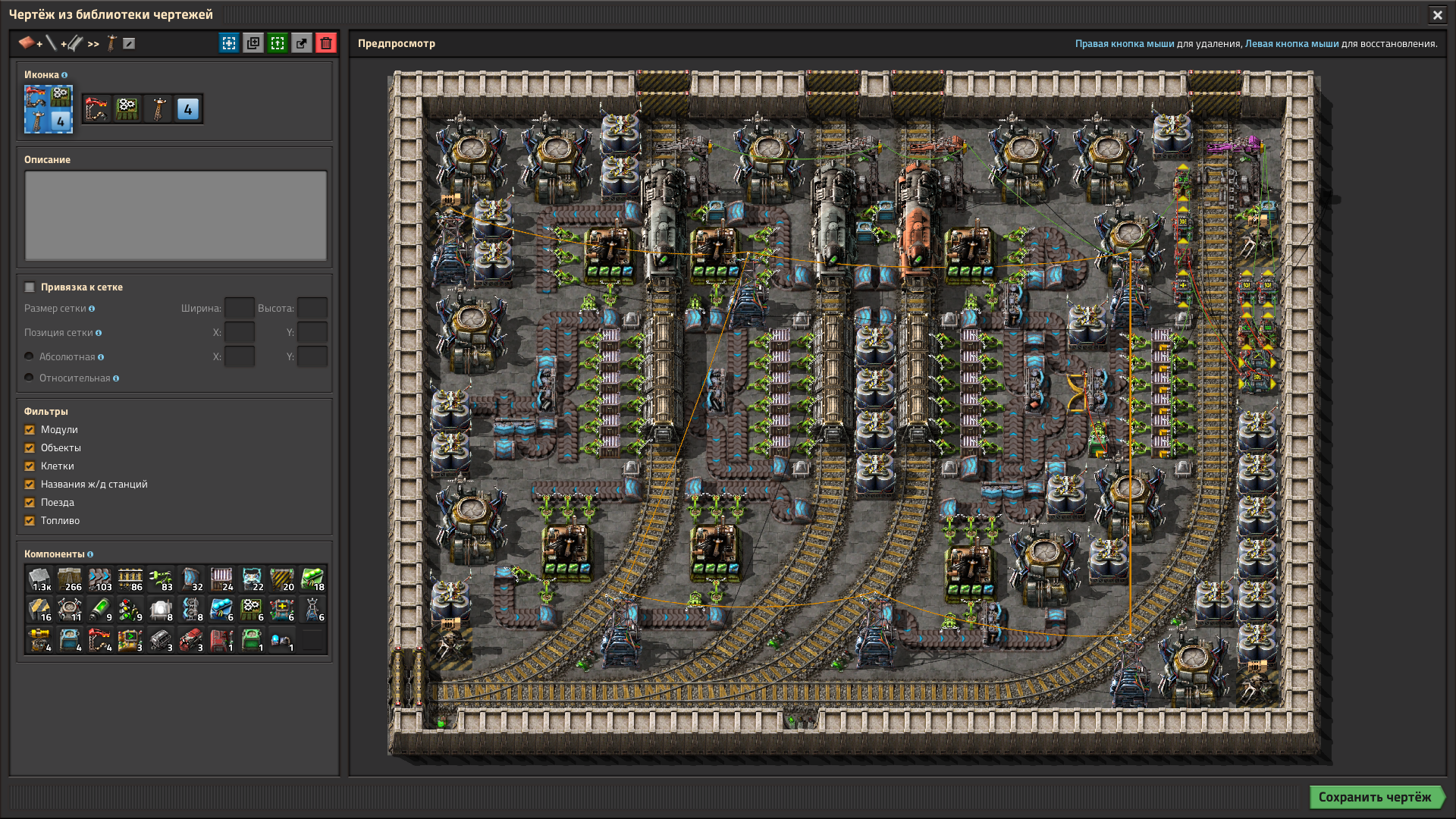

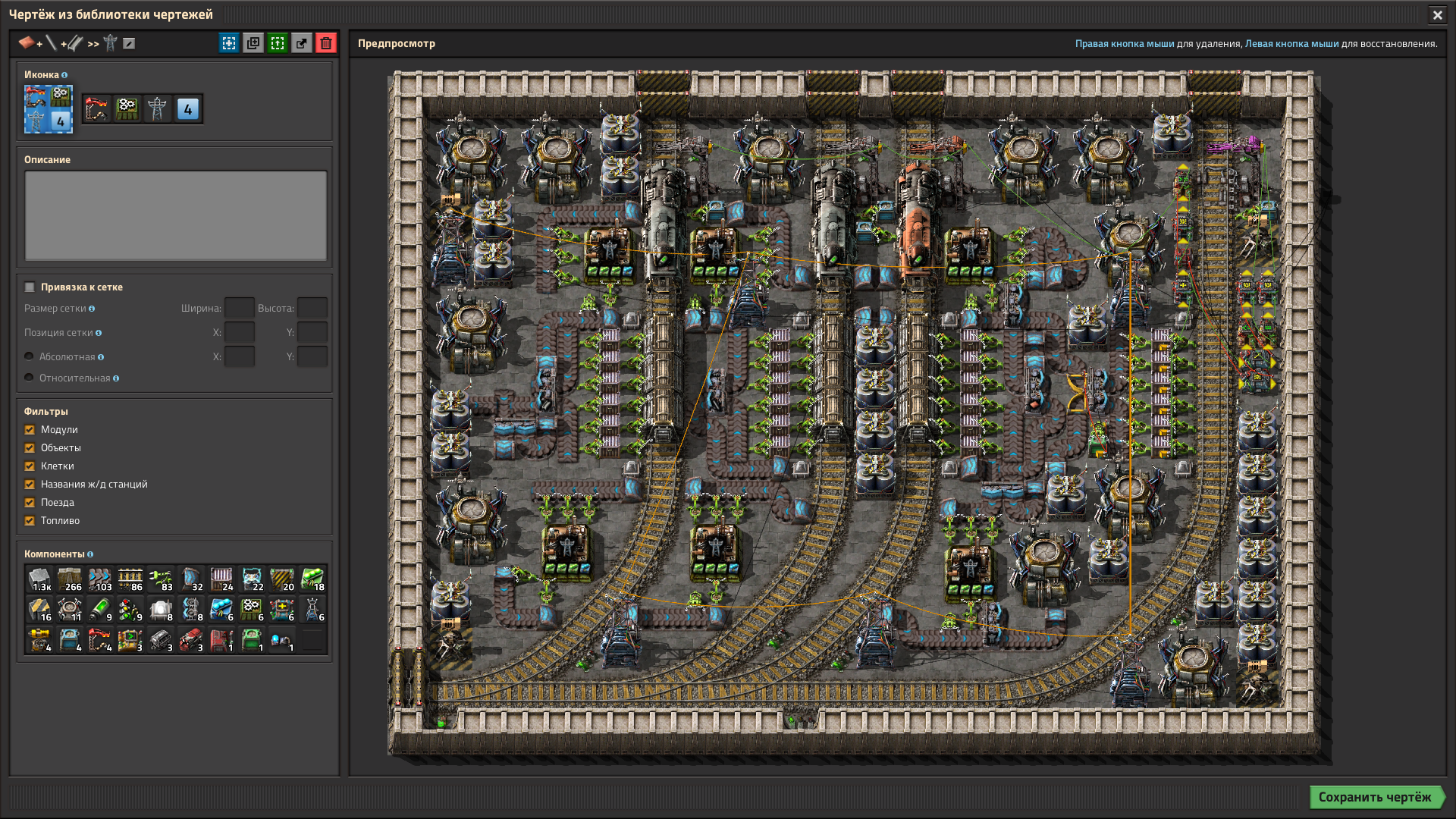

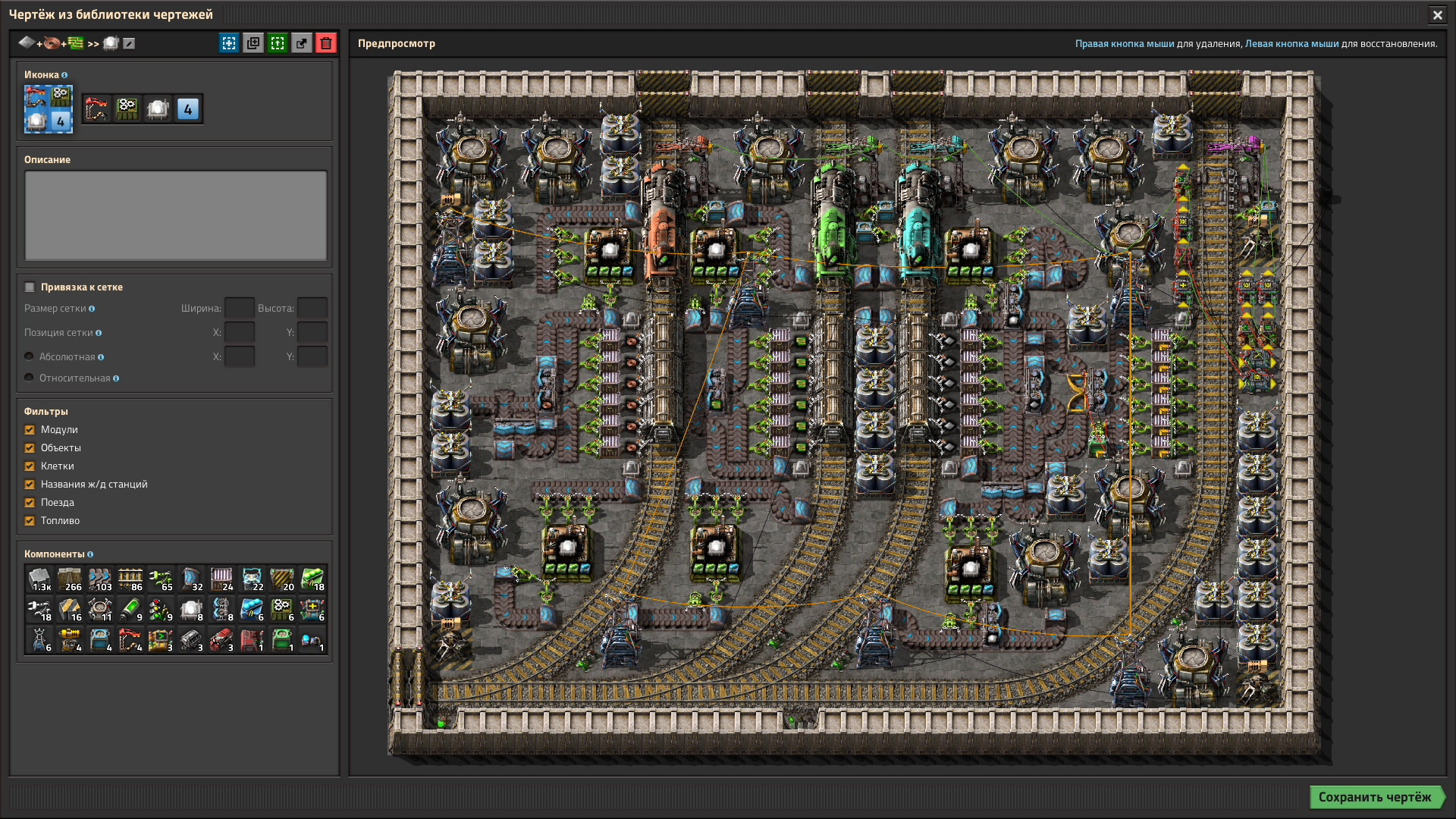

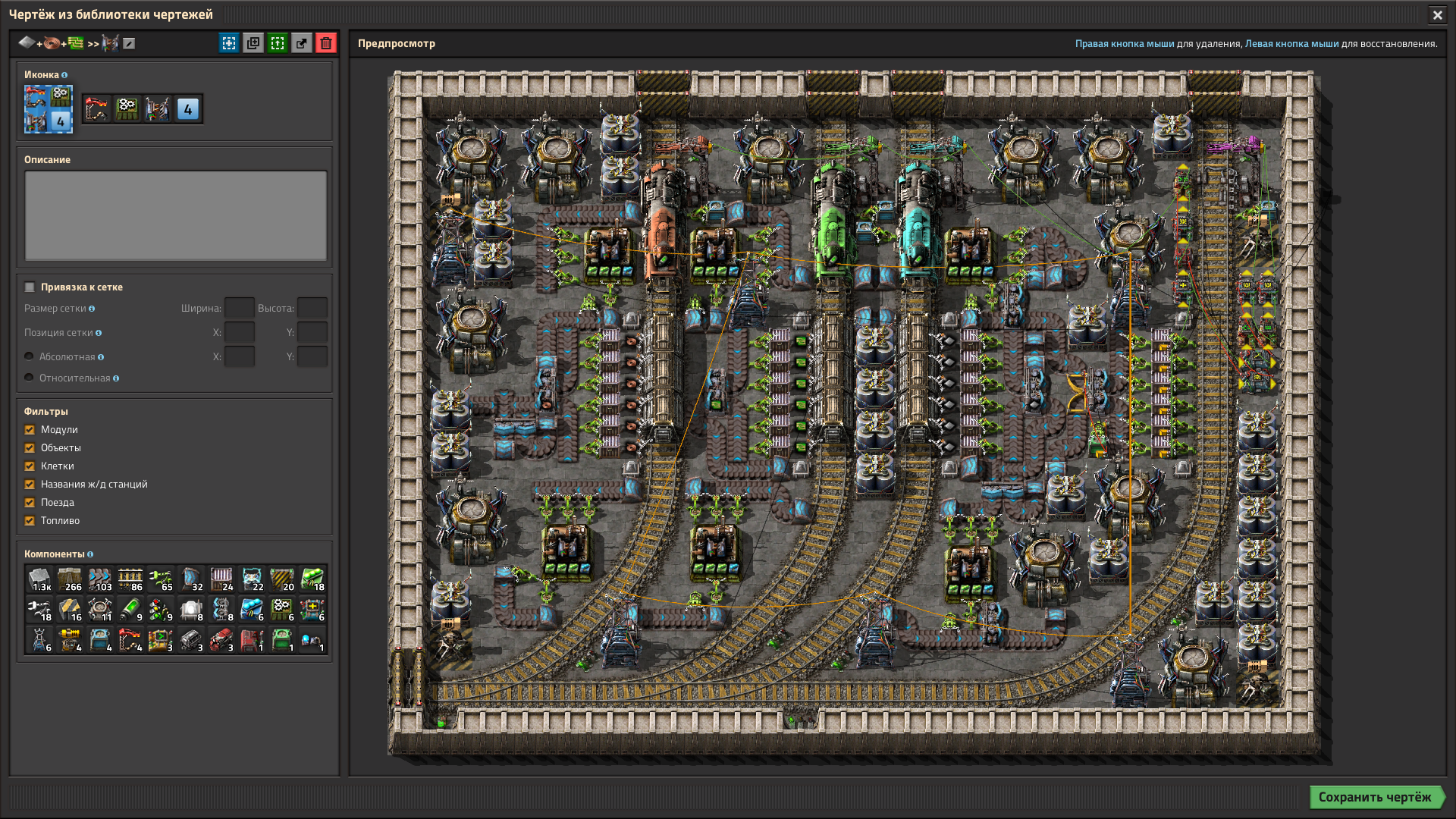

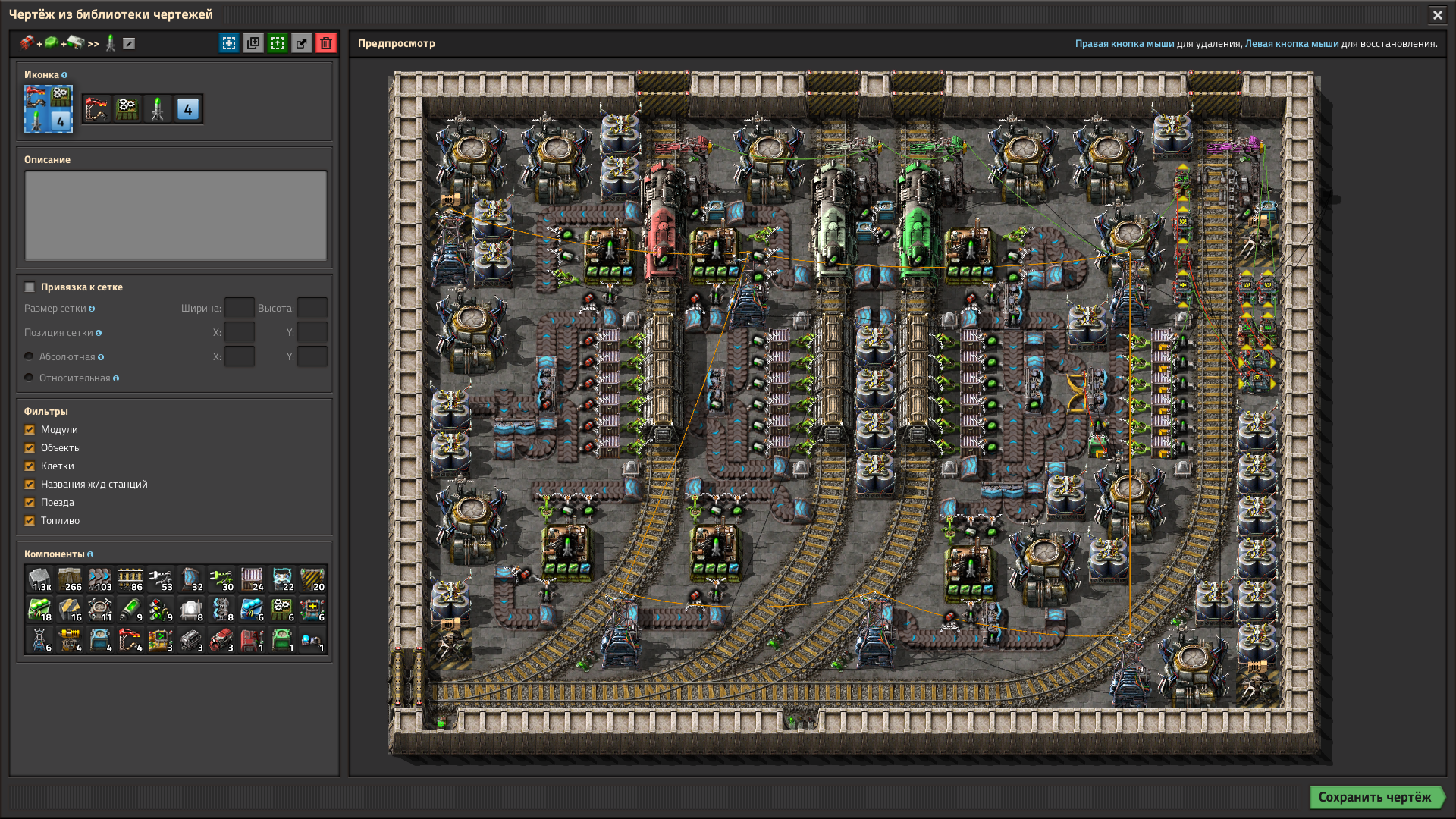

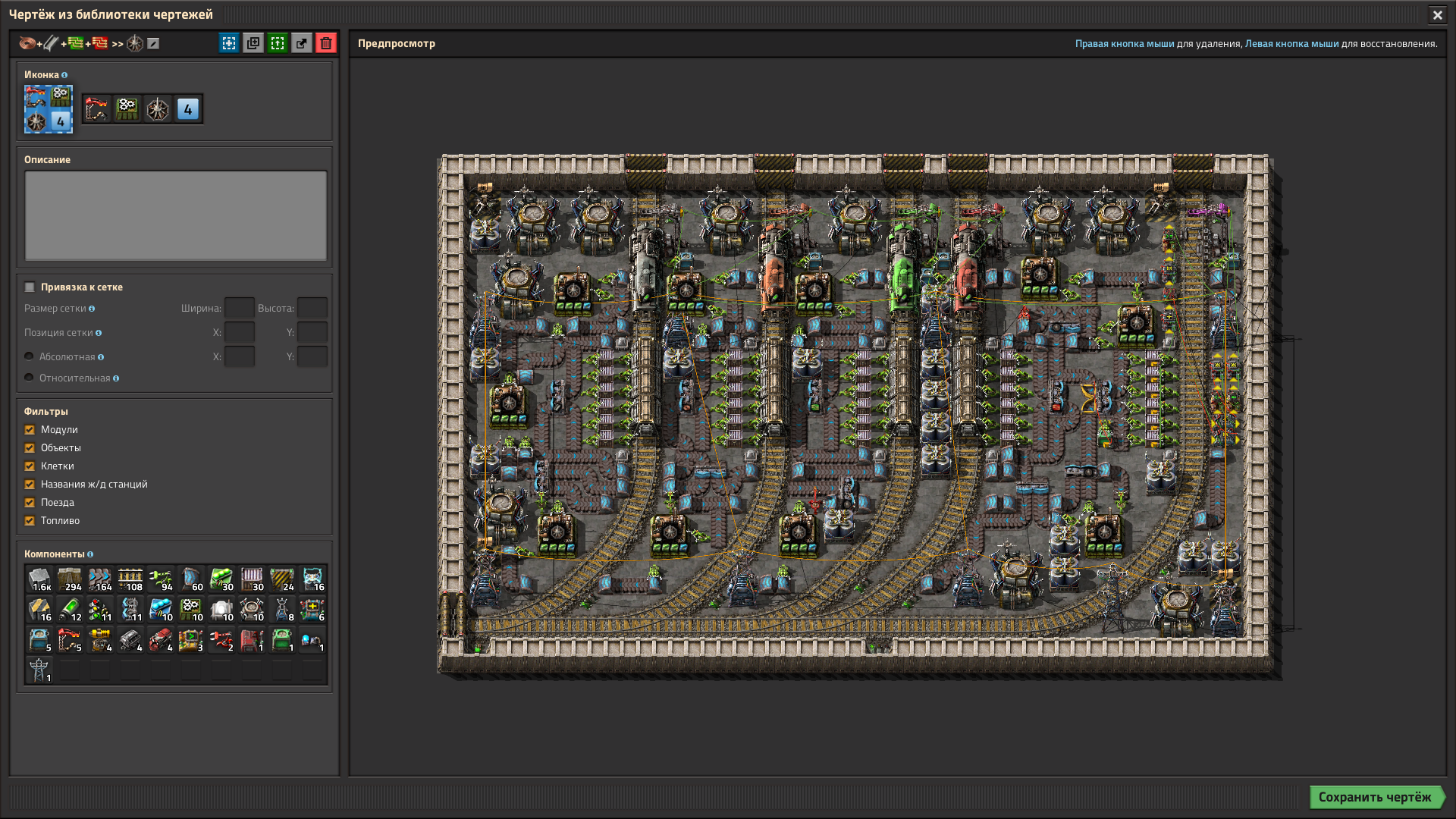

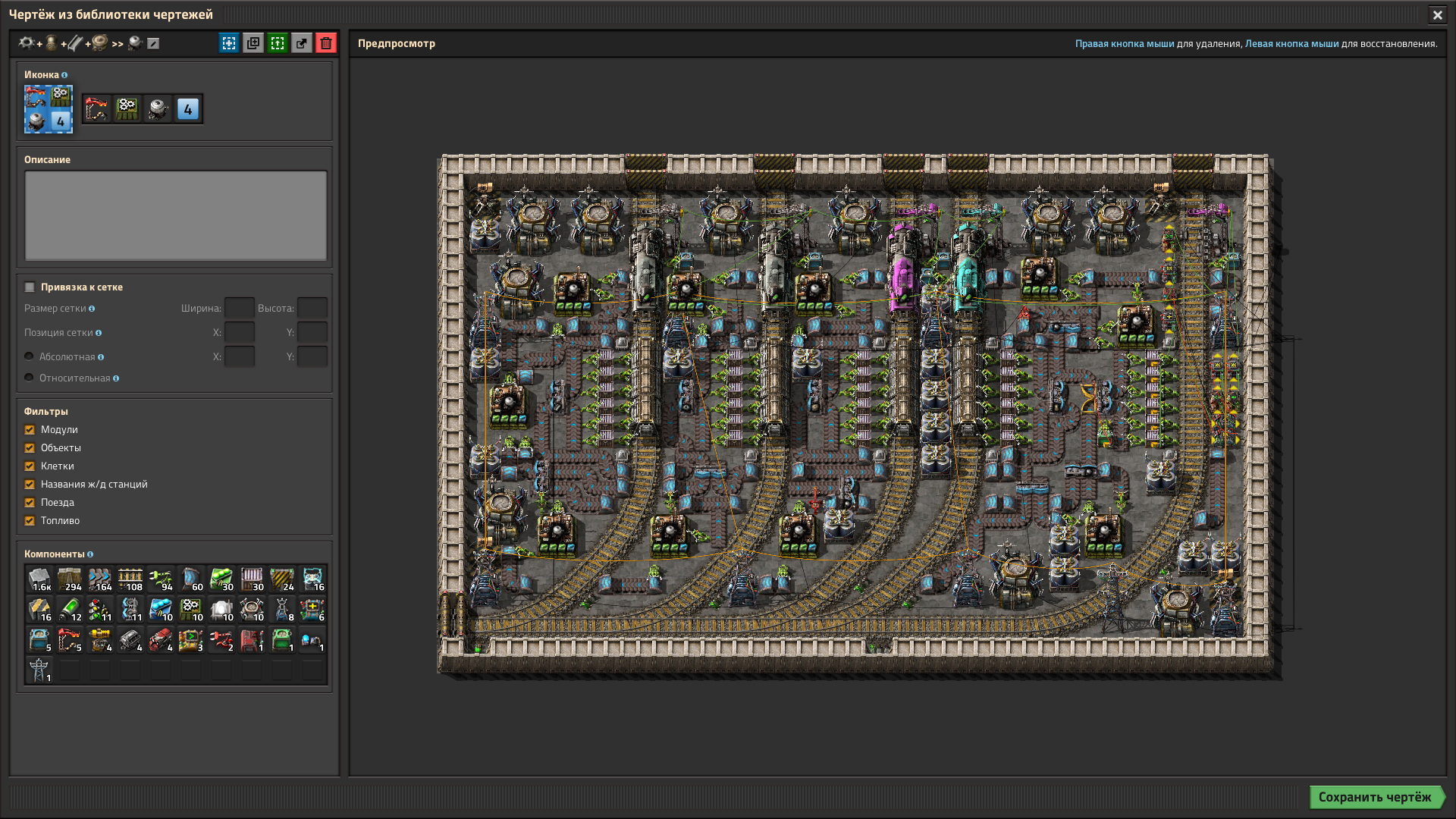

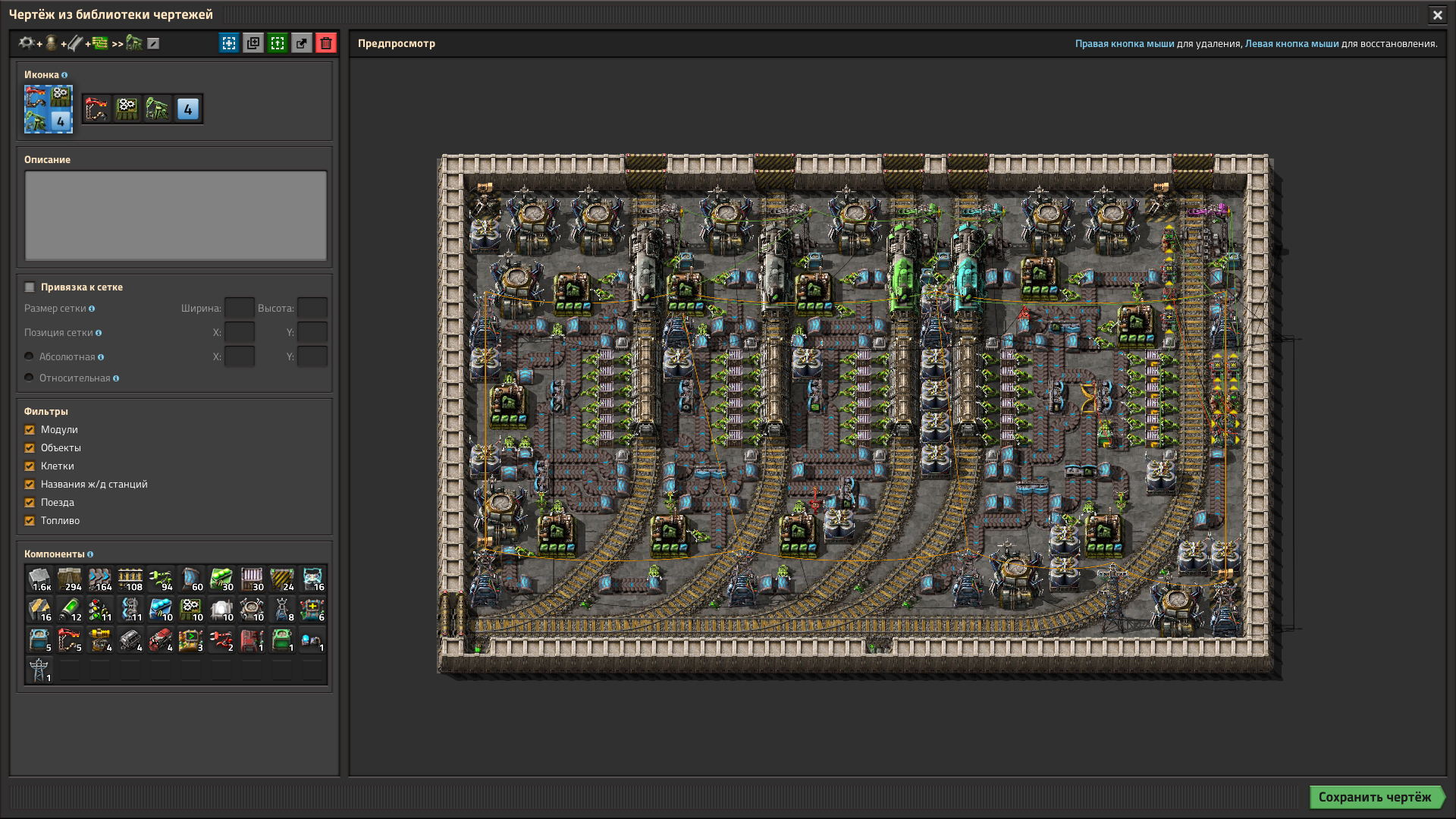

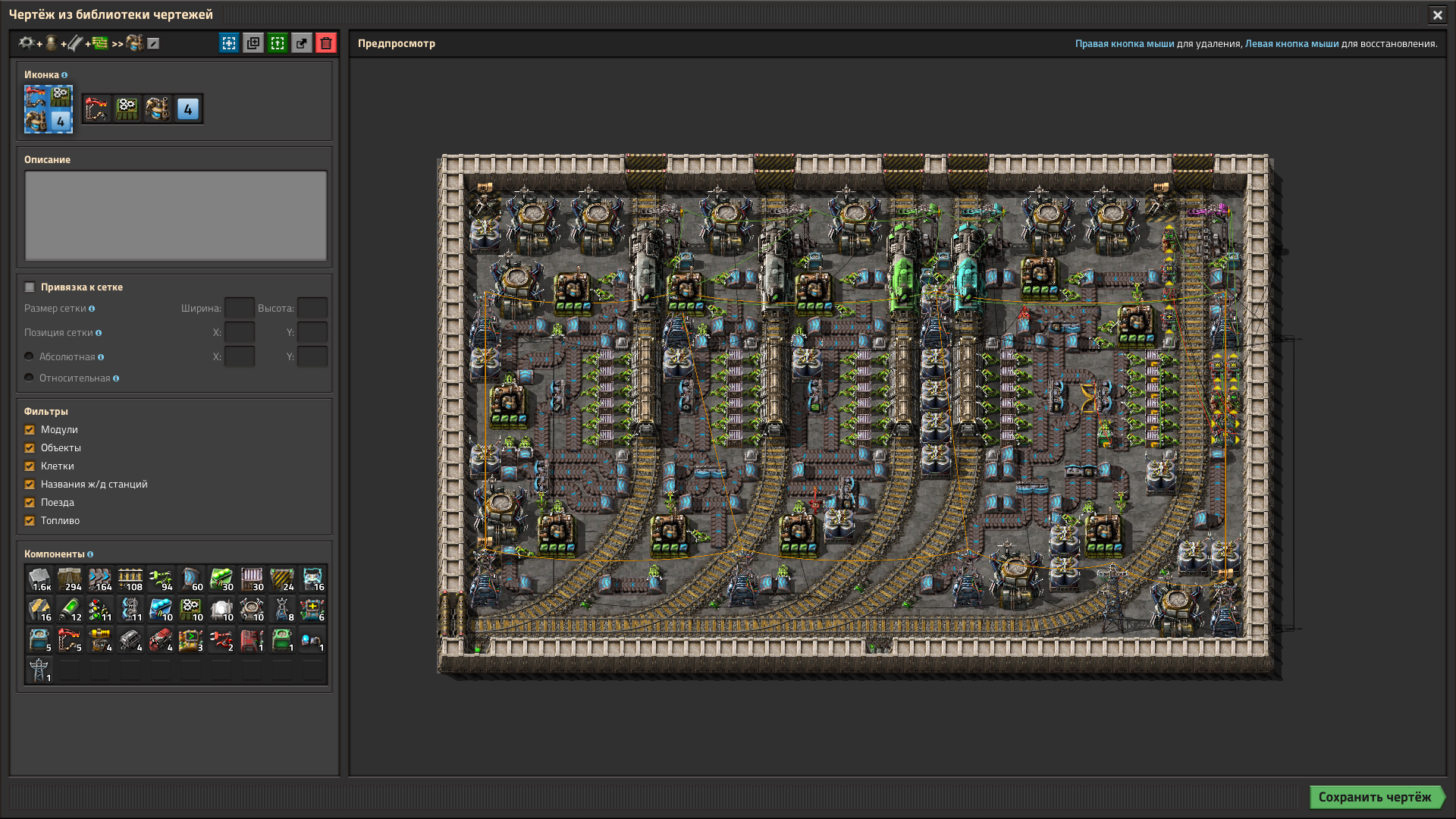

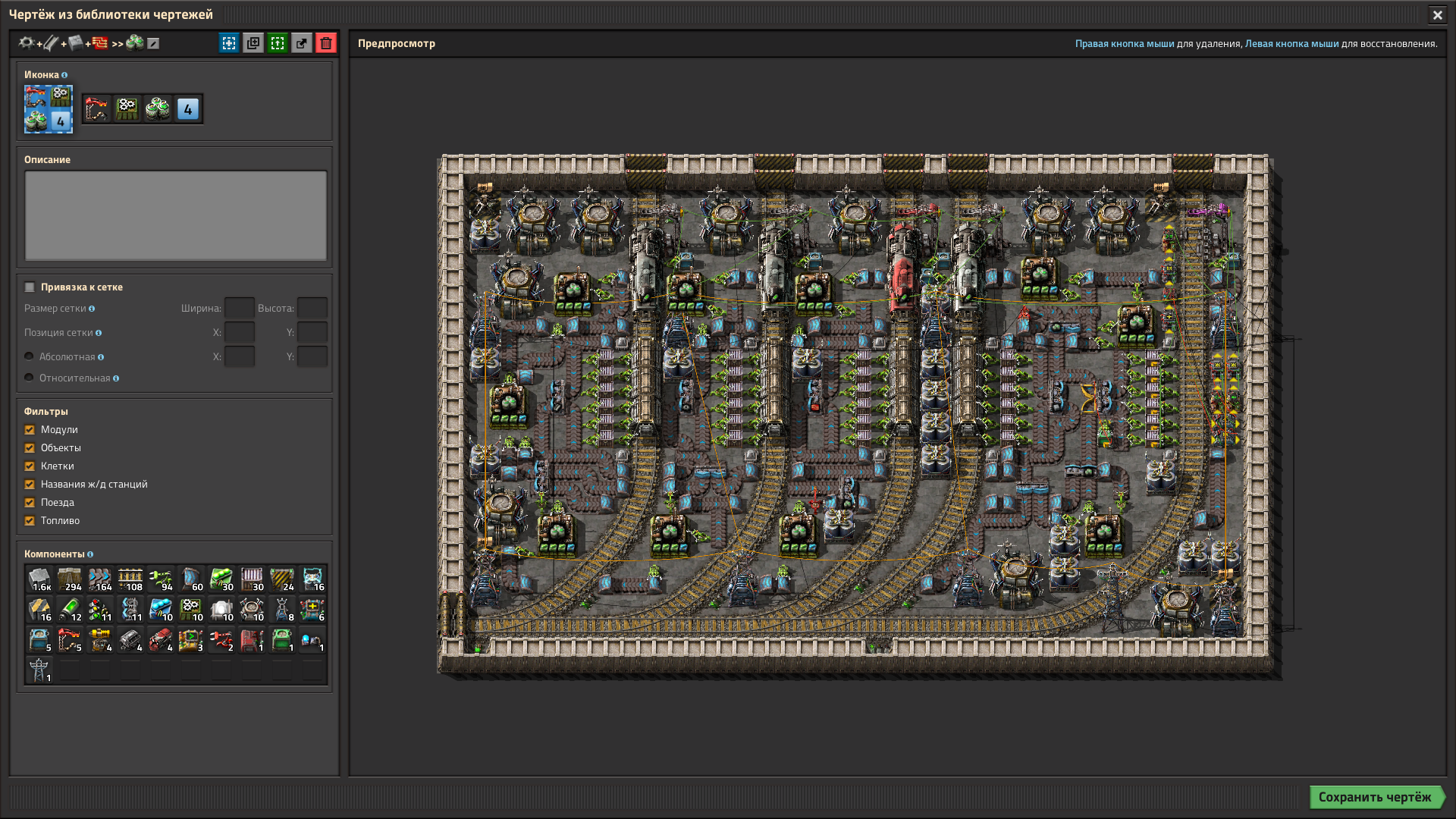

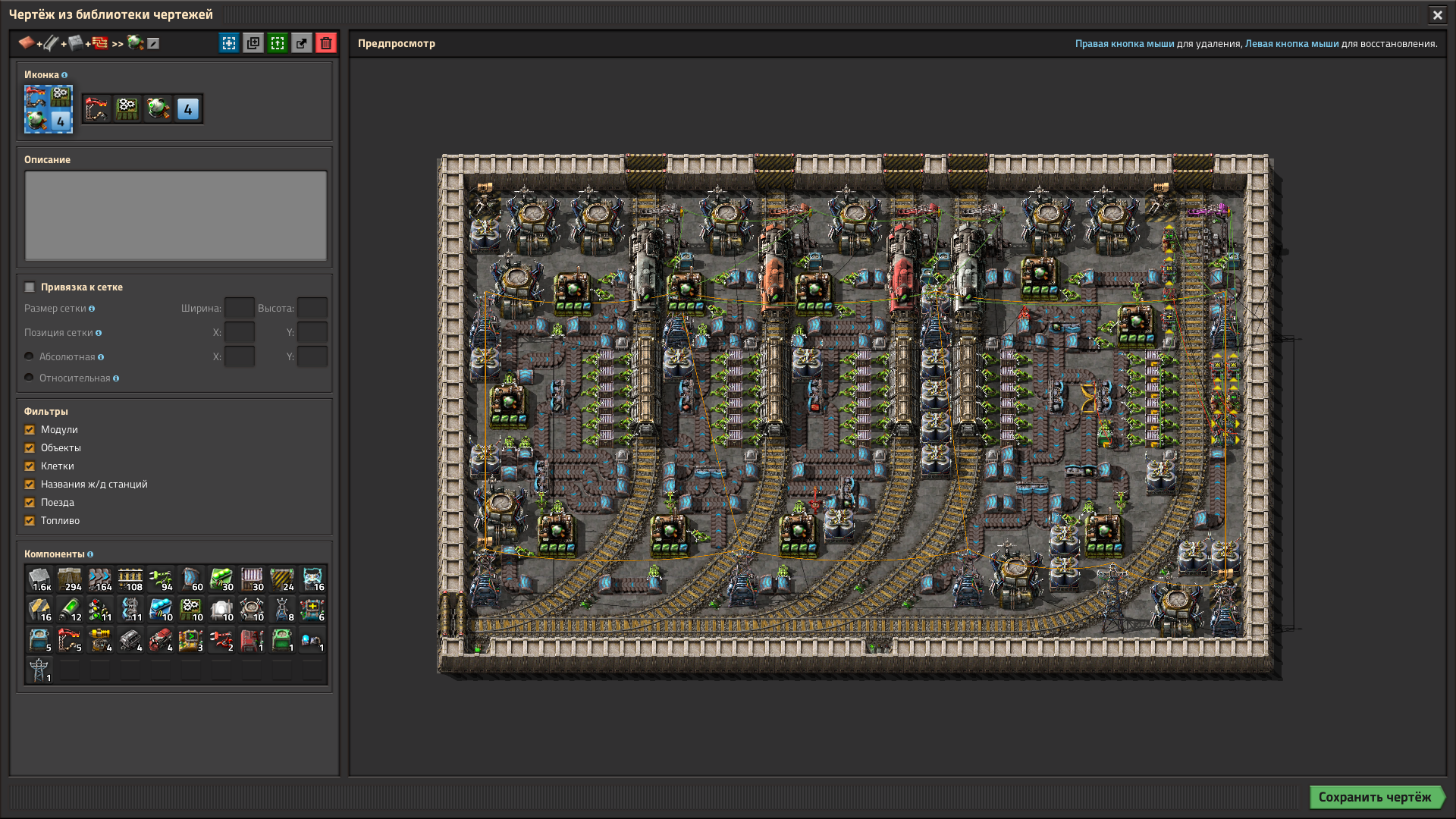

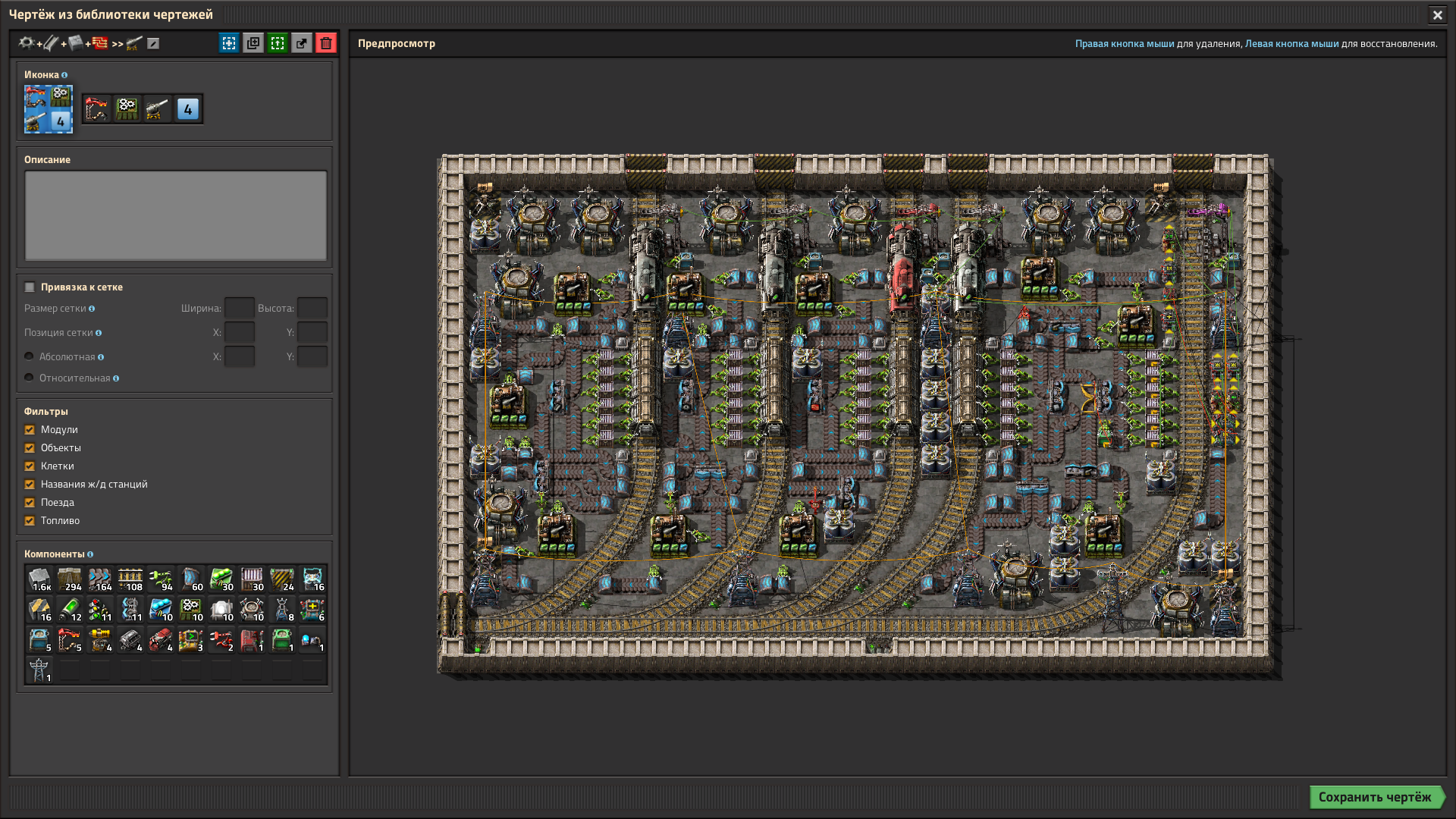

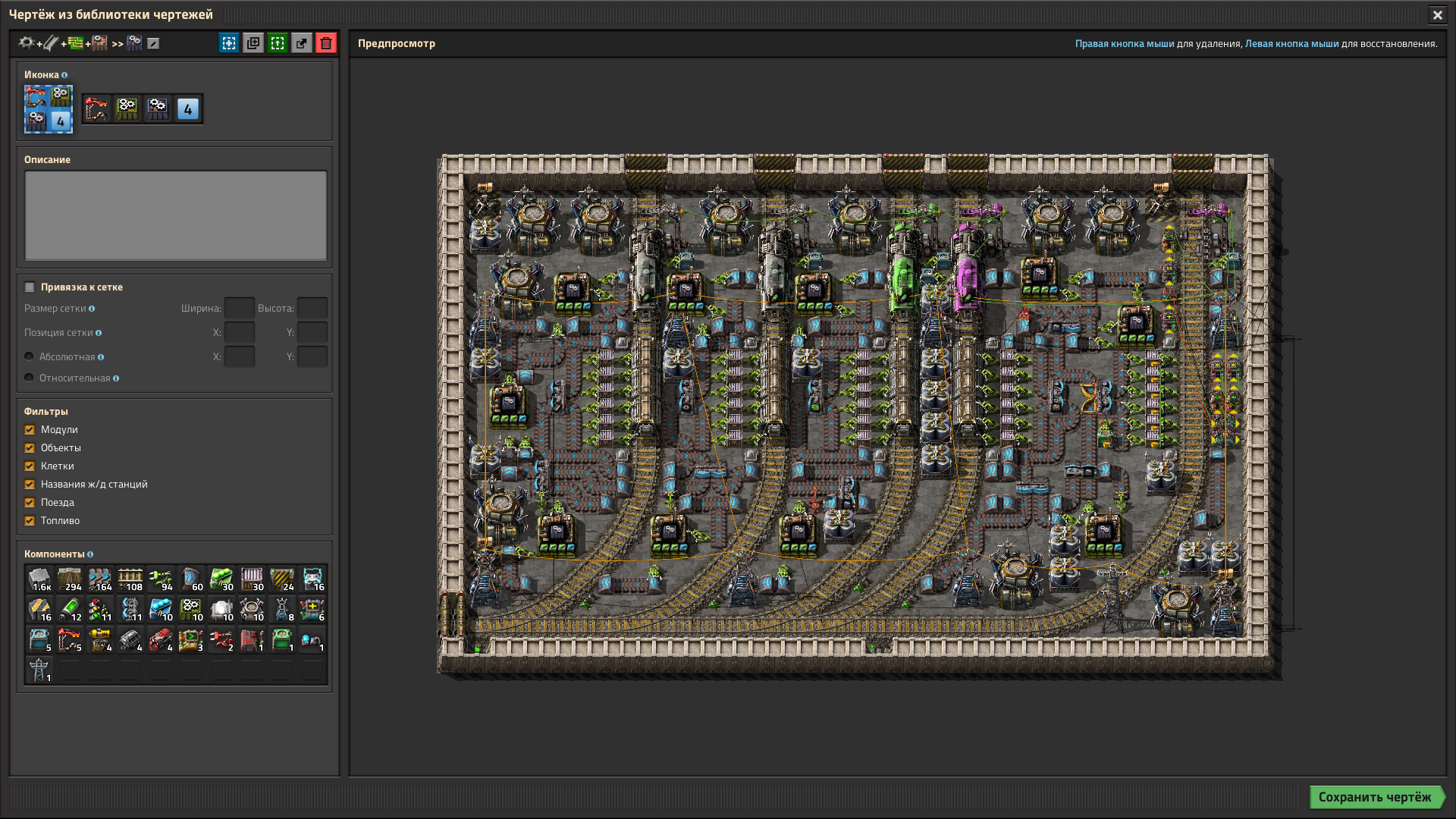

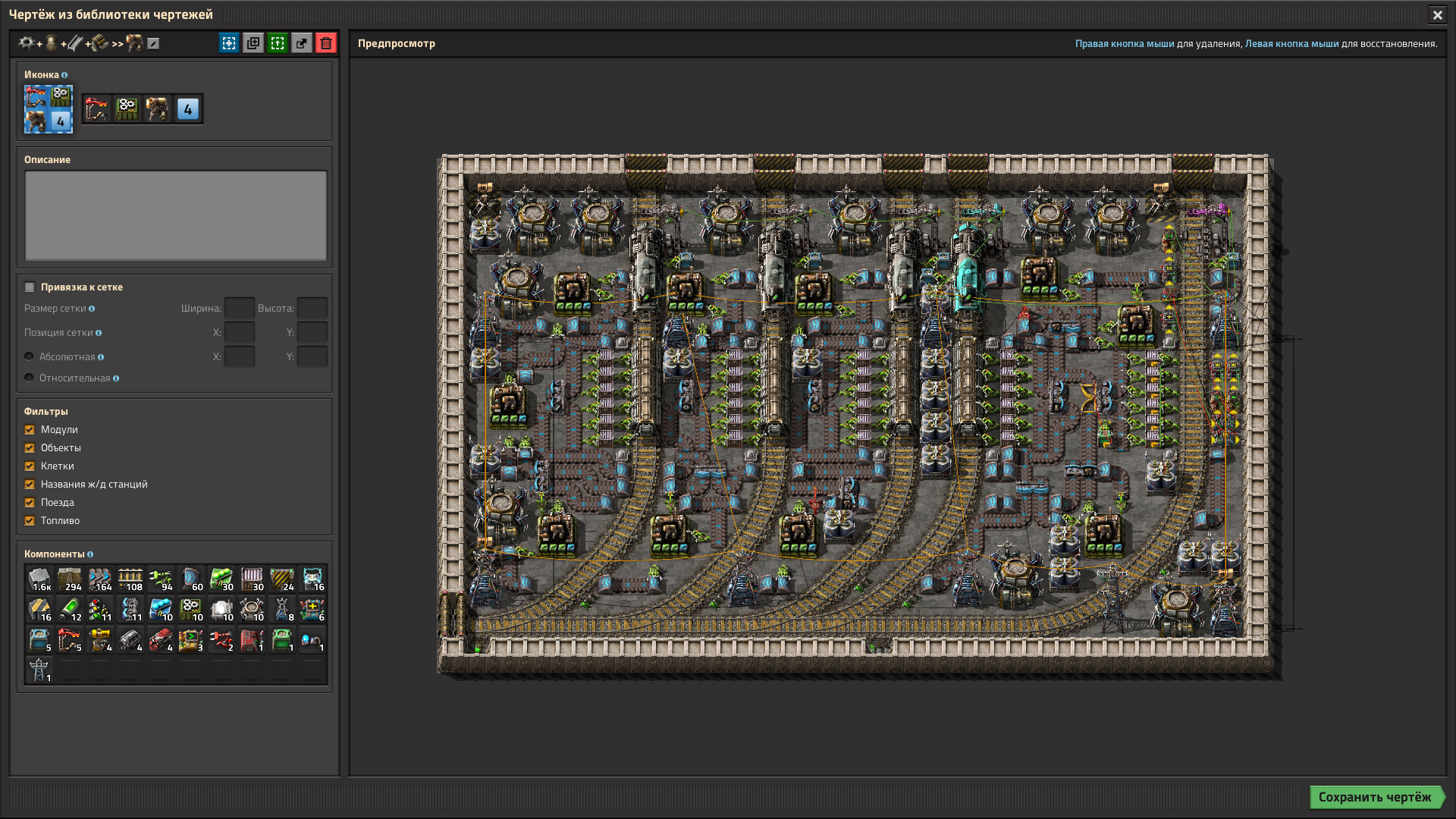

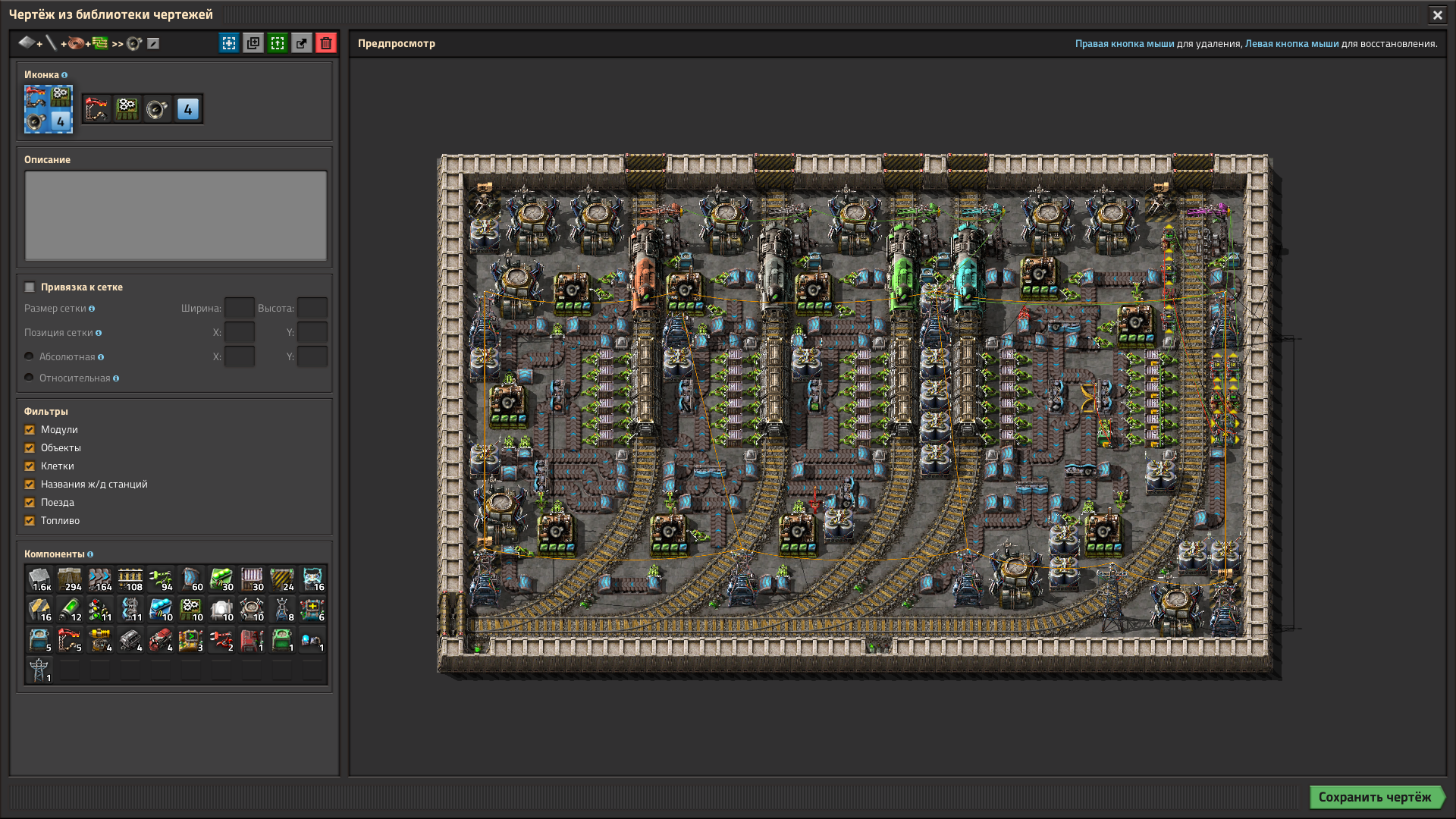

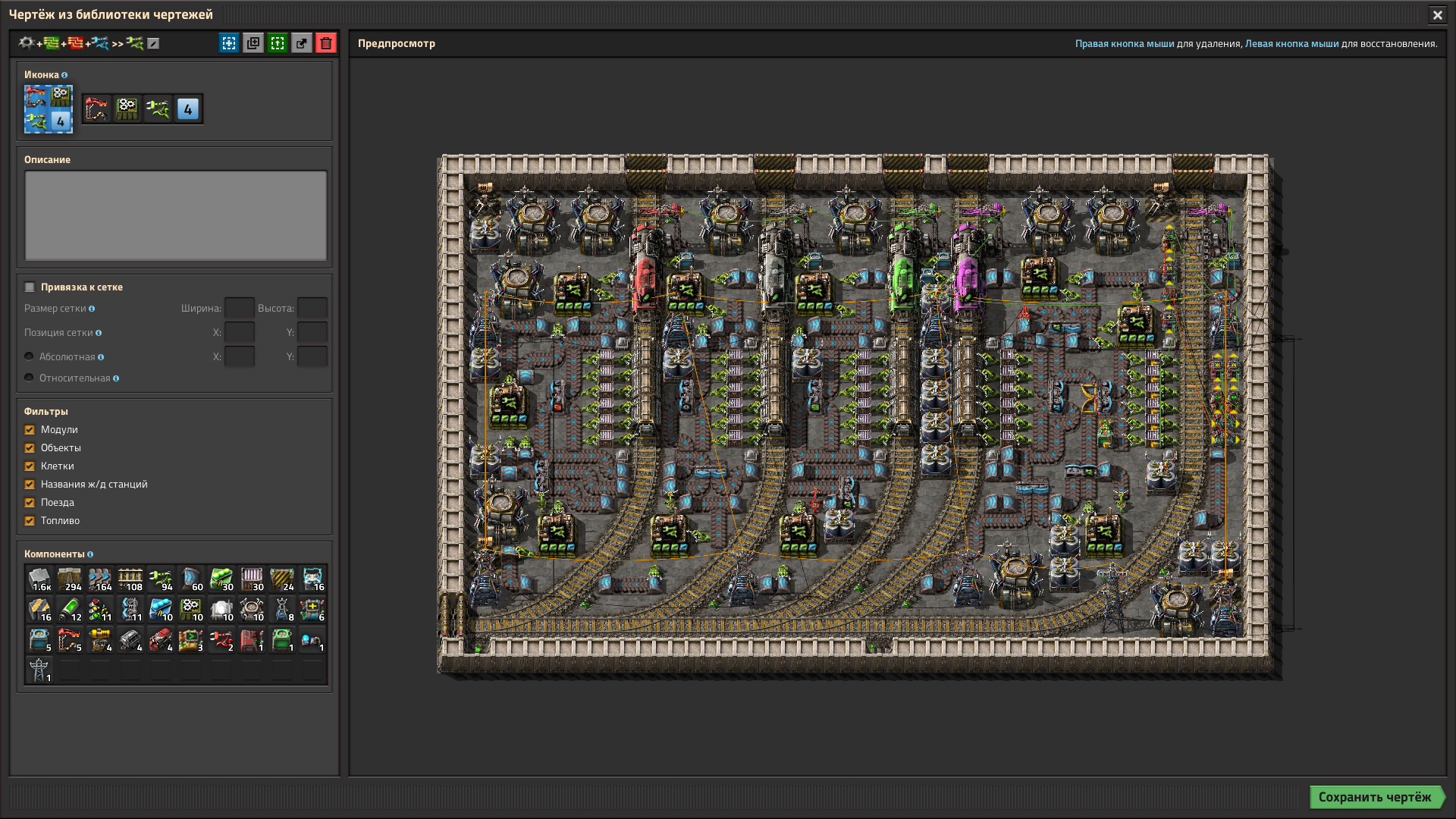

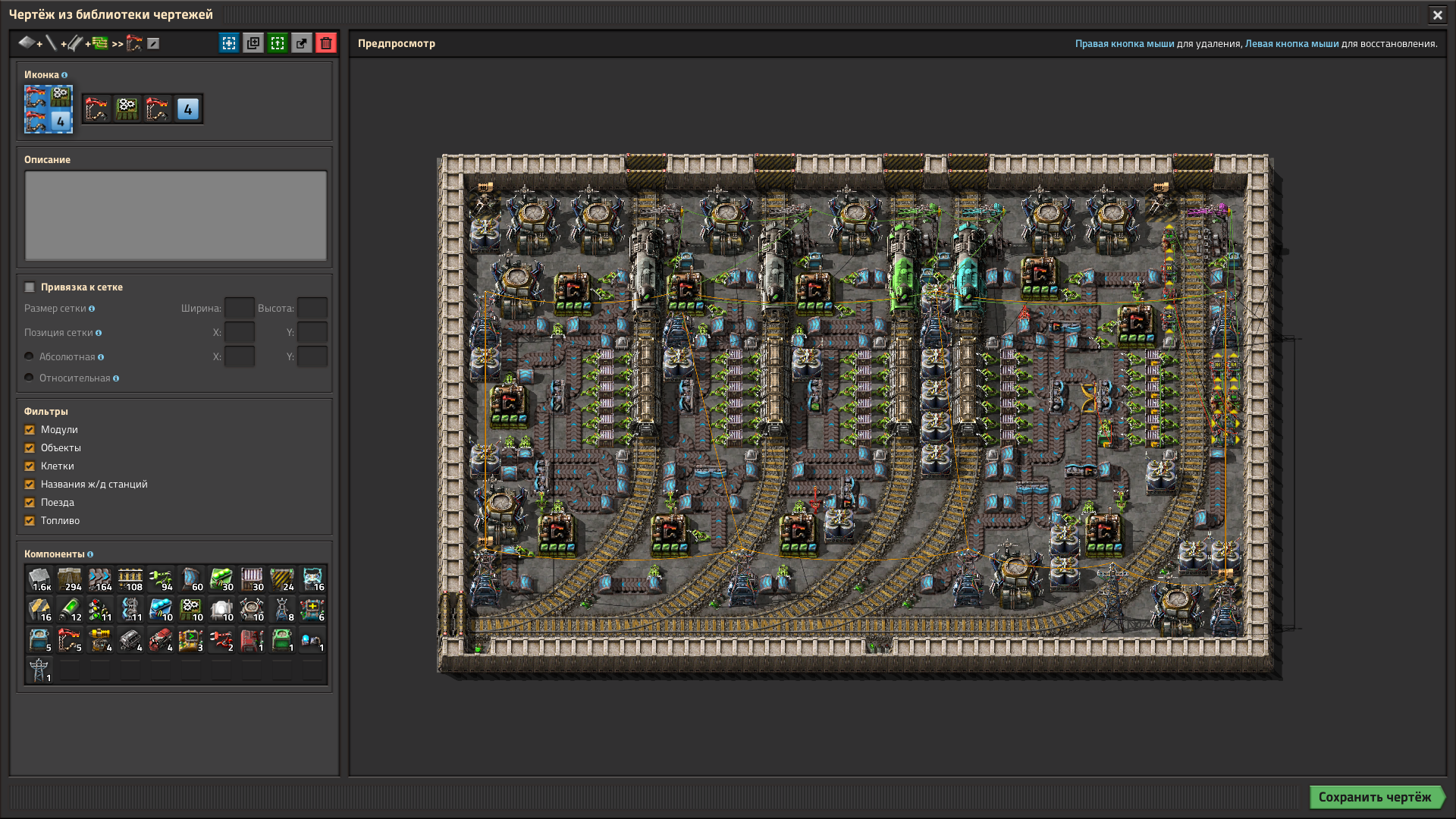

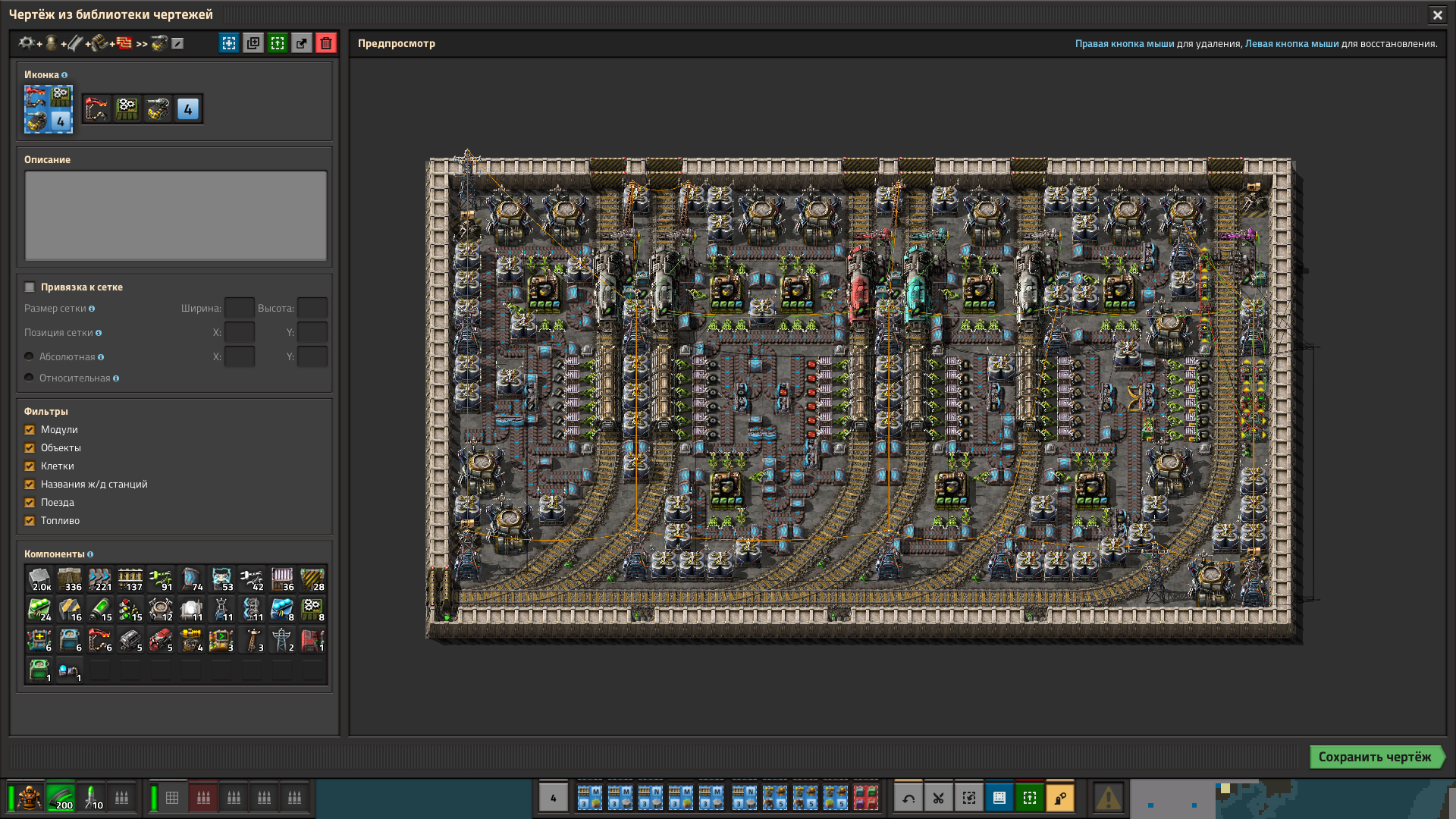

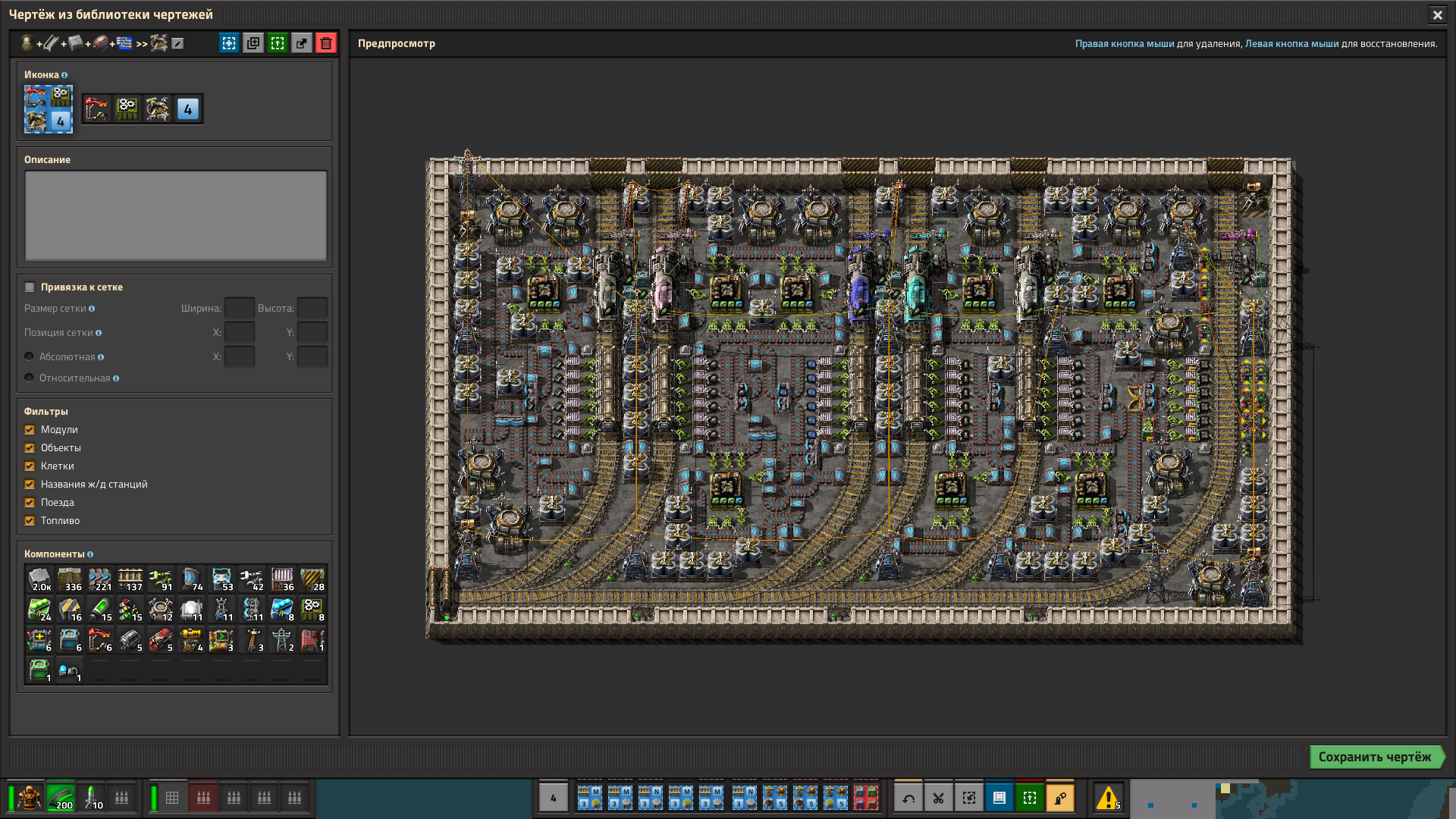

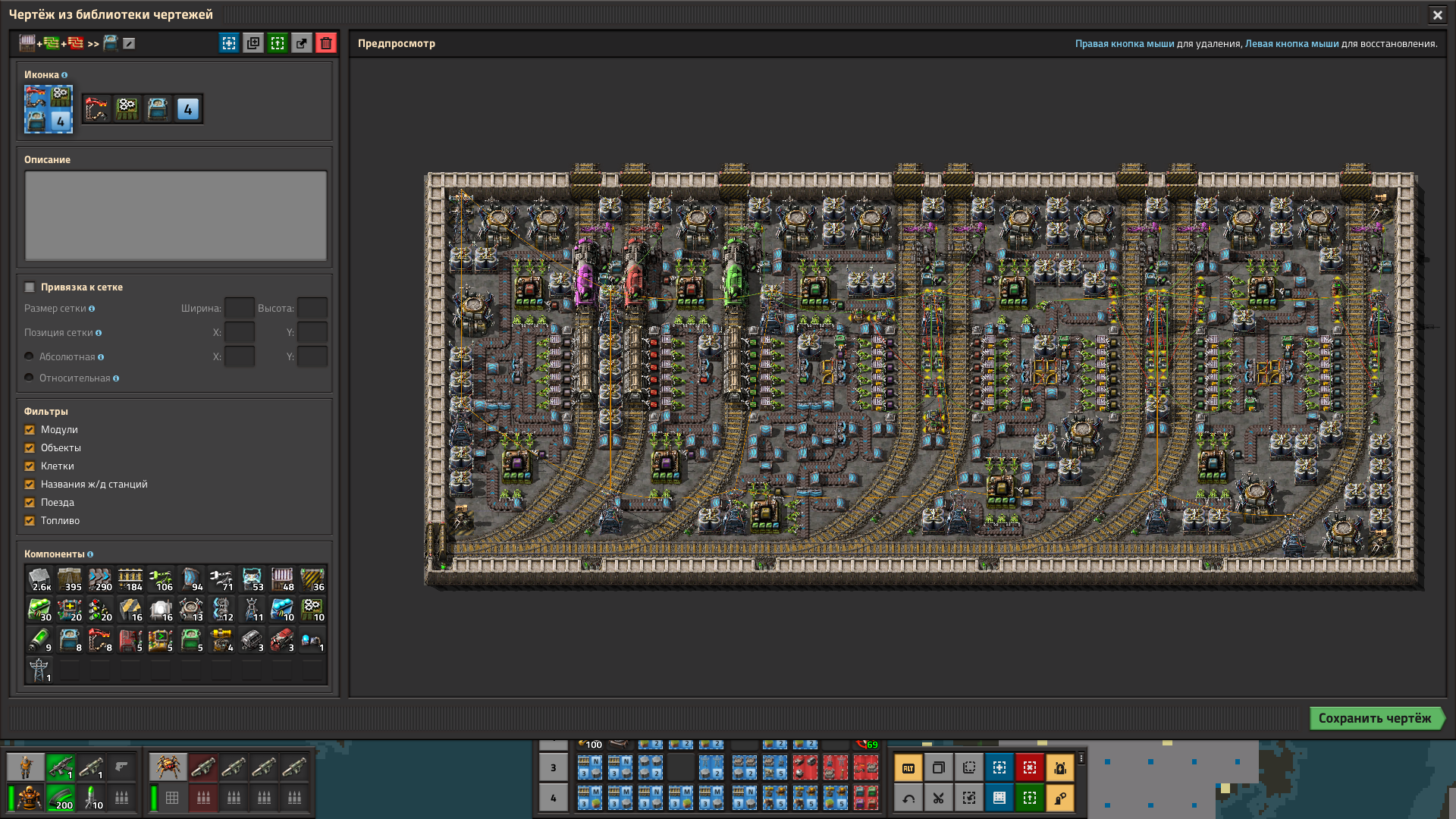

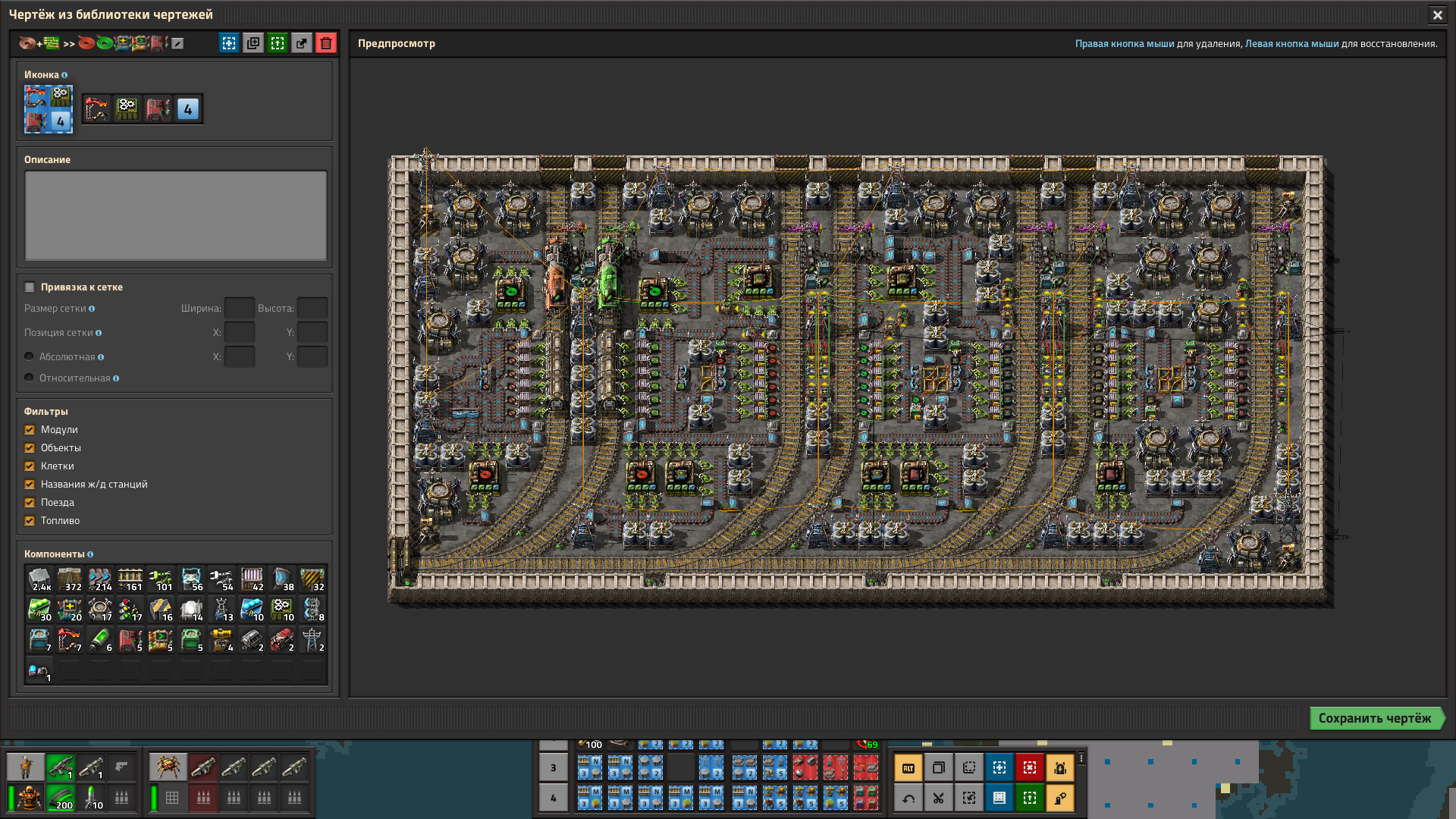

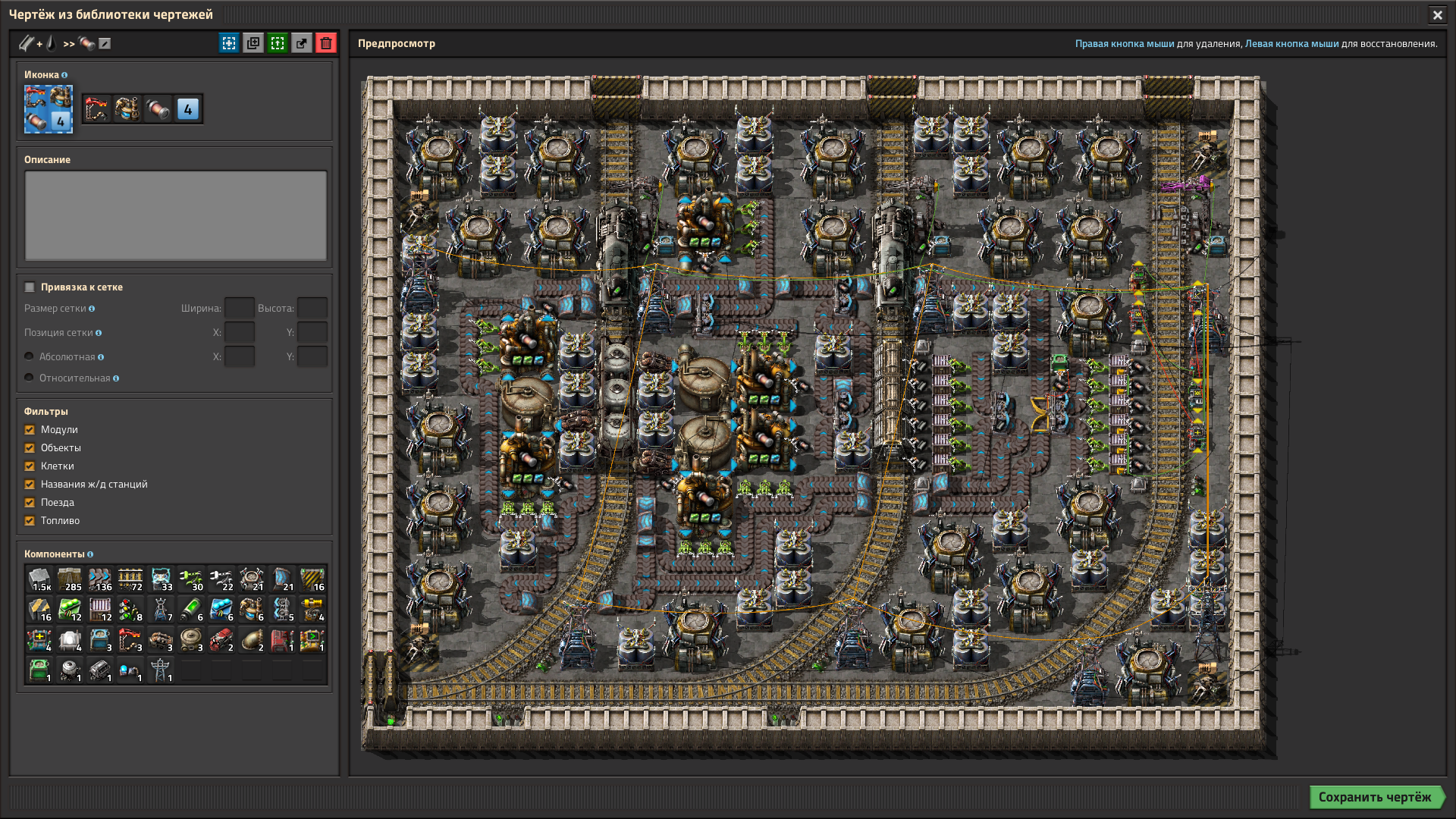

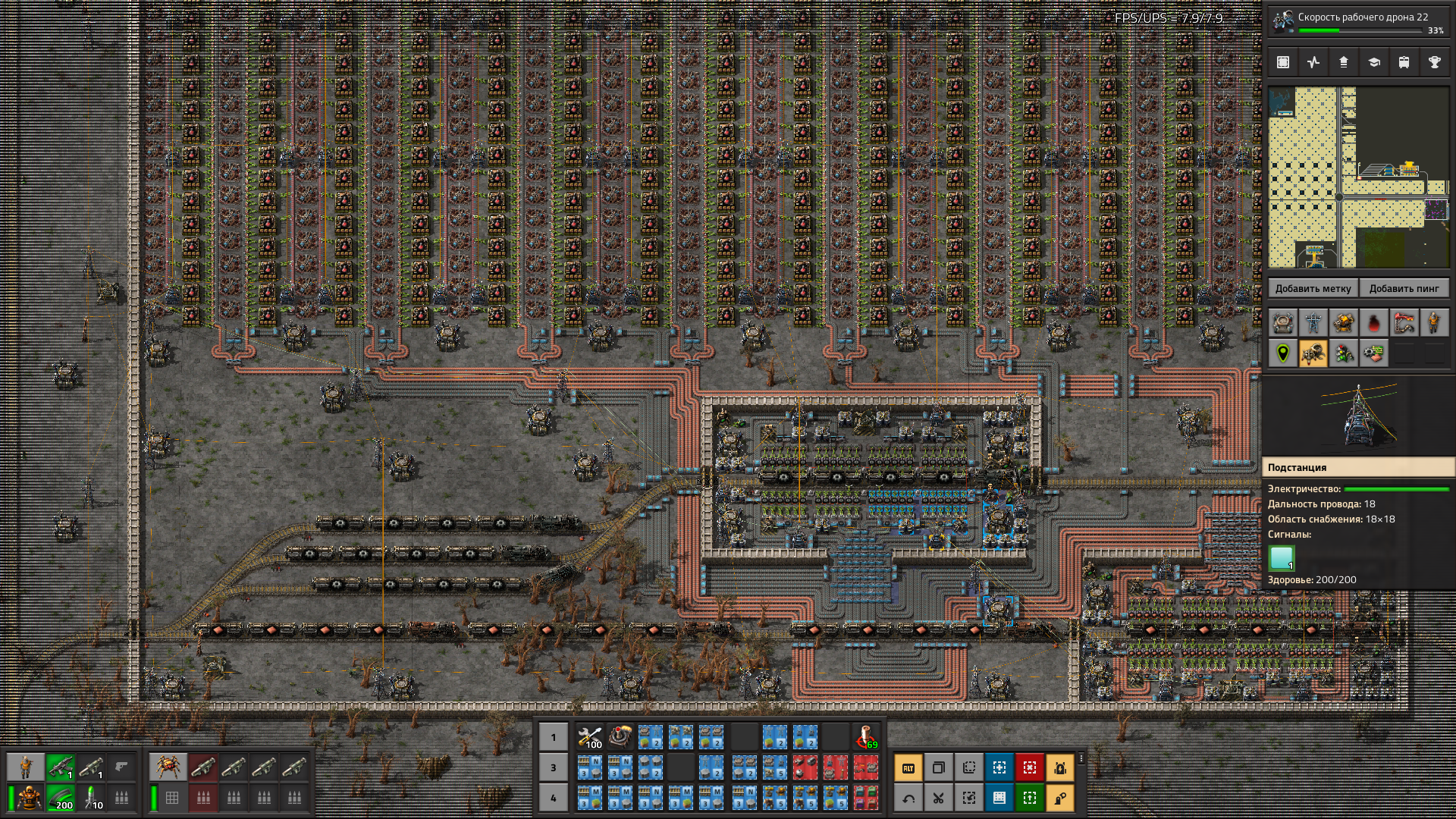

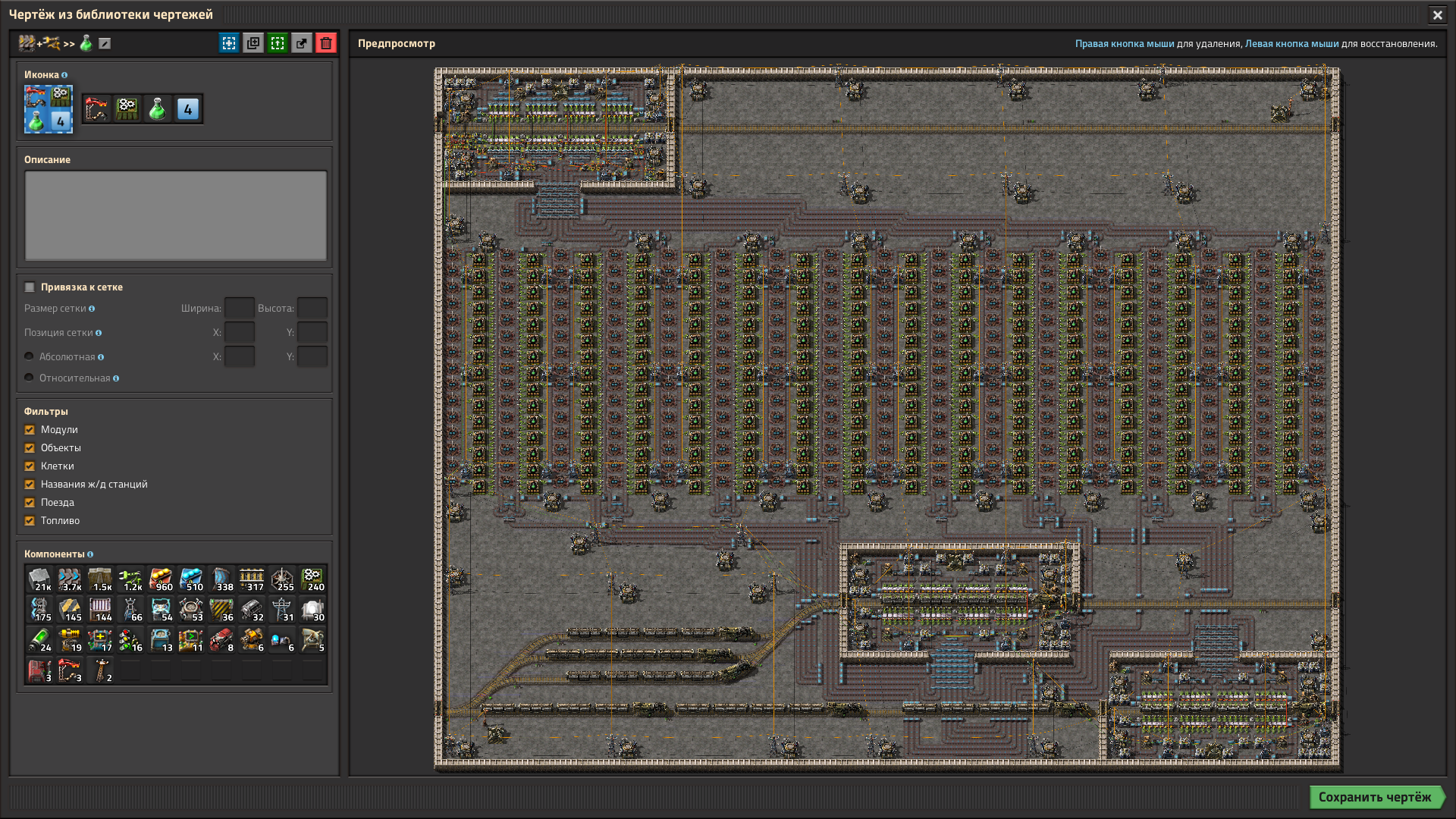

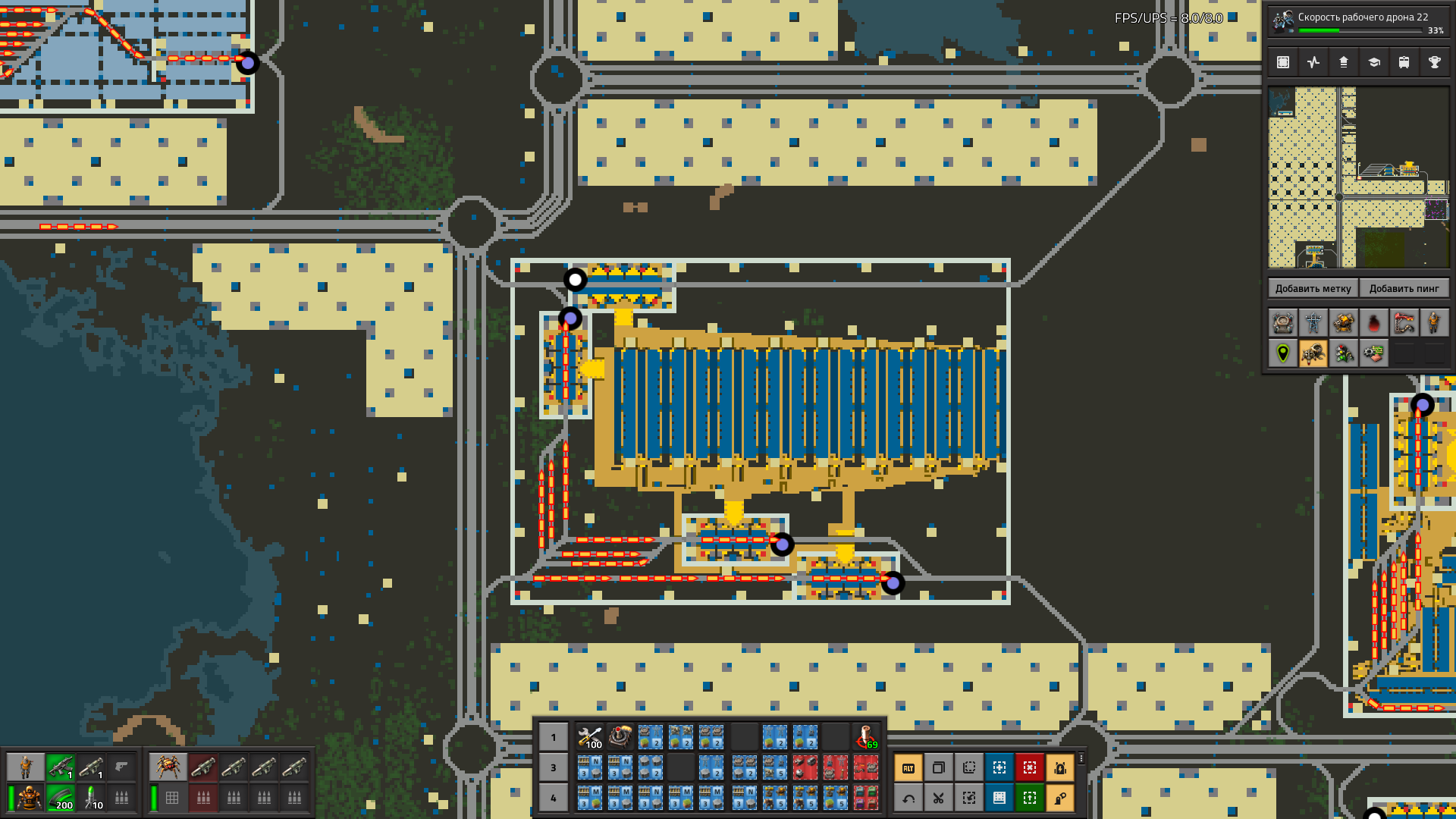

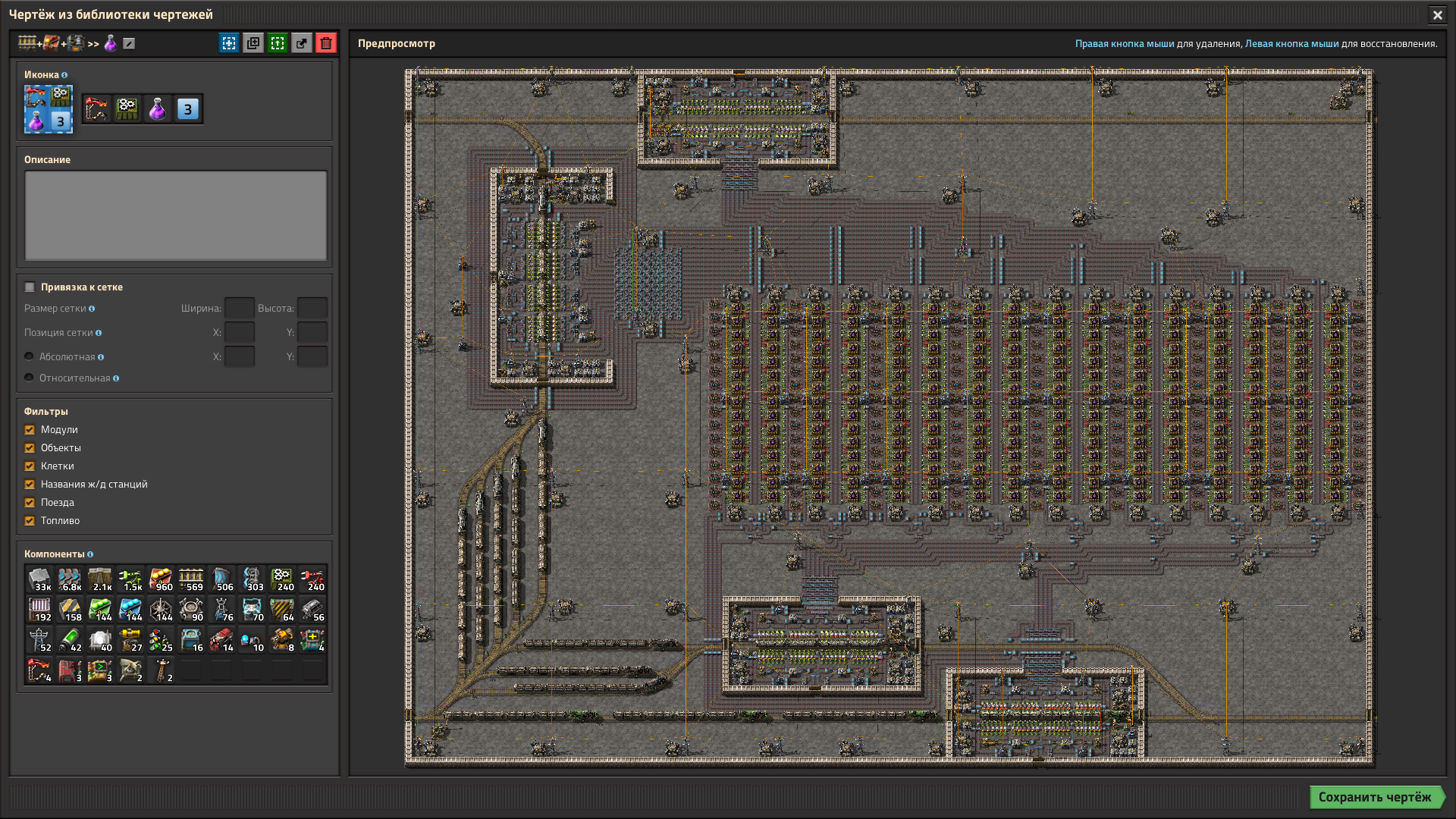

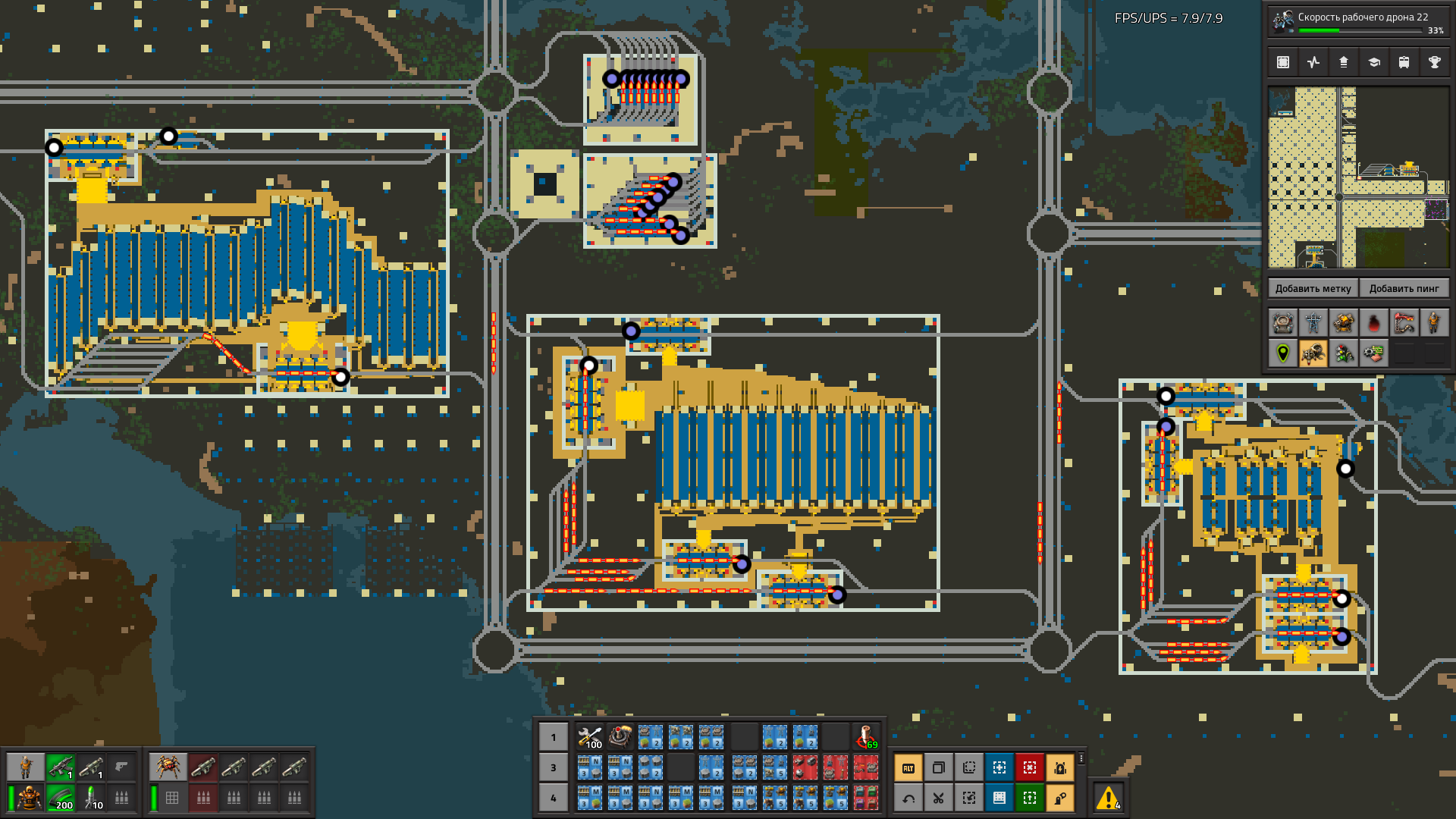

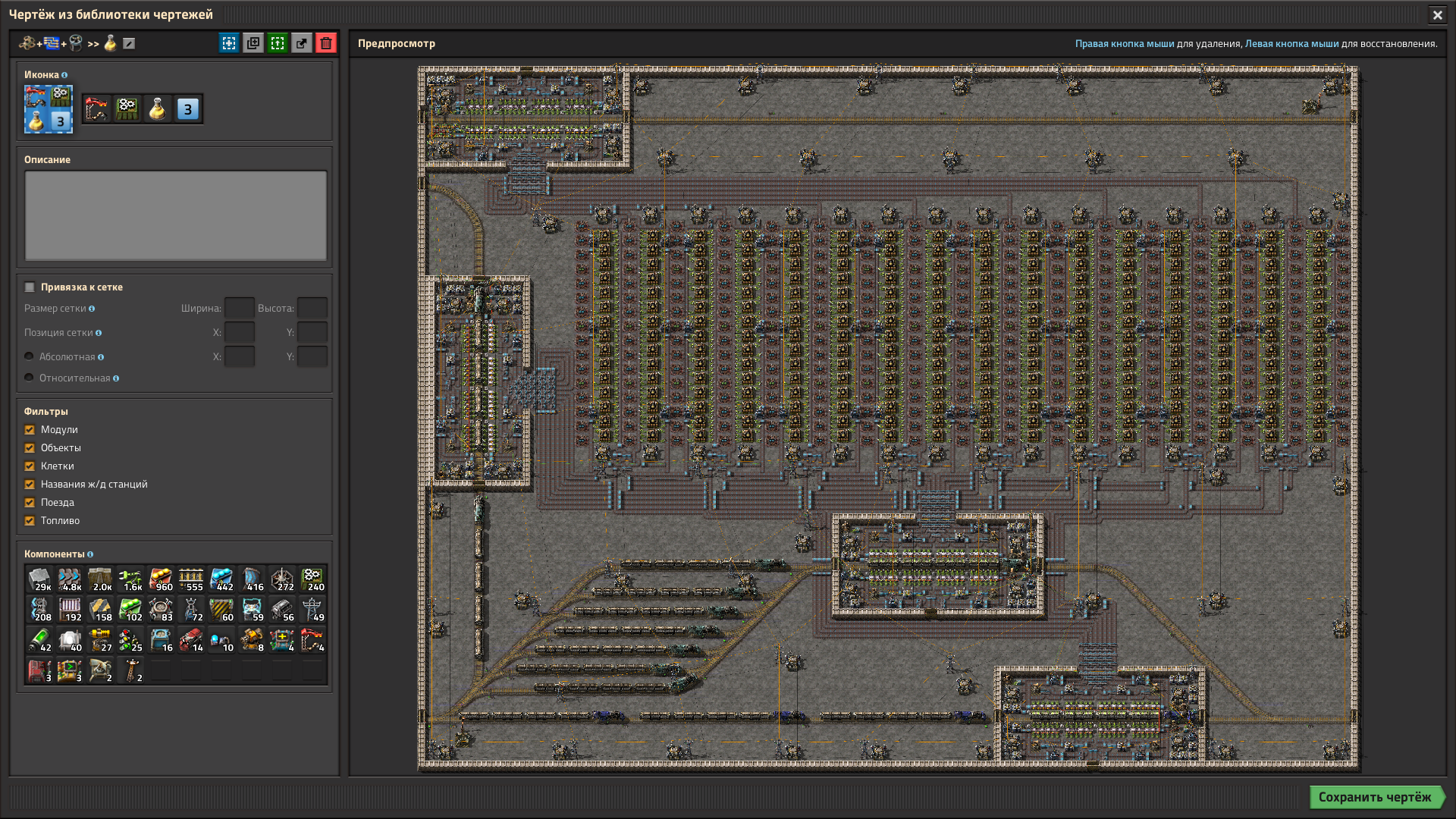

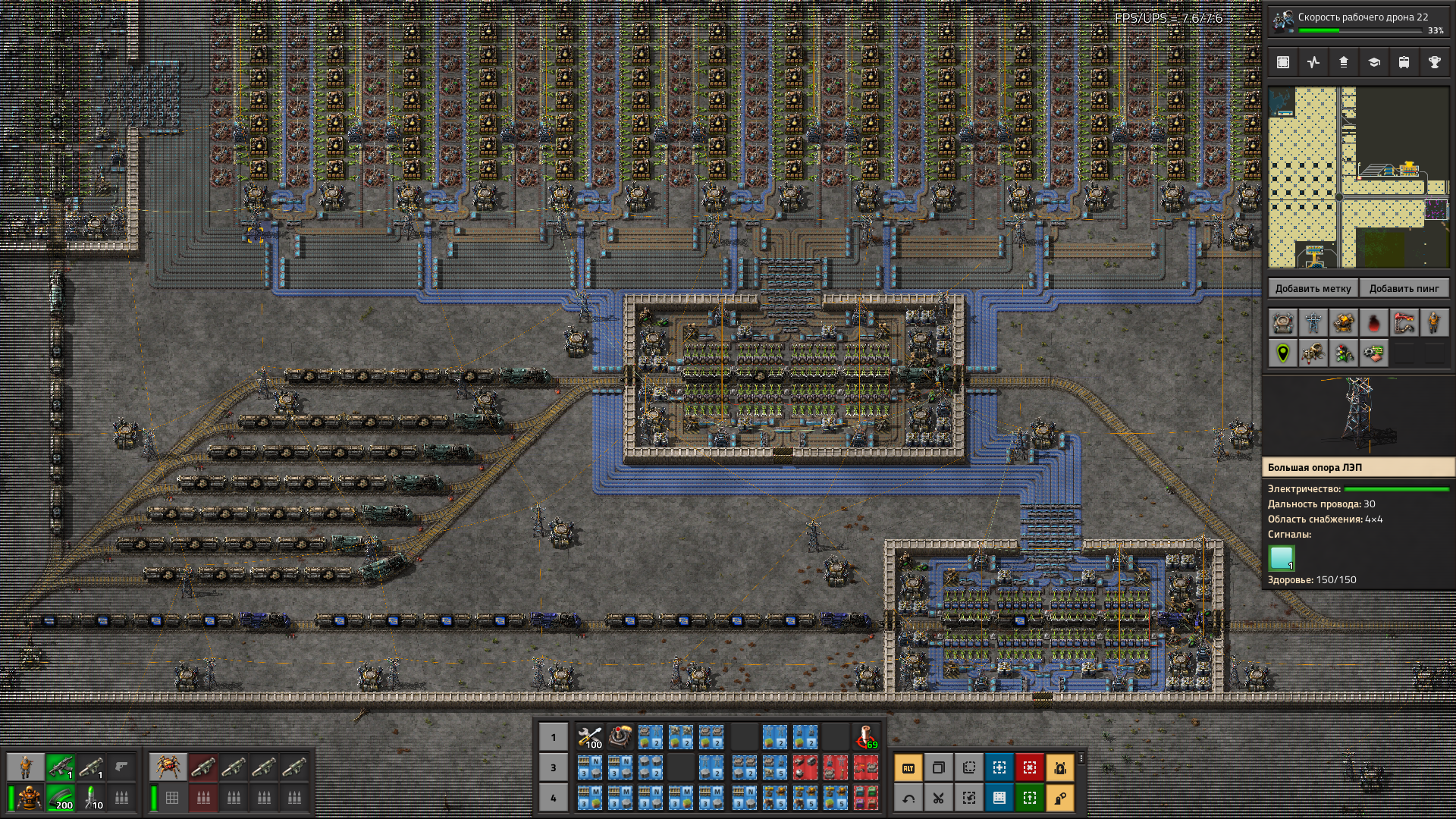

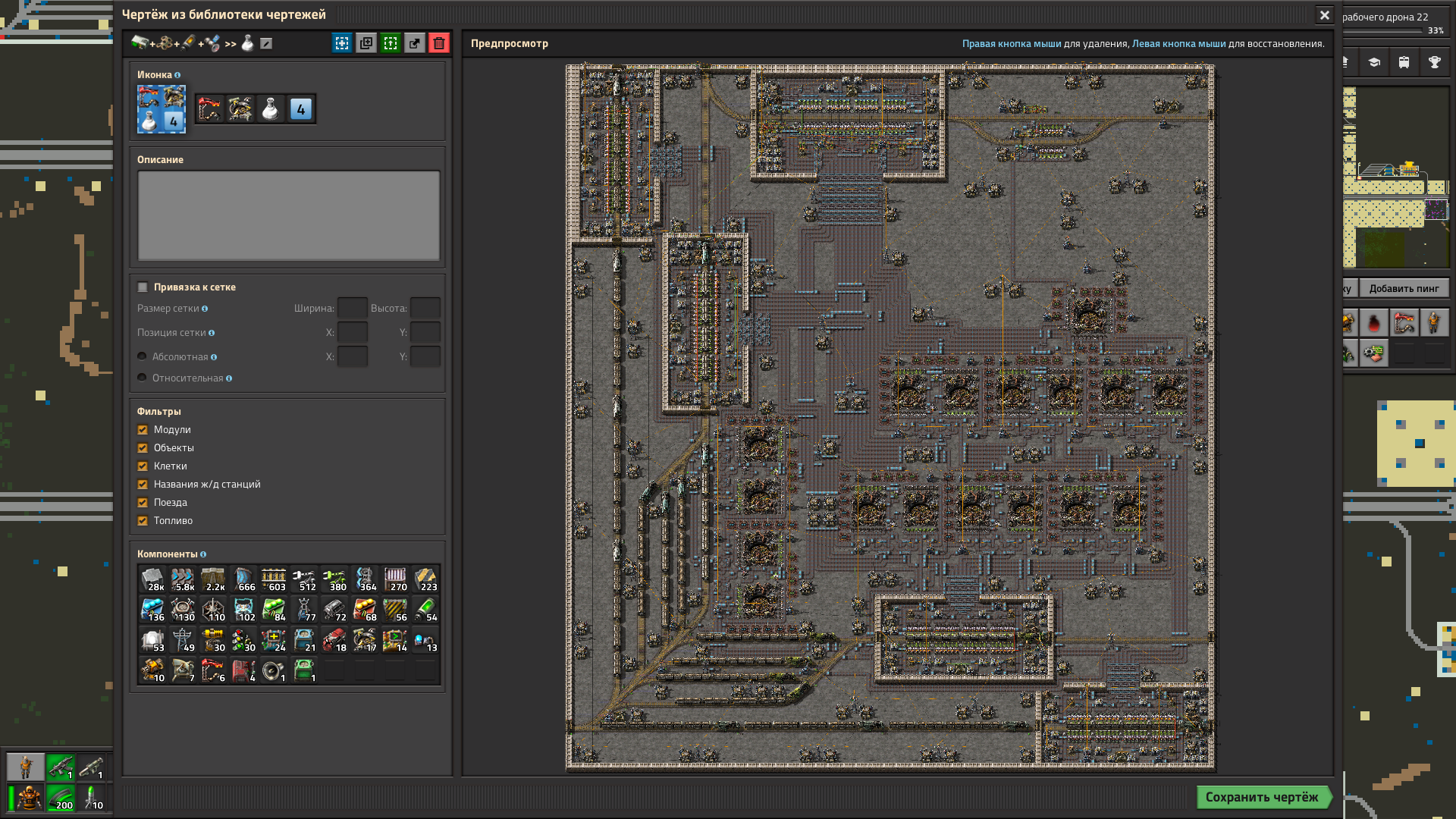

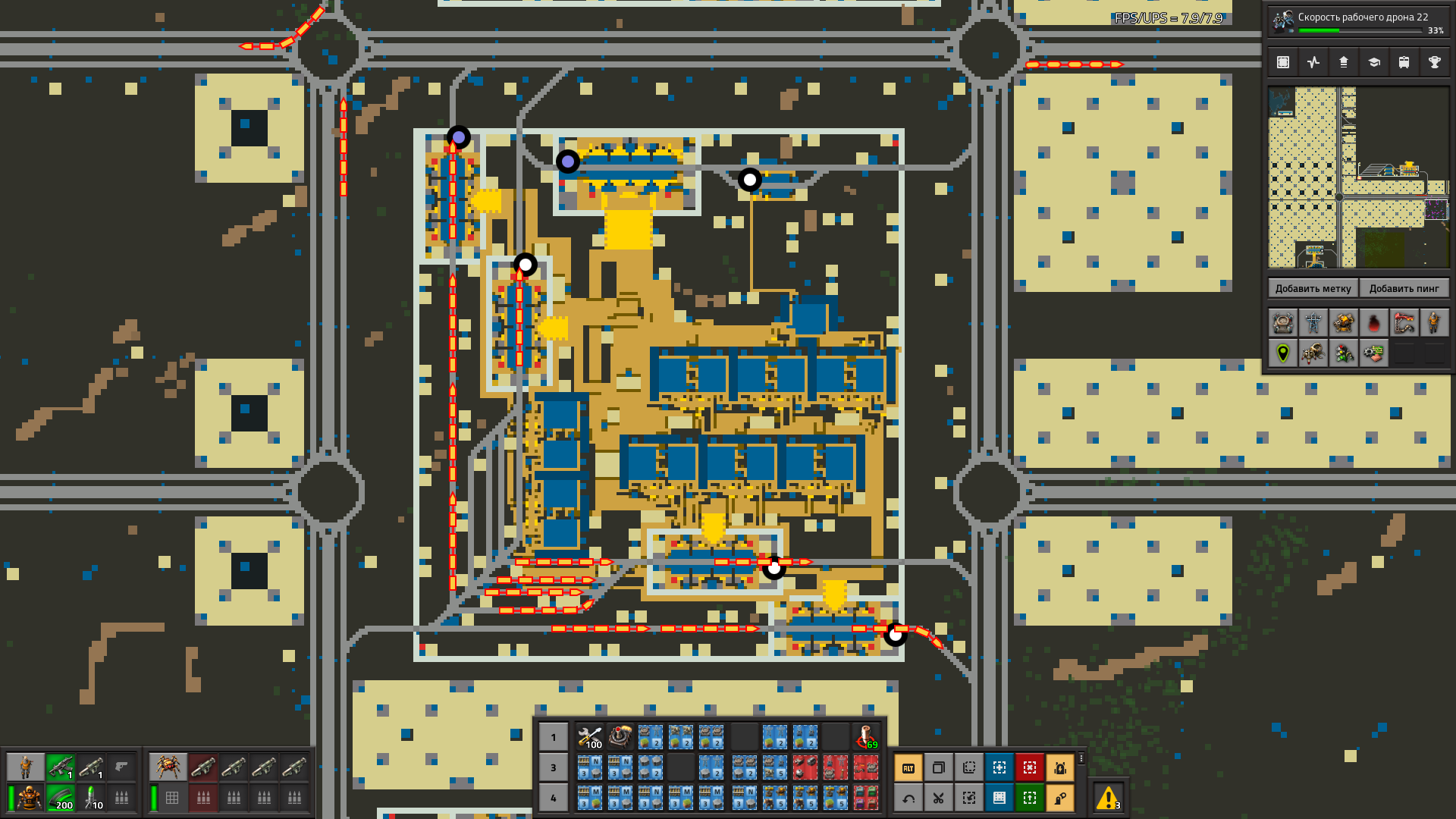

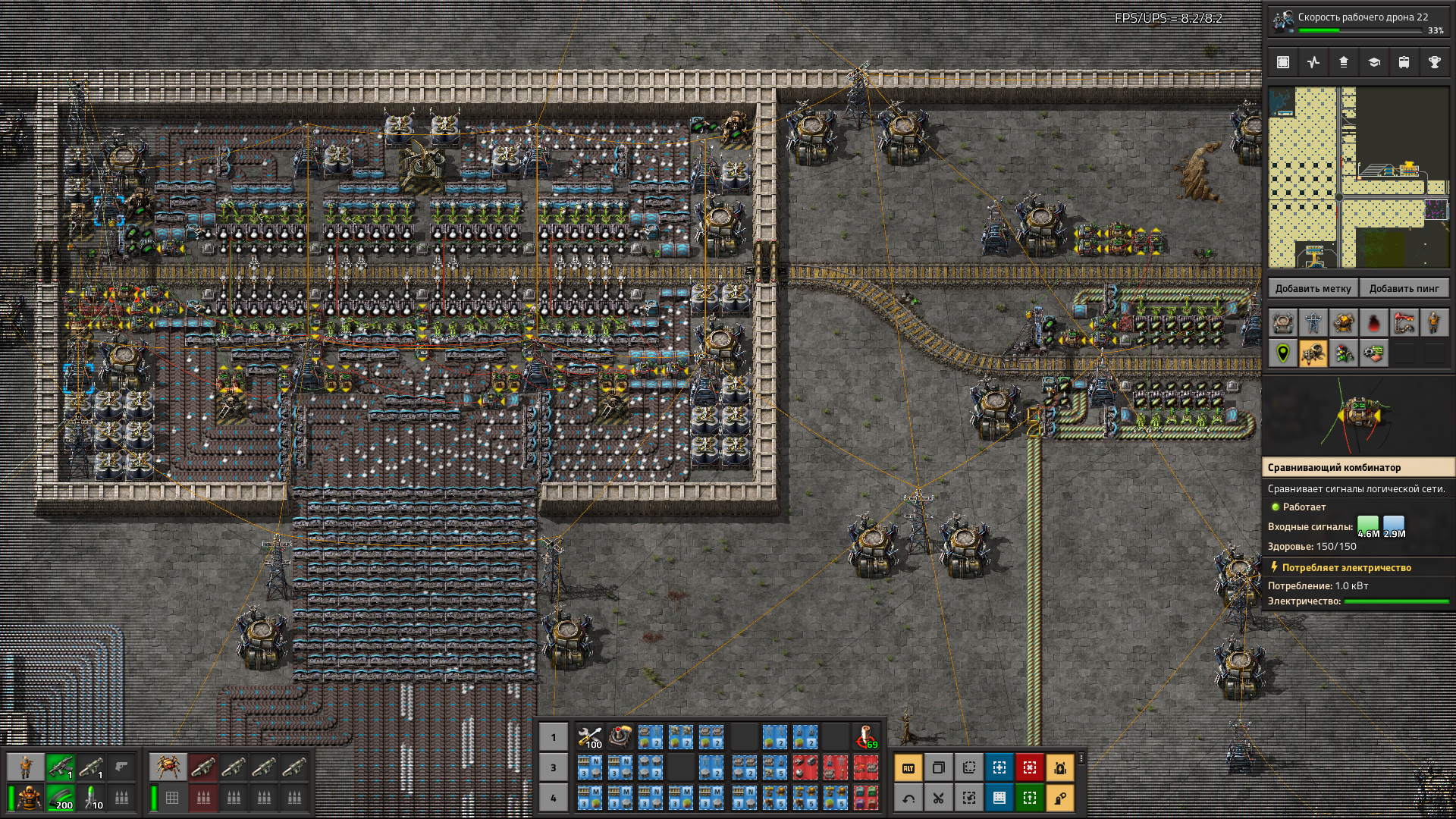

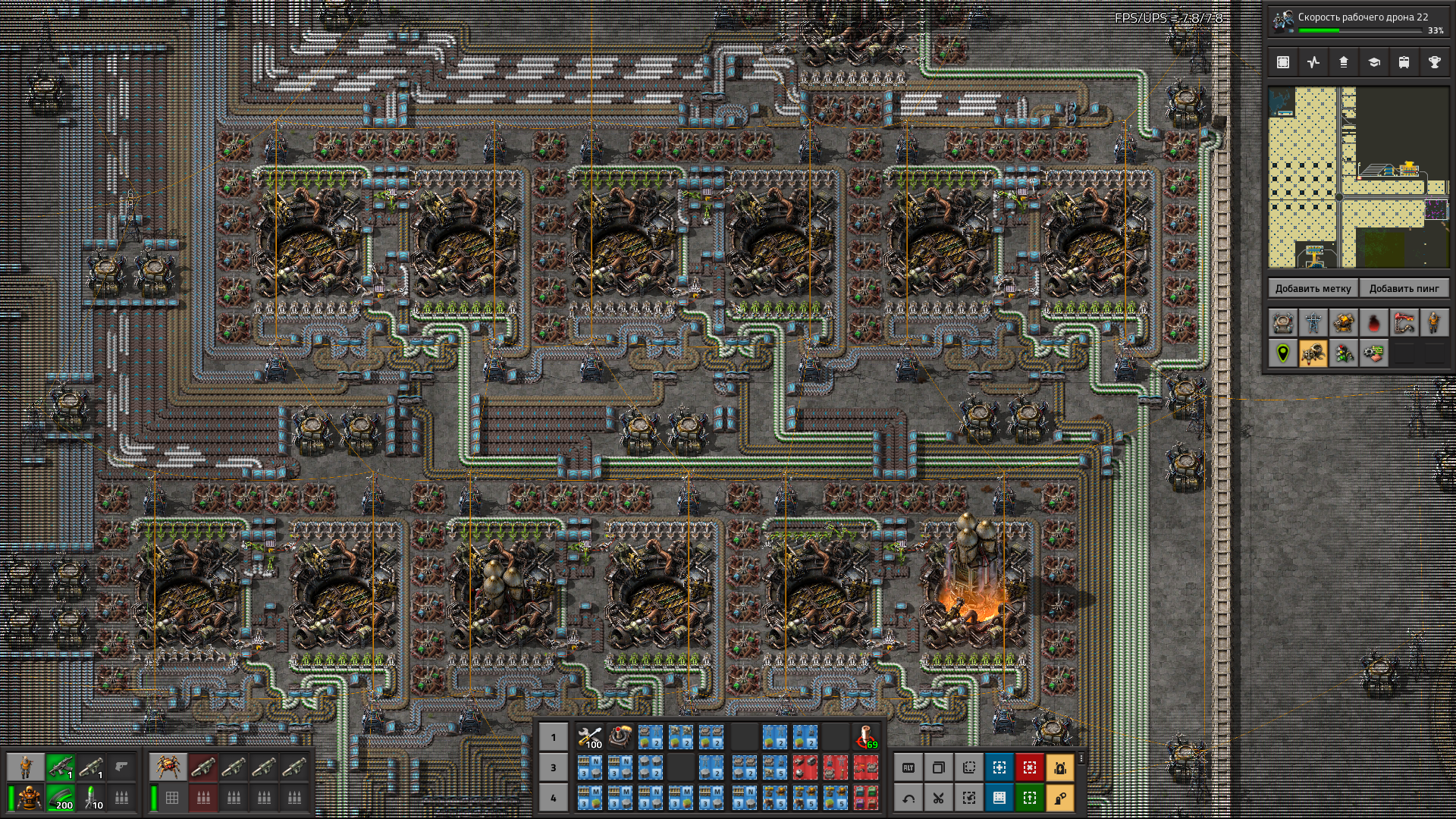

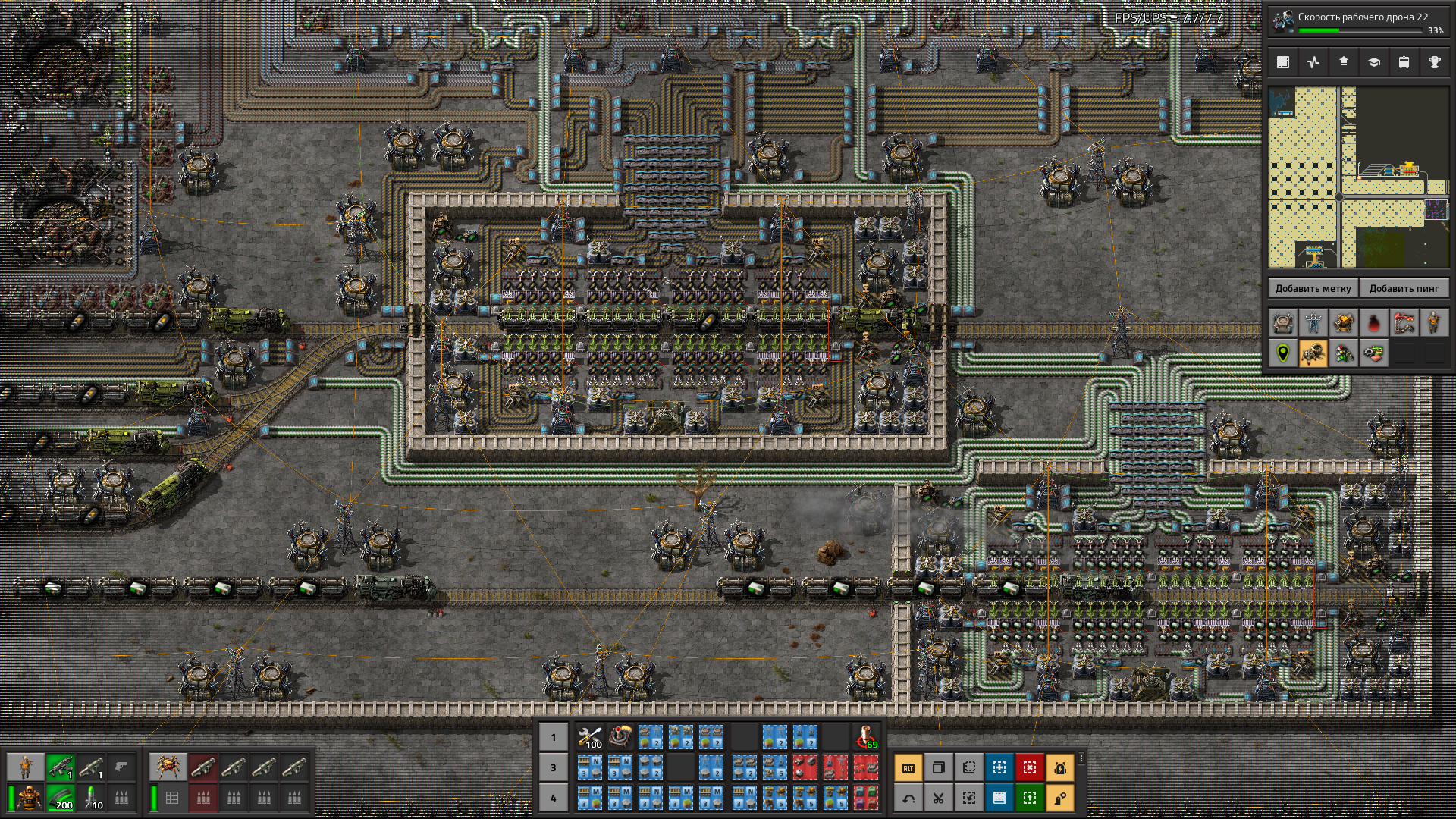

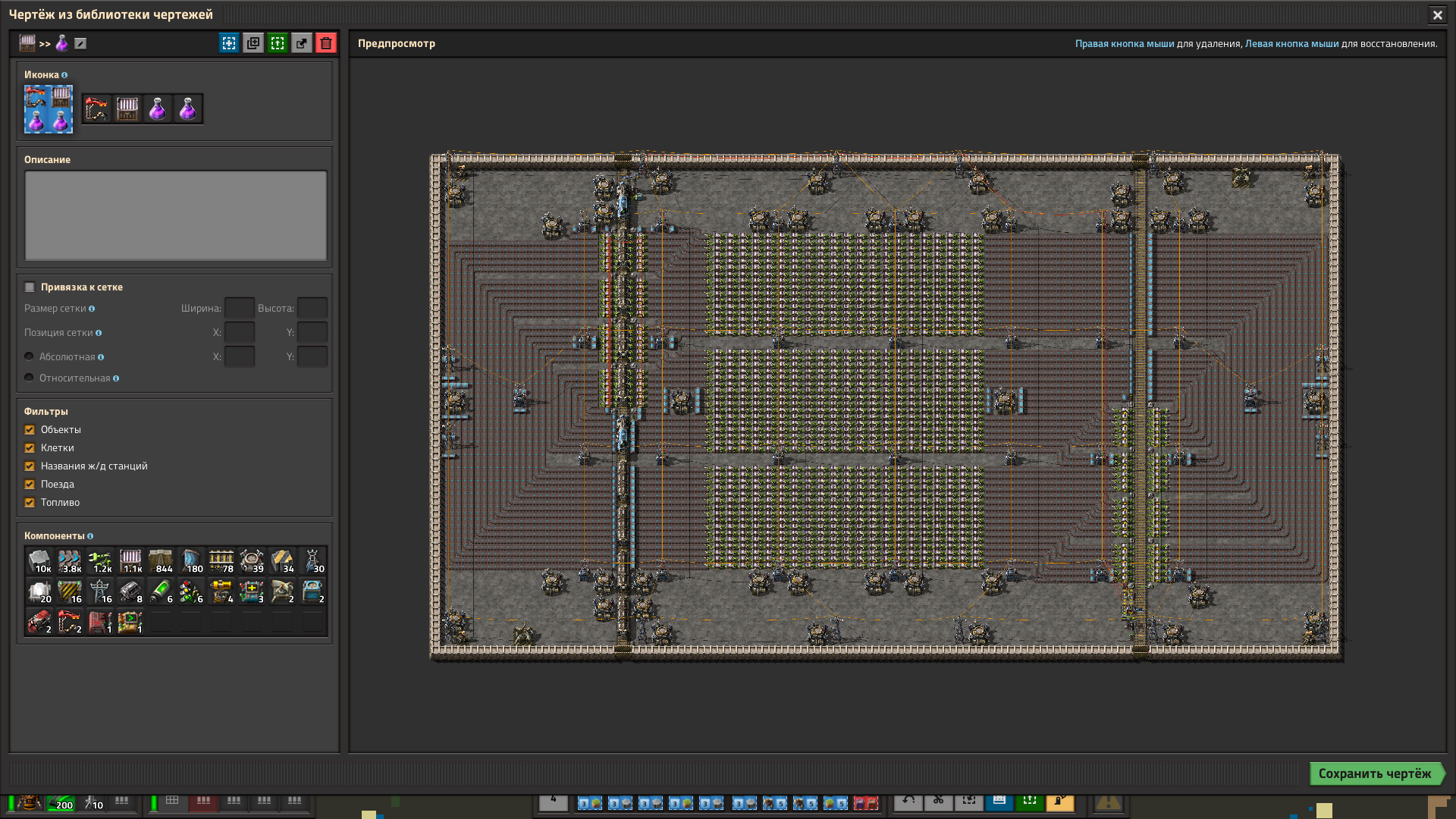

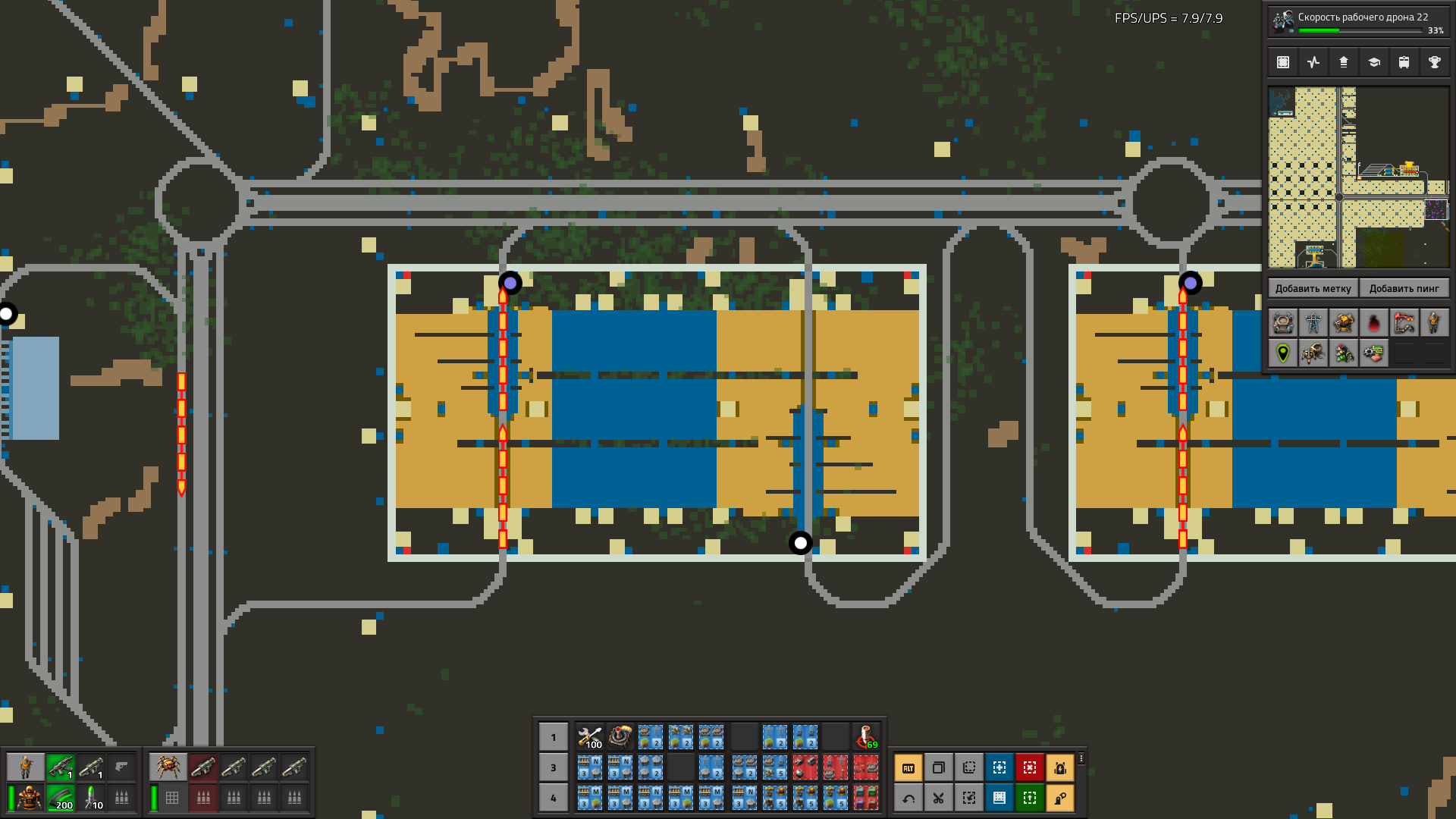

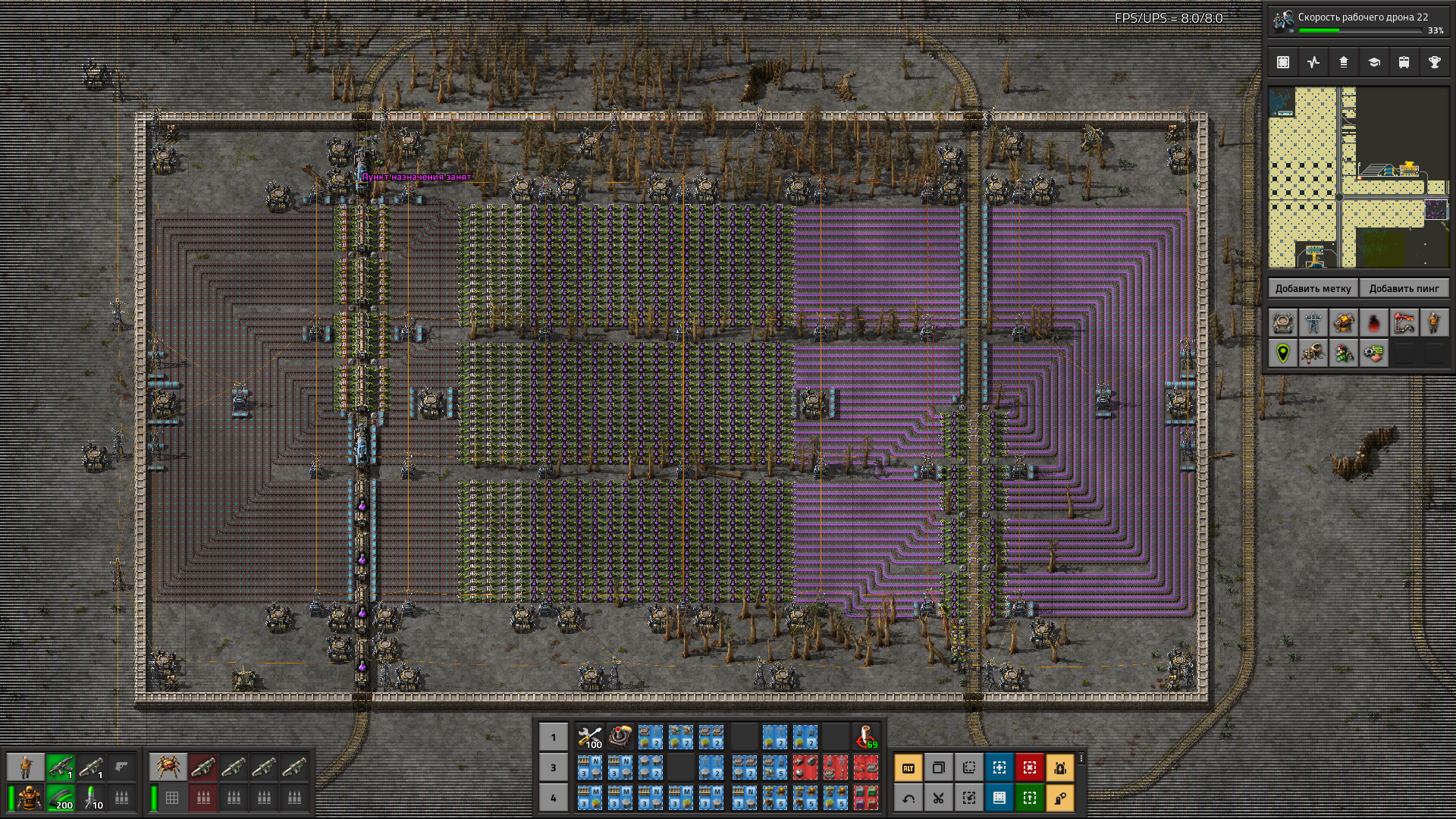

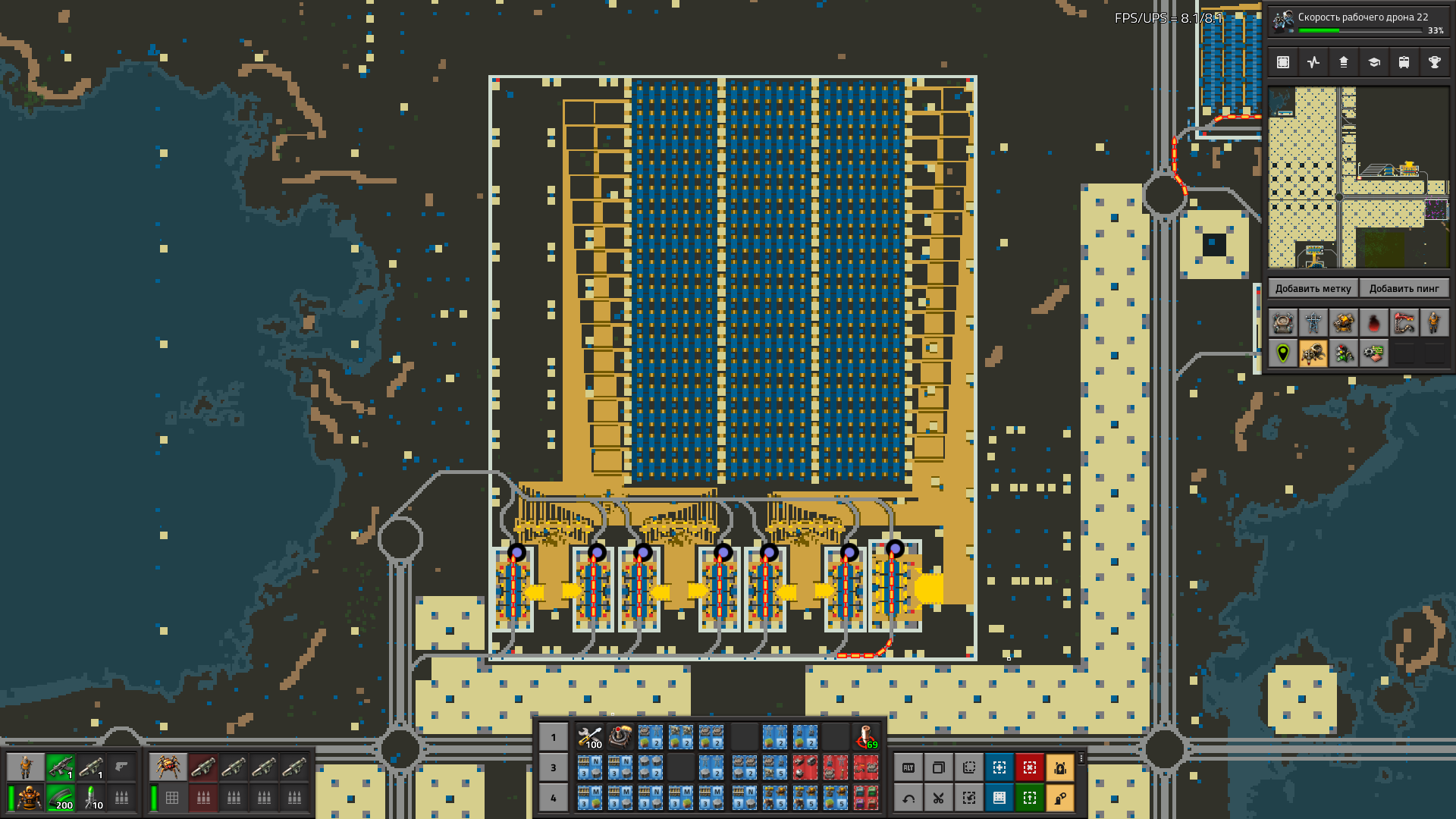

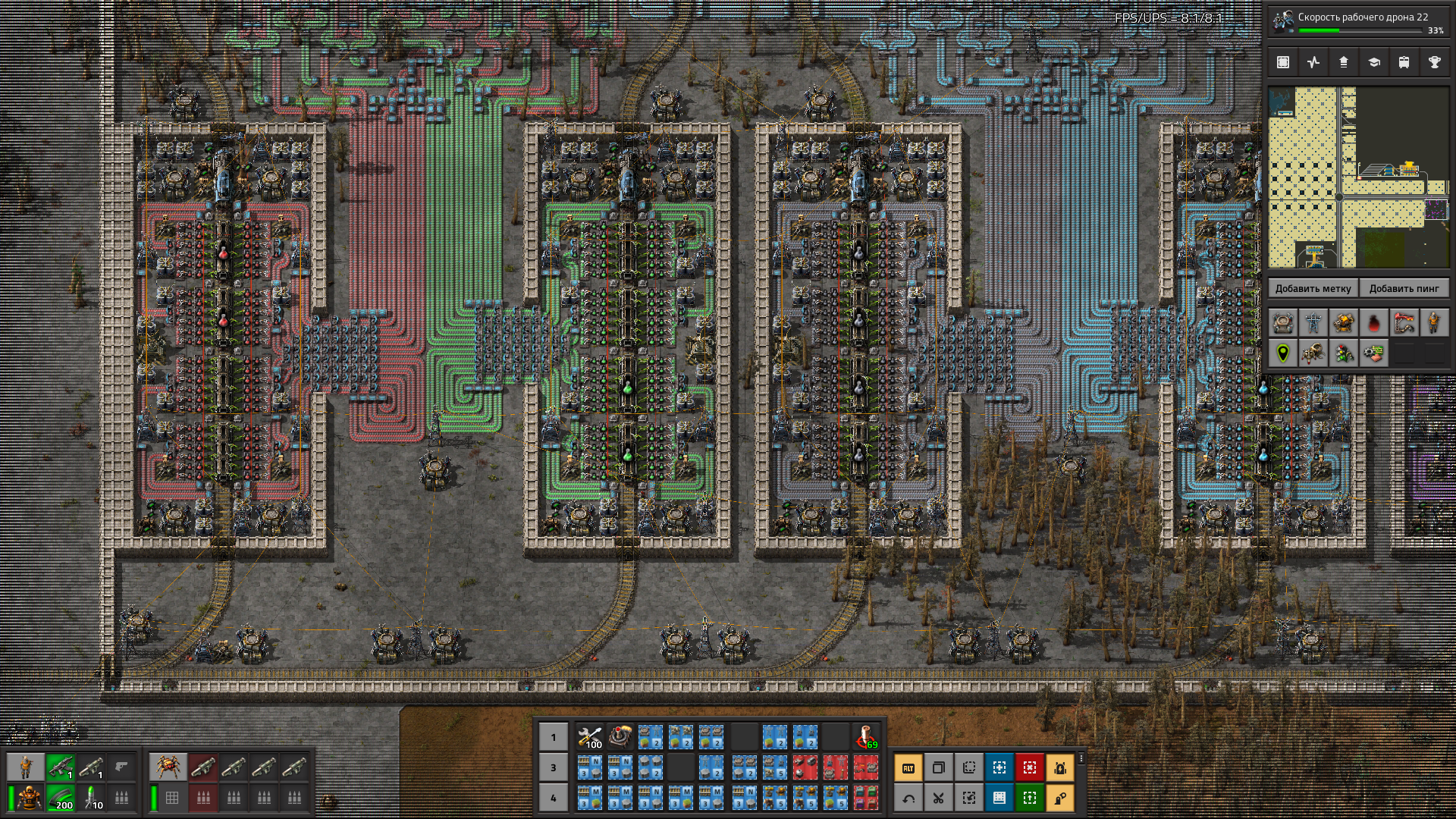

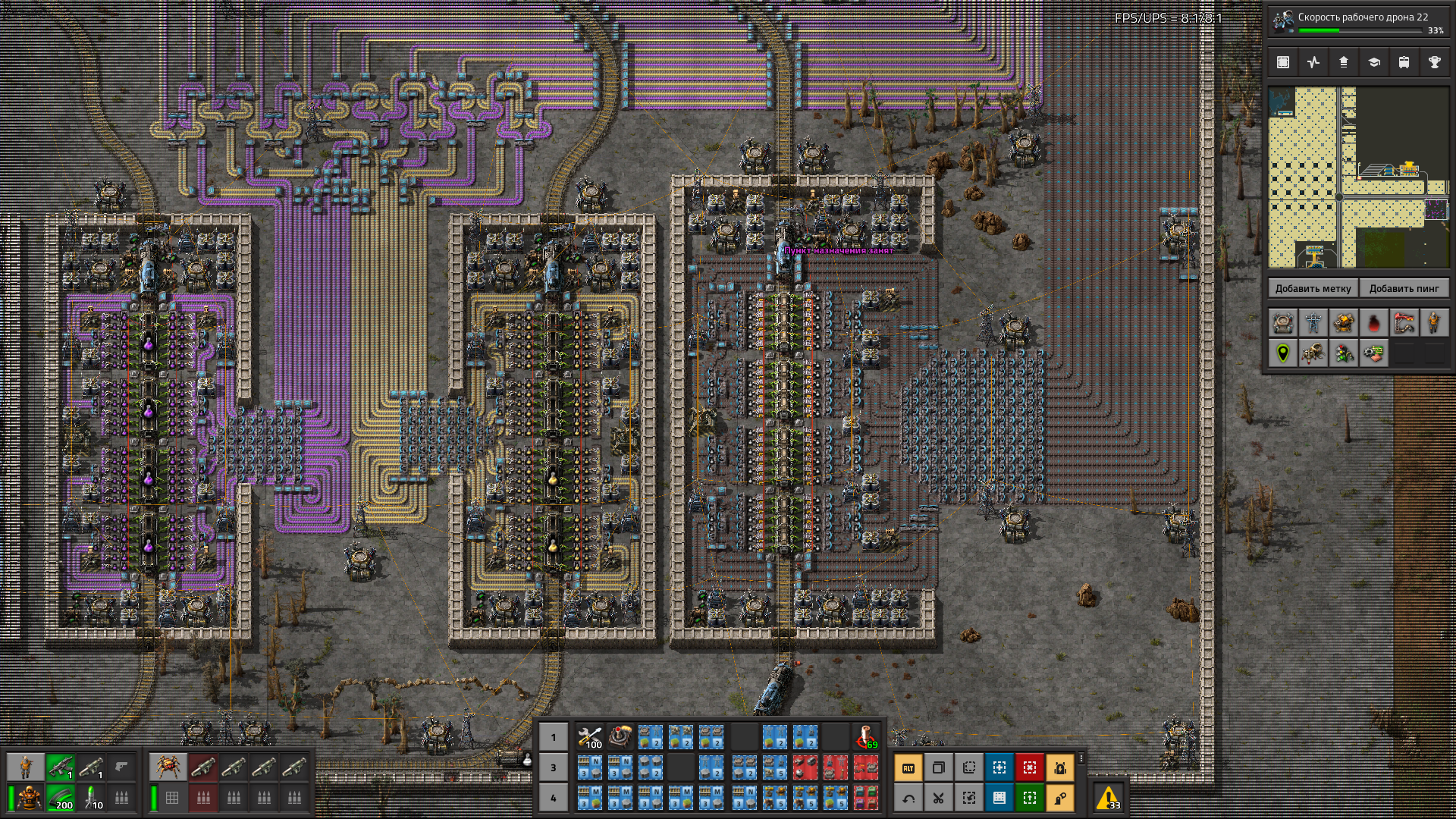

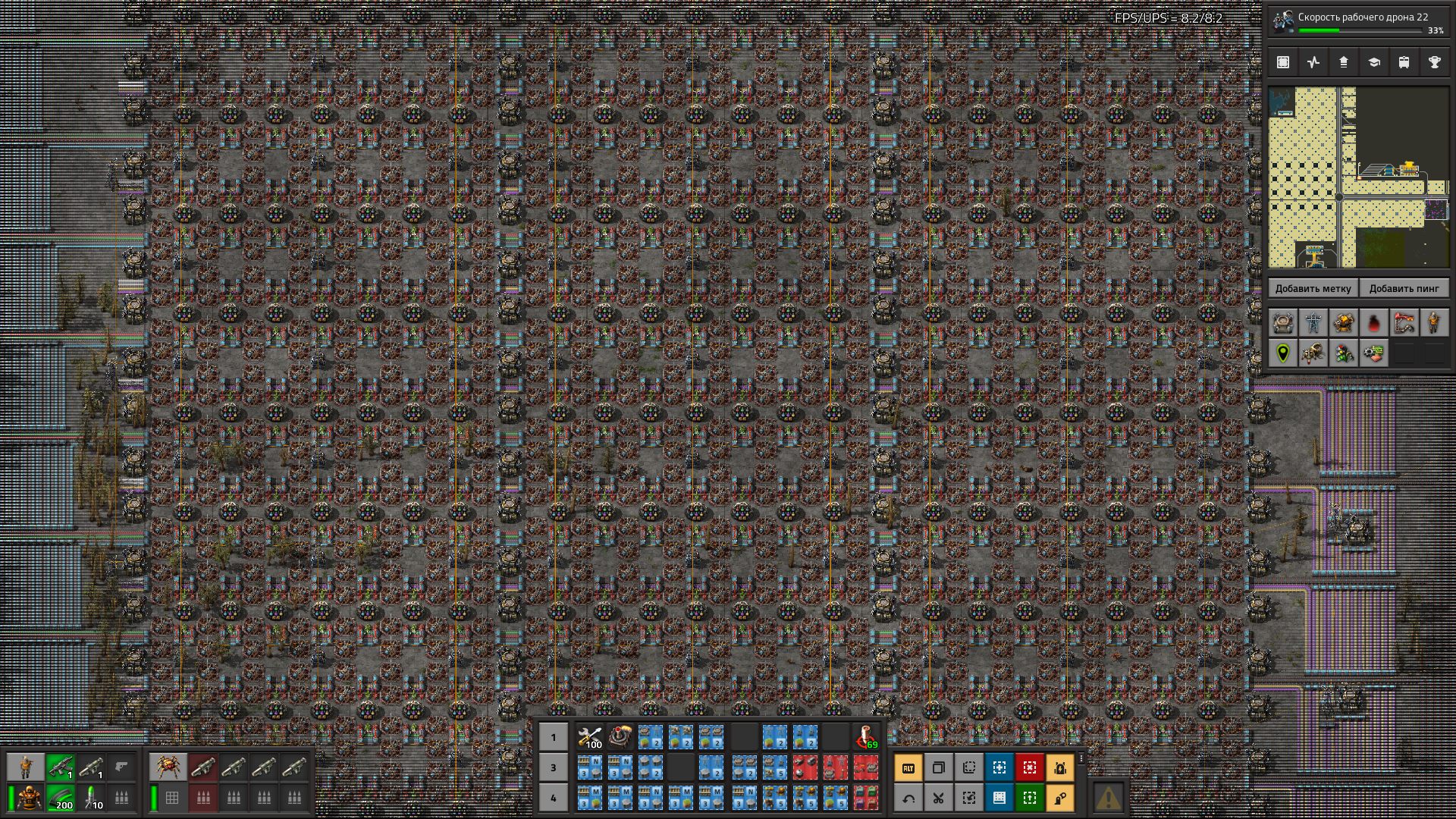

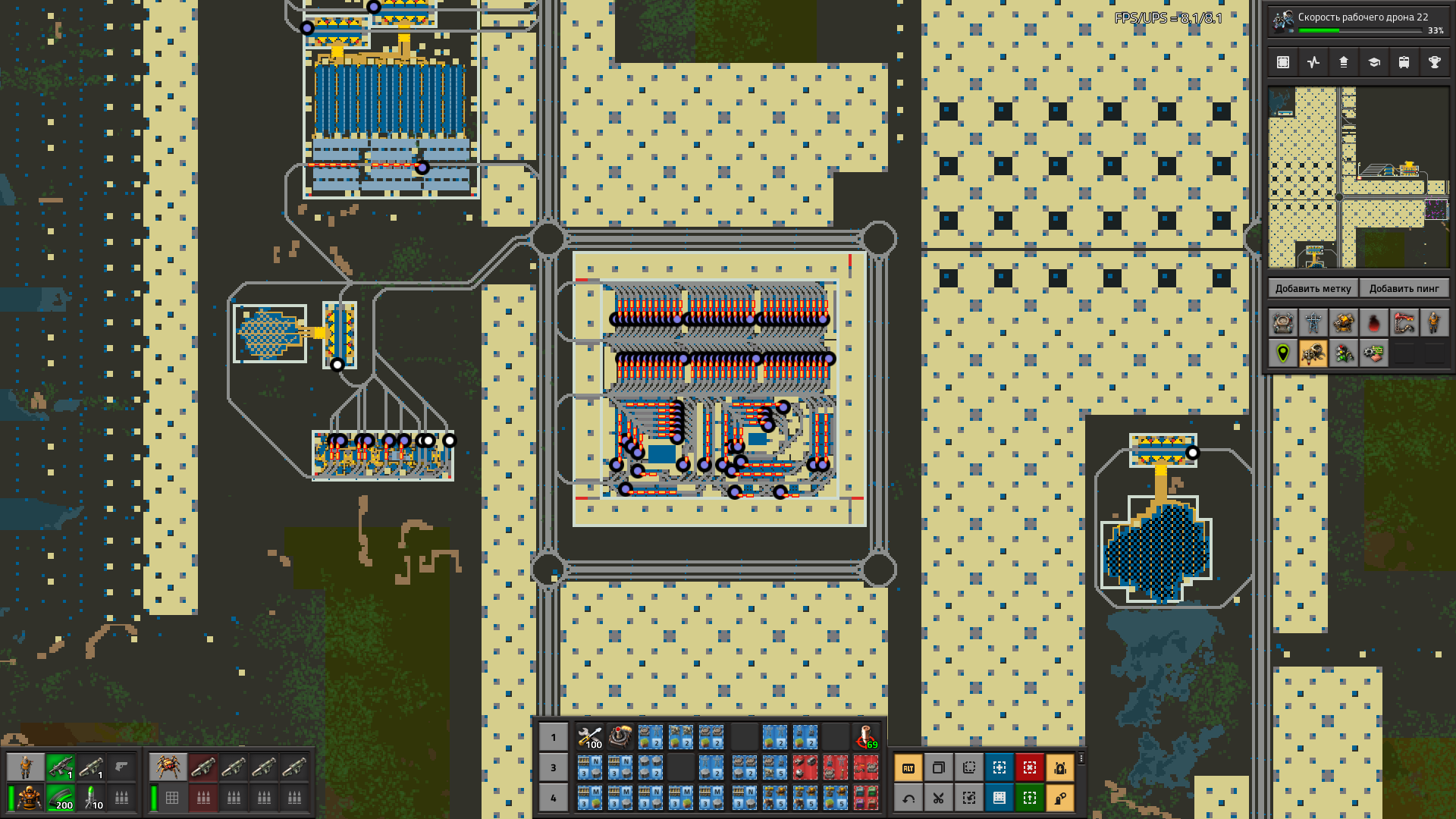

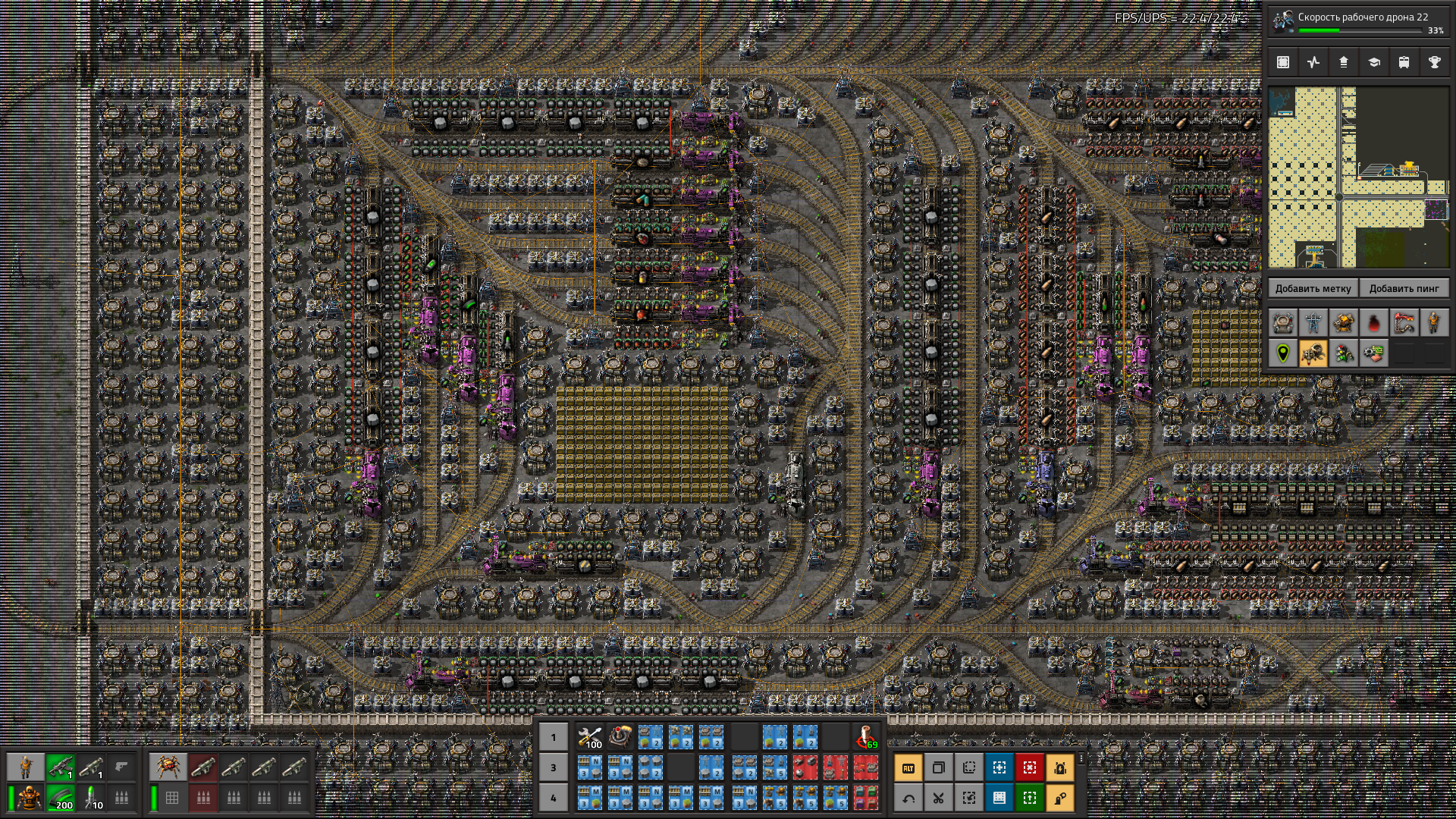

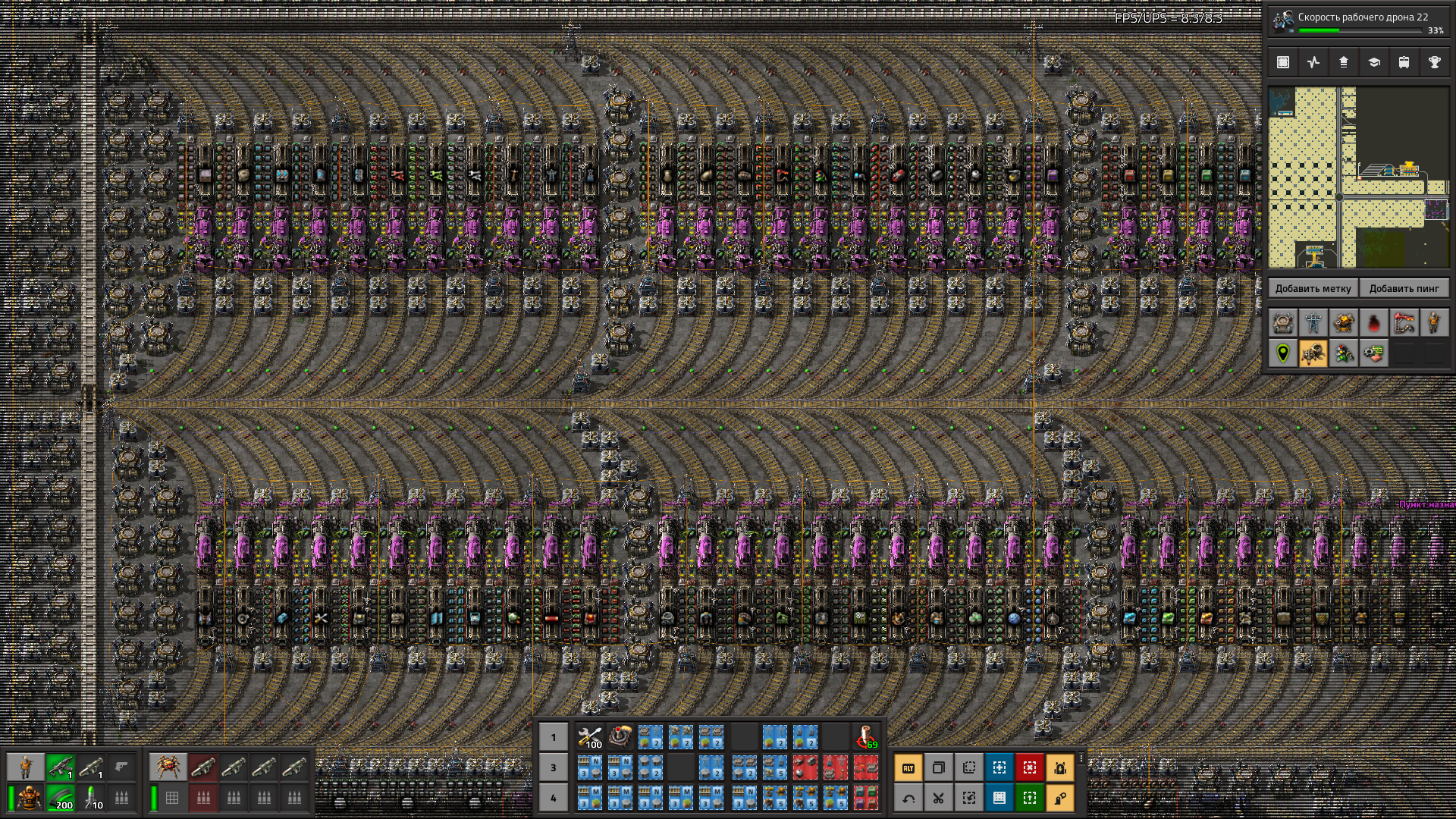

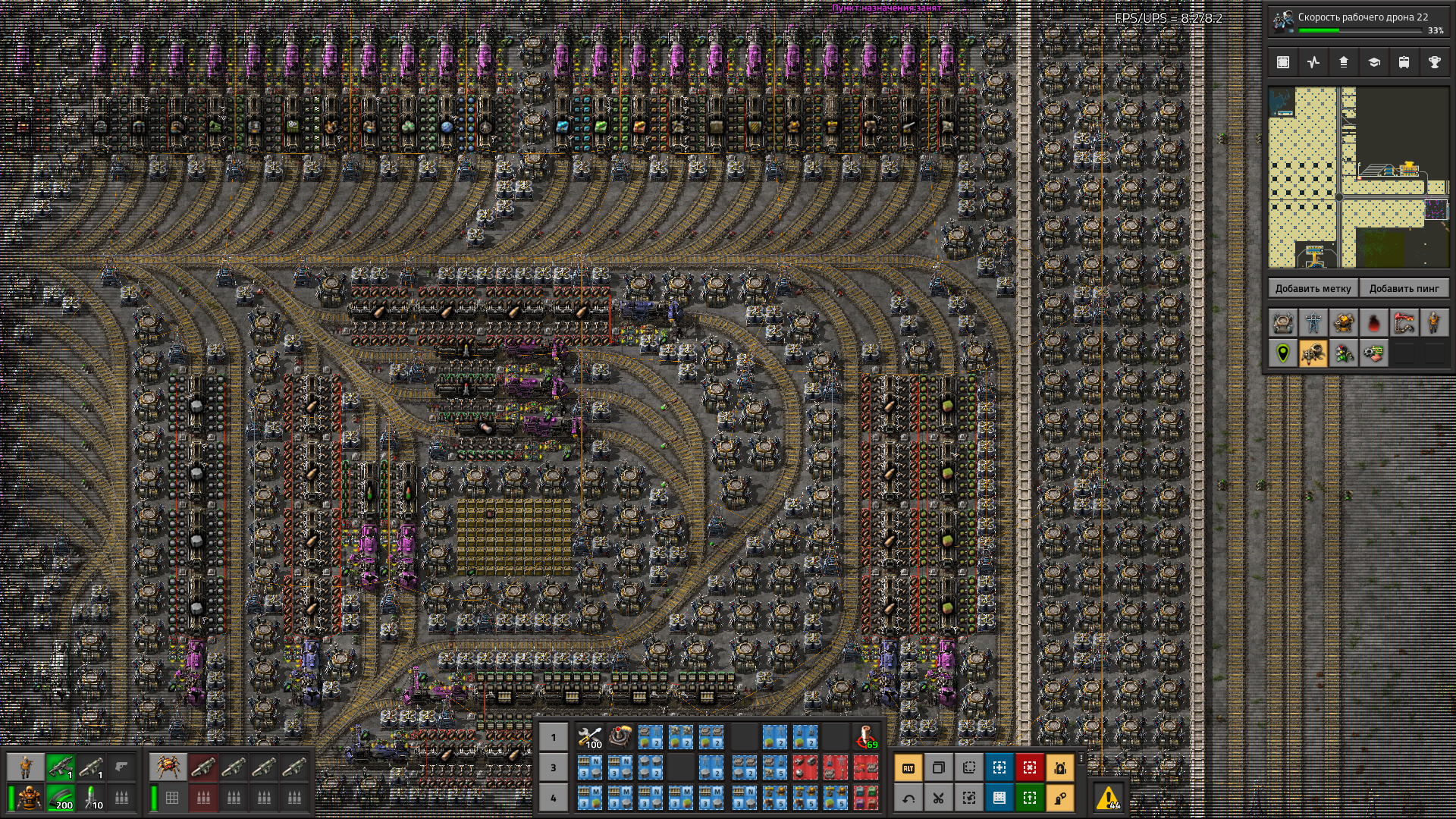

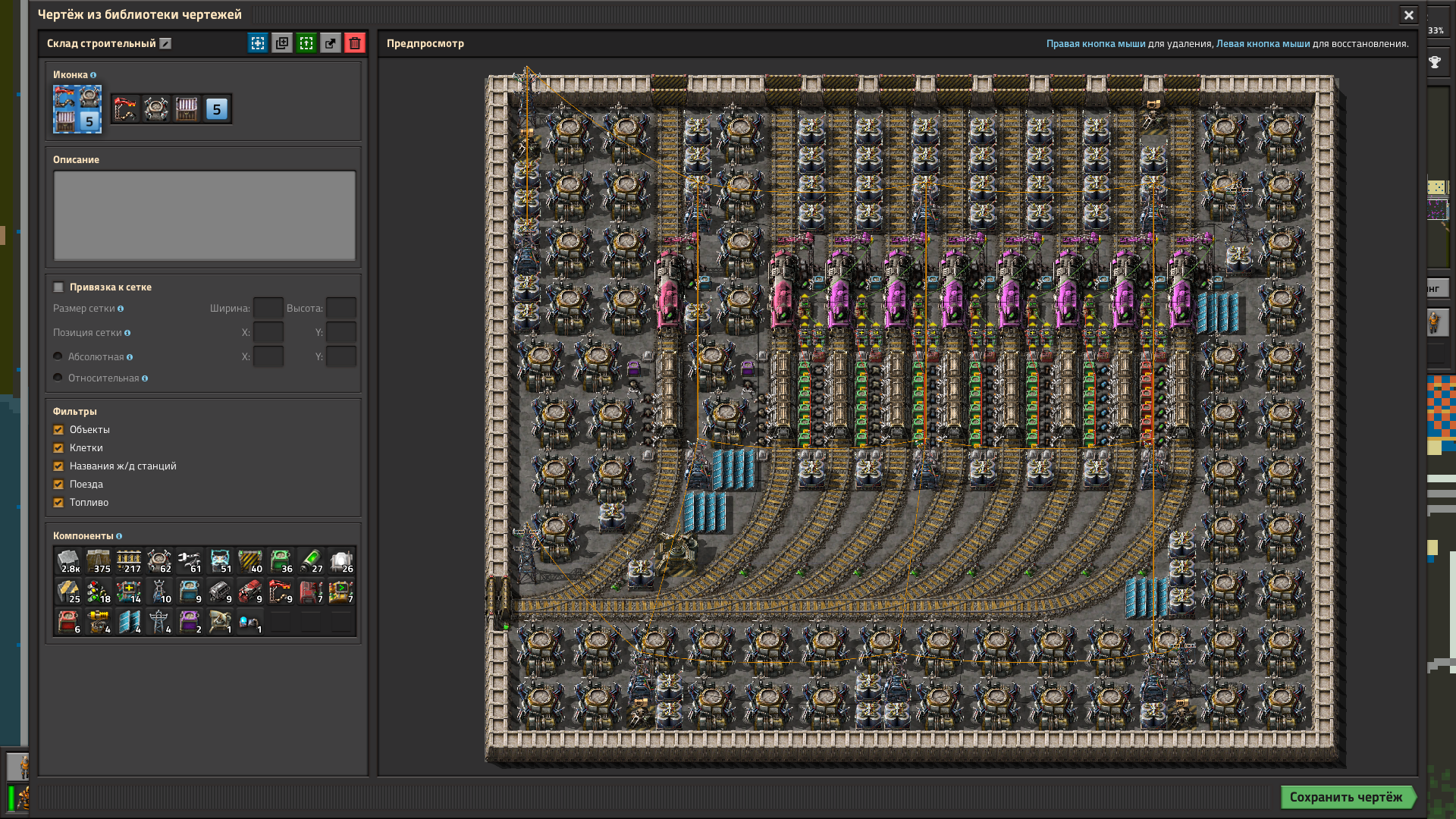

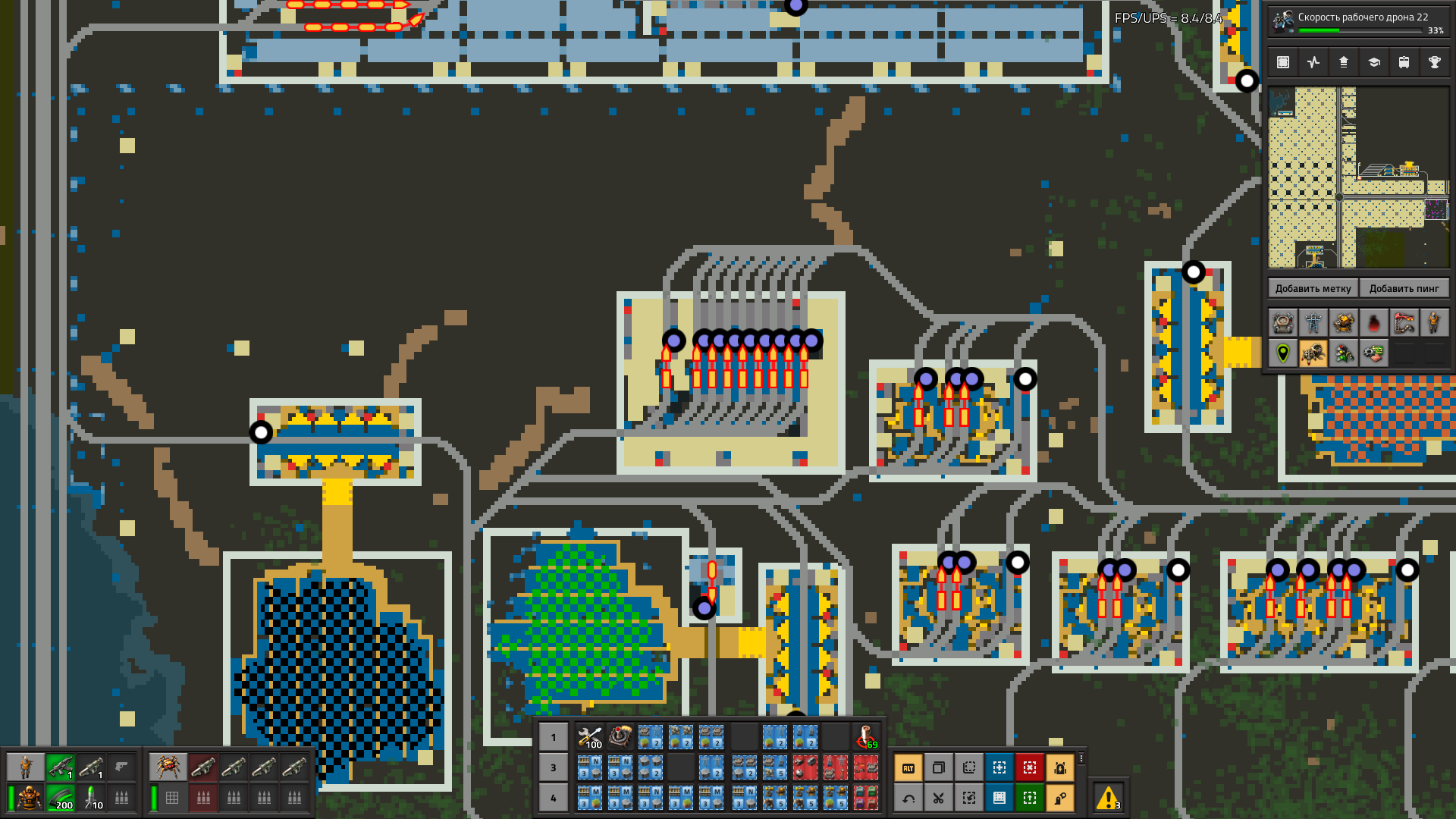

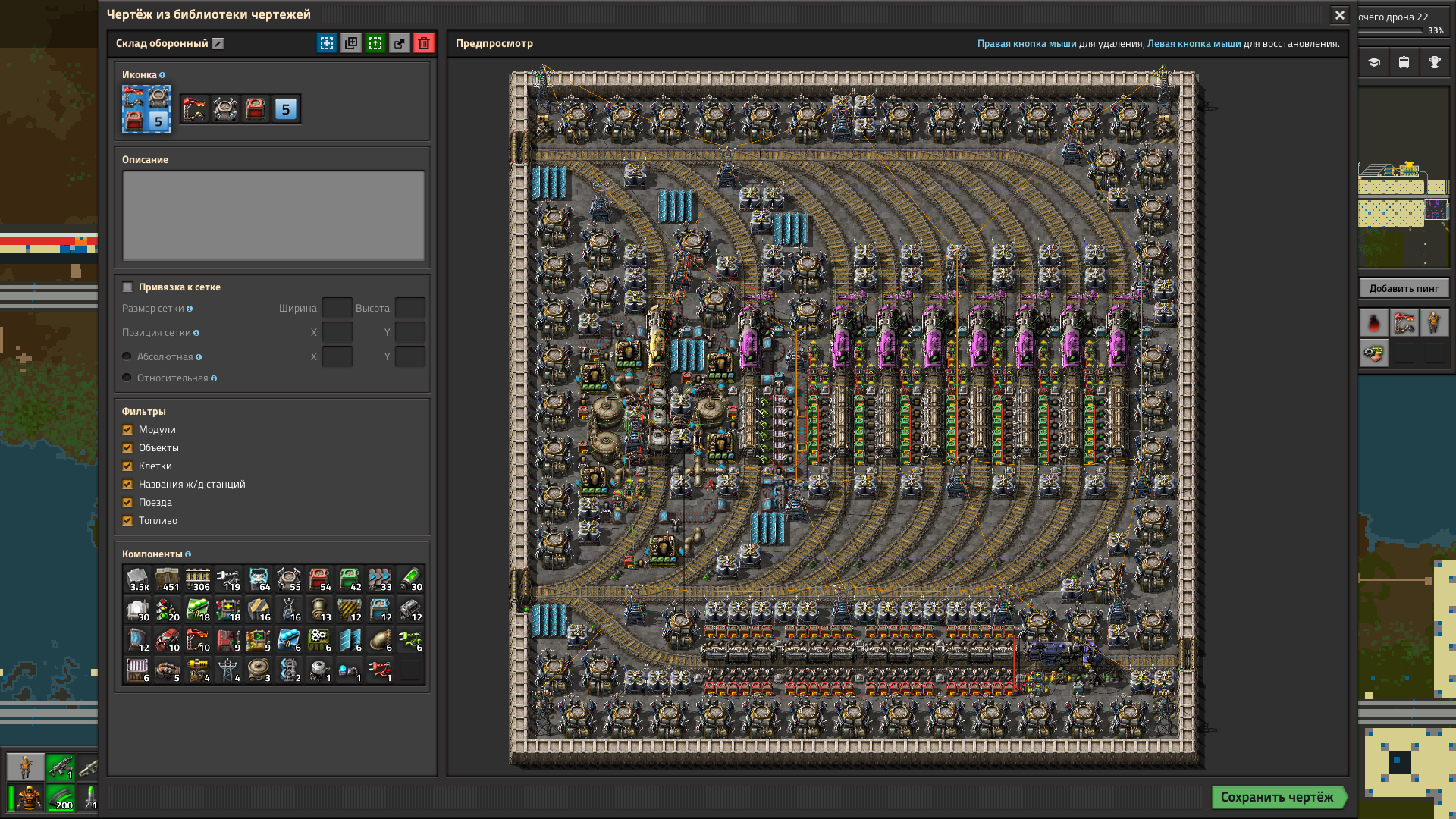

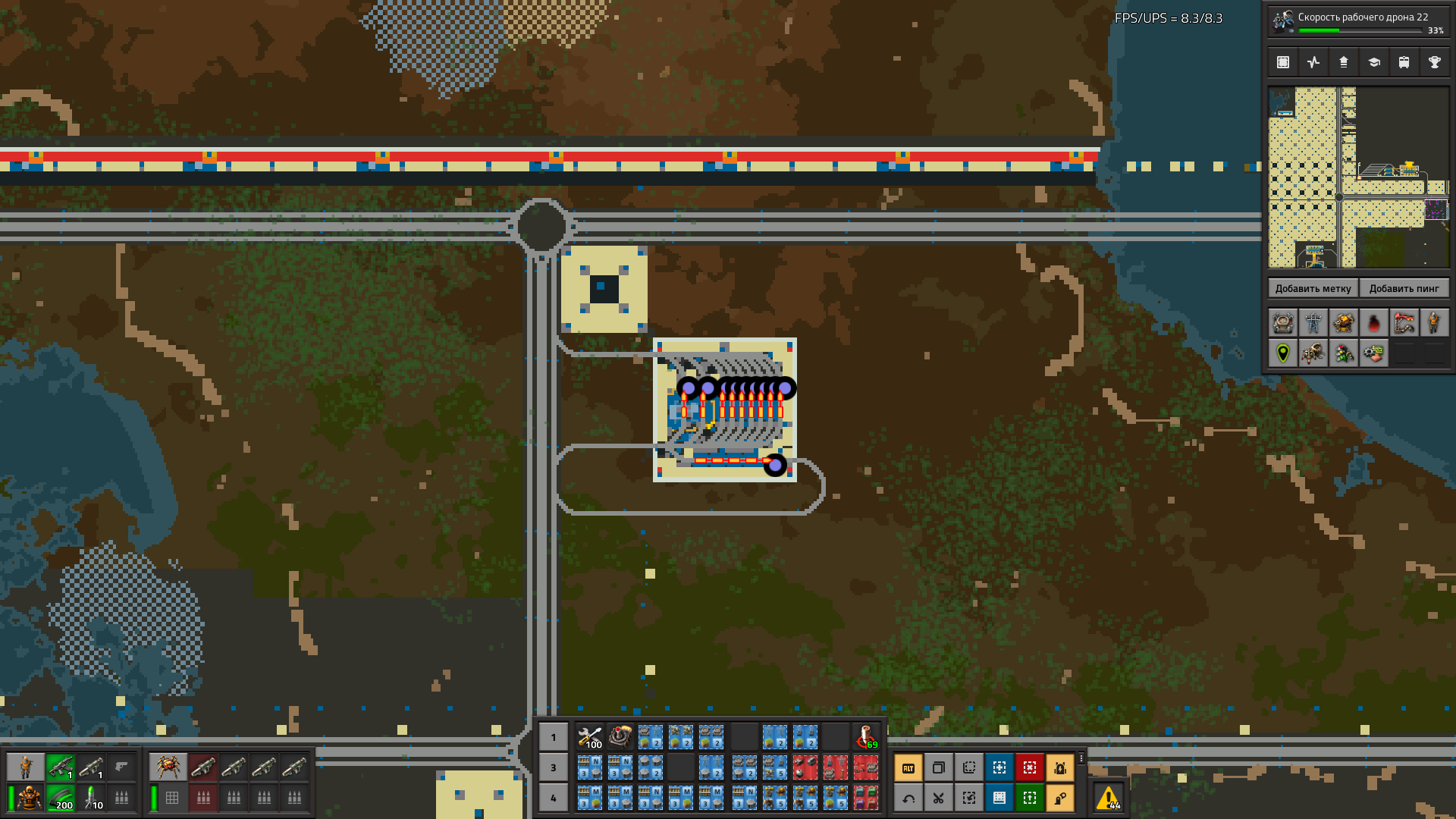

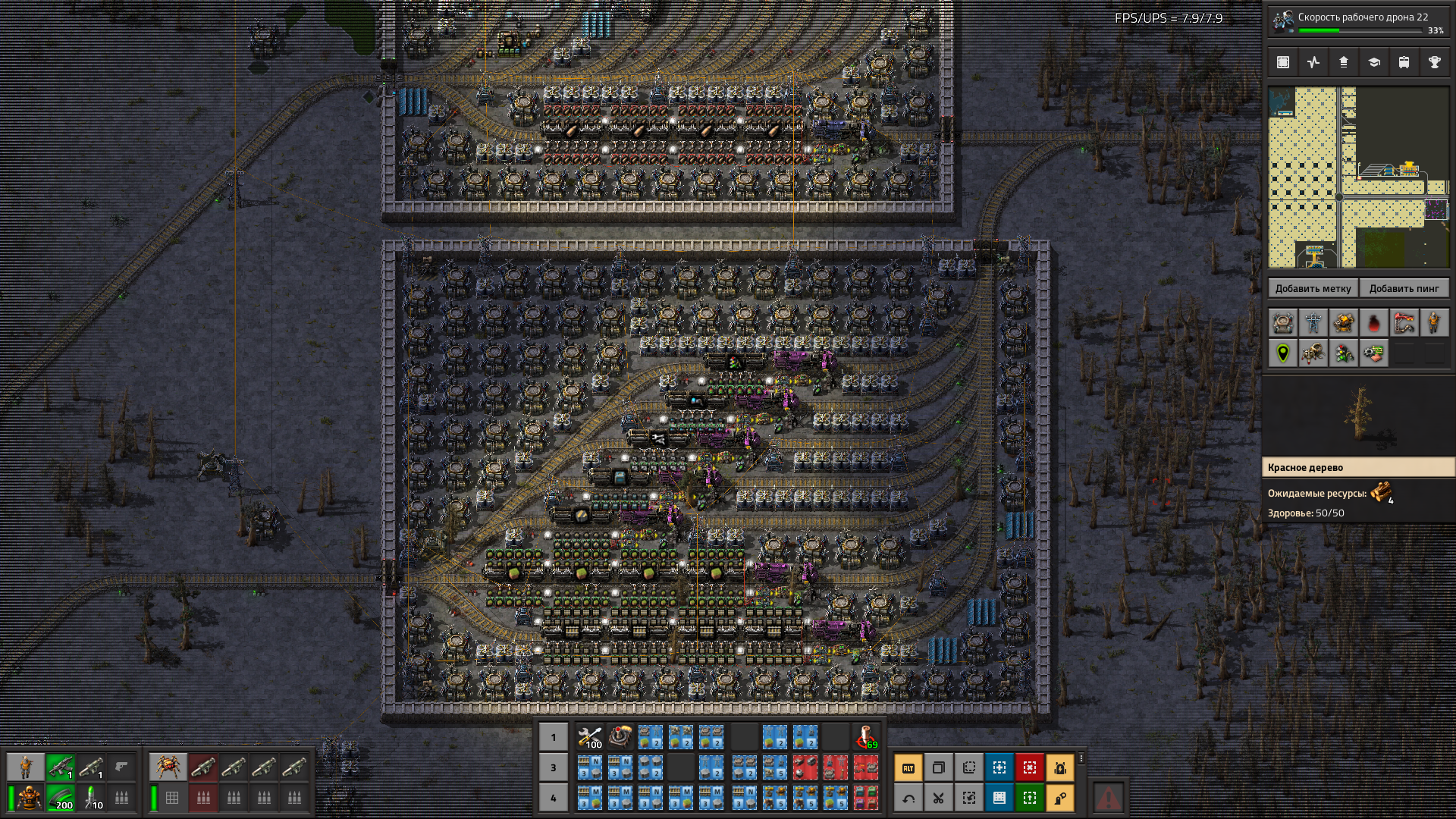

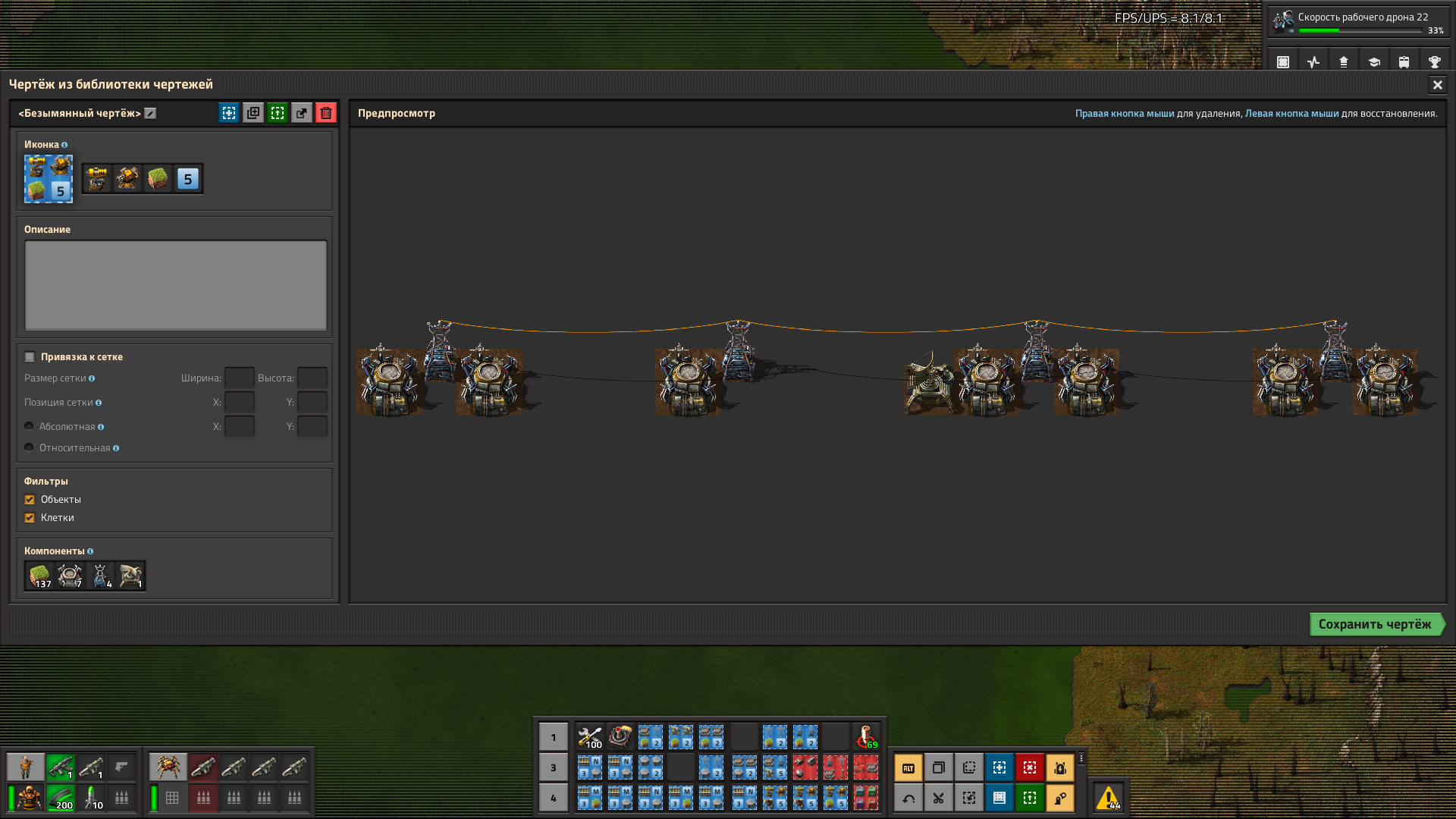

Here are screenshots of the factory scale

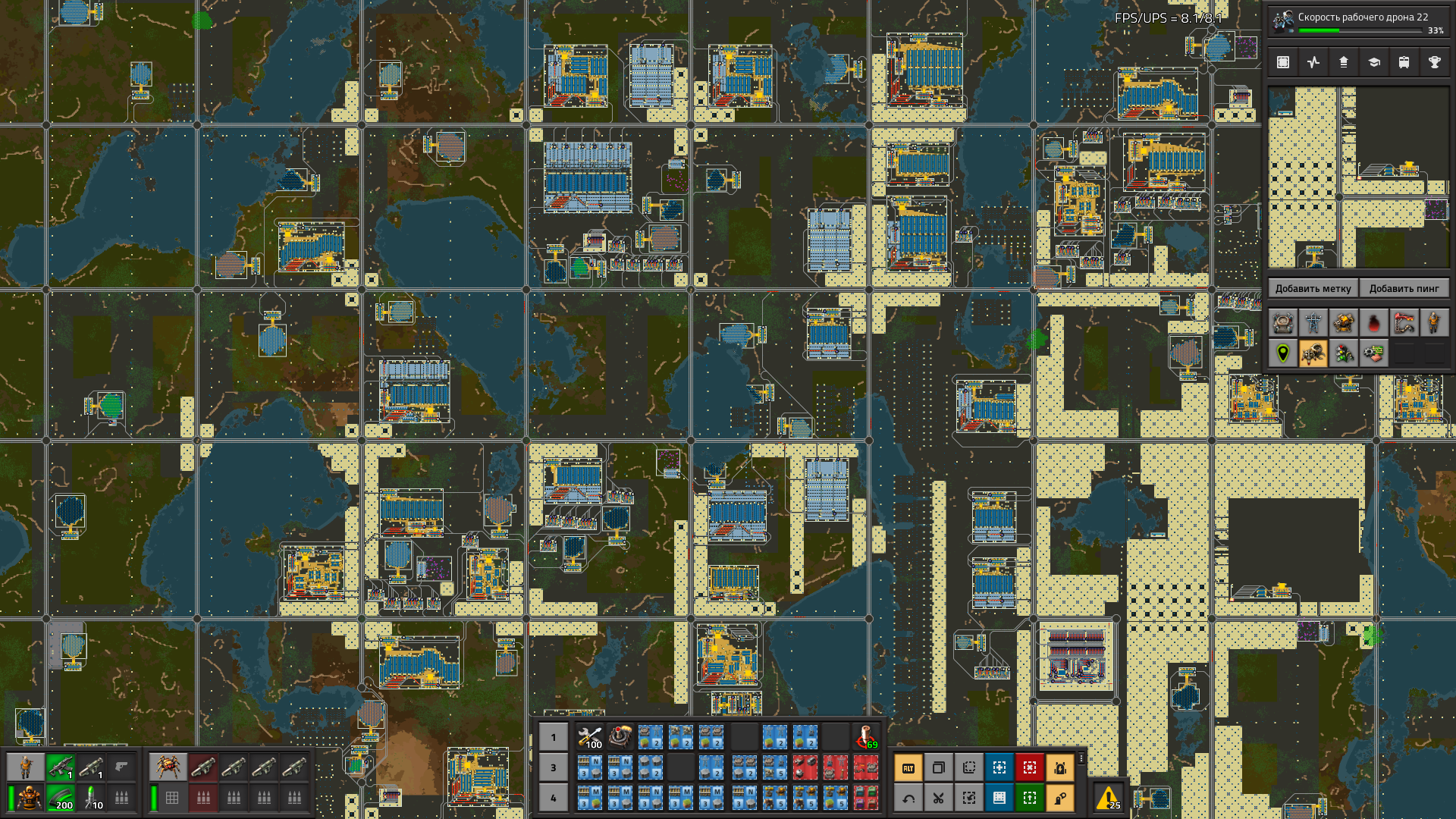

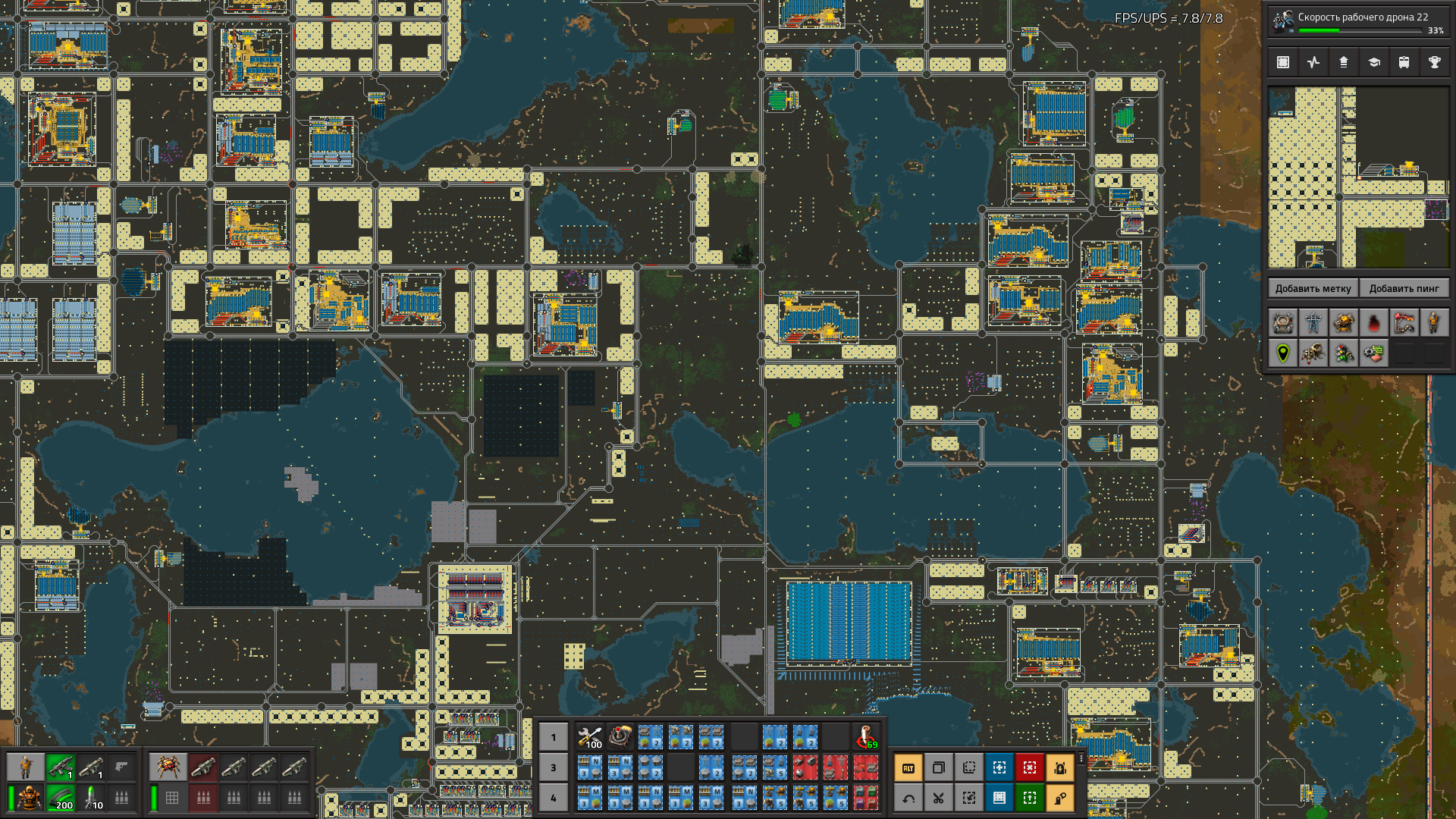

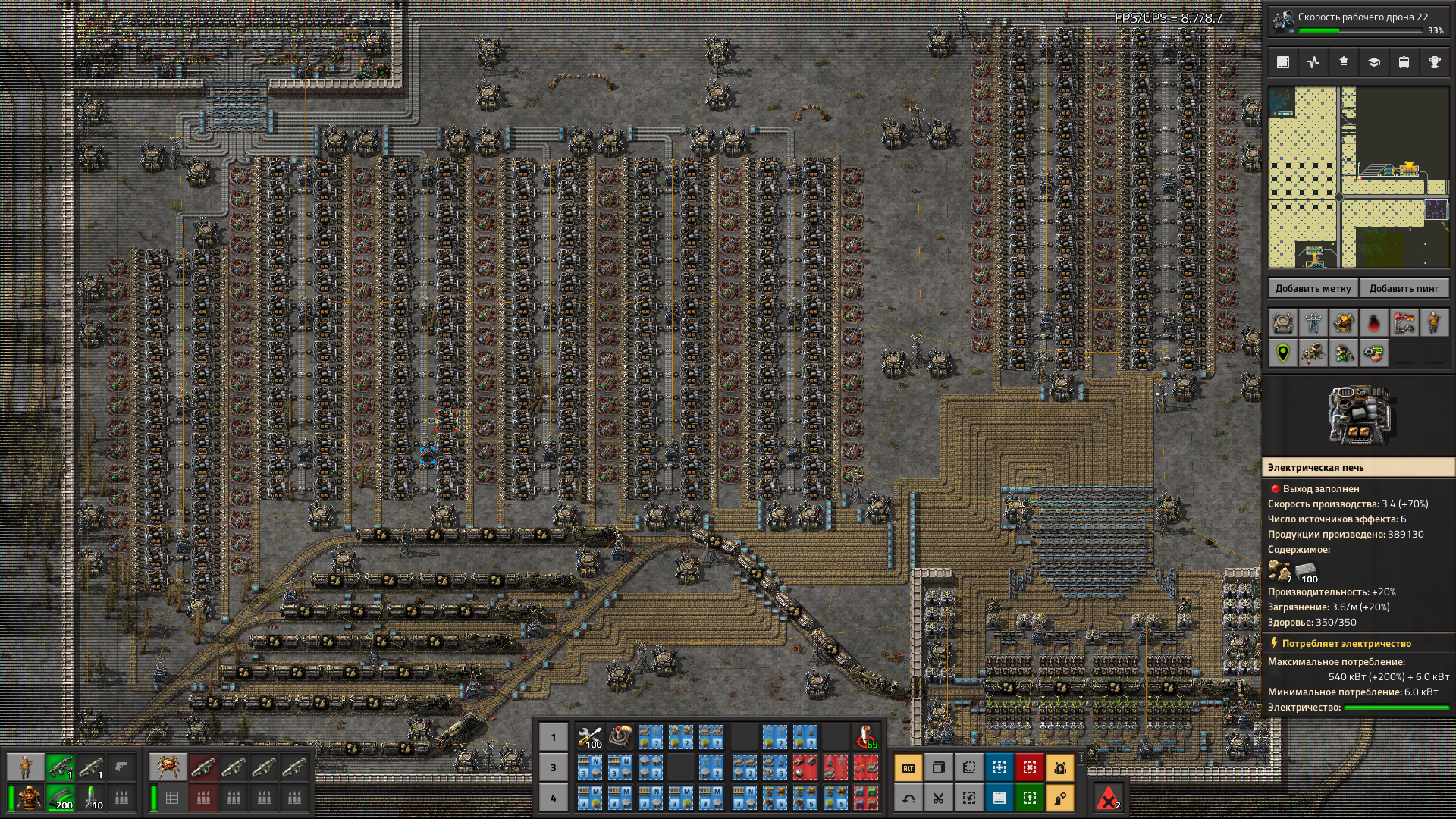

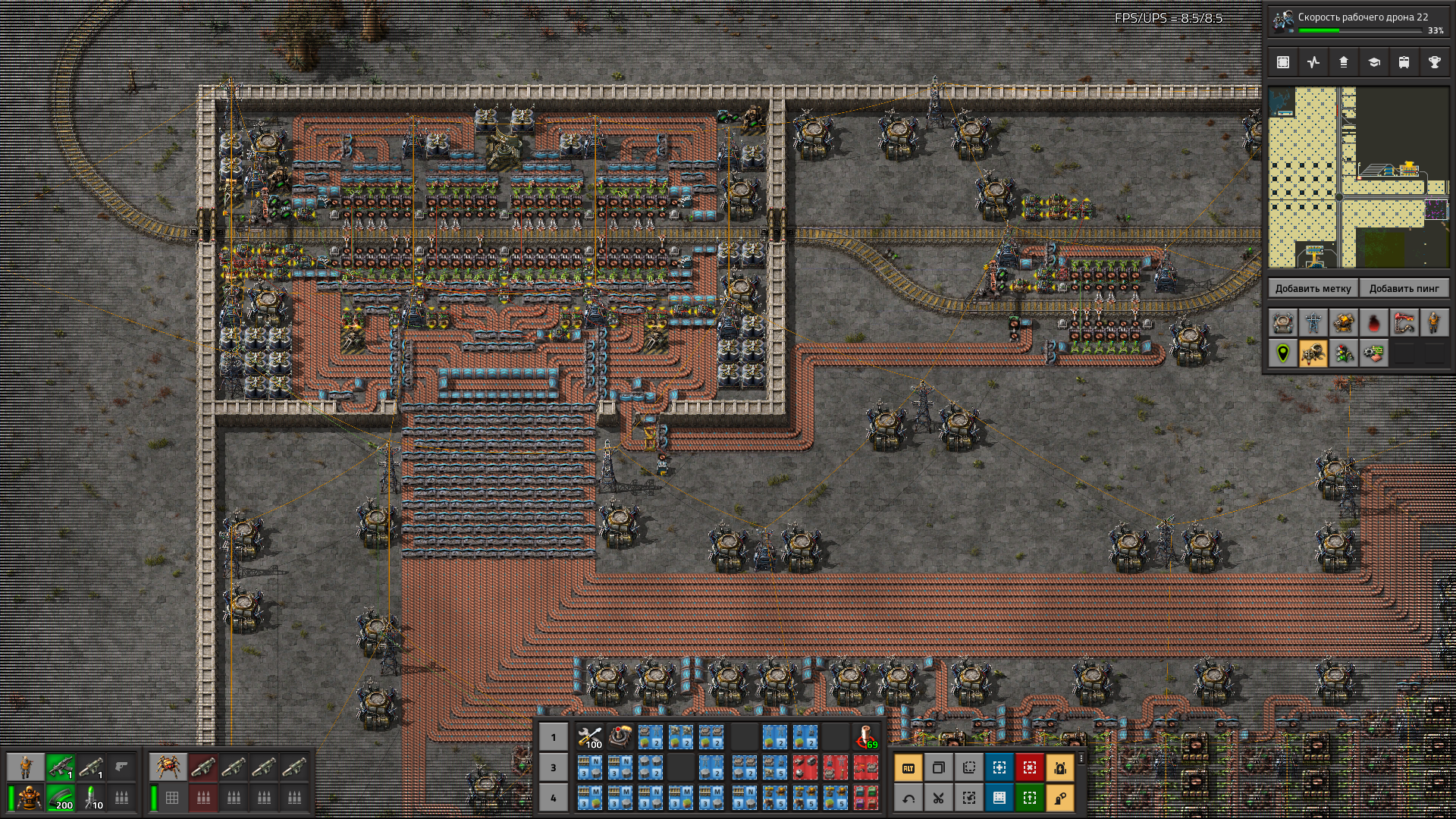

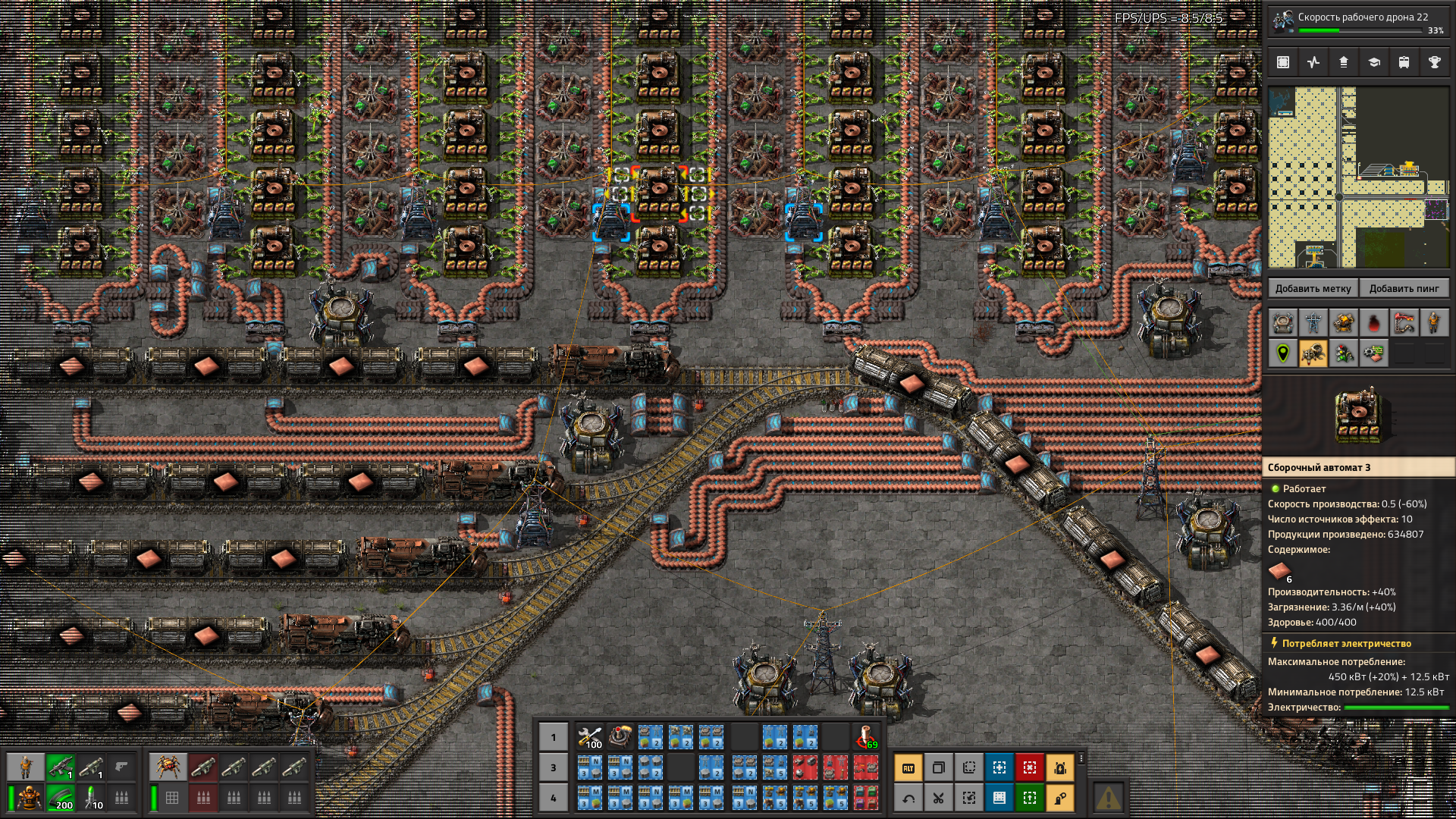

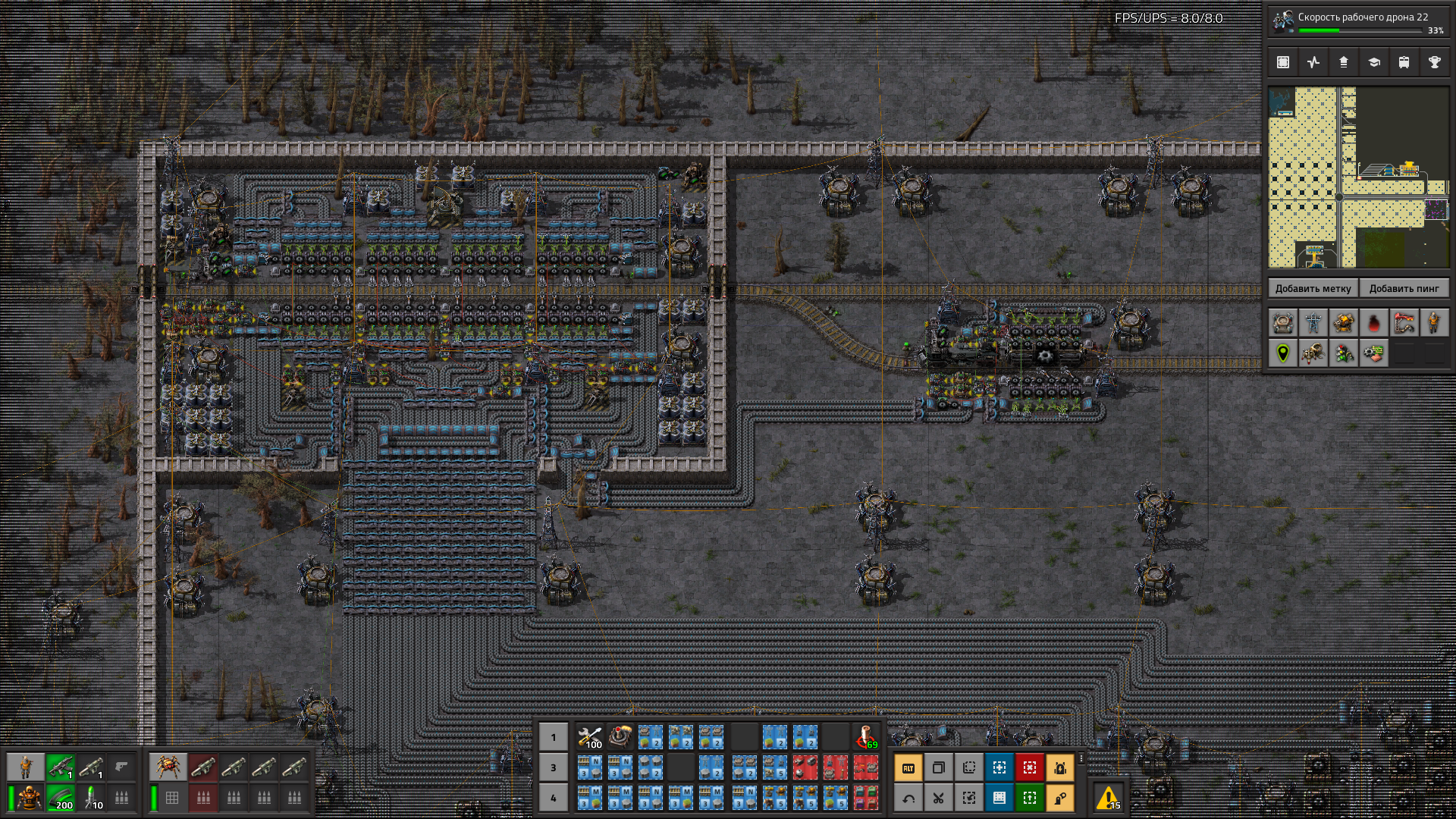

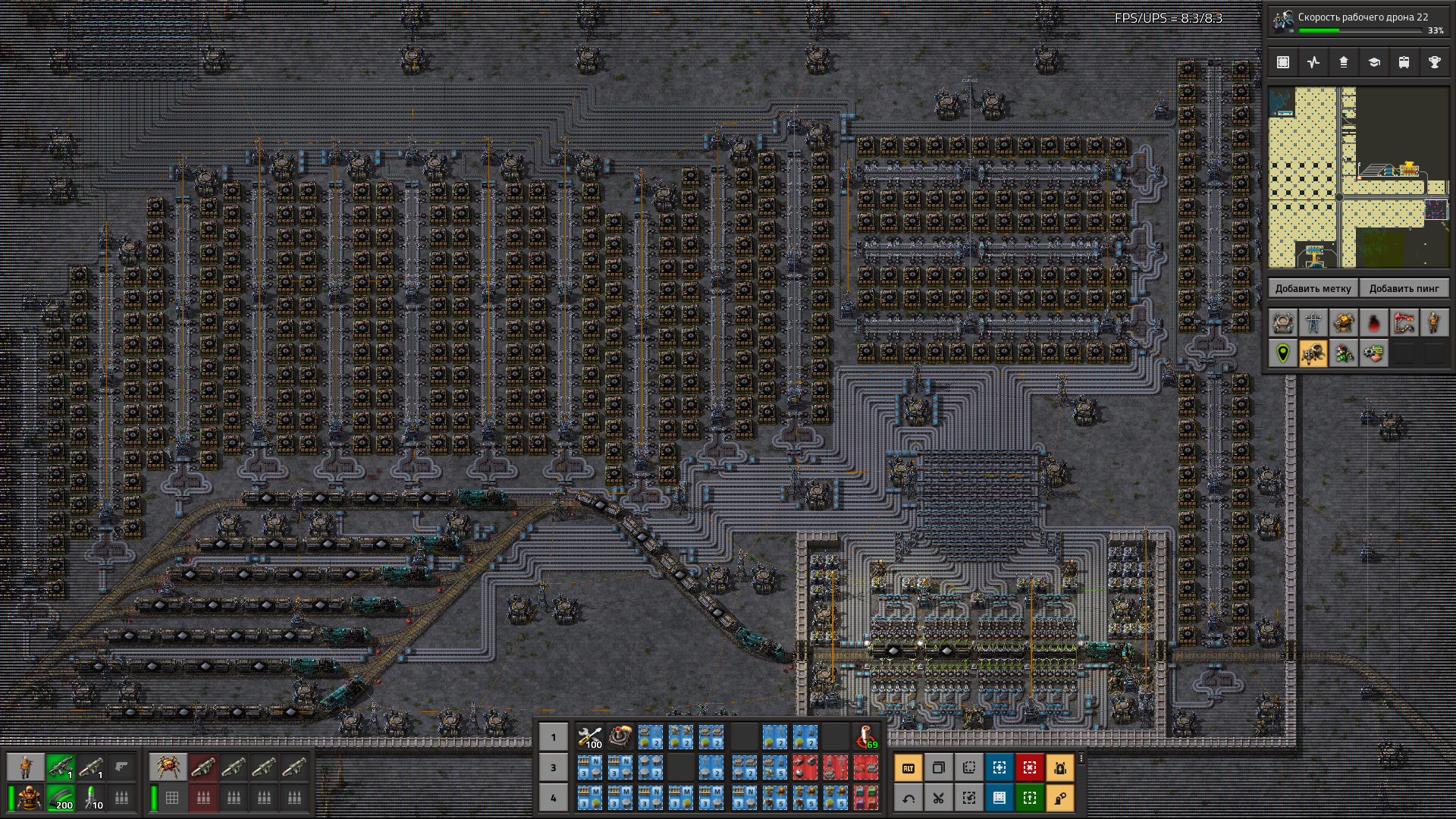

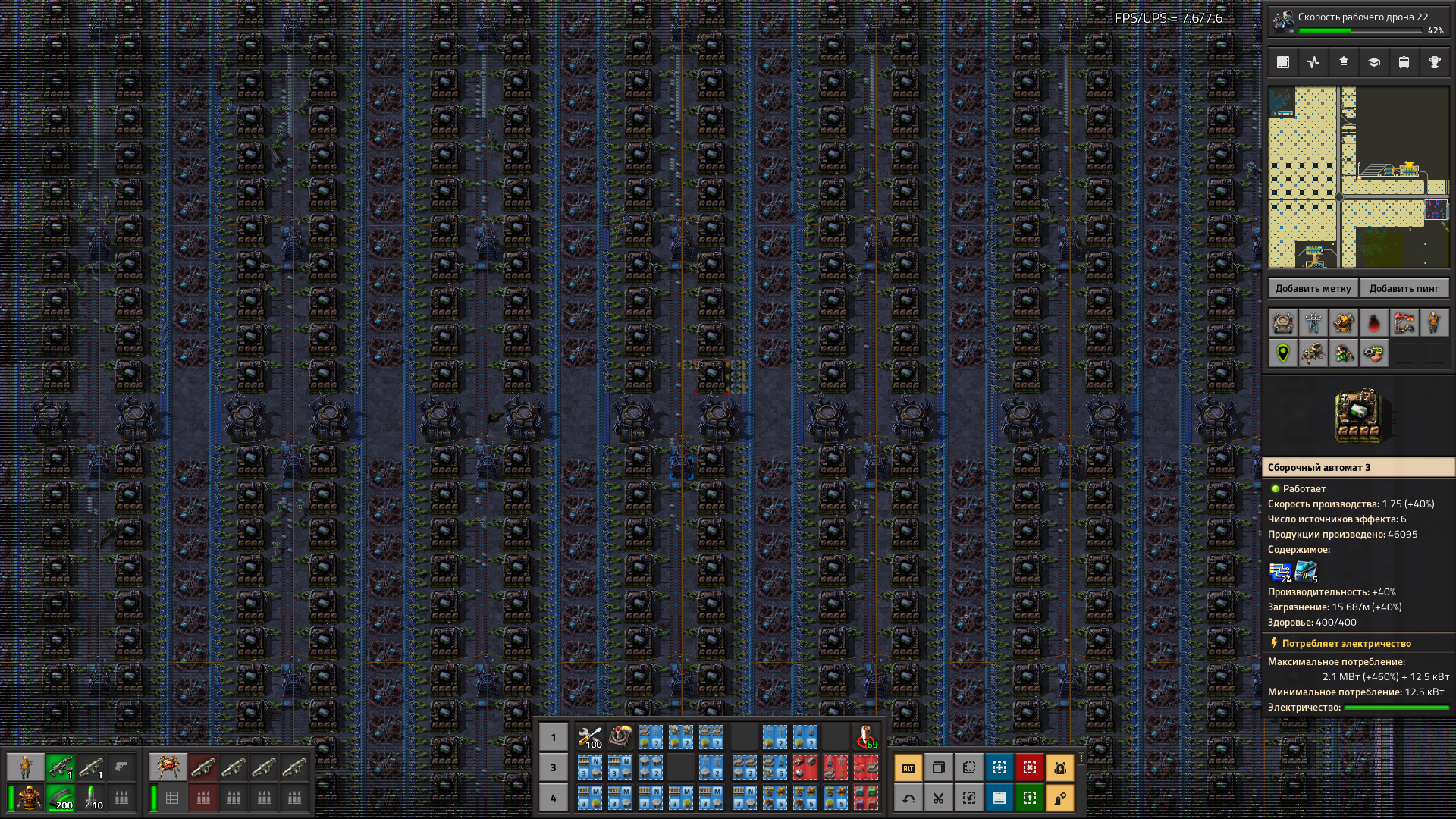

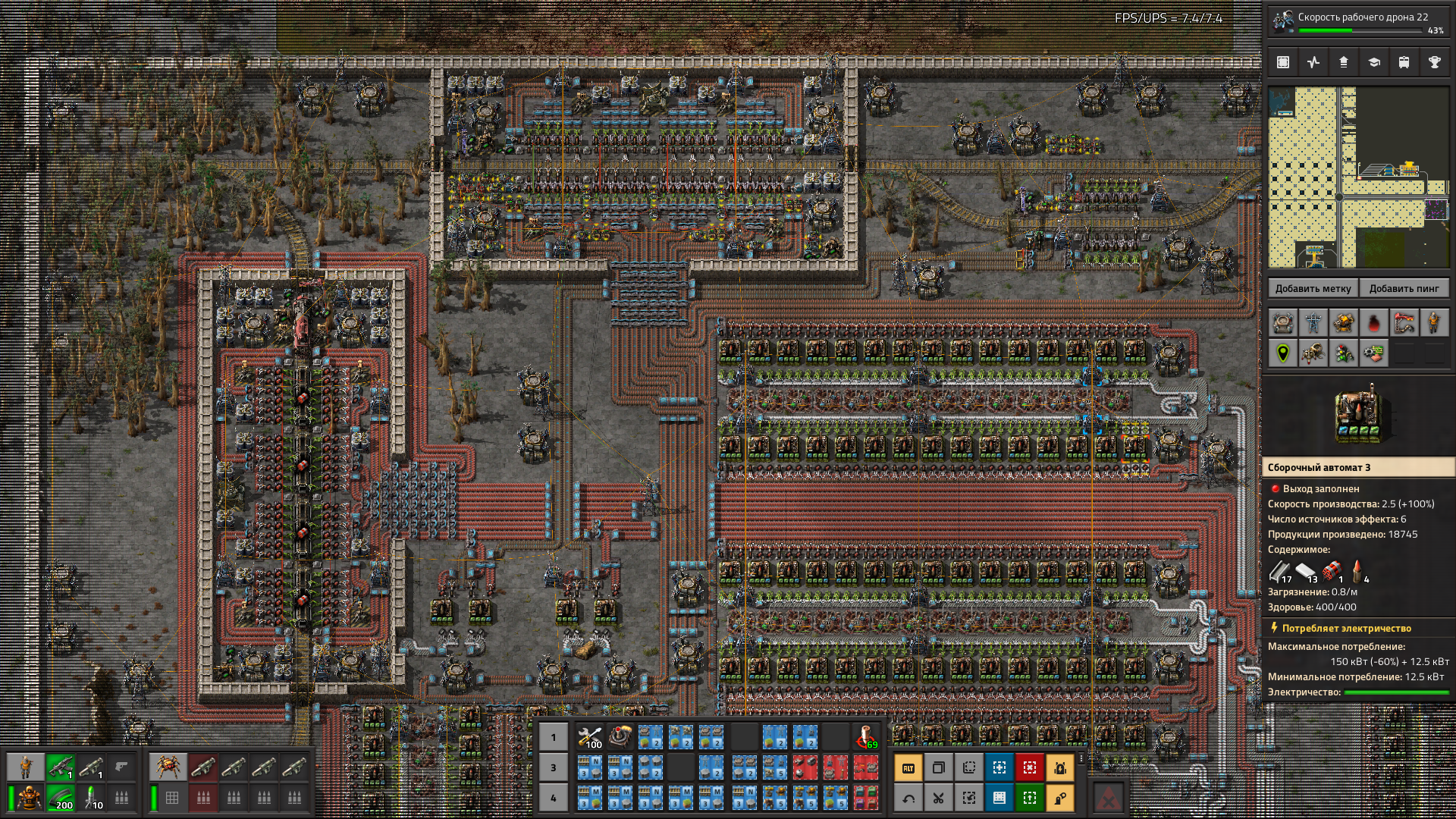

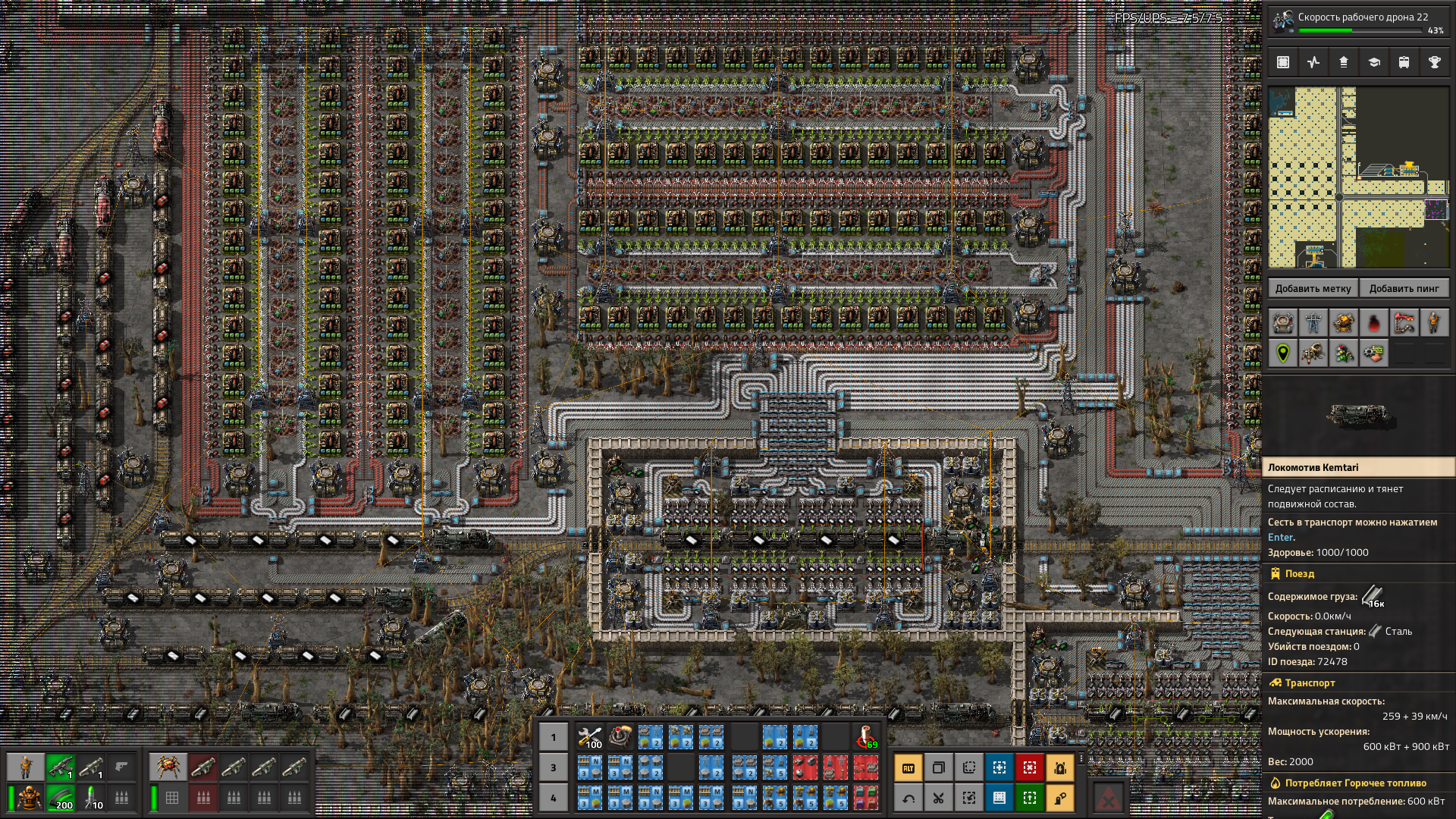

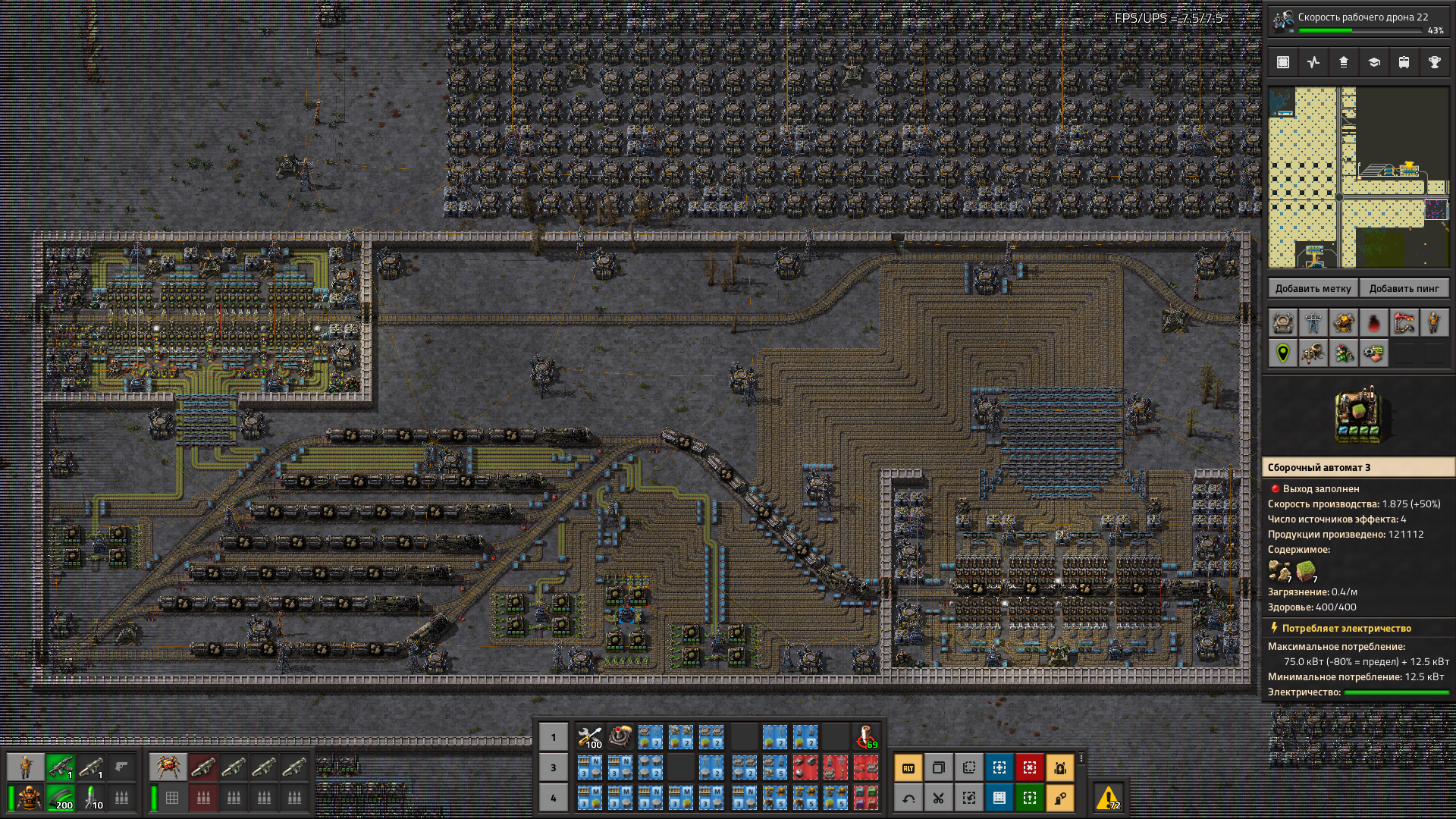

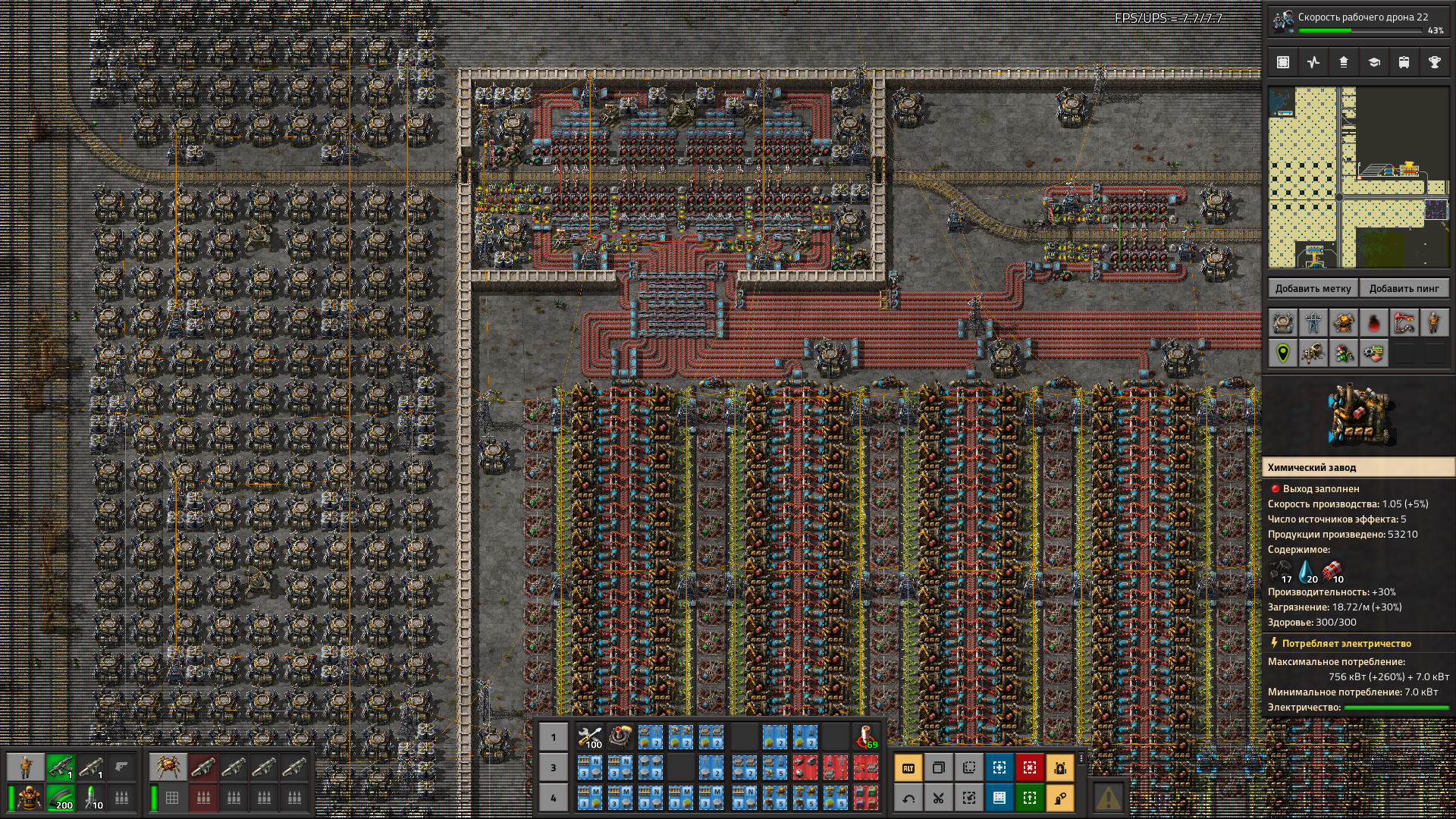

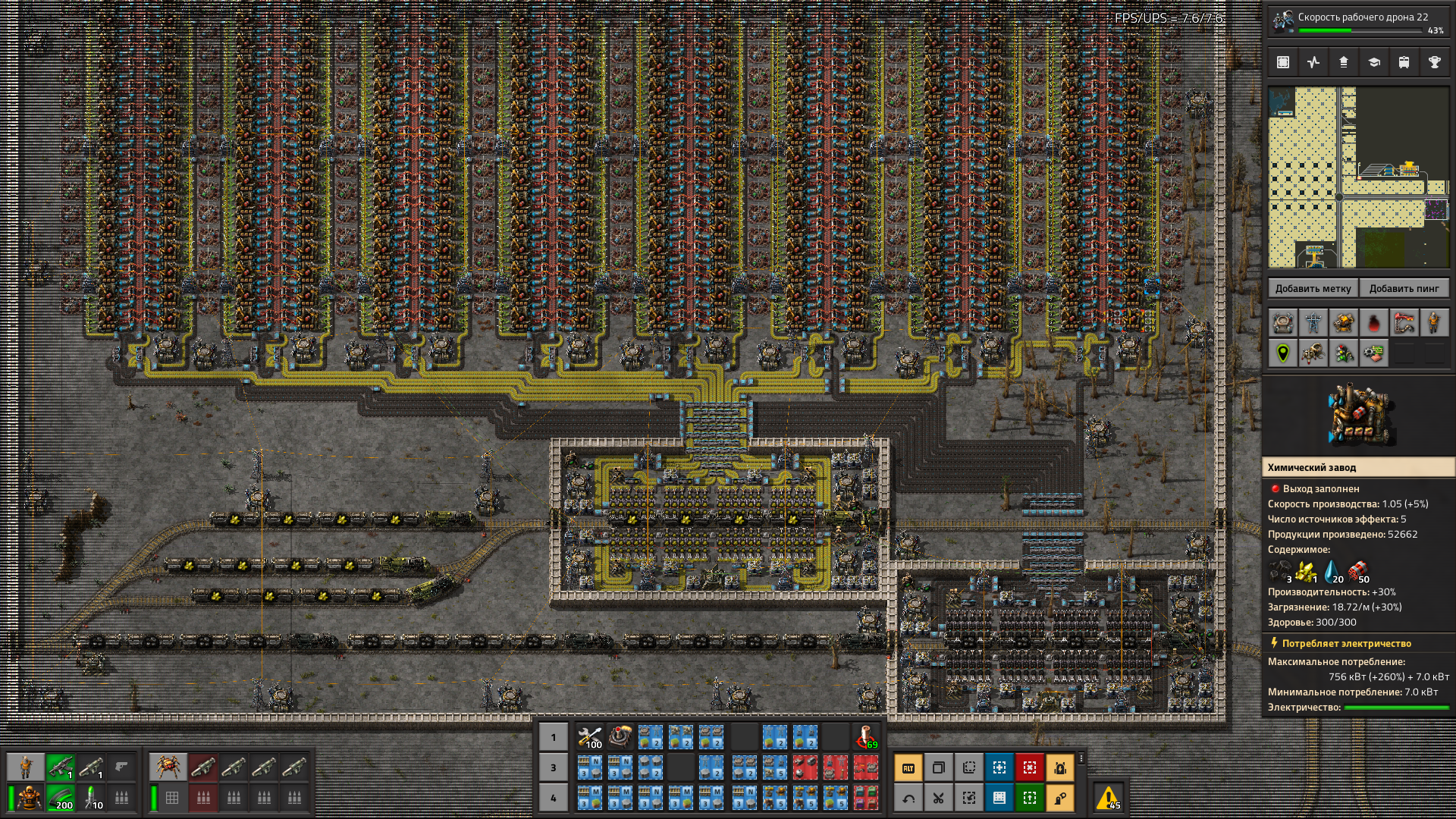

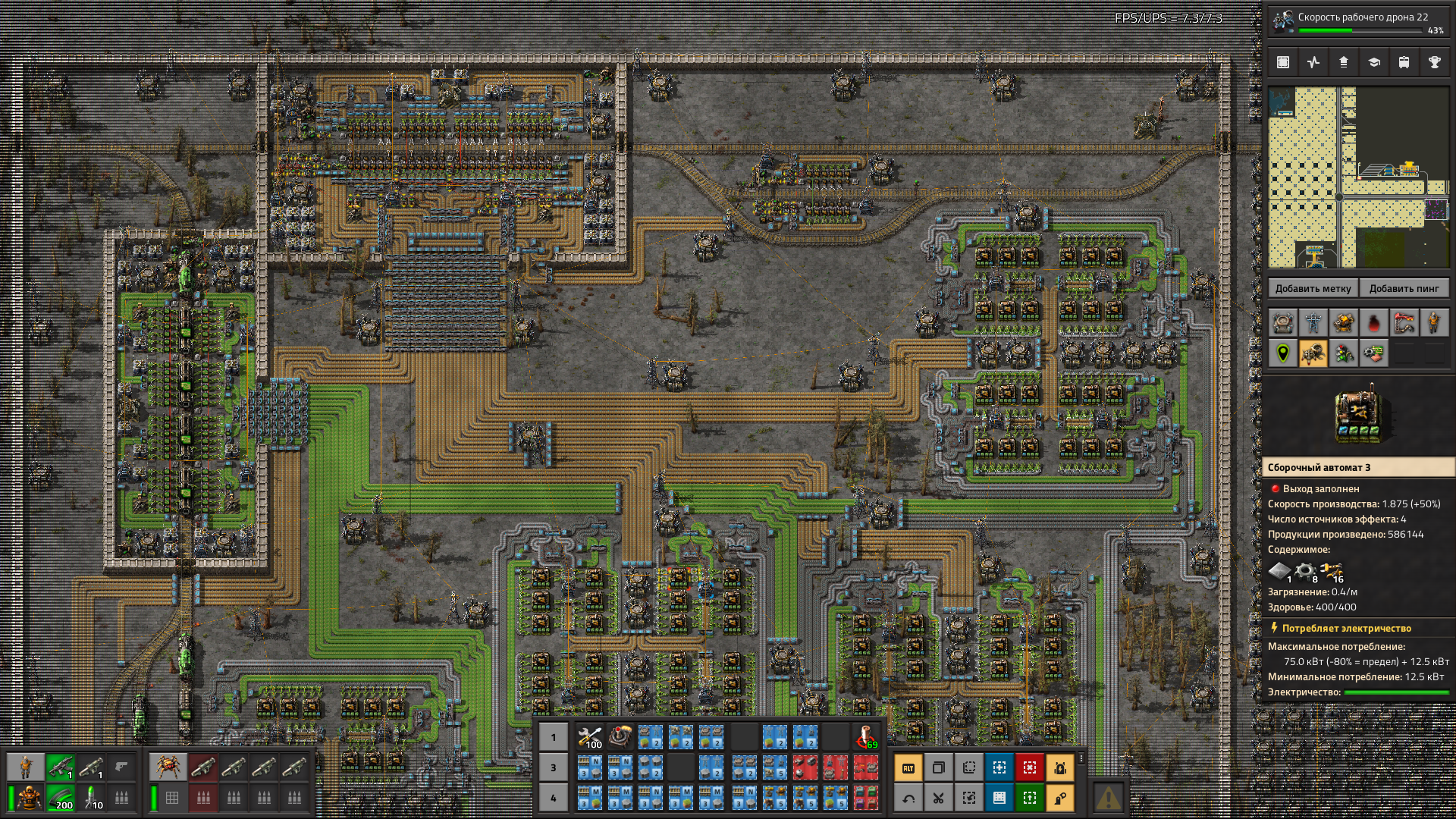

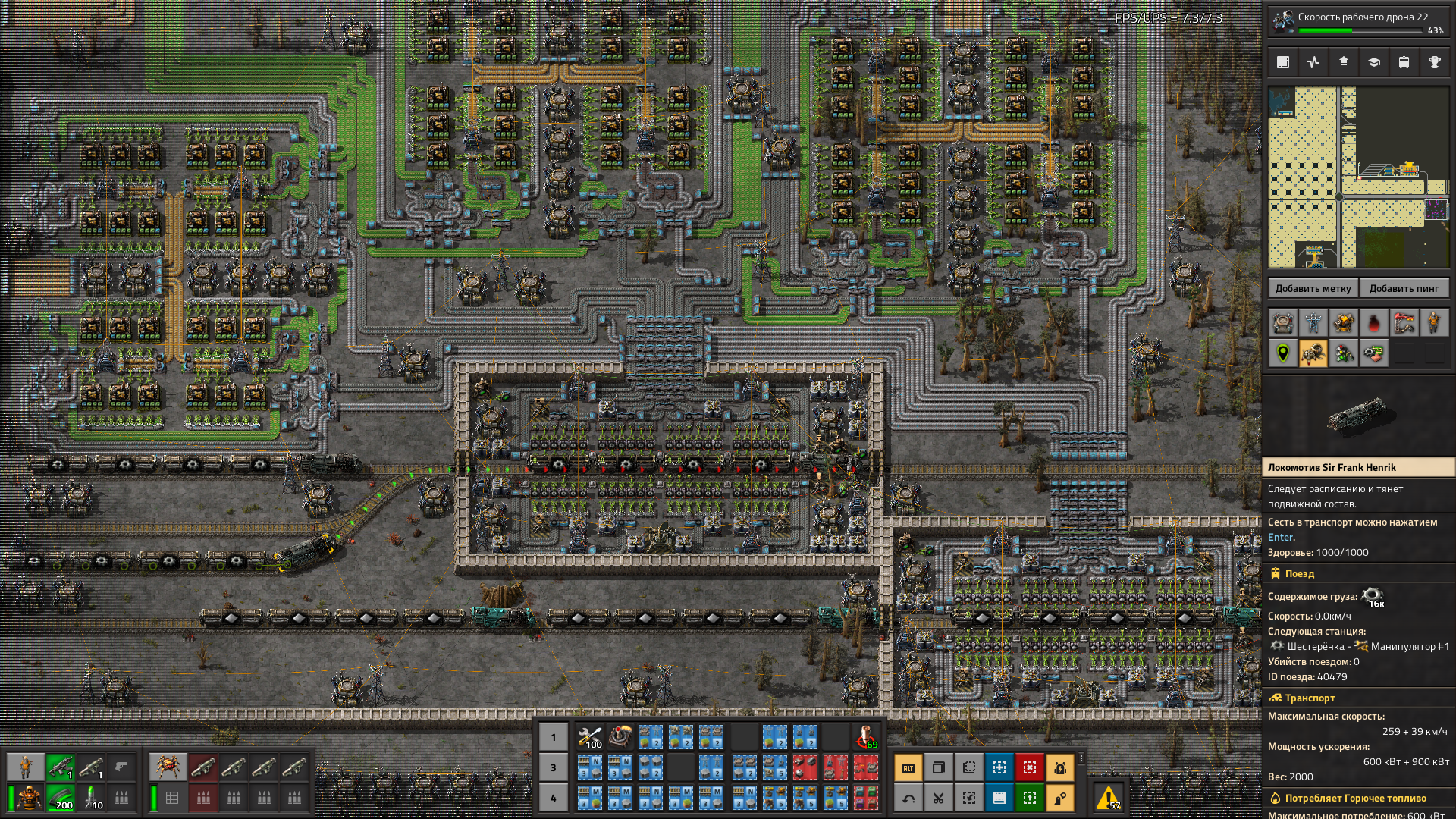

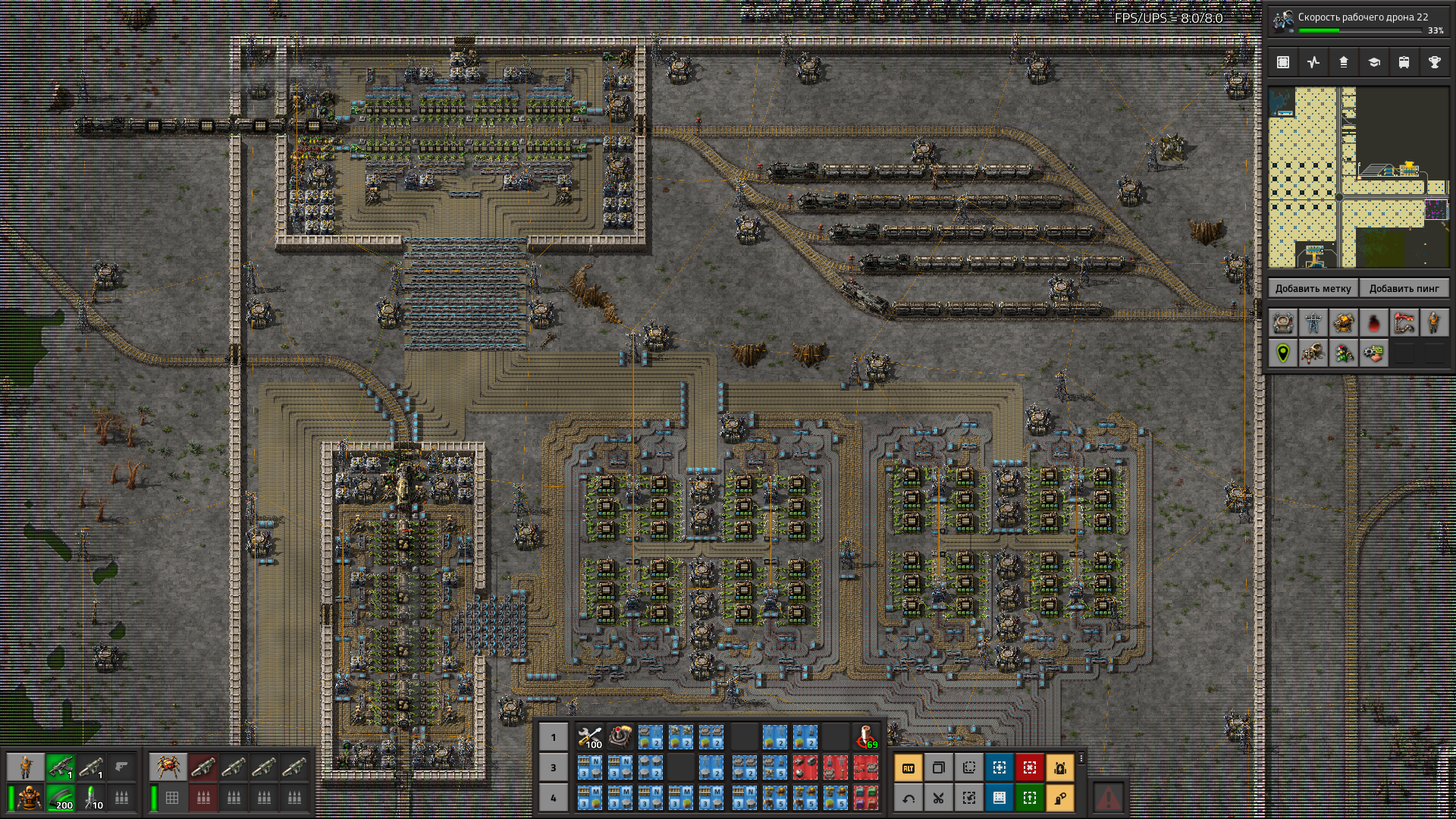

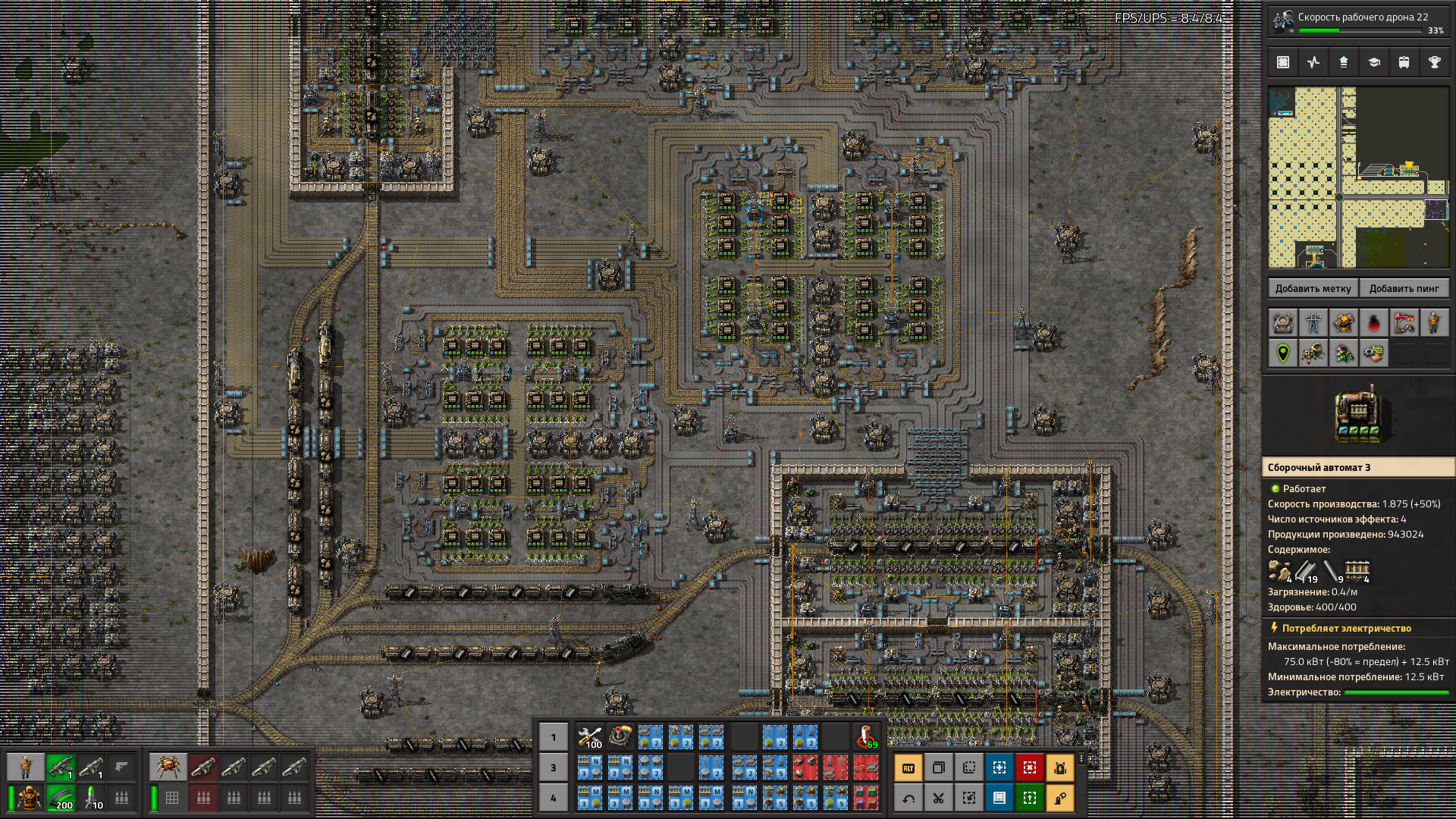

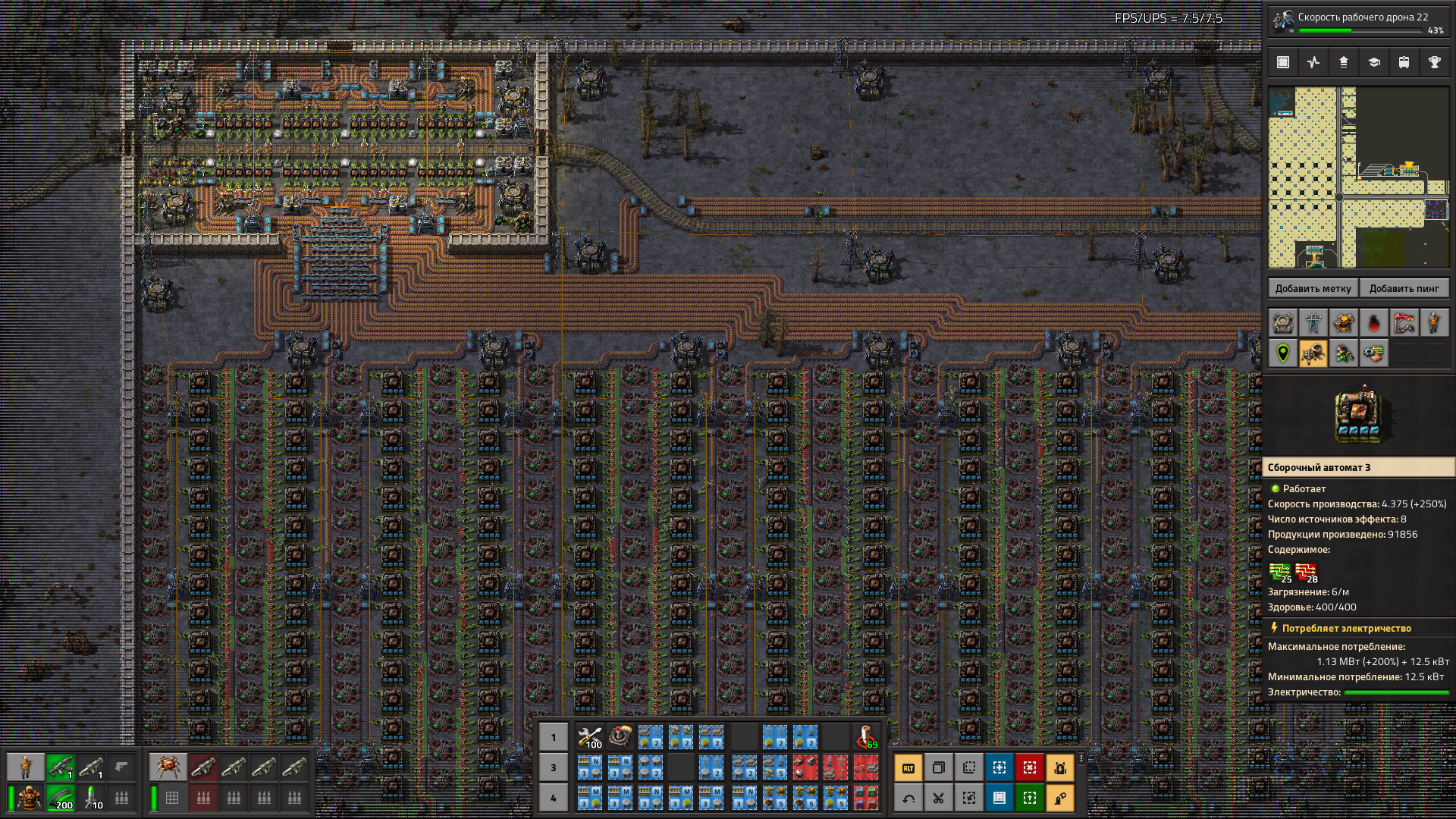

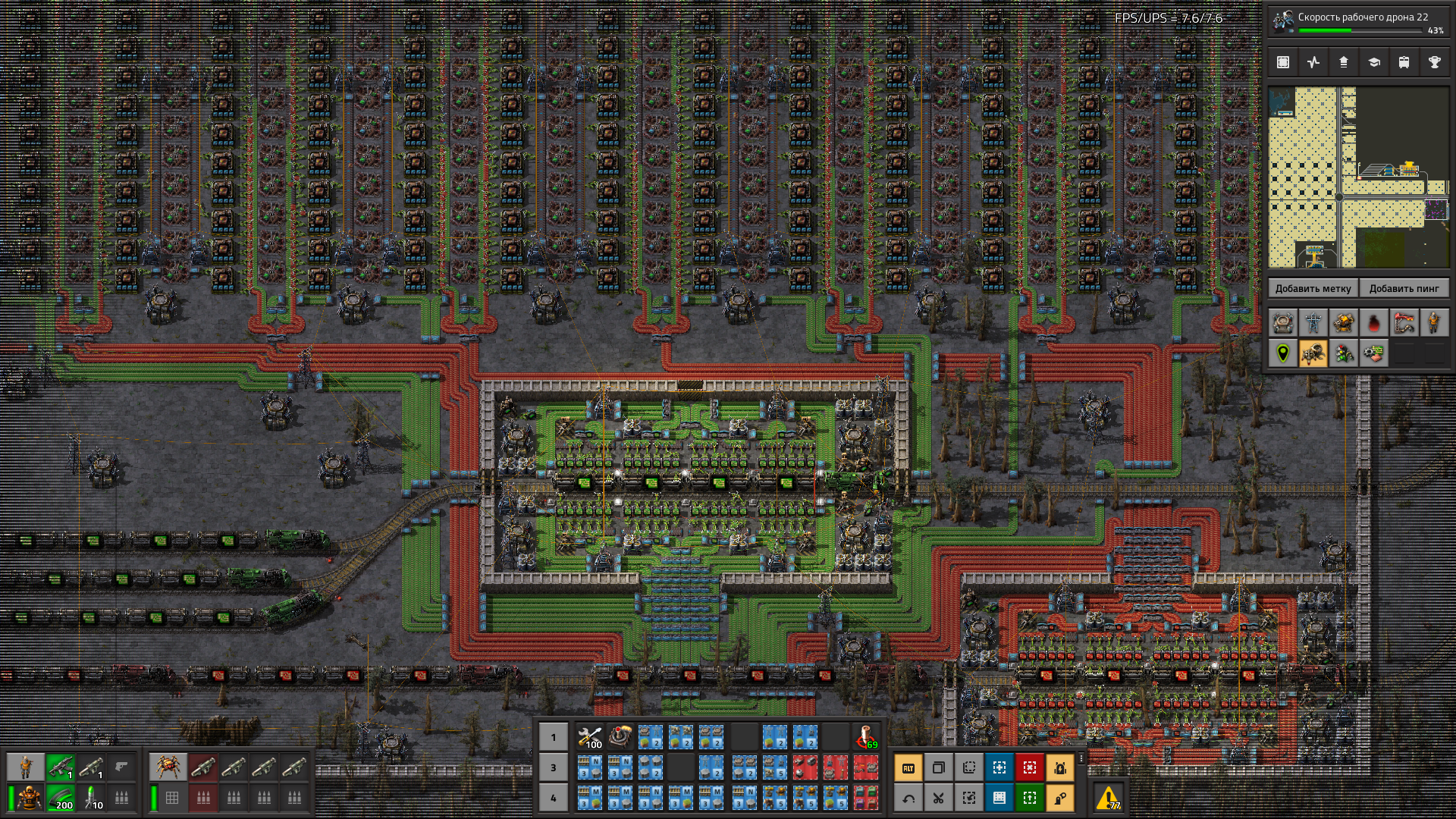

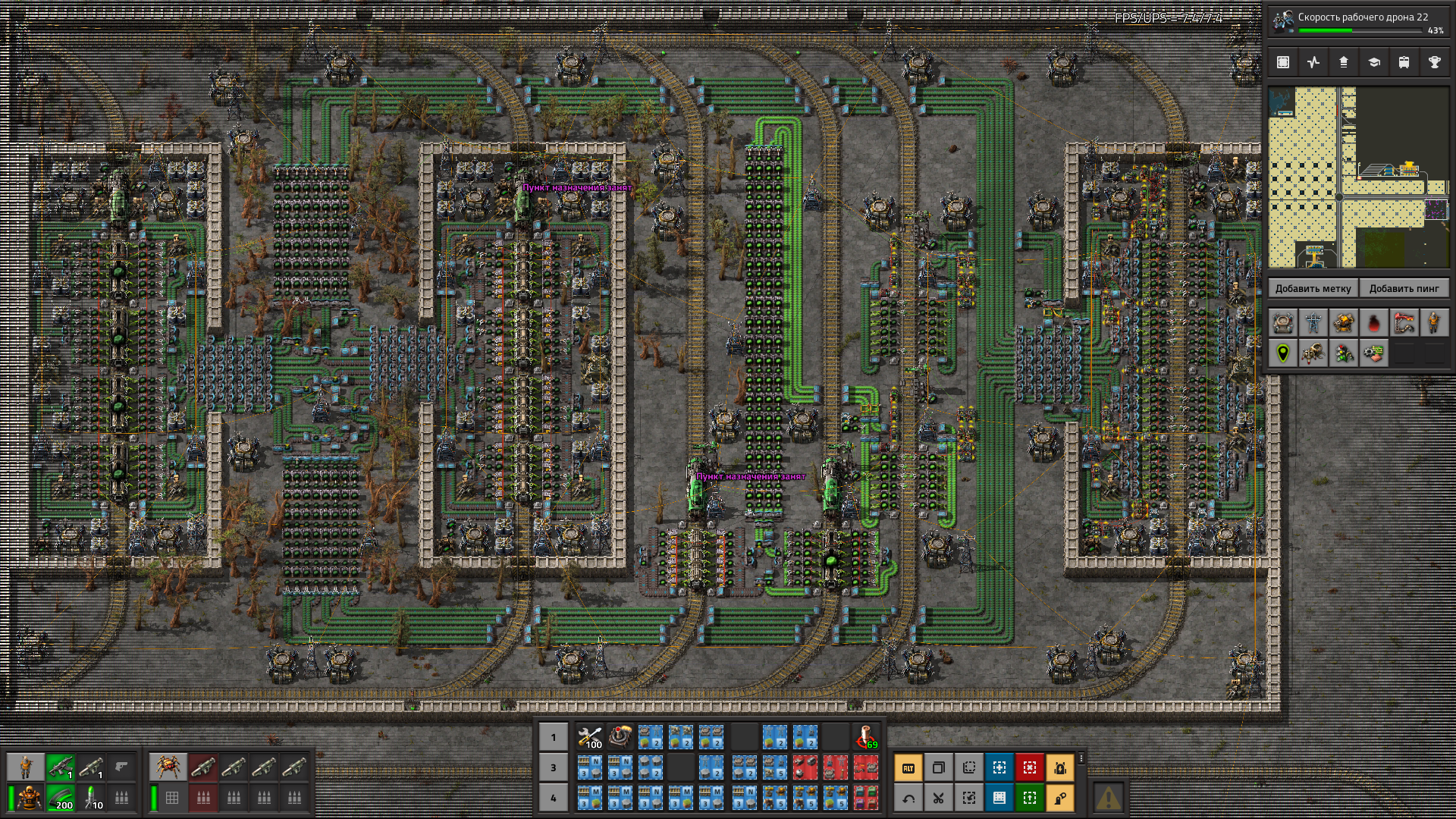

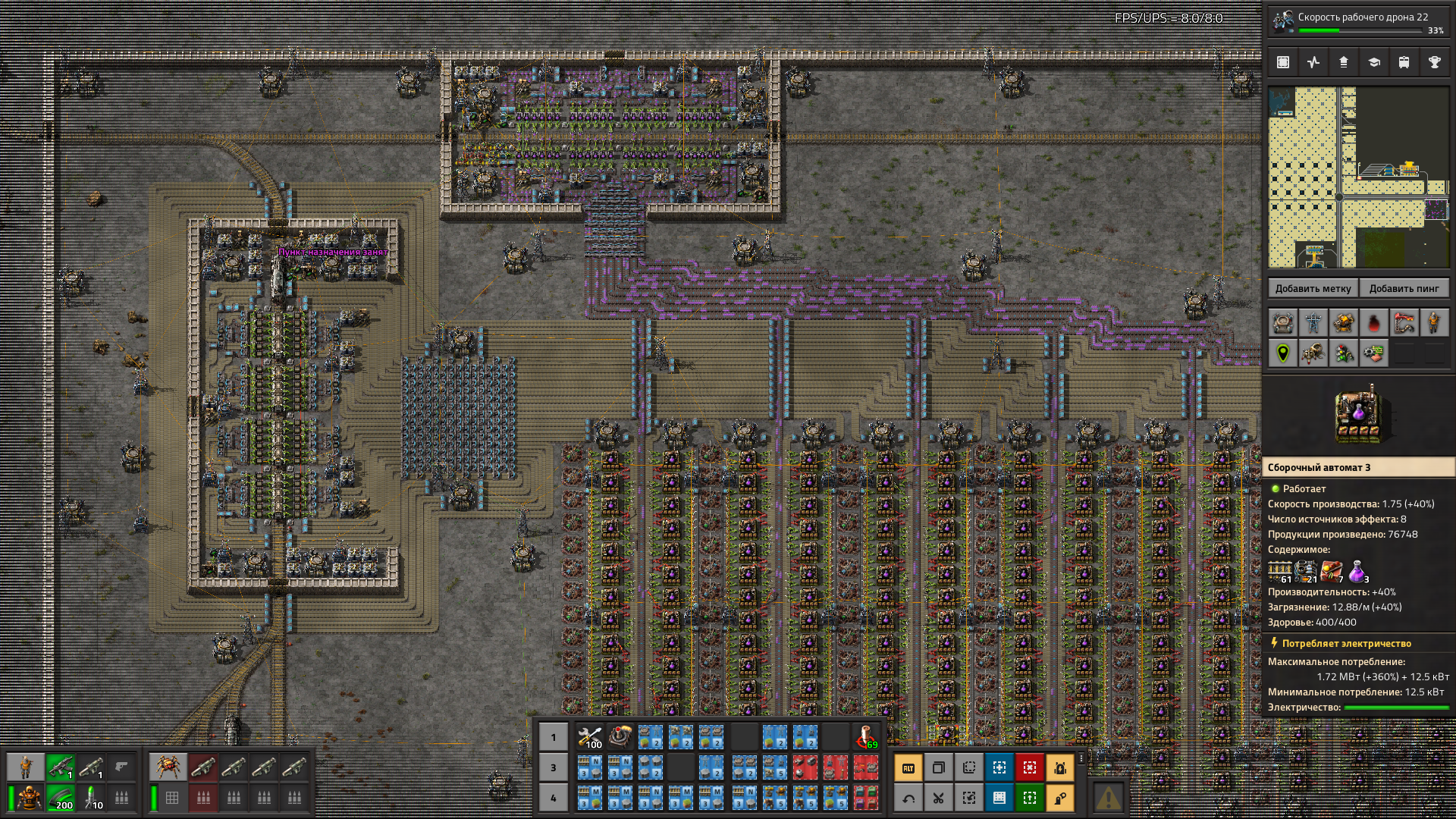

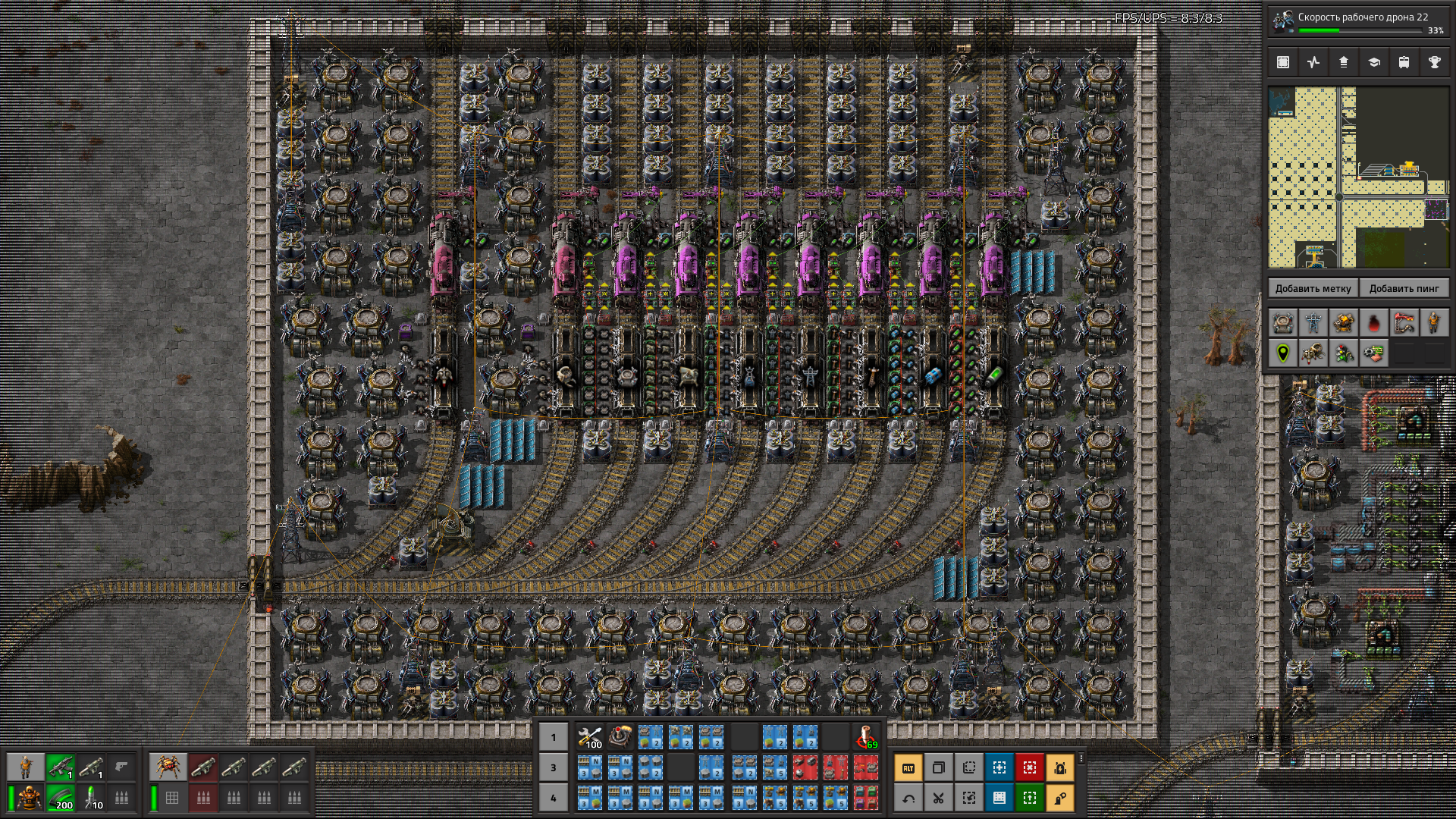

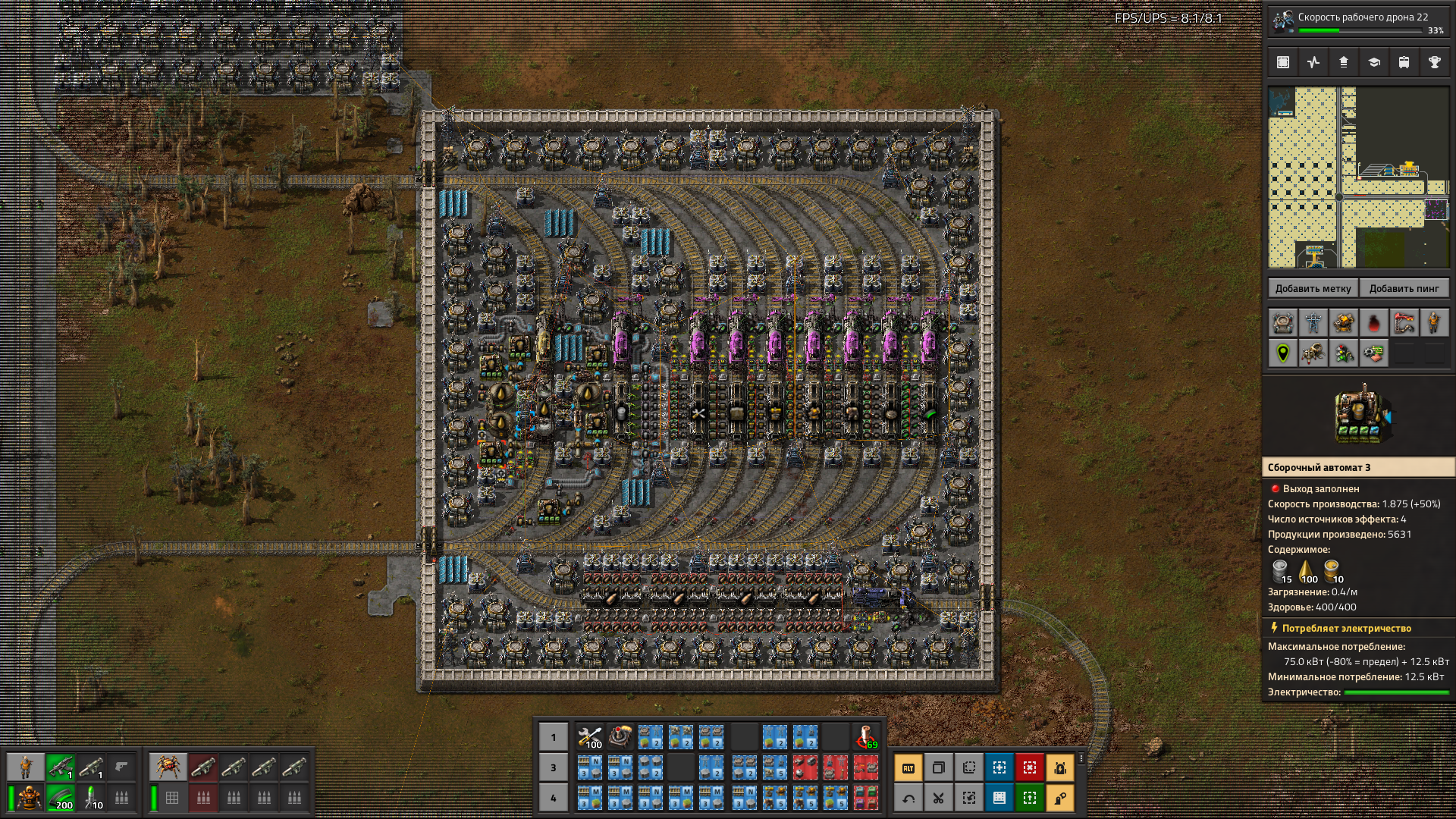

Here are screenshots of the scale of the factory in a little more detail

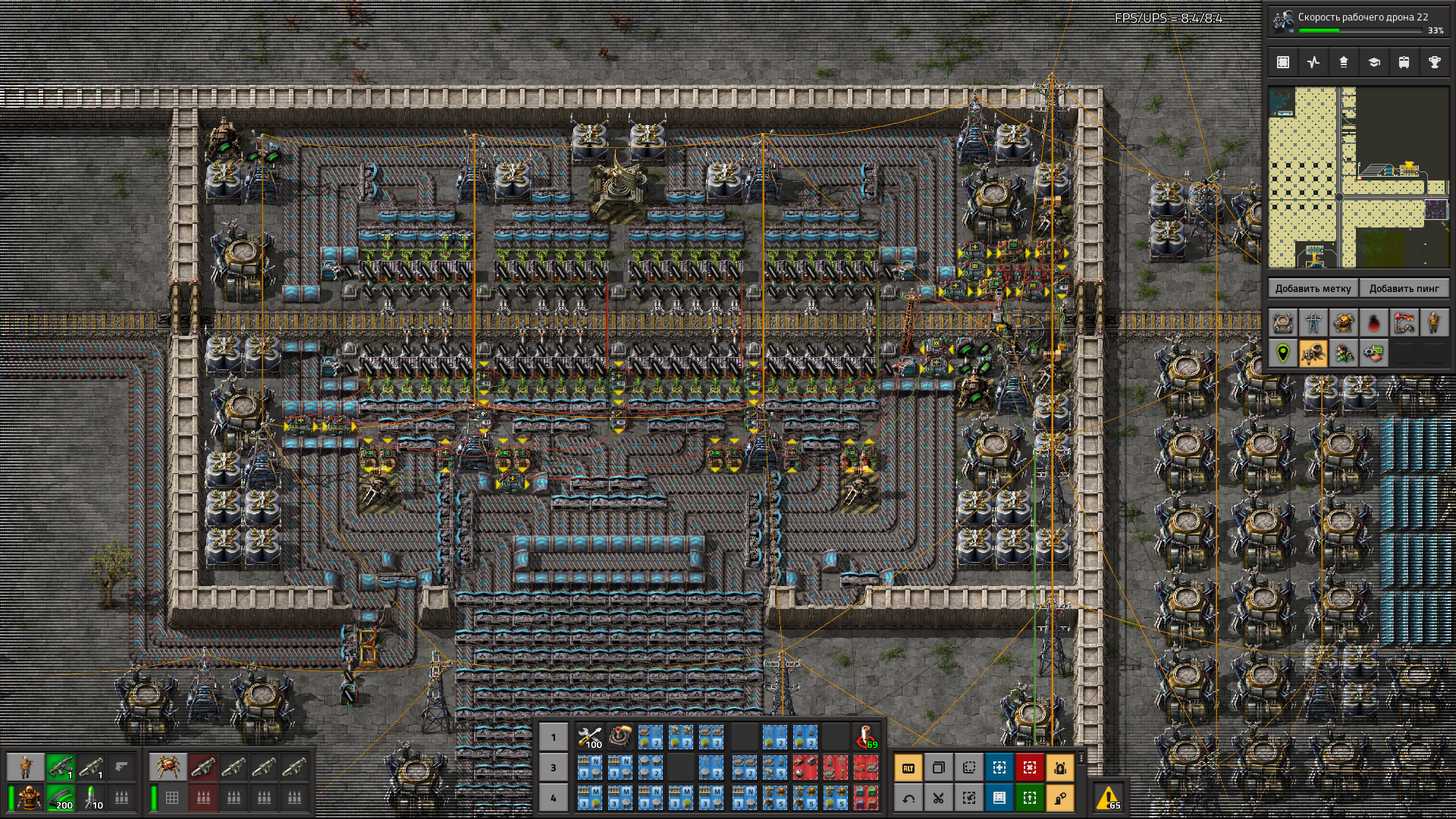

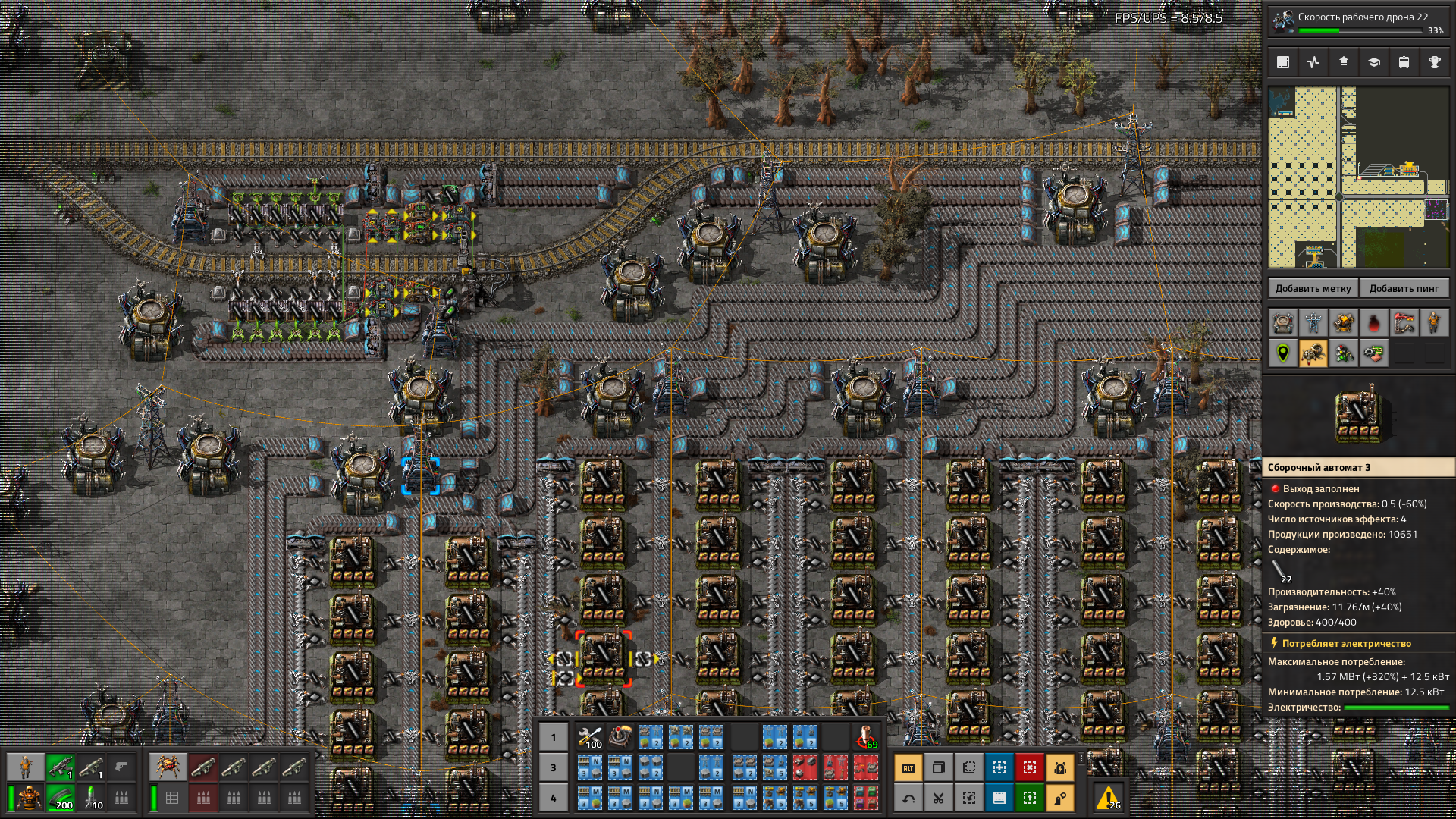

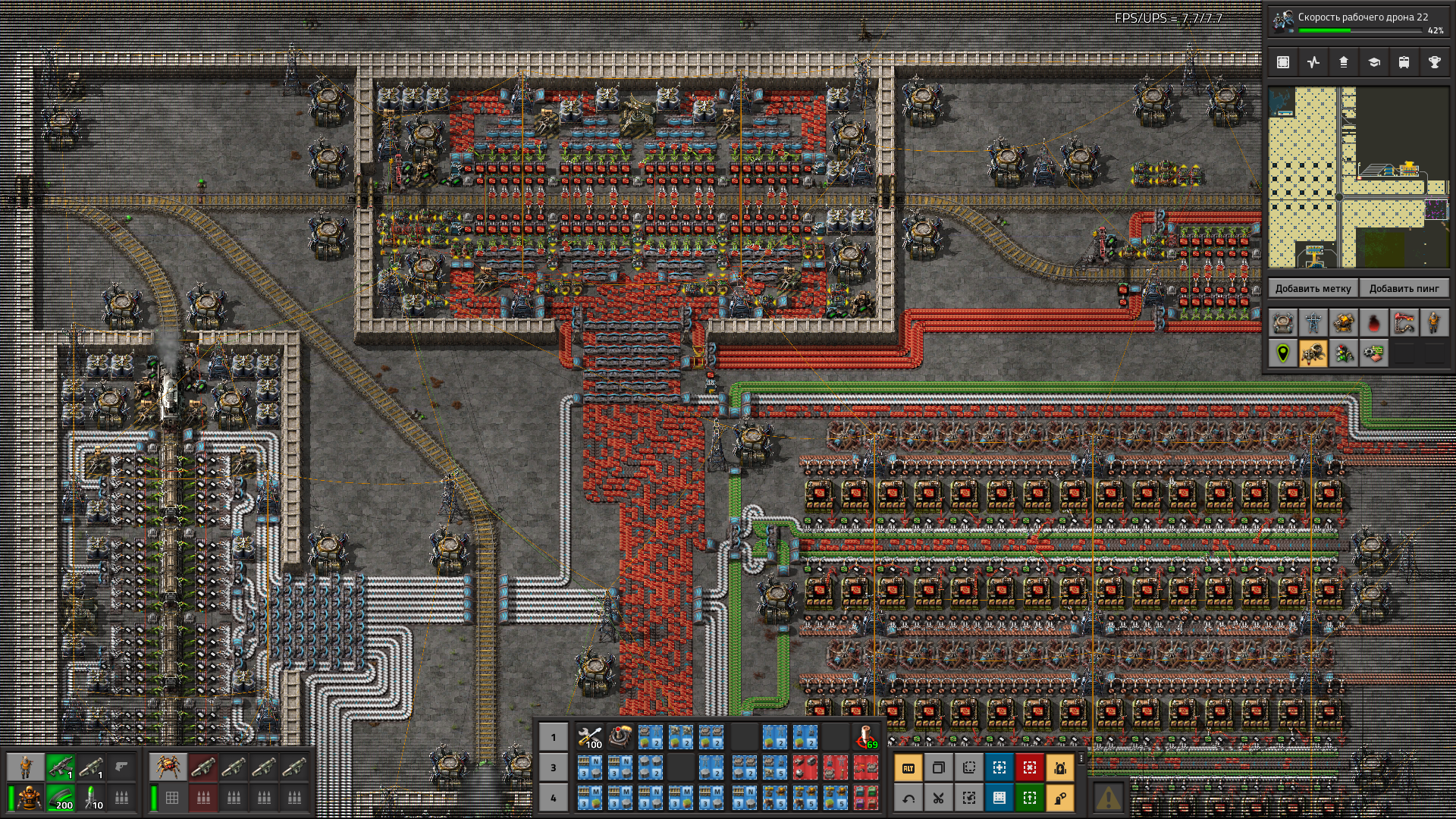

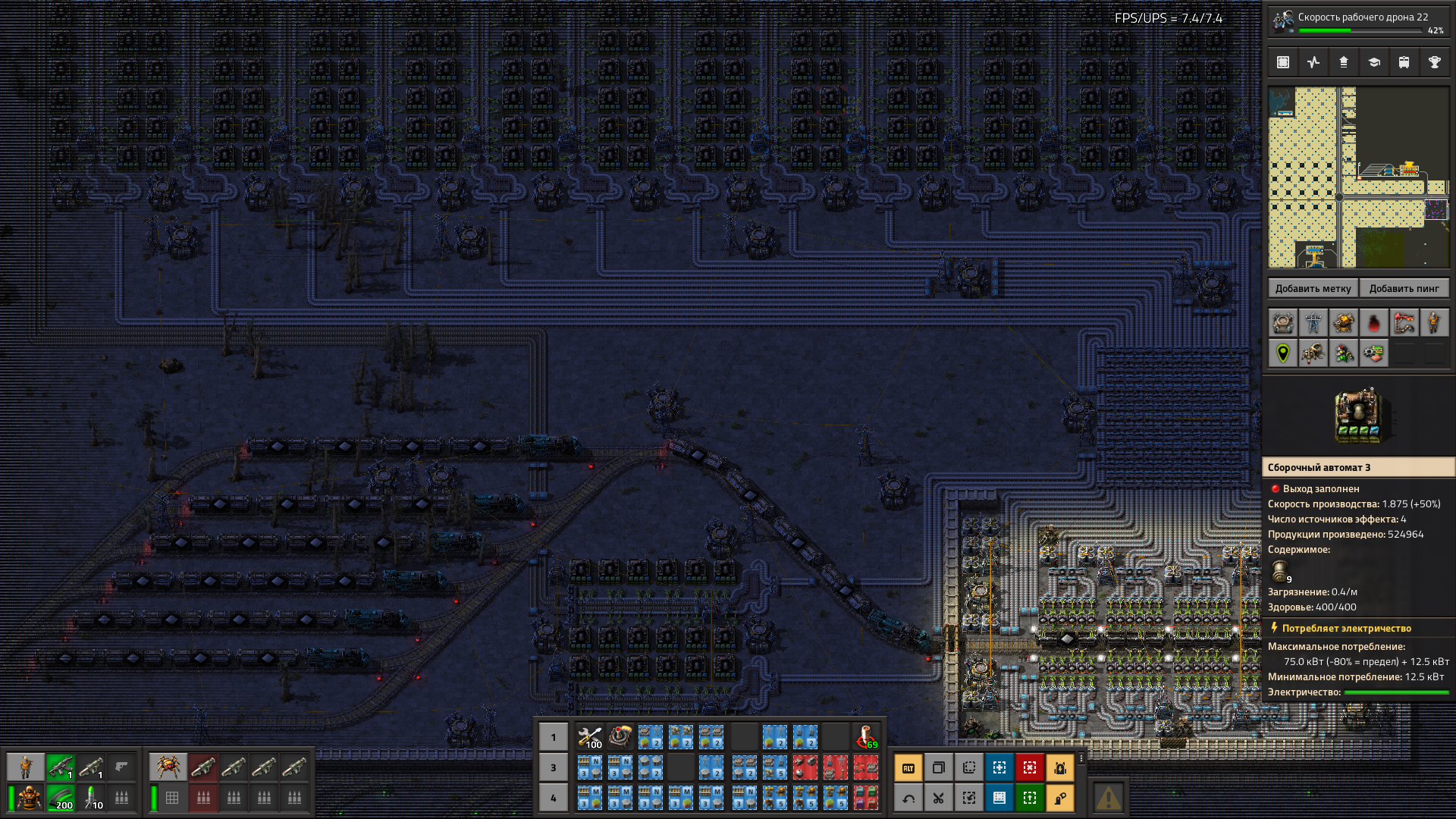

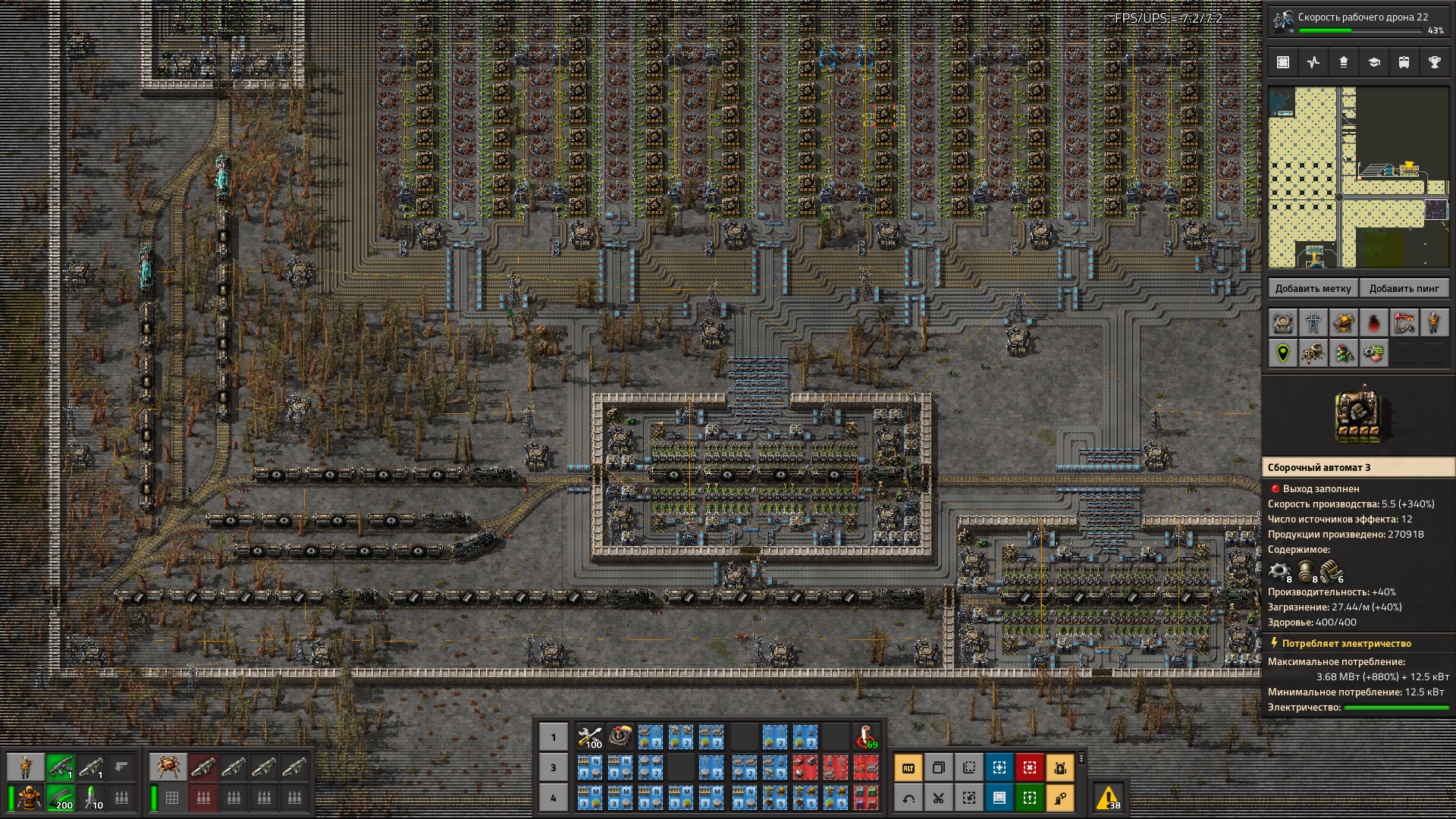

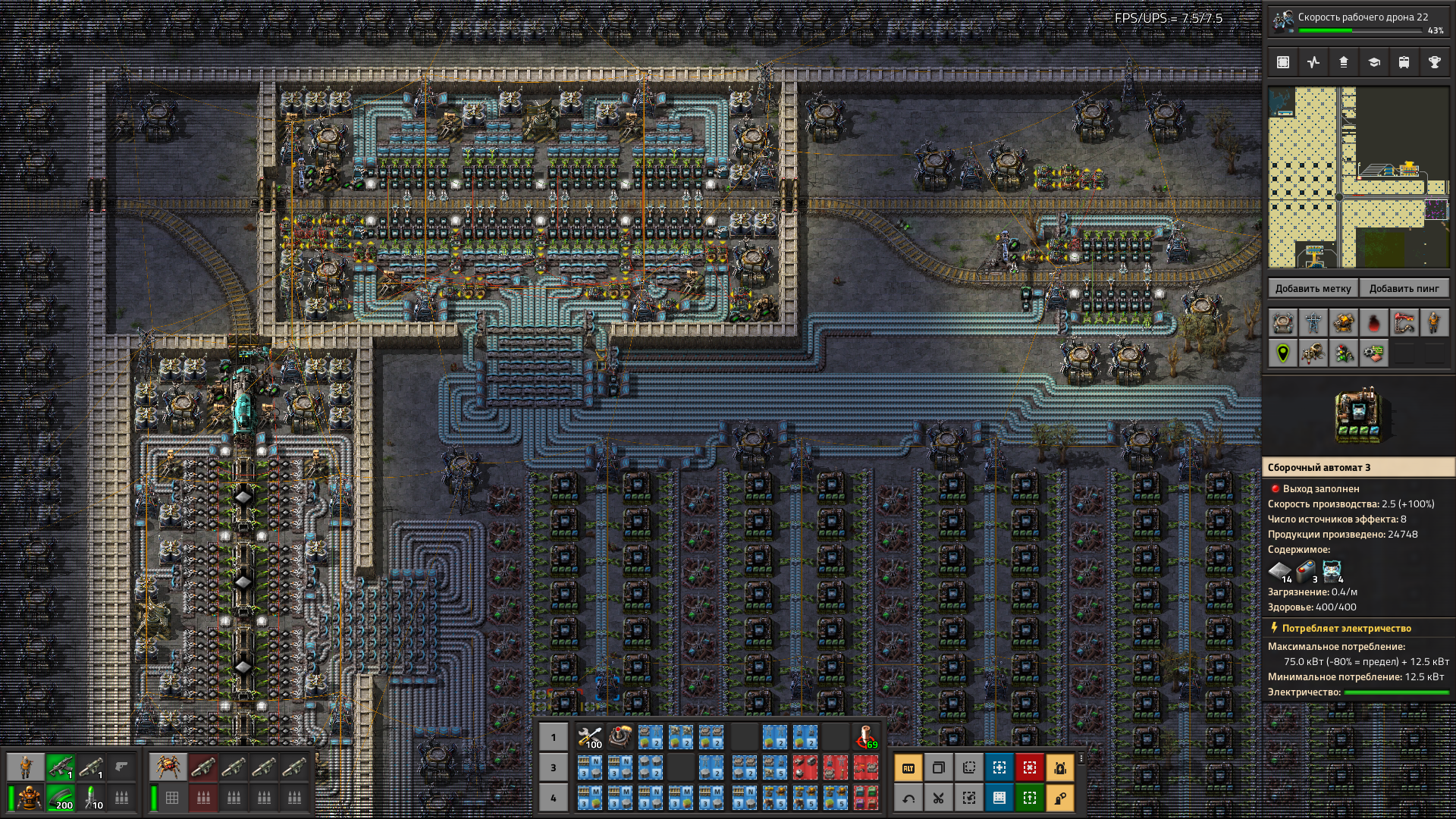

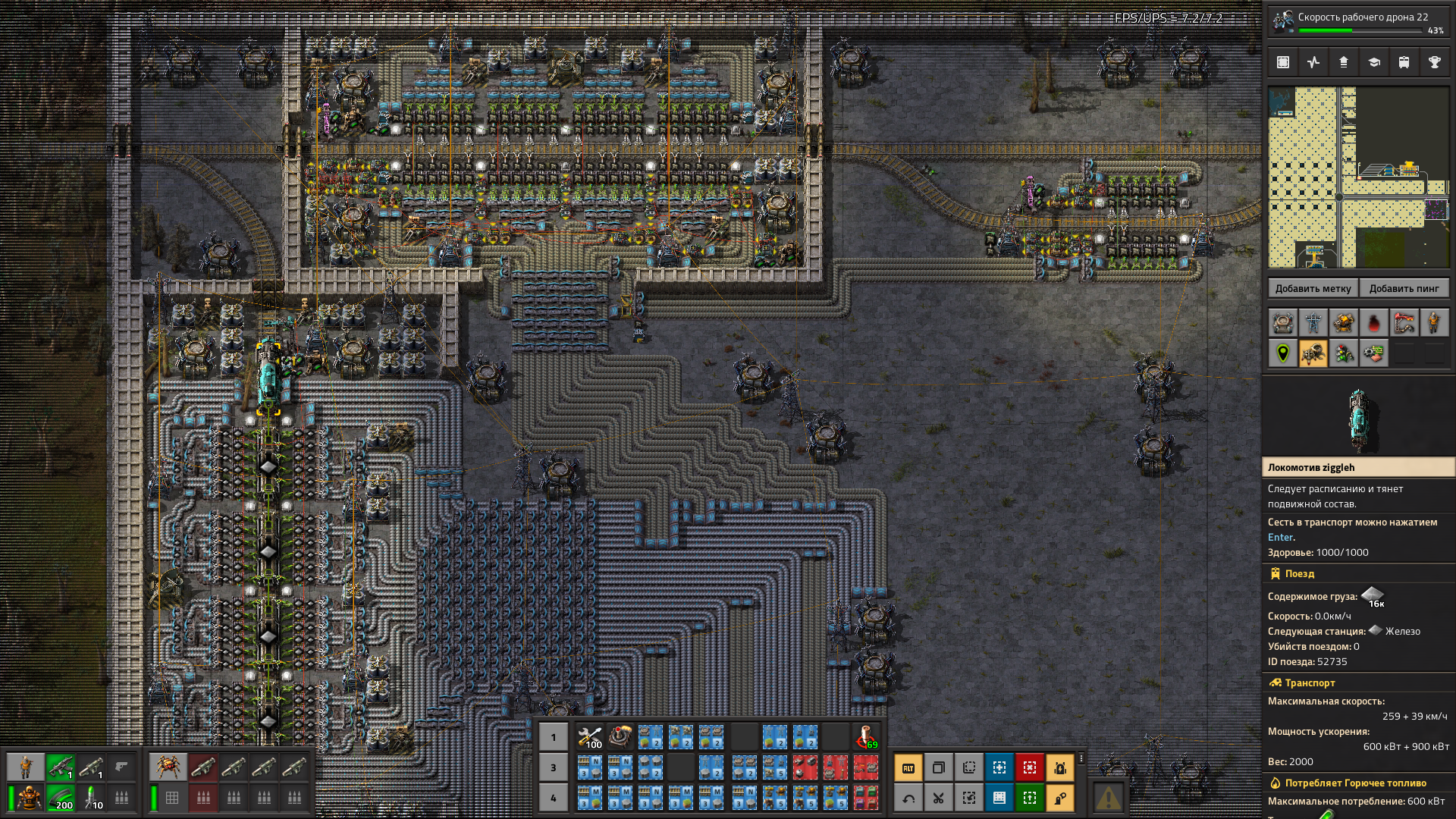

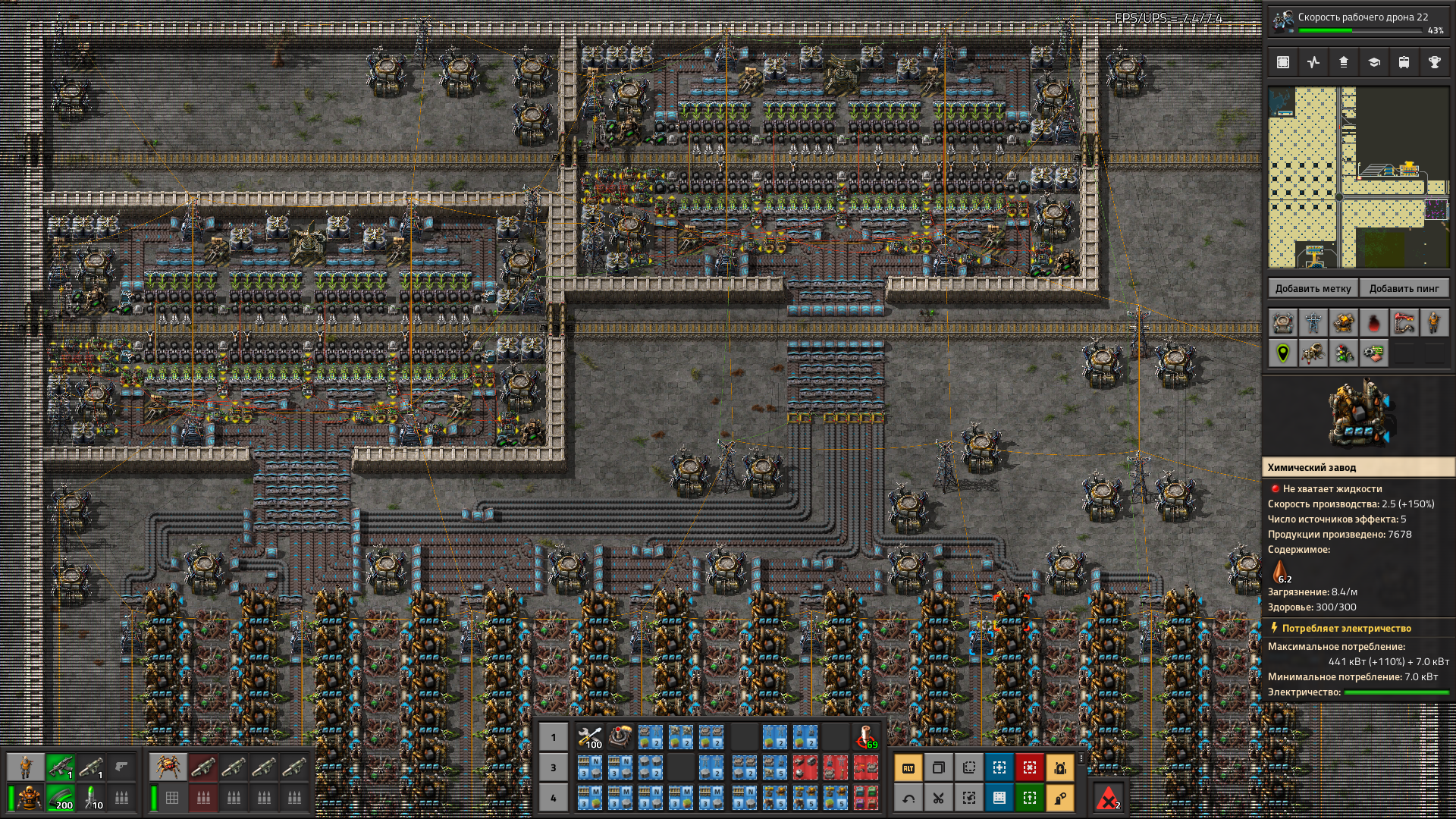

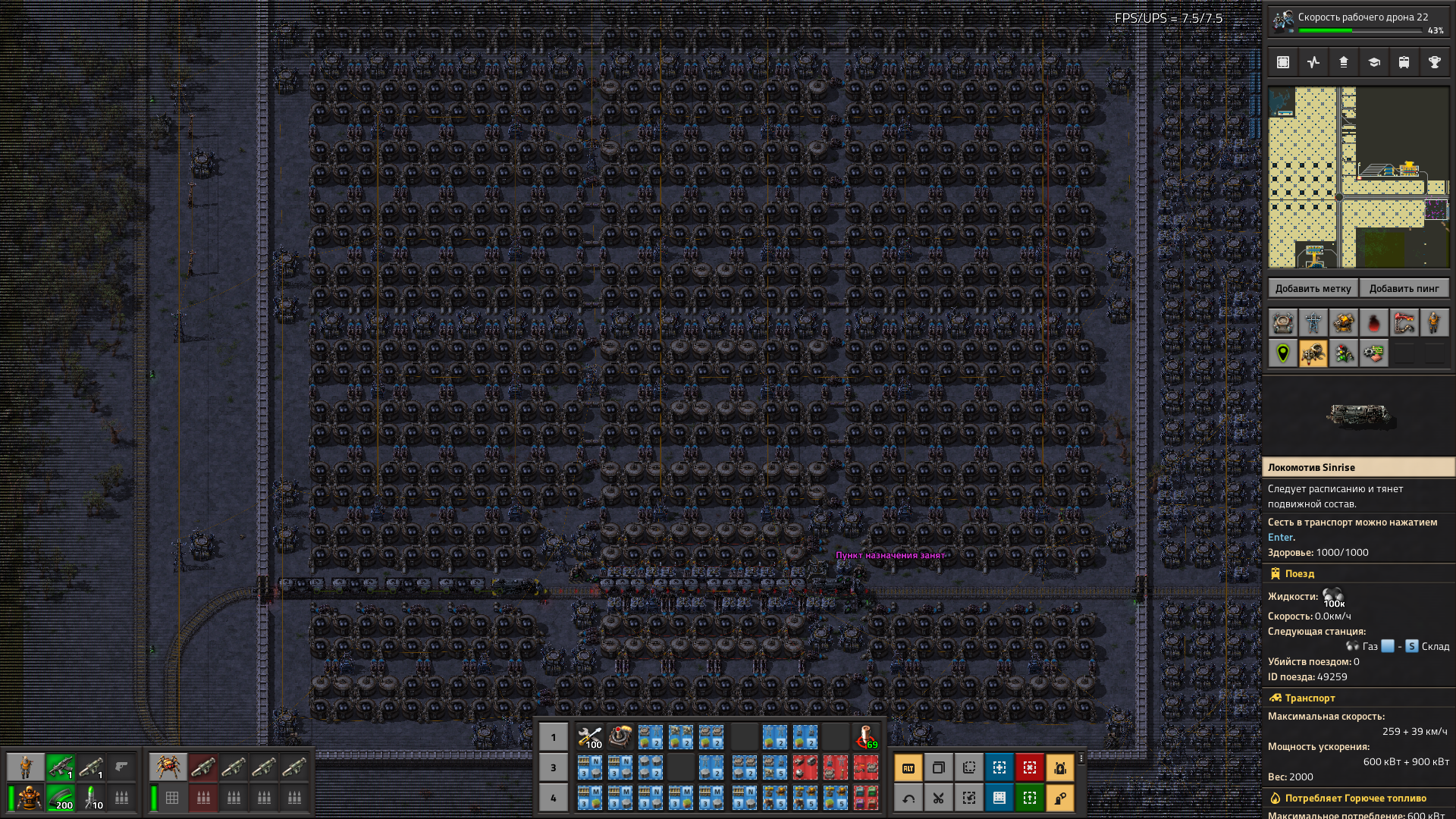

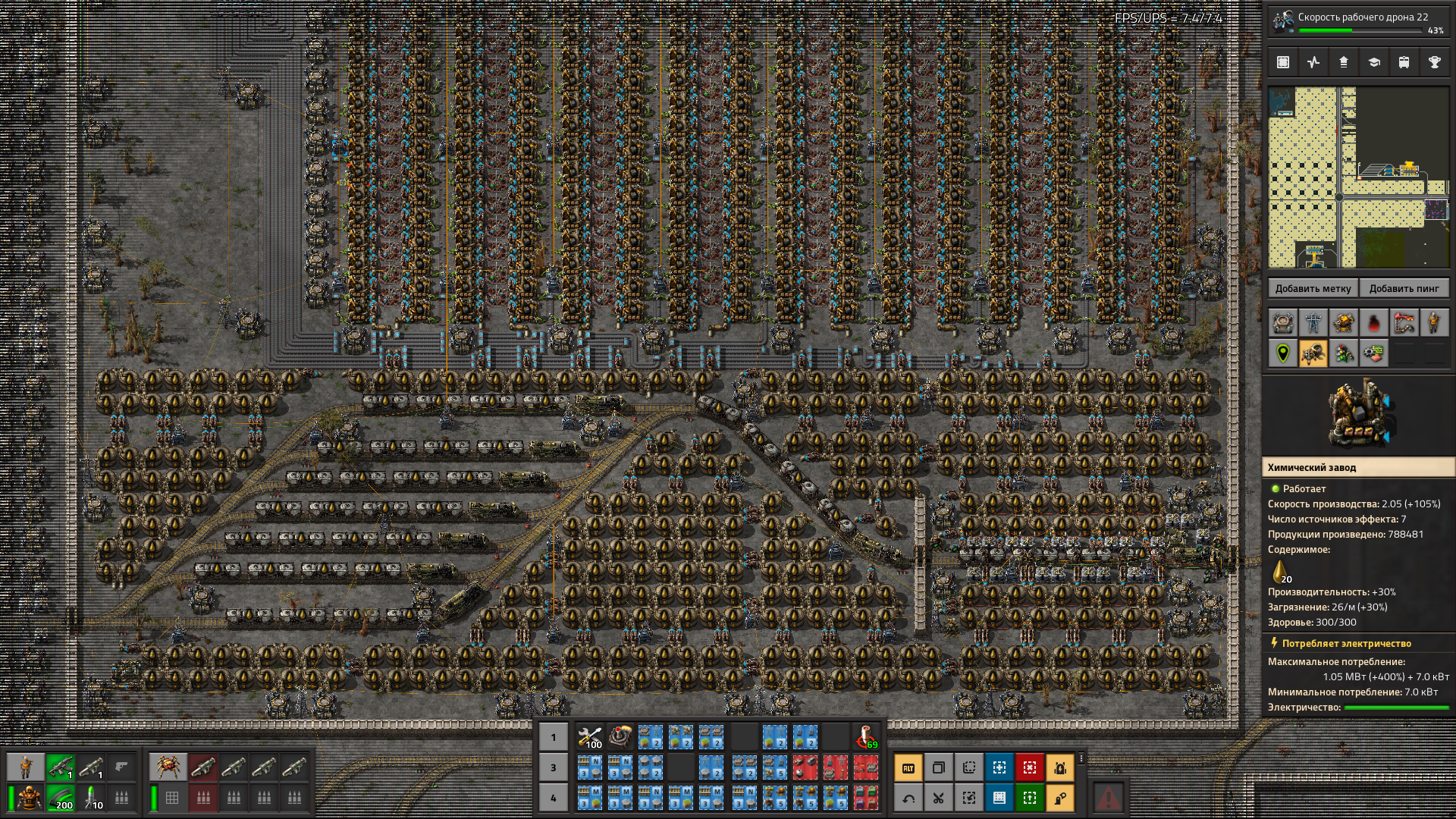

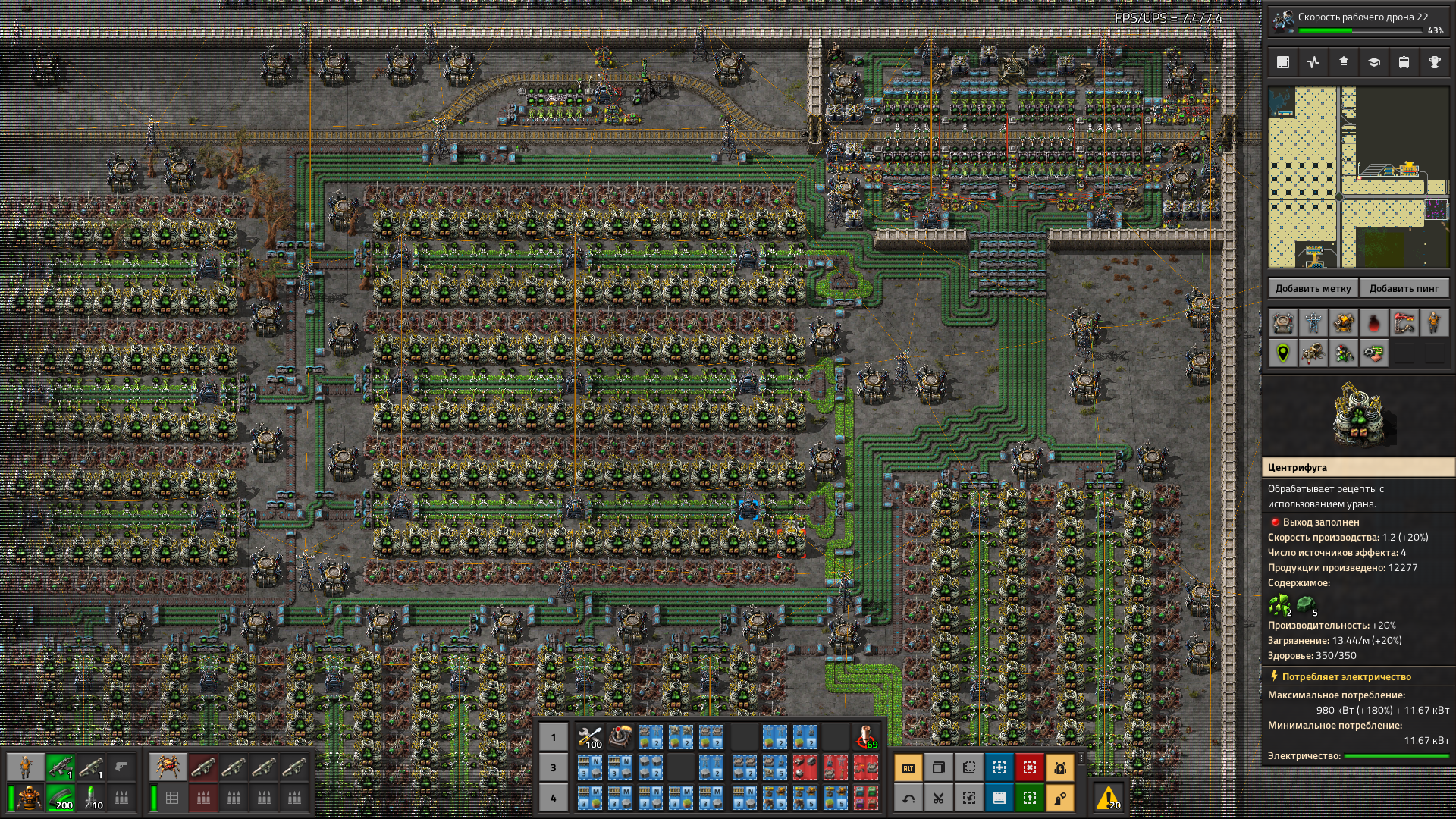

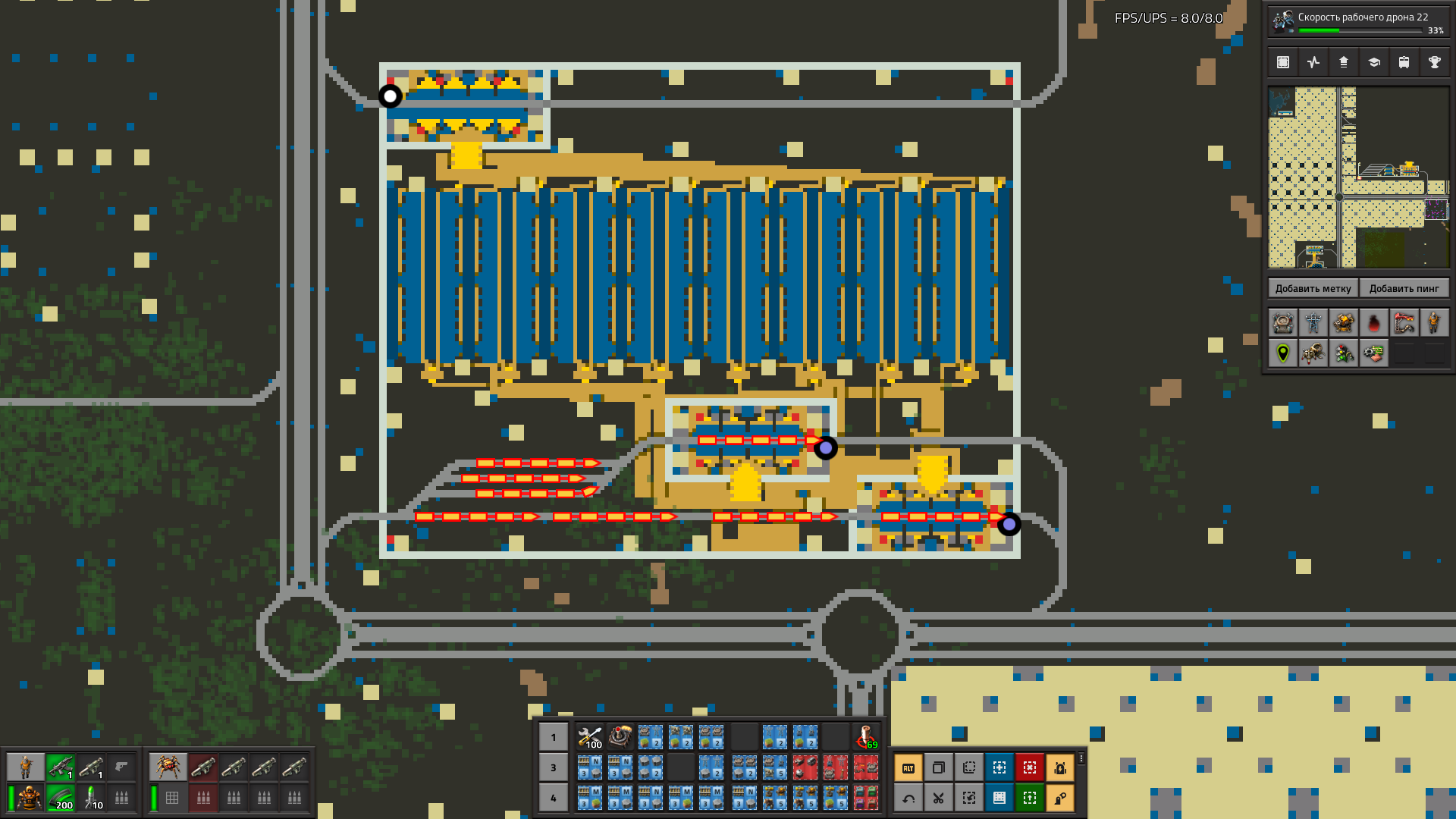

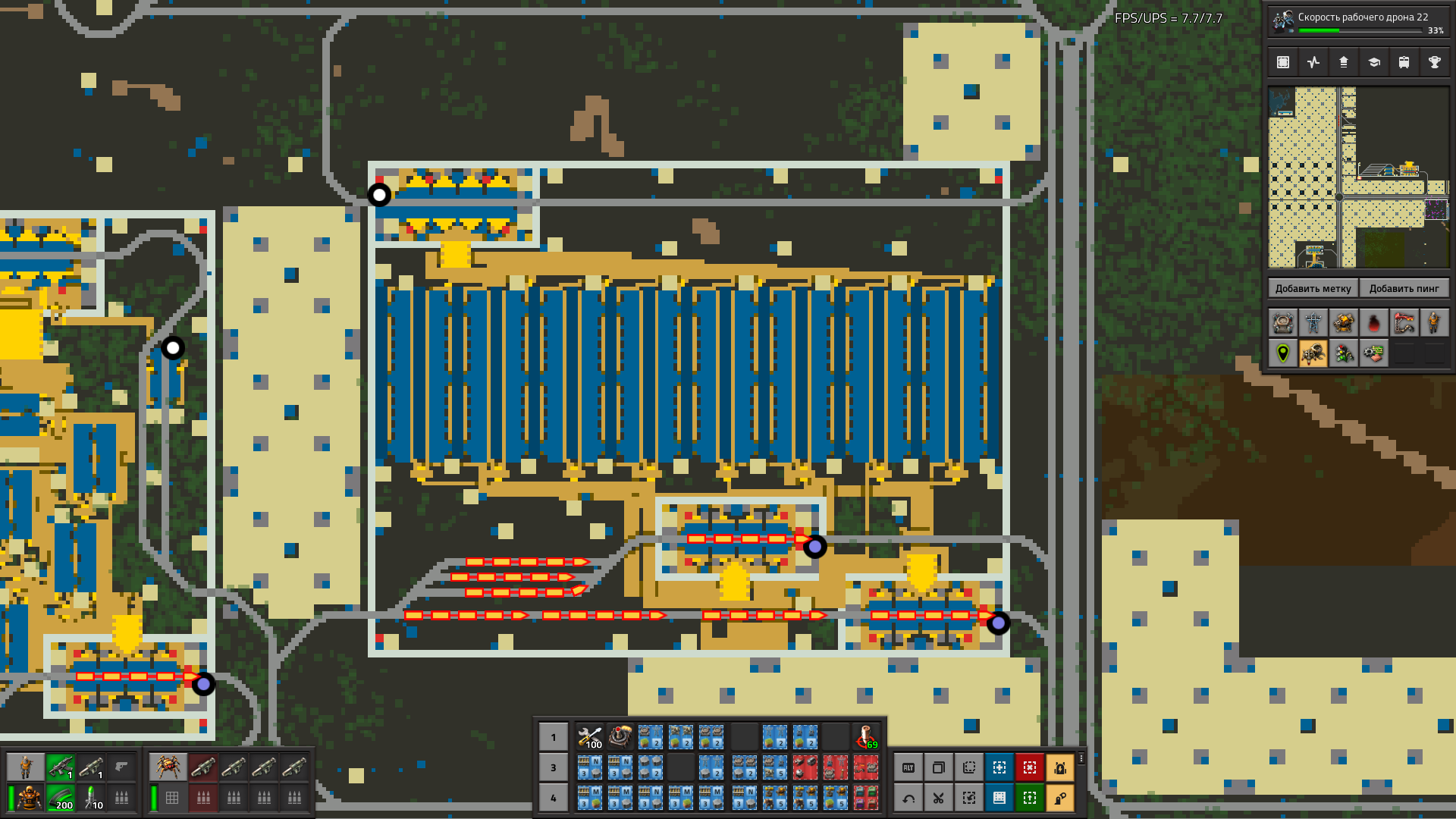

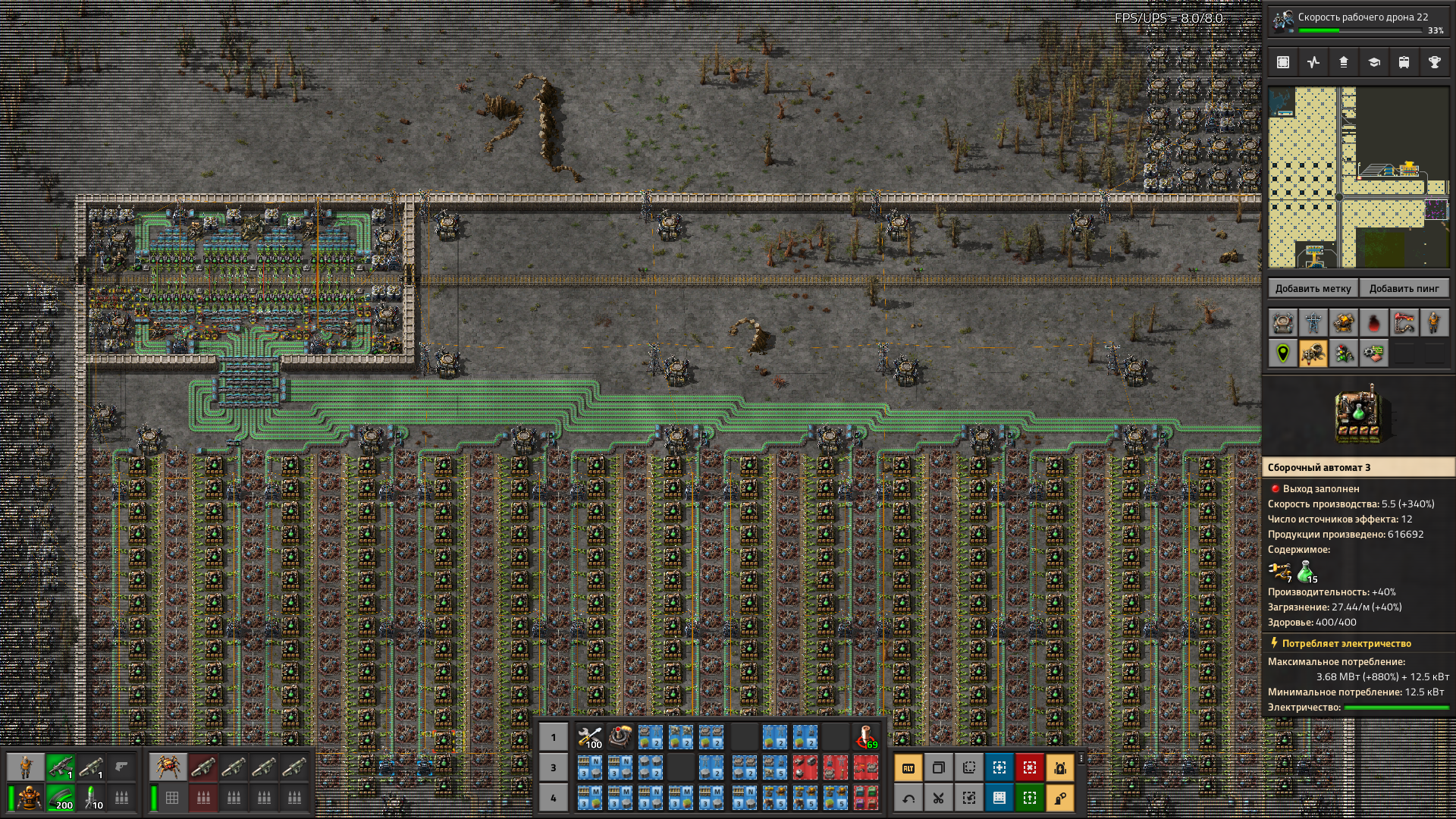

Here are screenshots of performance and electricity consumption

Stations: 2653Trains: 4049

Construction drones: 6.69m

Transport drones: 4.39m

Save-game weighs about 450Mb.

As a map, I chose a railway world with a standard beetle expansion. It was put up a long time ago and of course I won’t play it again, this is the card I have - that’s what I’ll play.

The giga-factory concept includes a lot of rules.

Main rule: The factory must function uninterruptedly, provided that I can leave the computer for a week at any time.

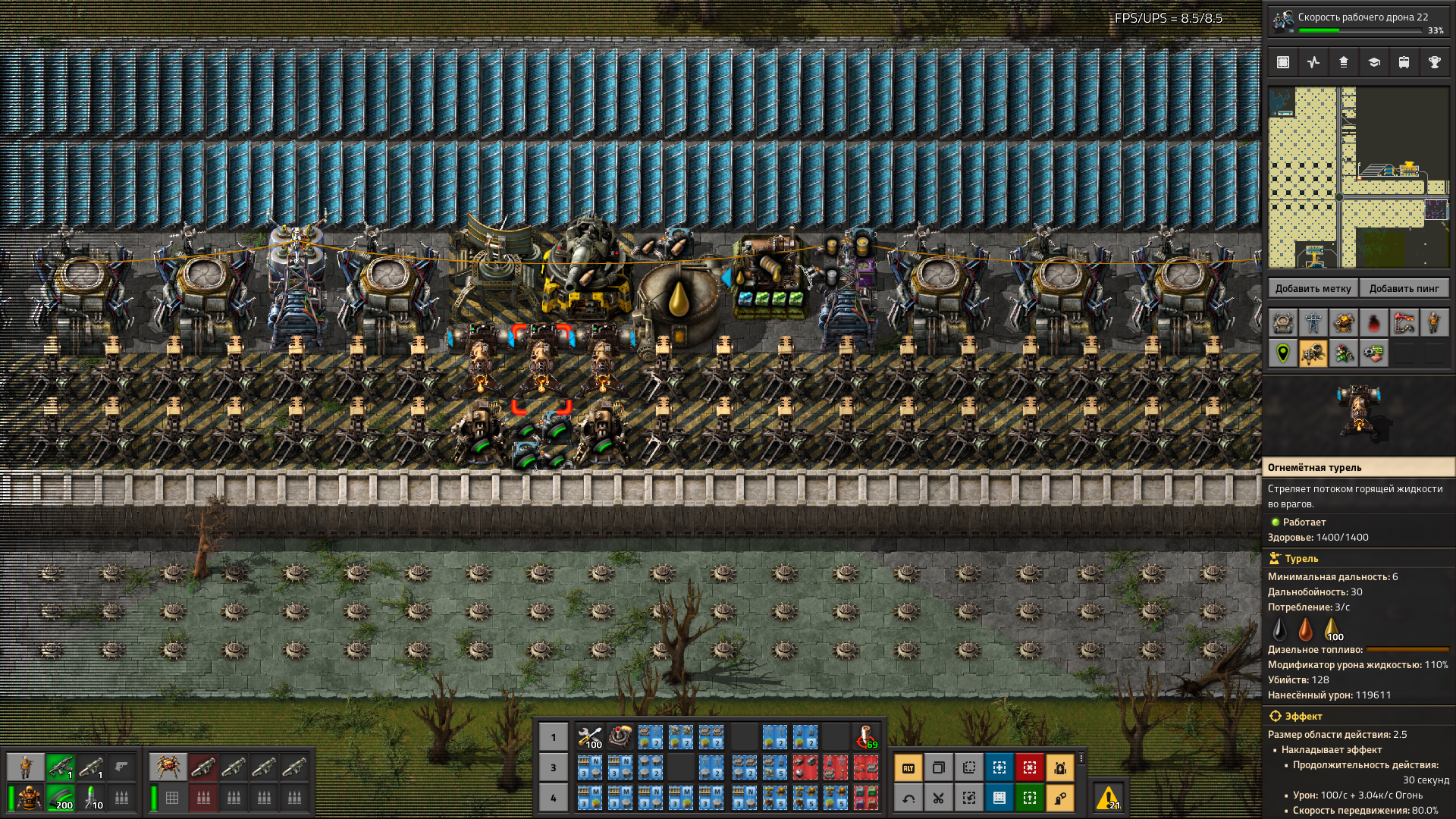

Main rule: Setting up a redundant circular defense perimeter, organizing uninterrupted, fault-tolerant production of everything.

It was determined empirically that absolutely everything that can be produced with productivity must be produced with productivity. Excludes ore of any form.

The explanation is very simple - let's imagine how many resources are needed to produce all 7 science-packs, 1 each. Now let’s take and remove the productivity modules from the laboratory.

It turns out that to produce the same number of science-packs, ALL trains will need to carry 40% more cargo. Now let's imagine at each step of production if we remove the productivity modules. Well, that's the whole answer to the whole question.

Why such a rule with such an exception? Because in such a factory one of the most problematic areas is railroad logistics and it is very important that

- There would be fewer trains.

- Trains would travel as loaded as possible.

- Production of everything that is directly needed for the production of all types of science-packs.

- Production of everything needed to provide the factory with consumables.

- Production of everything defense related factory.

- Production of everything related to the expansion of the factory.

- Production of everything related to the development of occupied territories.

I conducted tests in 1 wagon, 3 wagons and 4 wagons. On the one hand, the fewer wagons there are, the faster the train accelerates. But often in such a huge factory the train simply travels at maximum speed for quite a long time.

On the other hand, the more wagons, the faster you can unload at a time. From the blueprints you will see further that it is very important to have an even number of wagons. For unloading speed.

You can also consider setups like 2 locomotives and 8 wagons, but I believe that this cannot be done - because even one such train will wait at intersections for too long.

As a result, I chose that most trains will have four wagons, and some trains will have one wagon.

Main rule: that if some workshop has been idle for quite a long time and the train is not full, then the trains are still sent out in order to stand idle while being full.

This rule is implemented differently for warehouse trains, production trains, and liquid trains. But this idea is implemented in all trains without exception.

Main rule:

Of course, almost everything at such a factory is delivered by train. For drones, only this is provided:

- Nuclear fuel for trains.

- Stores for turrets.

- Artillery shells.

- Diesel barrels for flamethrowers and empty barrels.

There is a separate workshop for equipment, more about it at the end of this post.

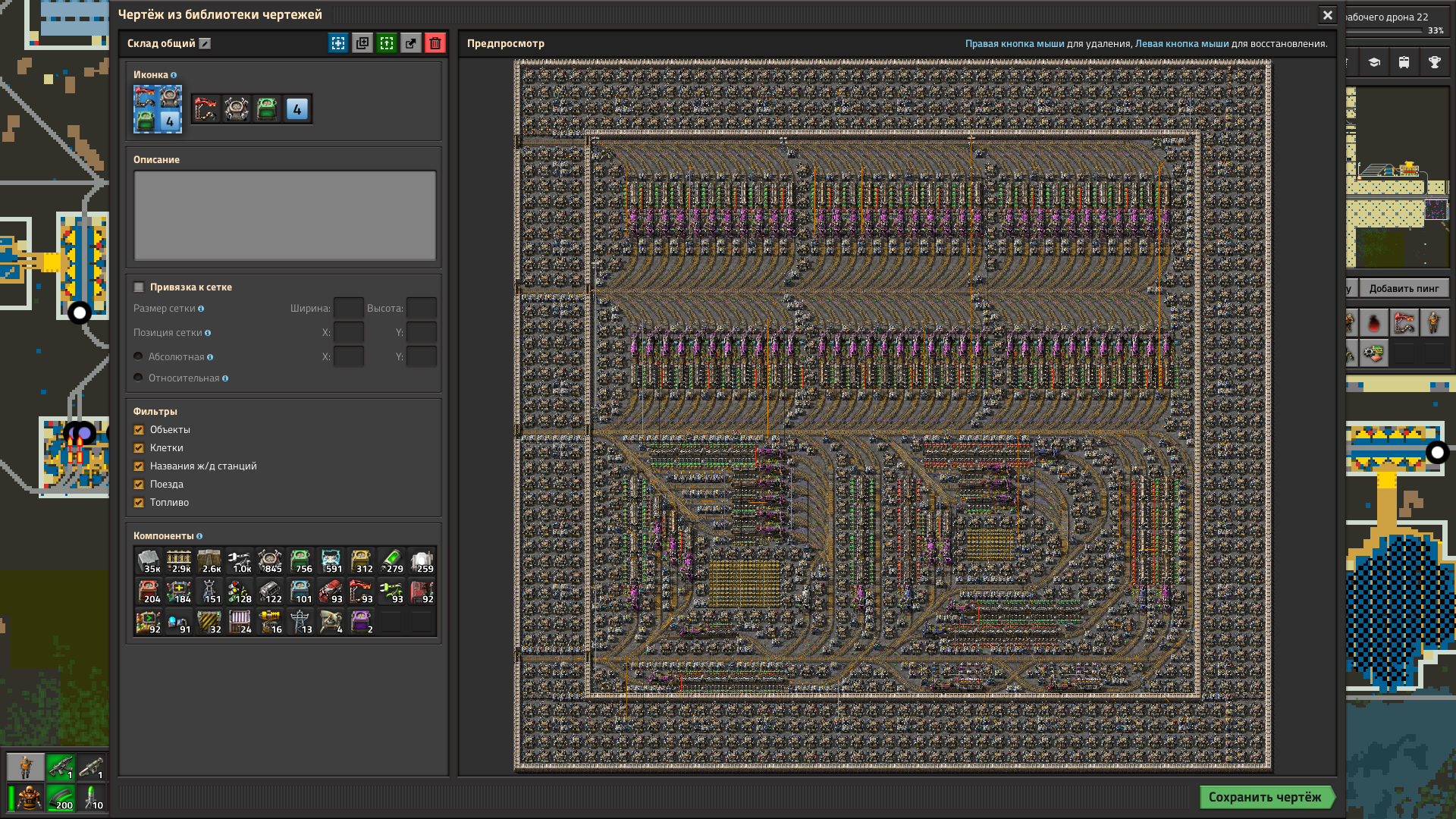

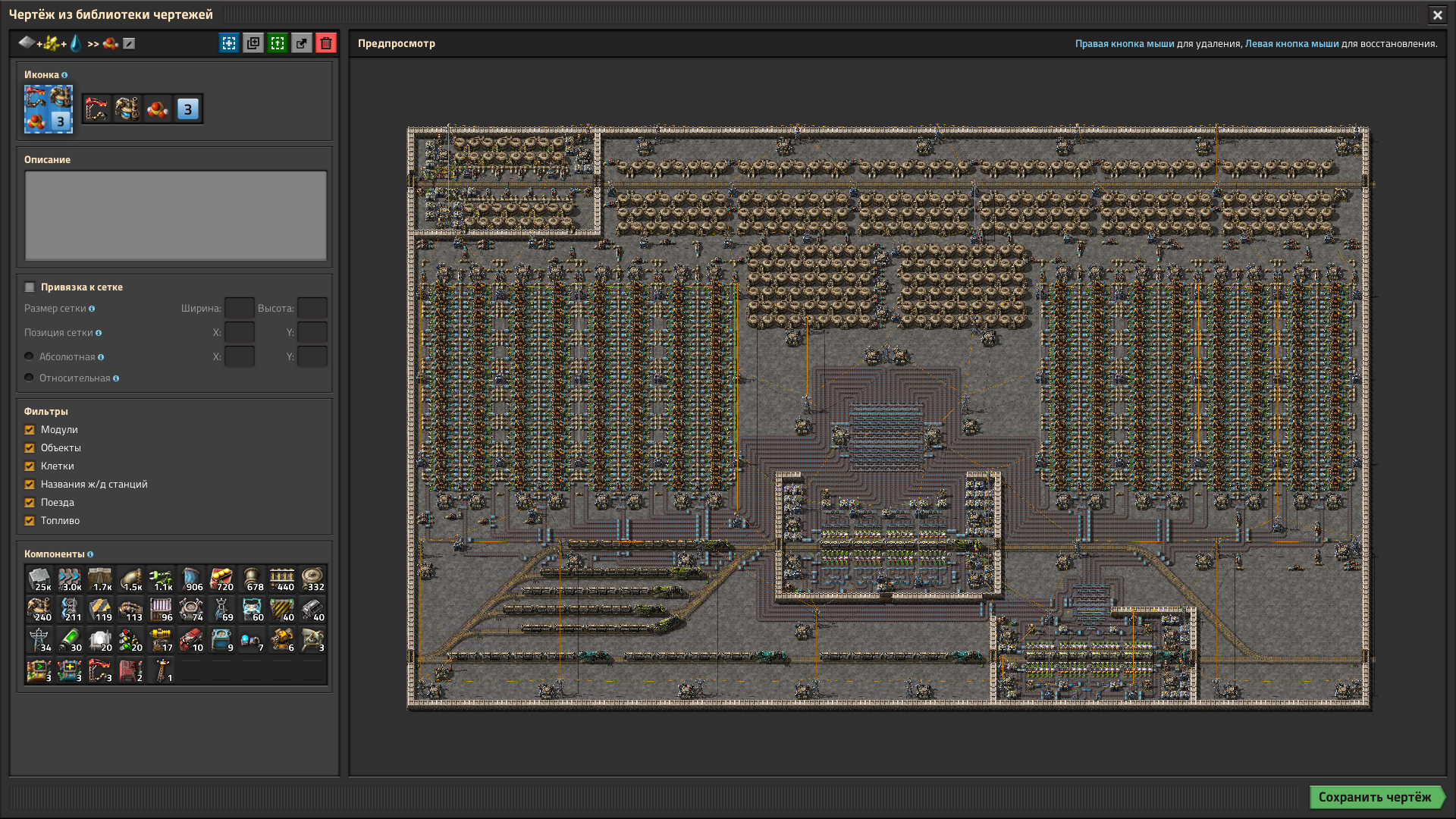

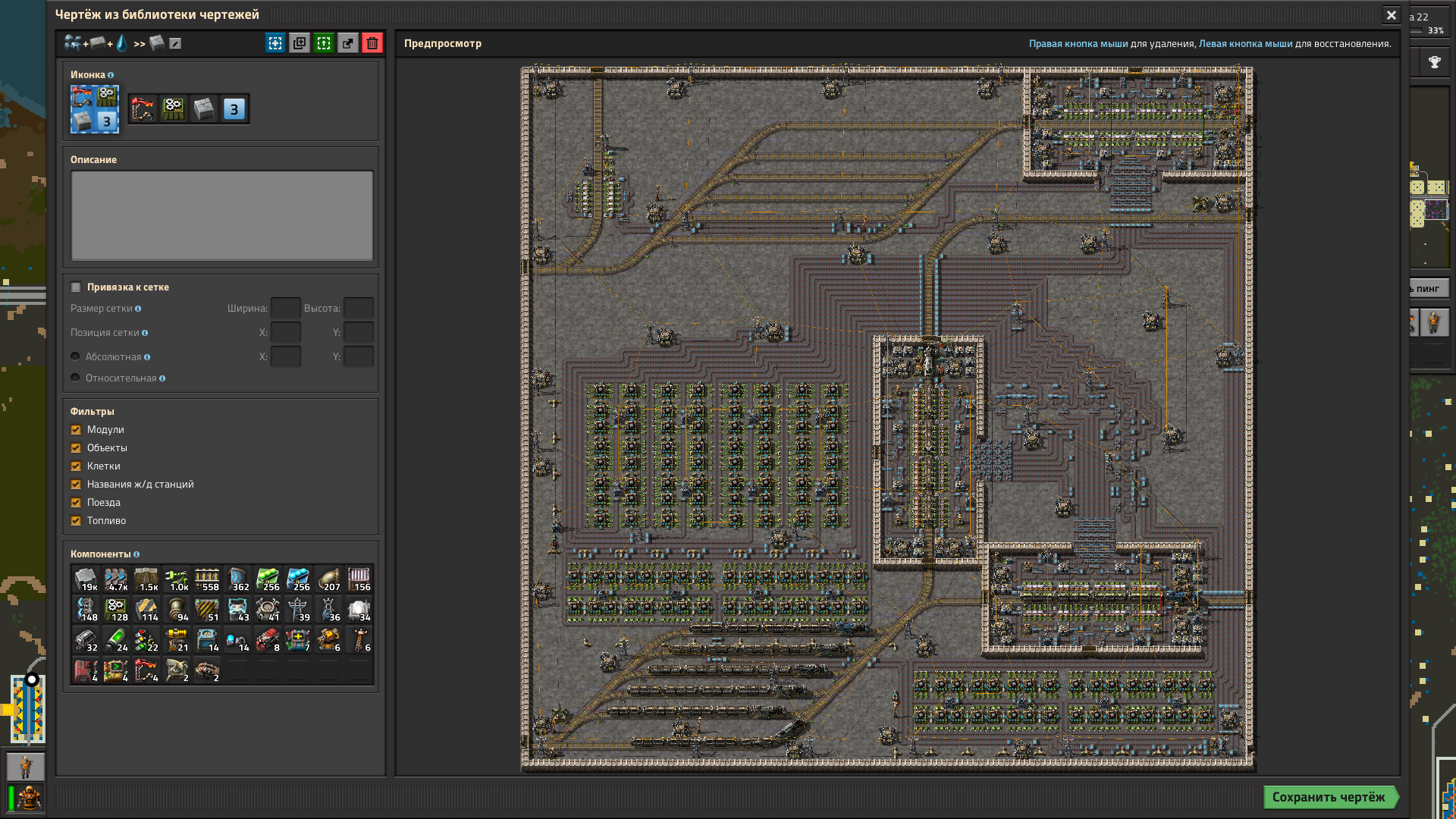

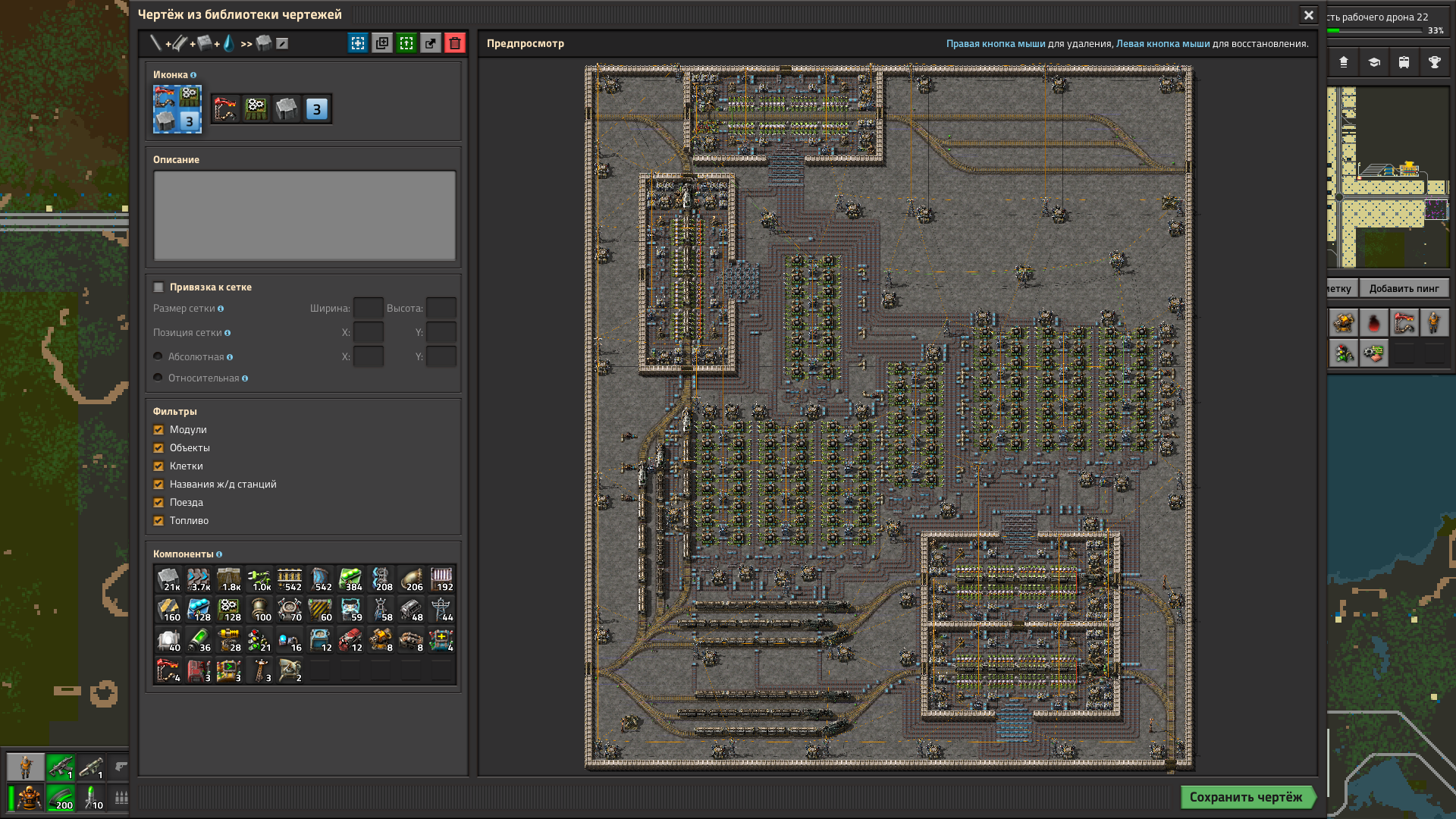

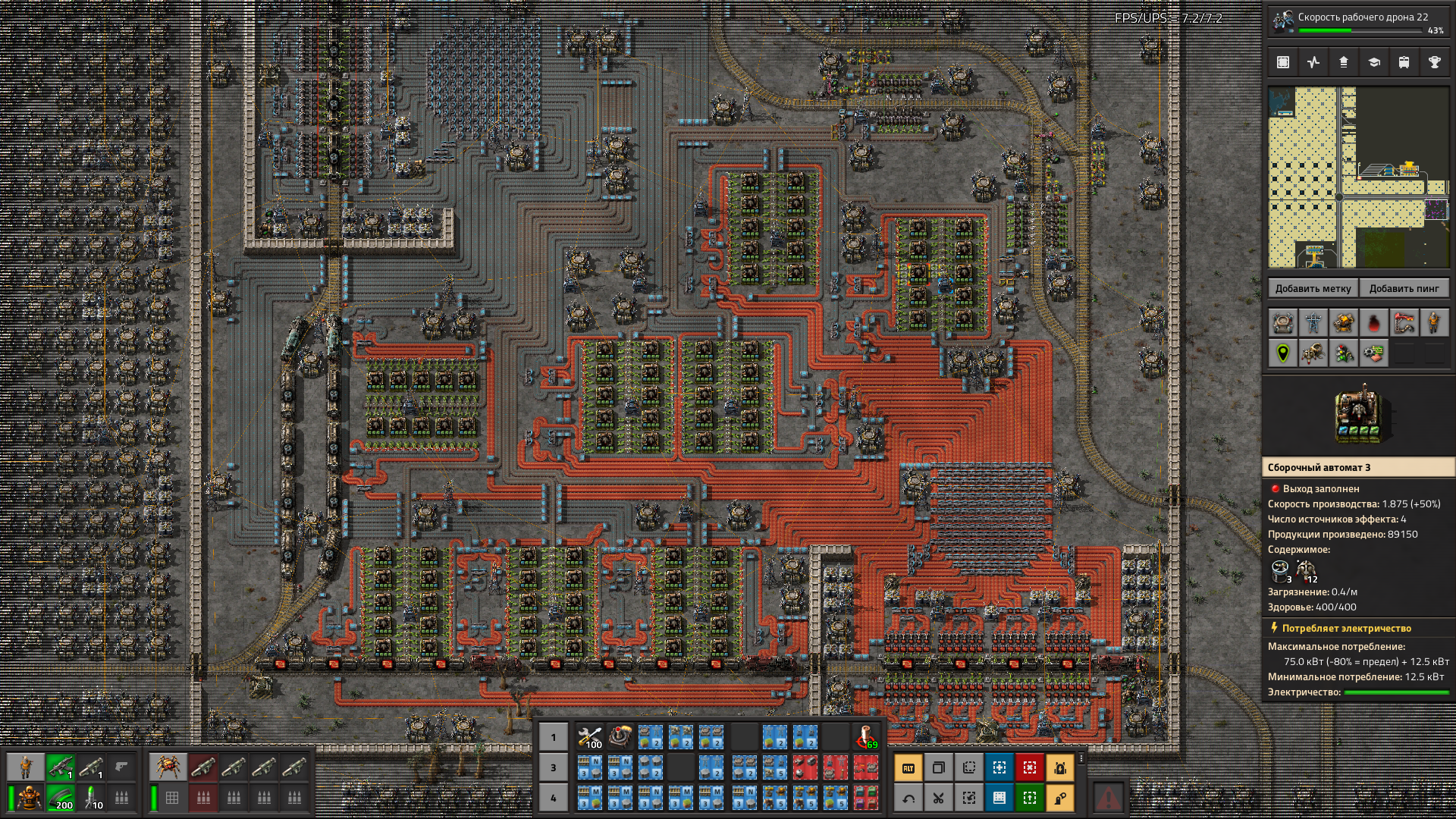

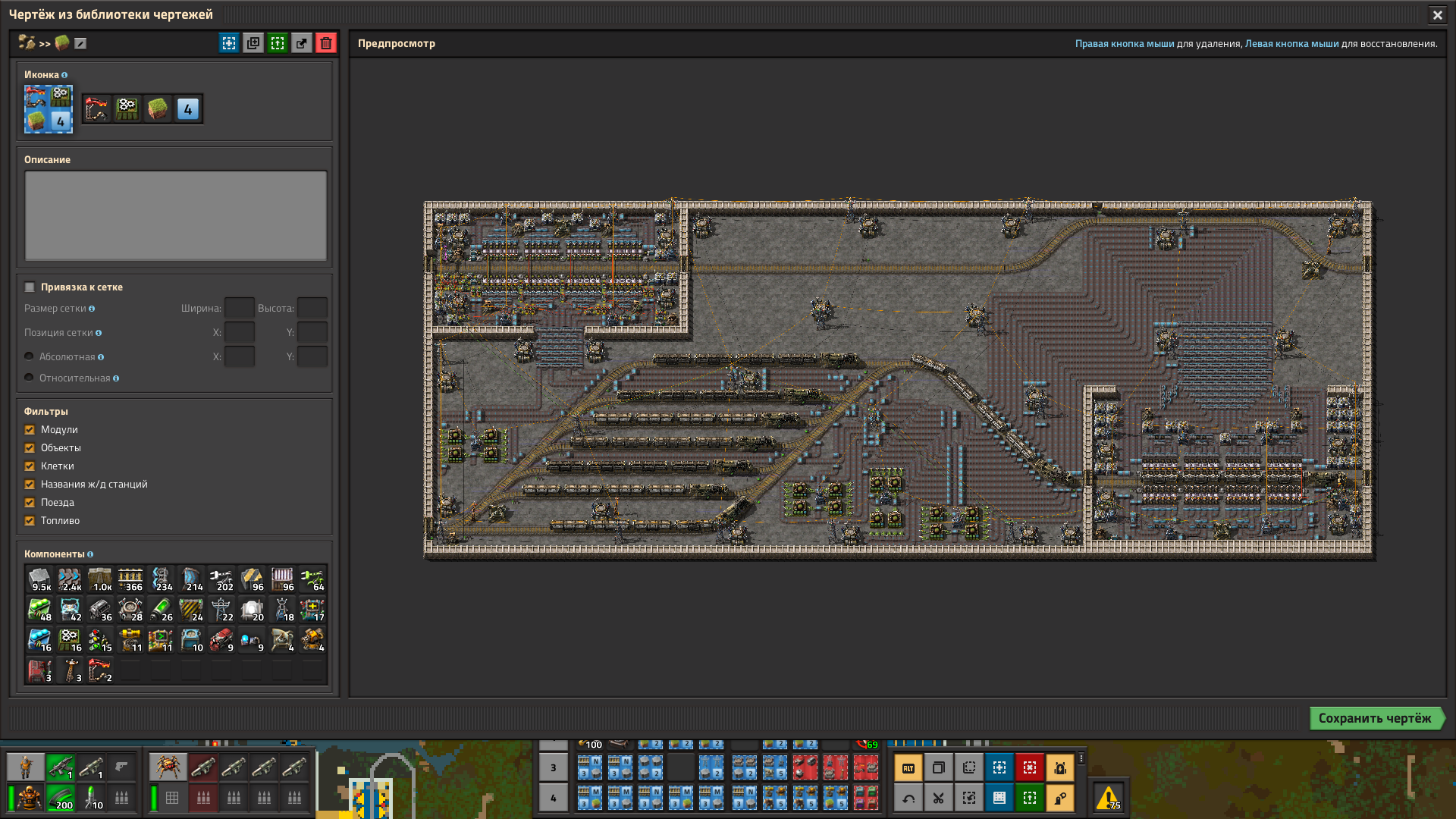

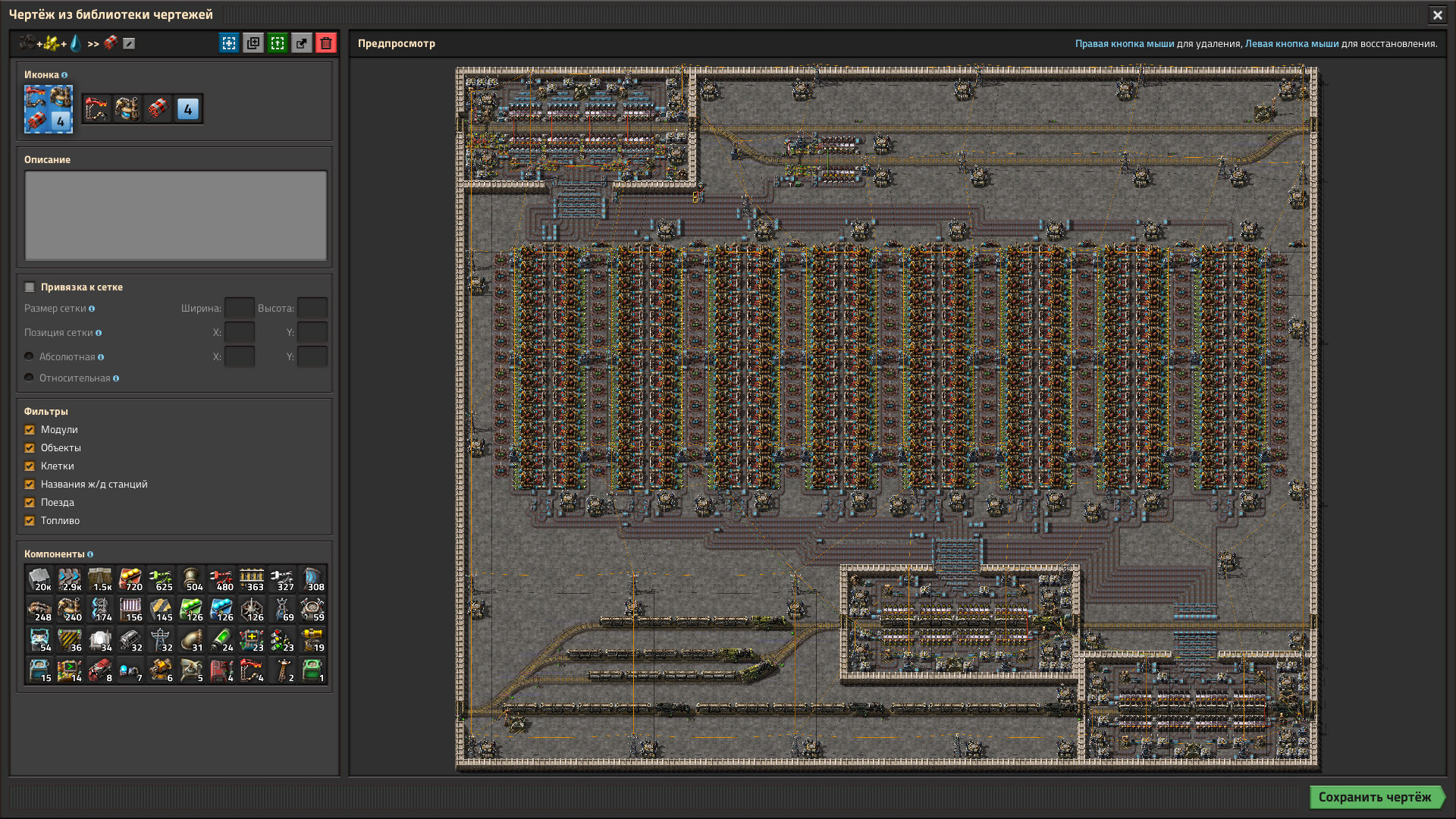

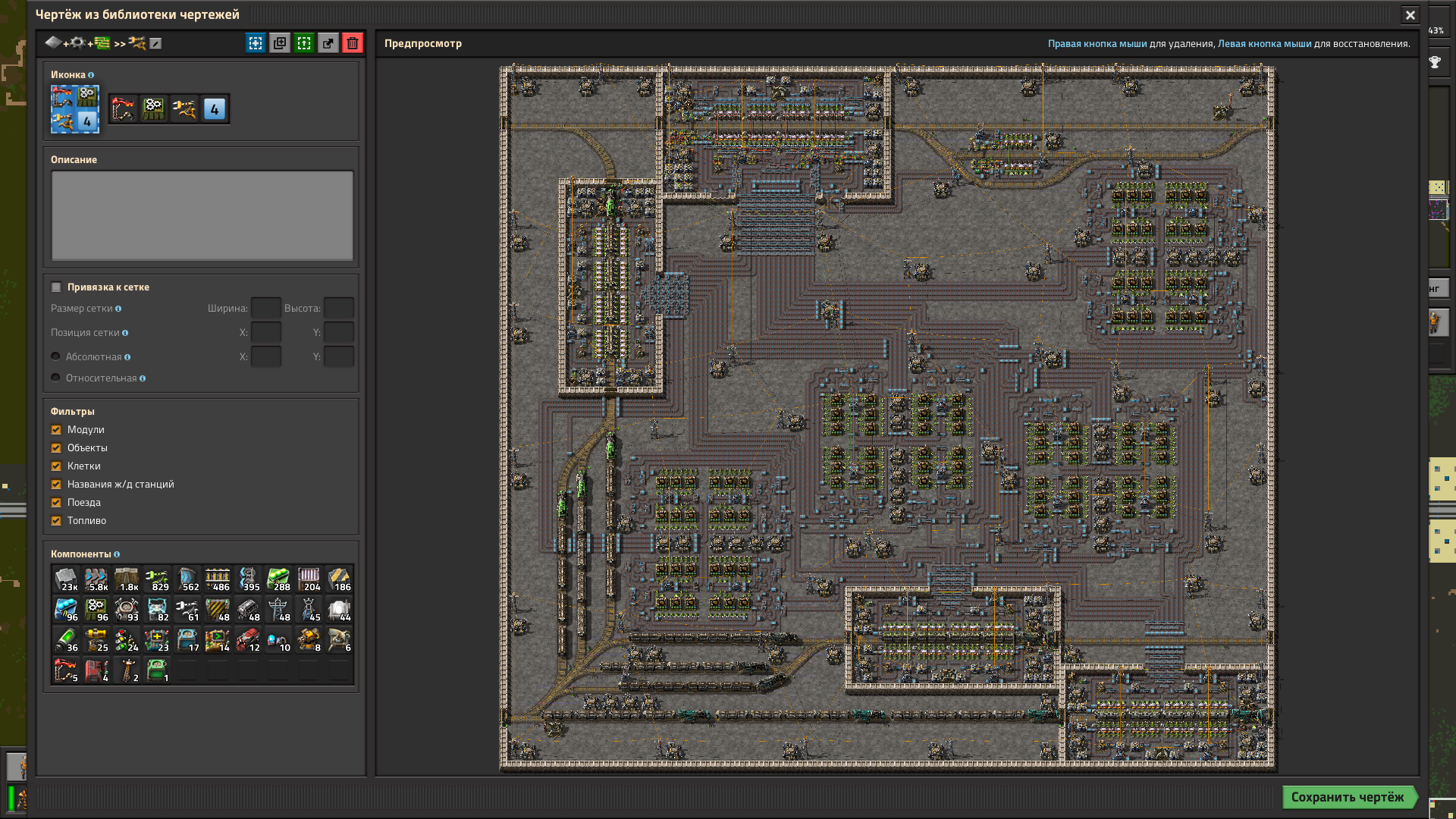

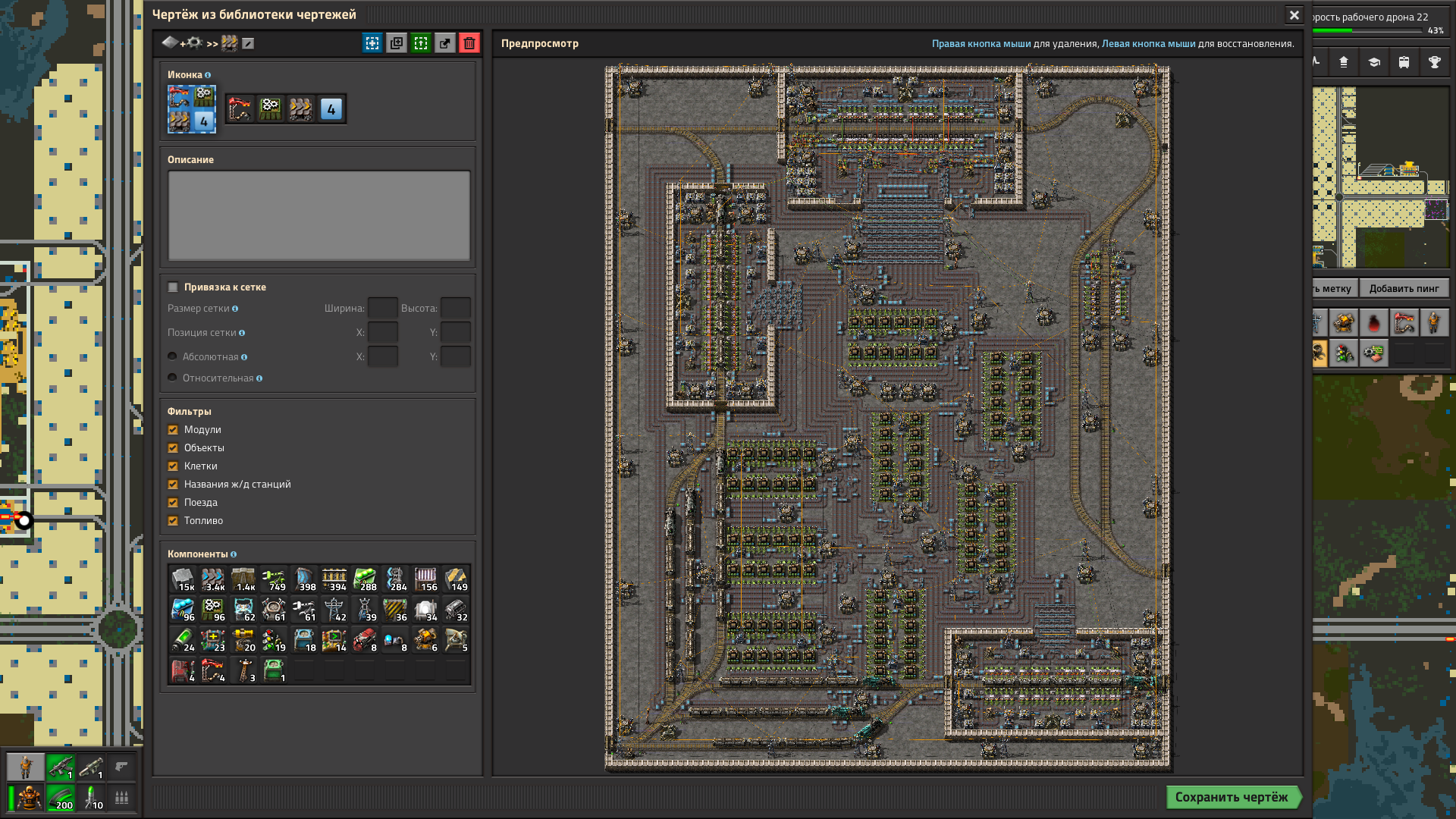

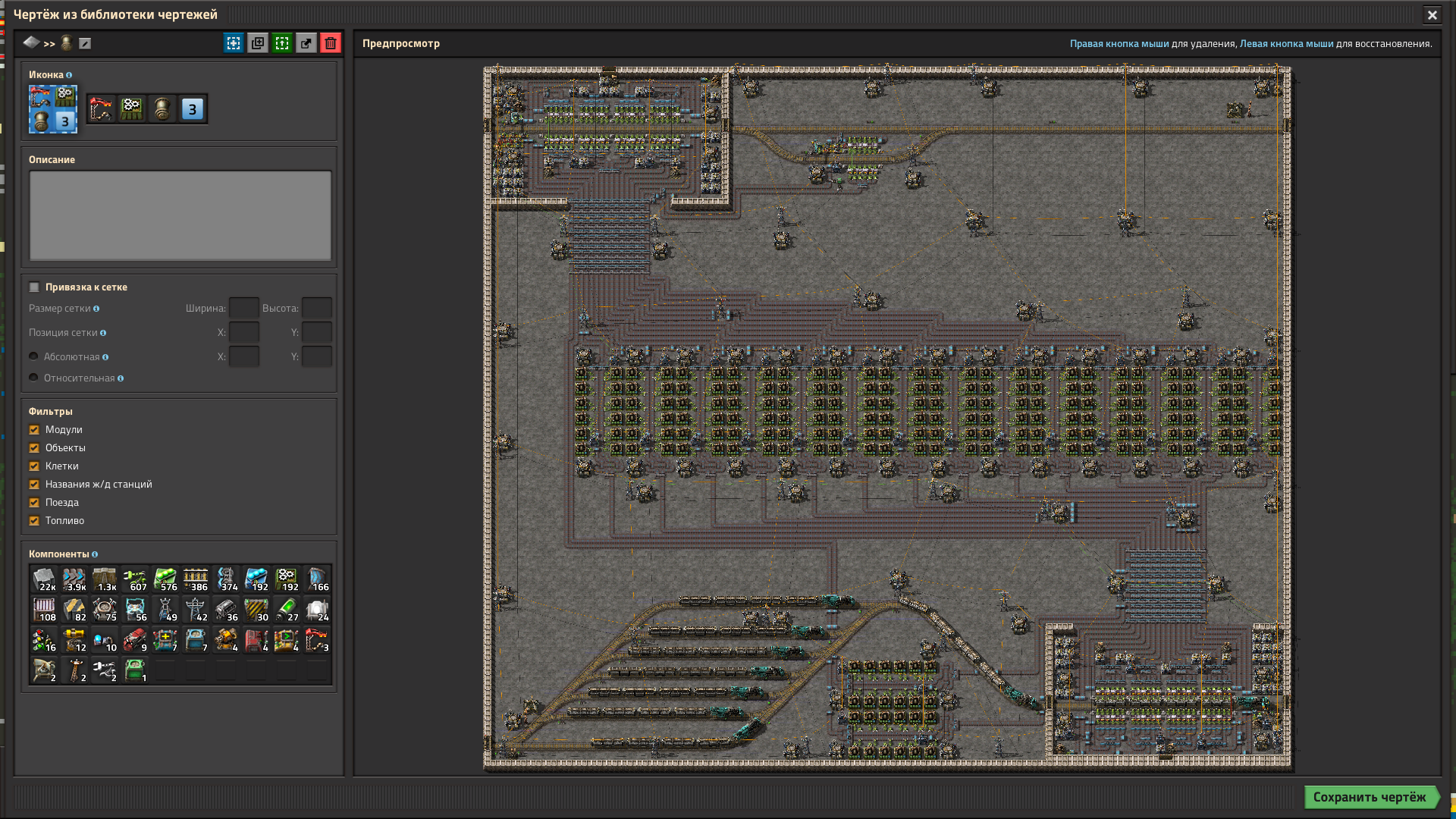

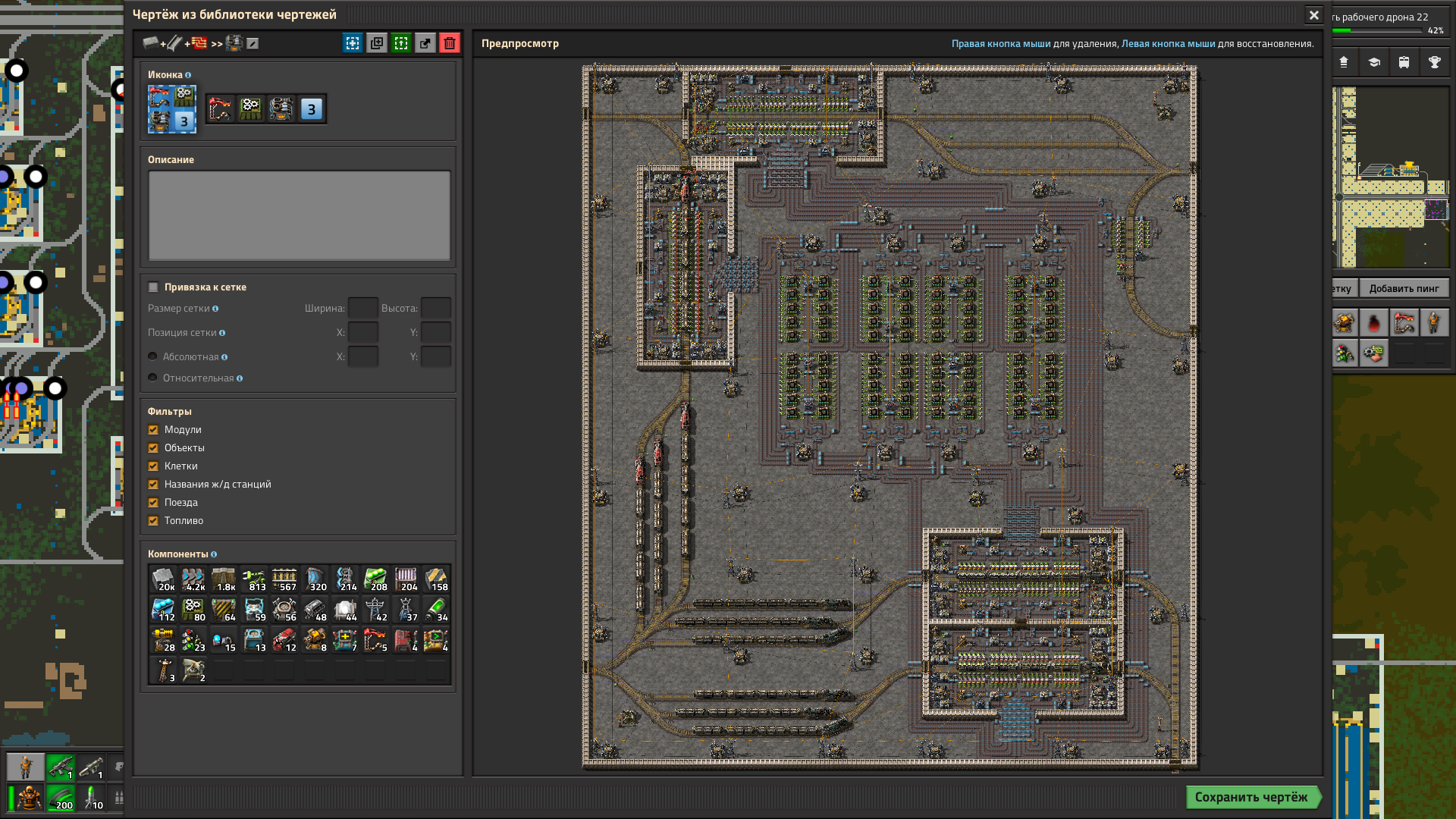

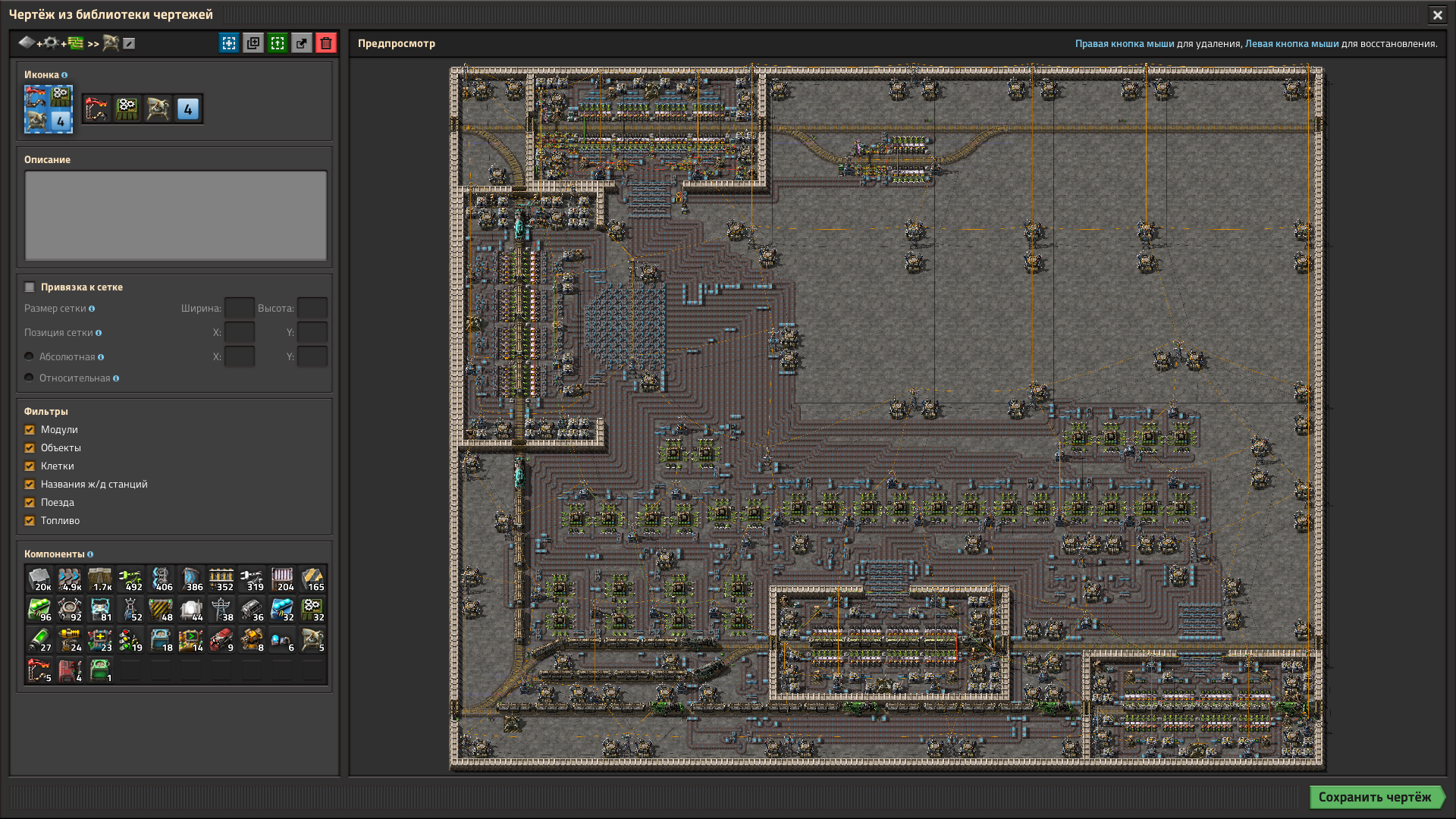

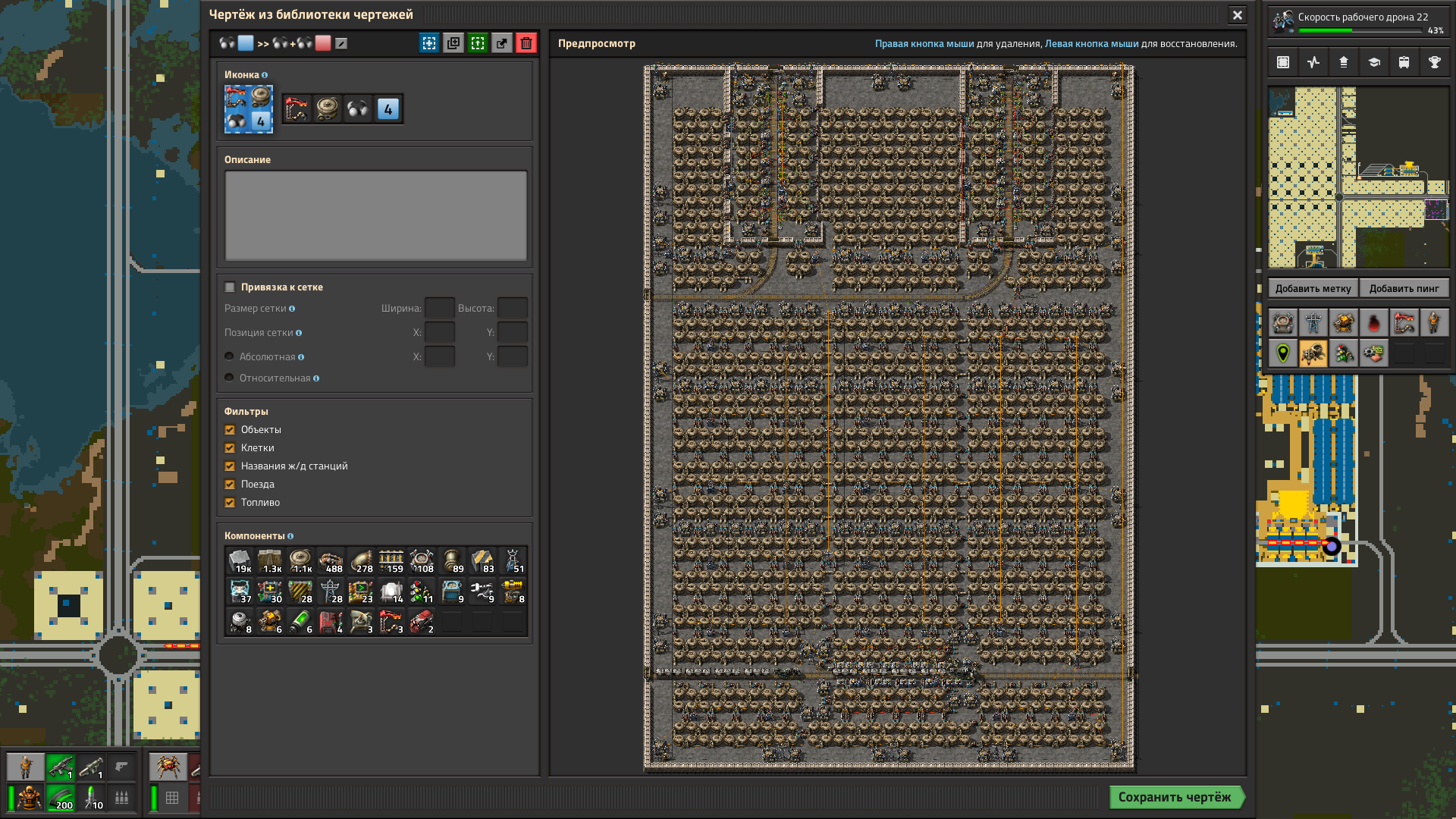

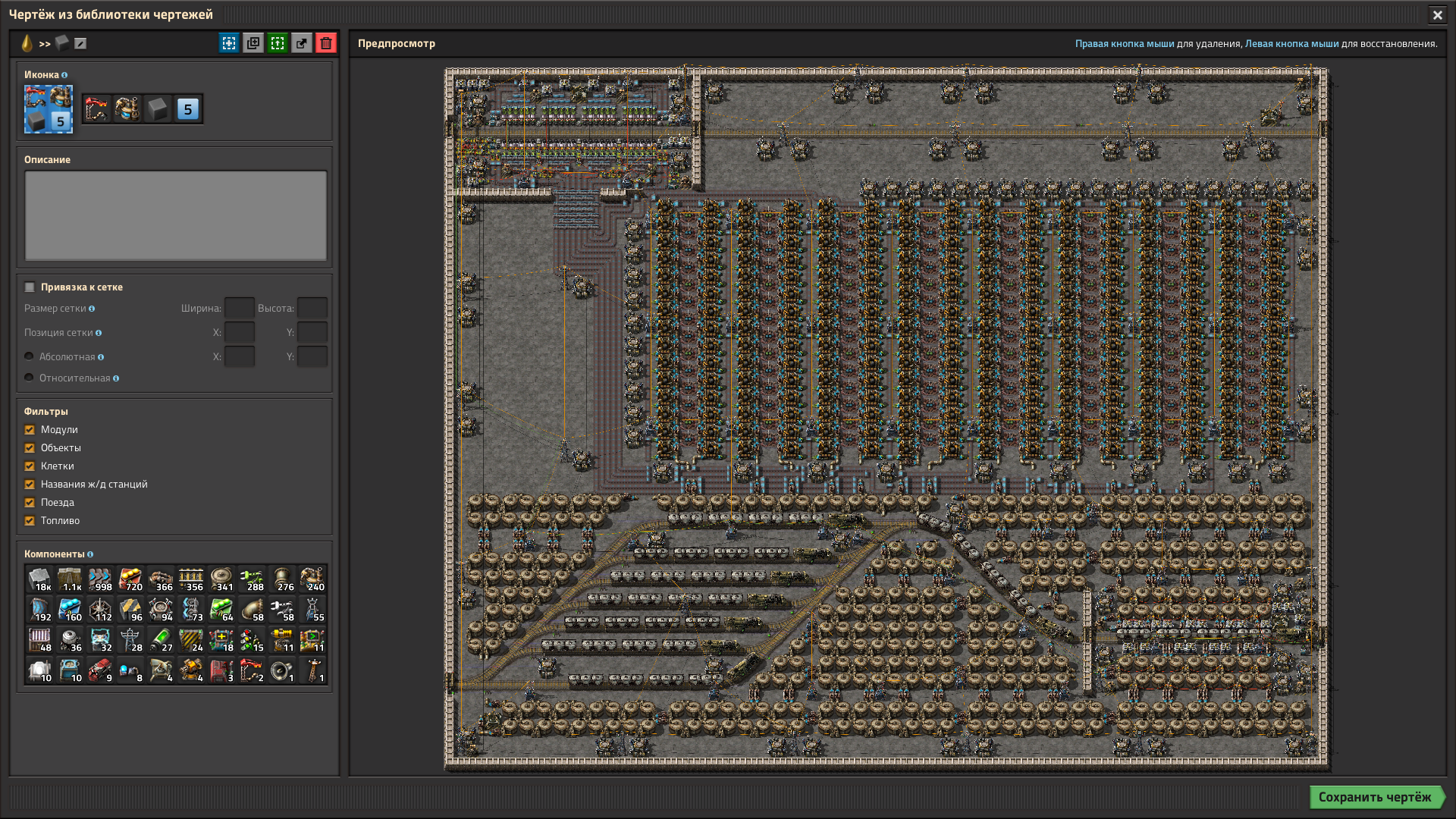

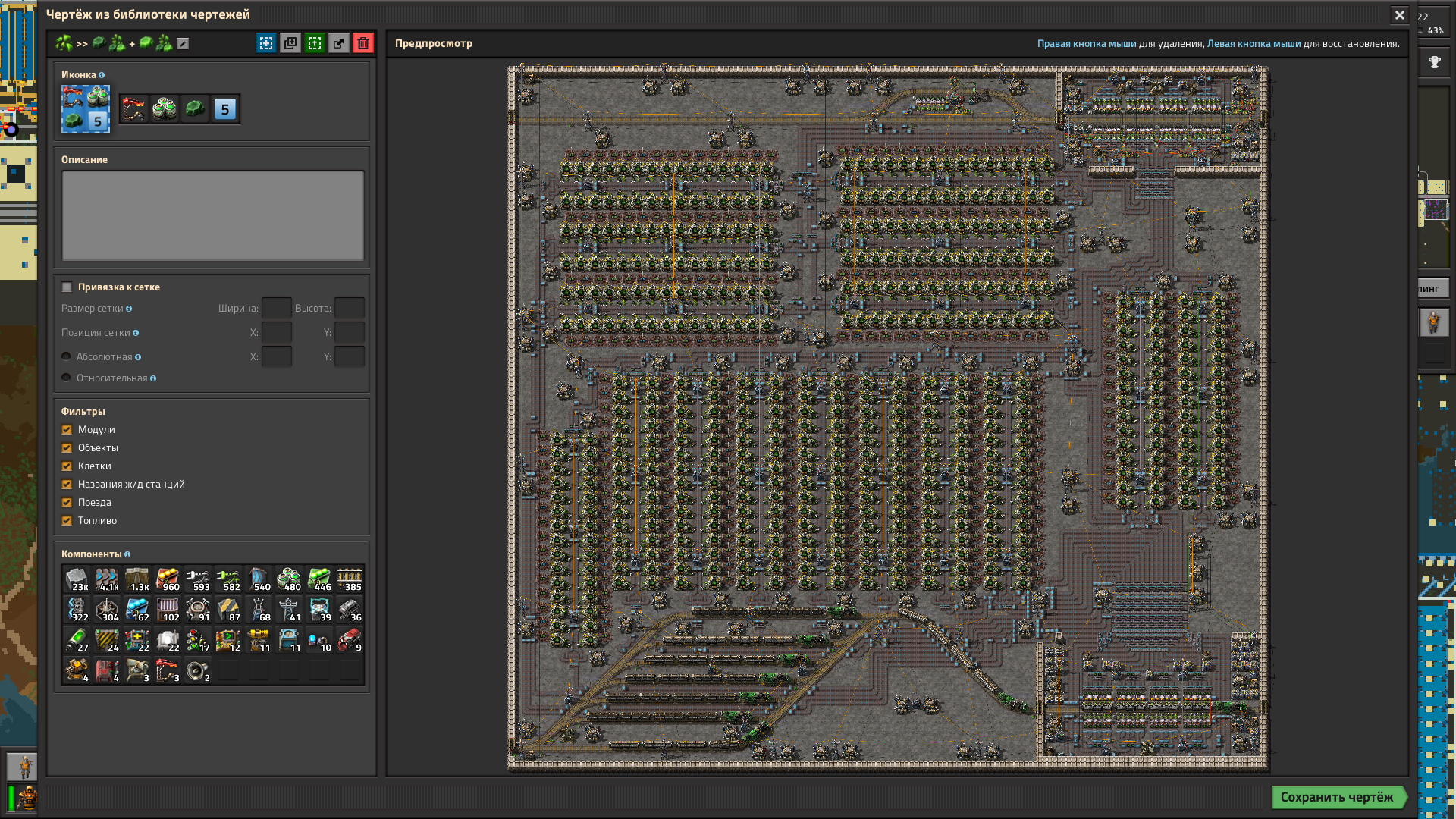

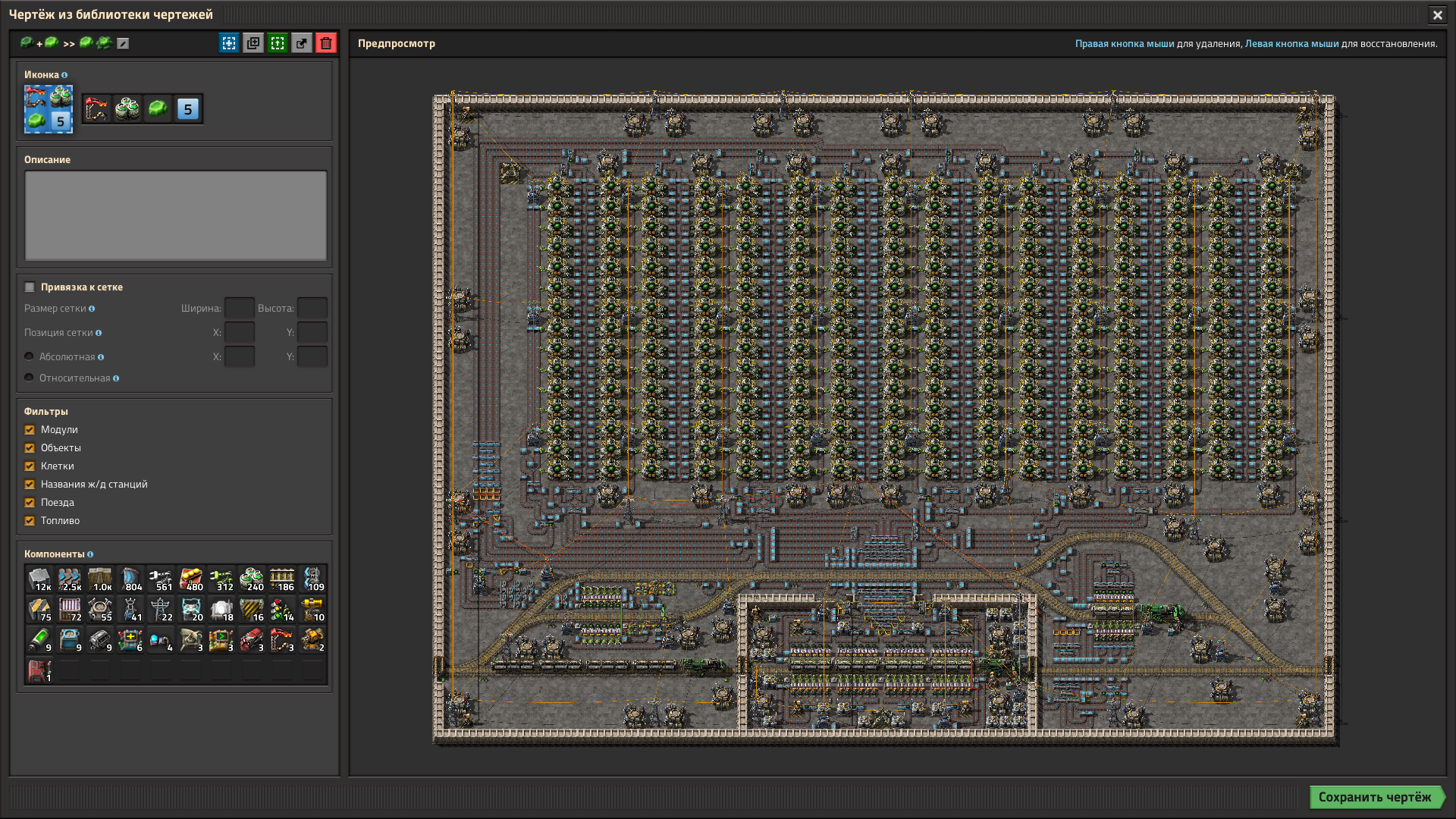

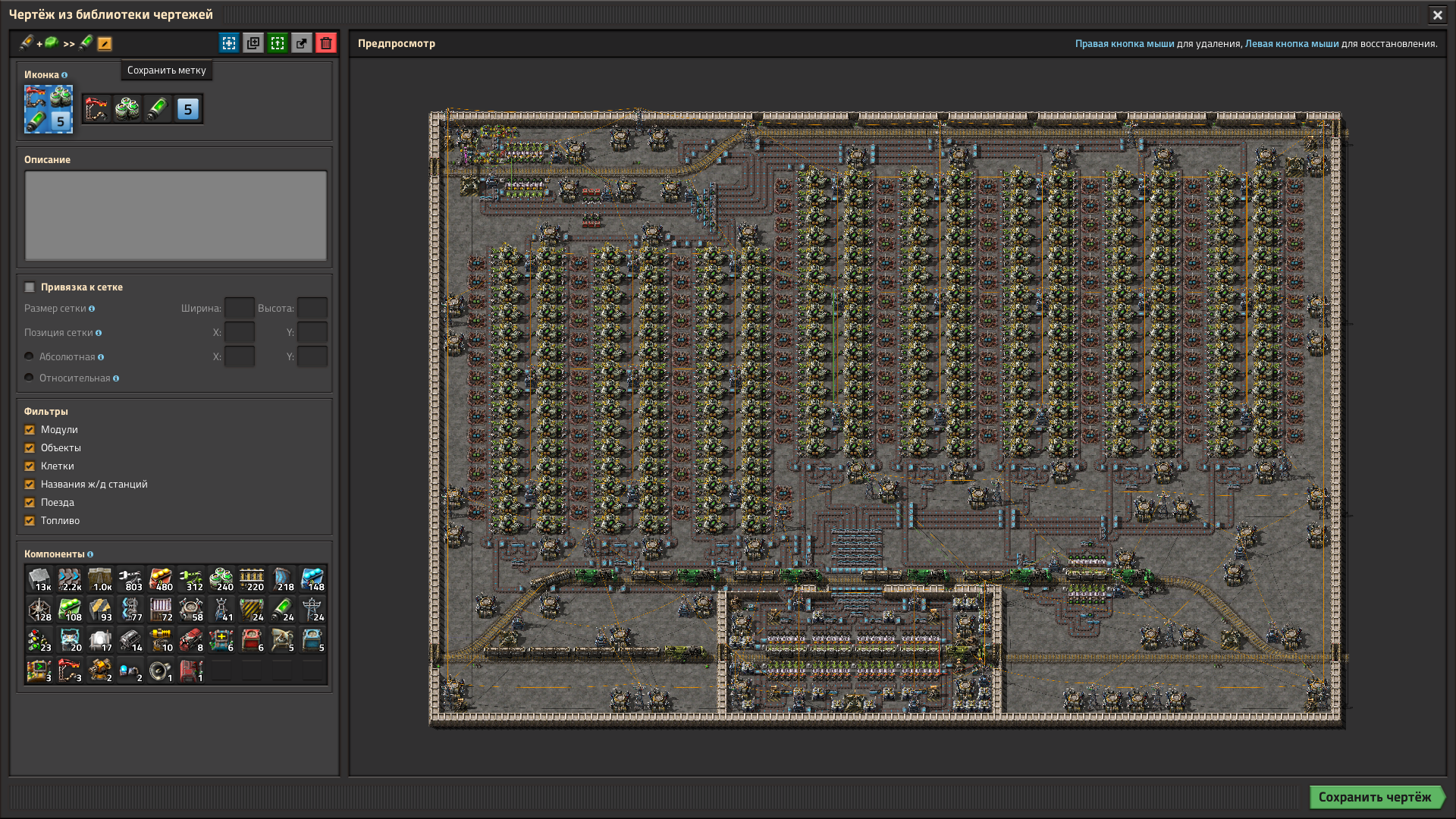

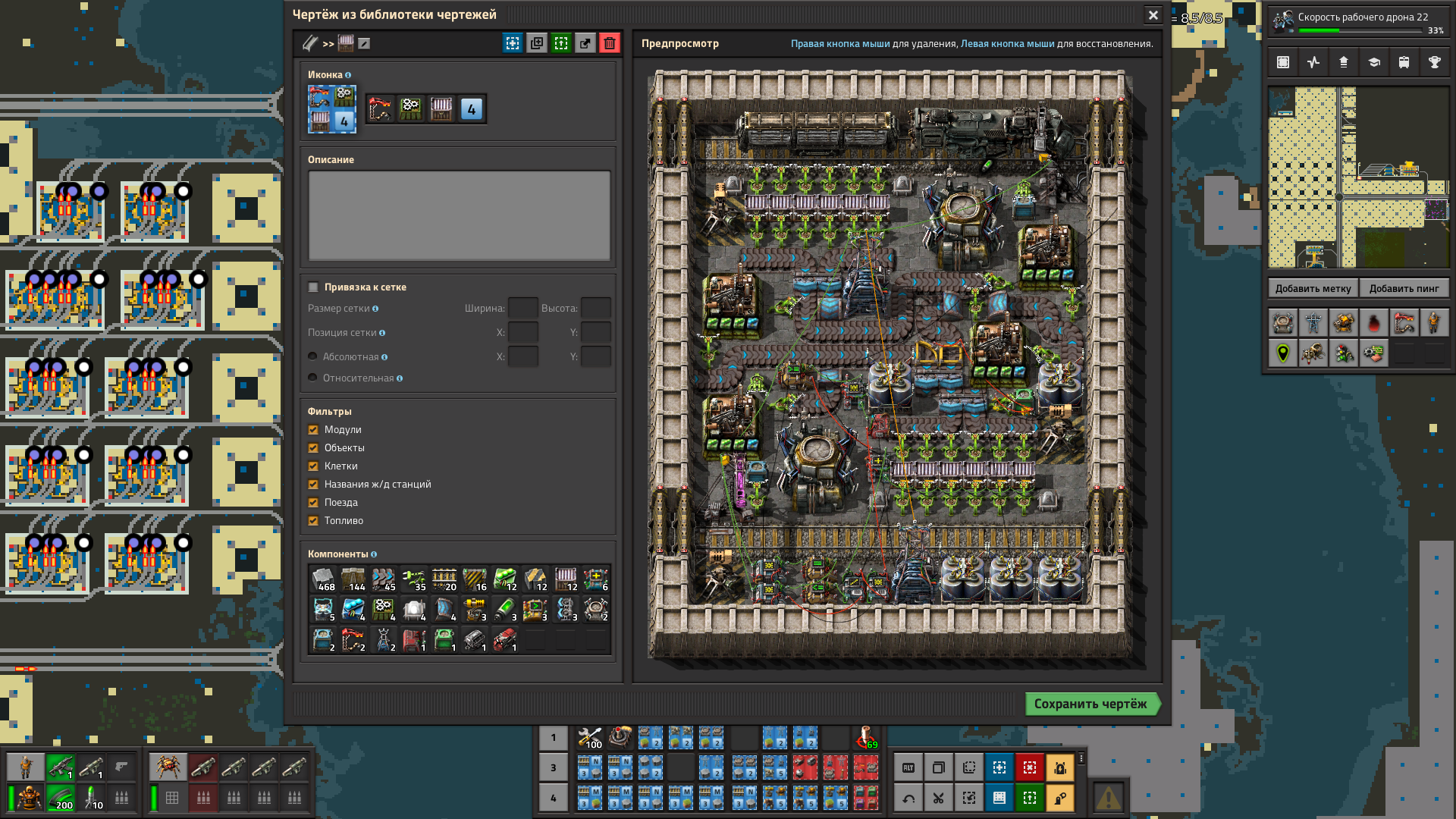

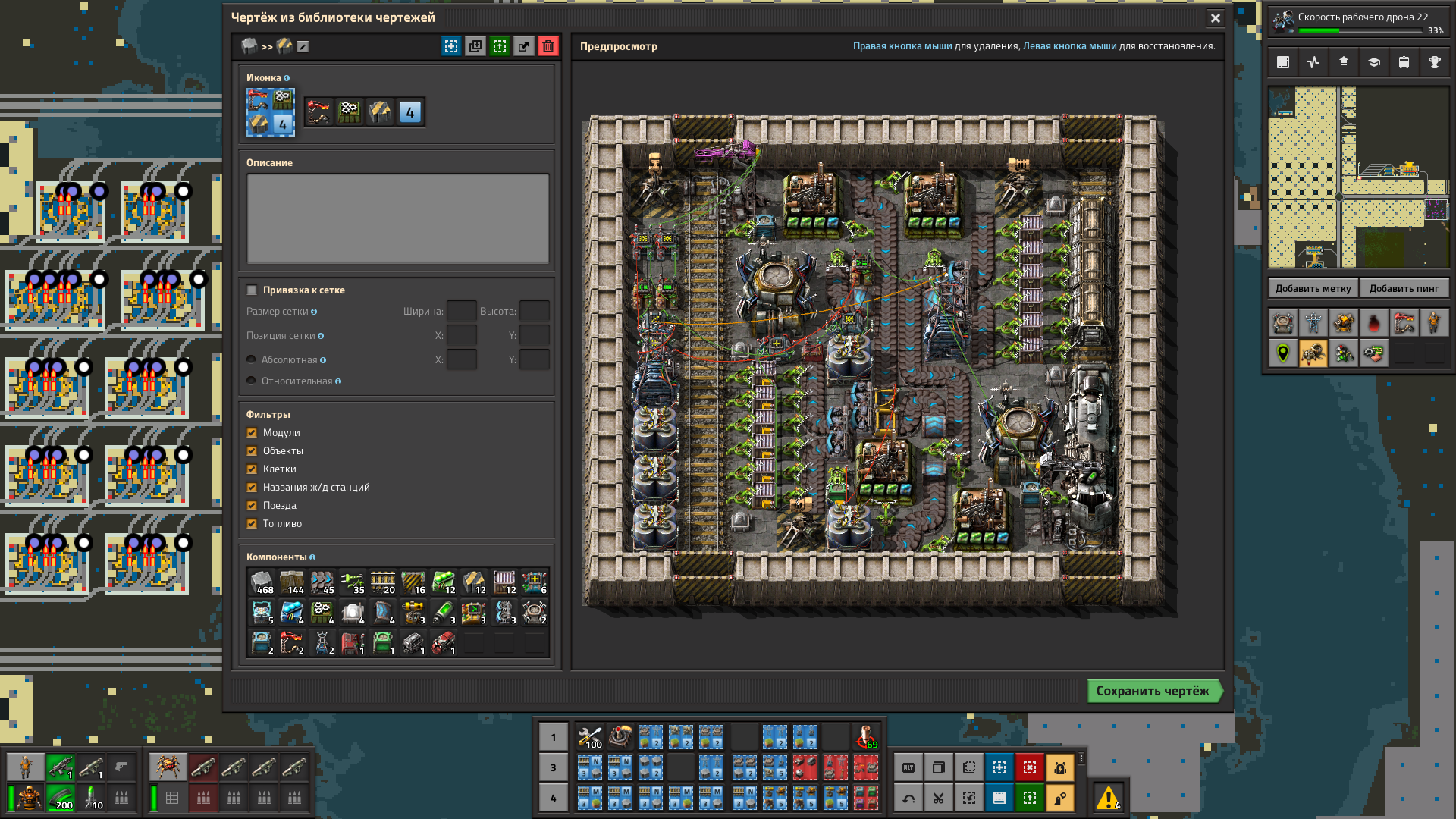

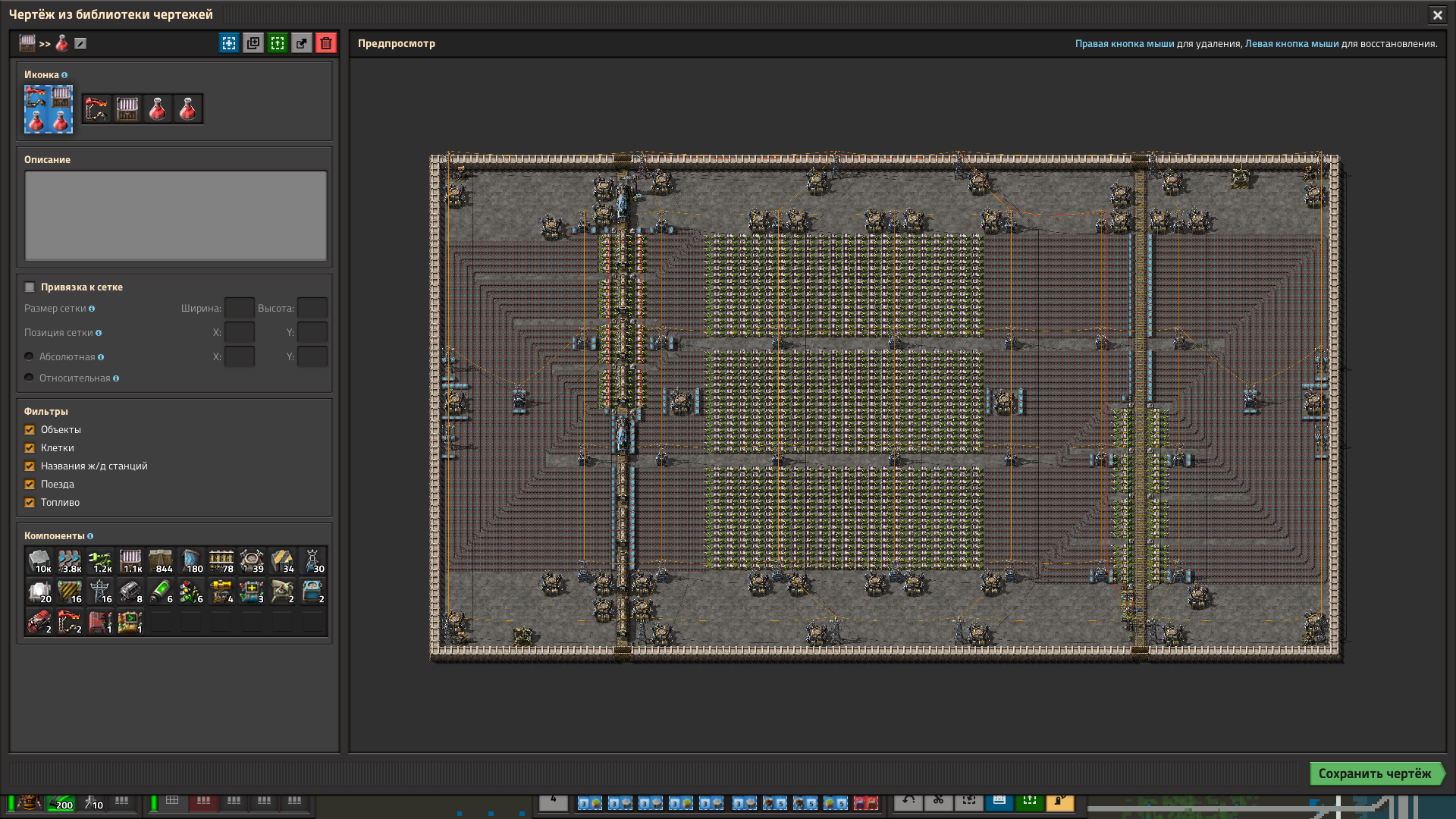

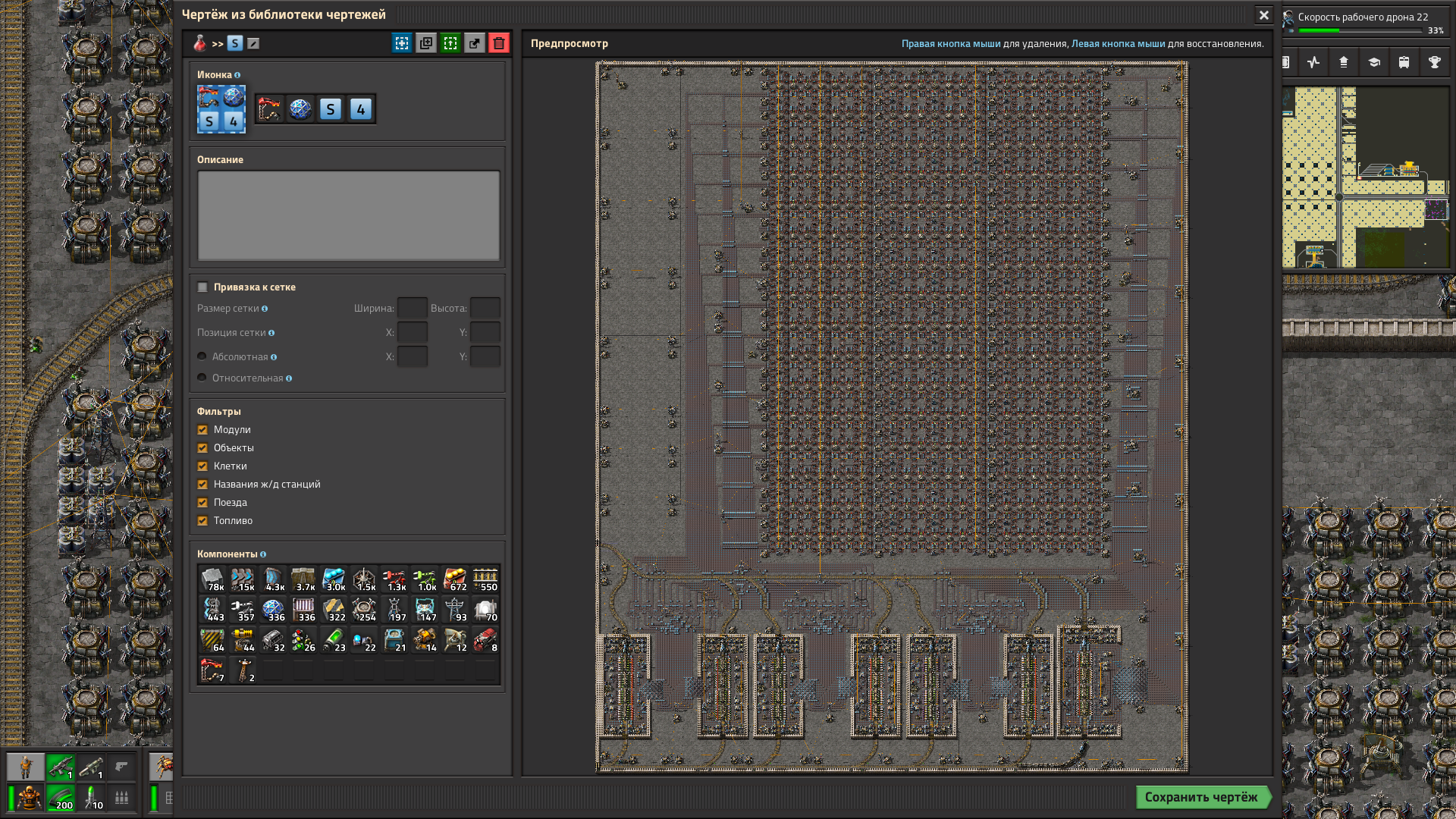

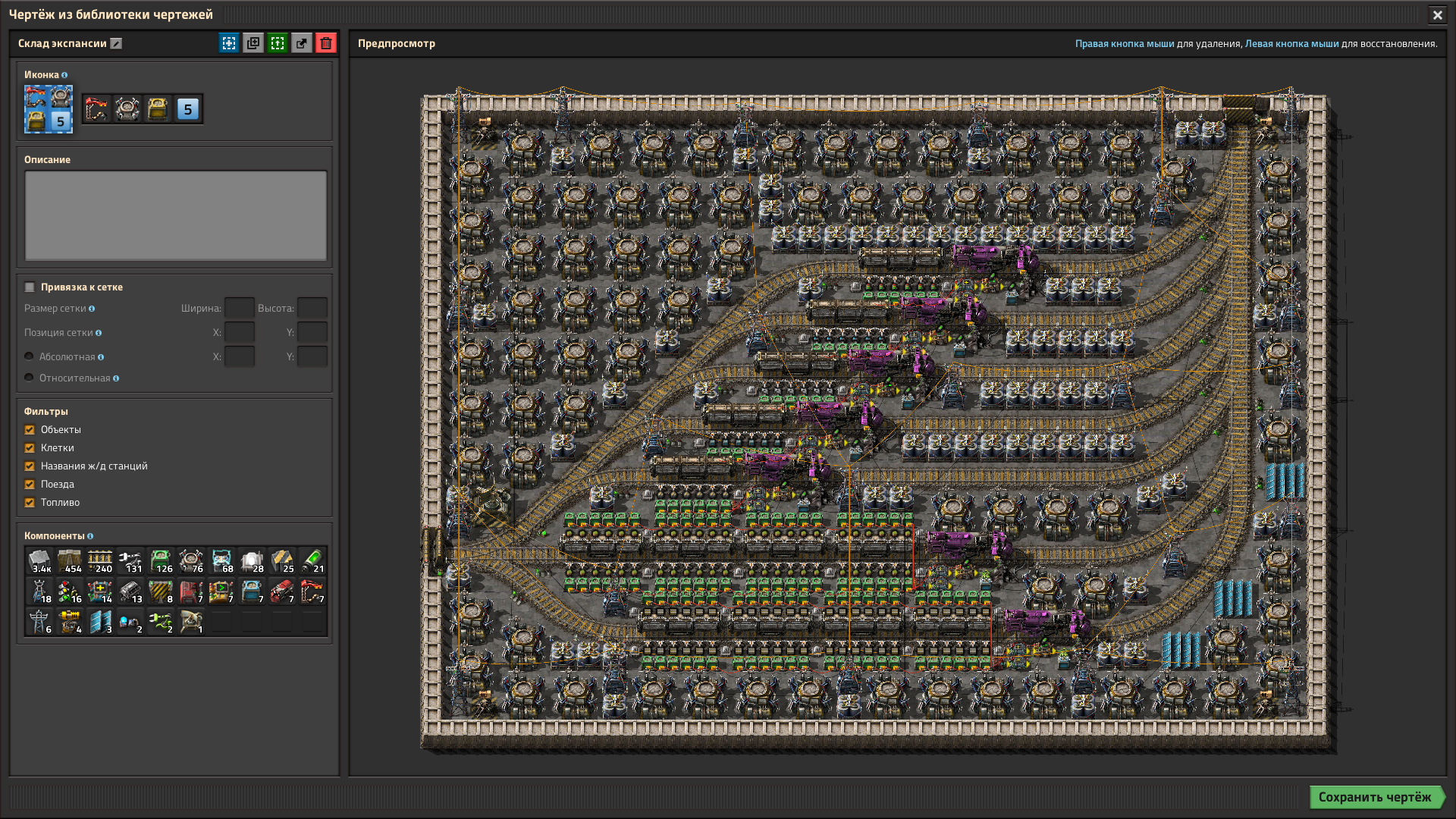

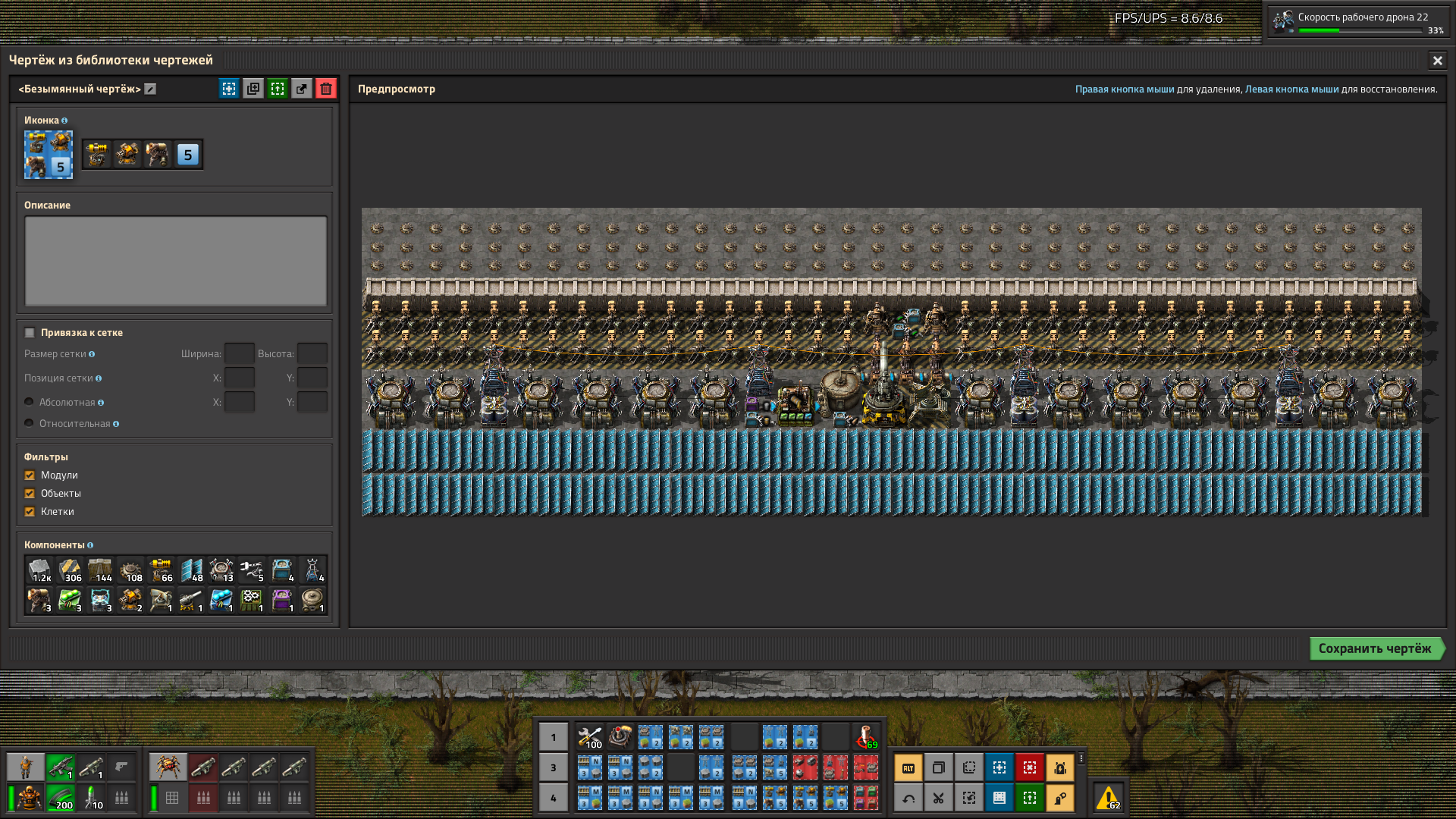

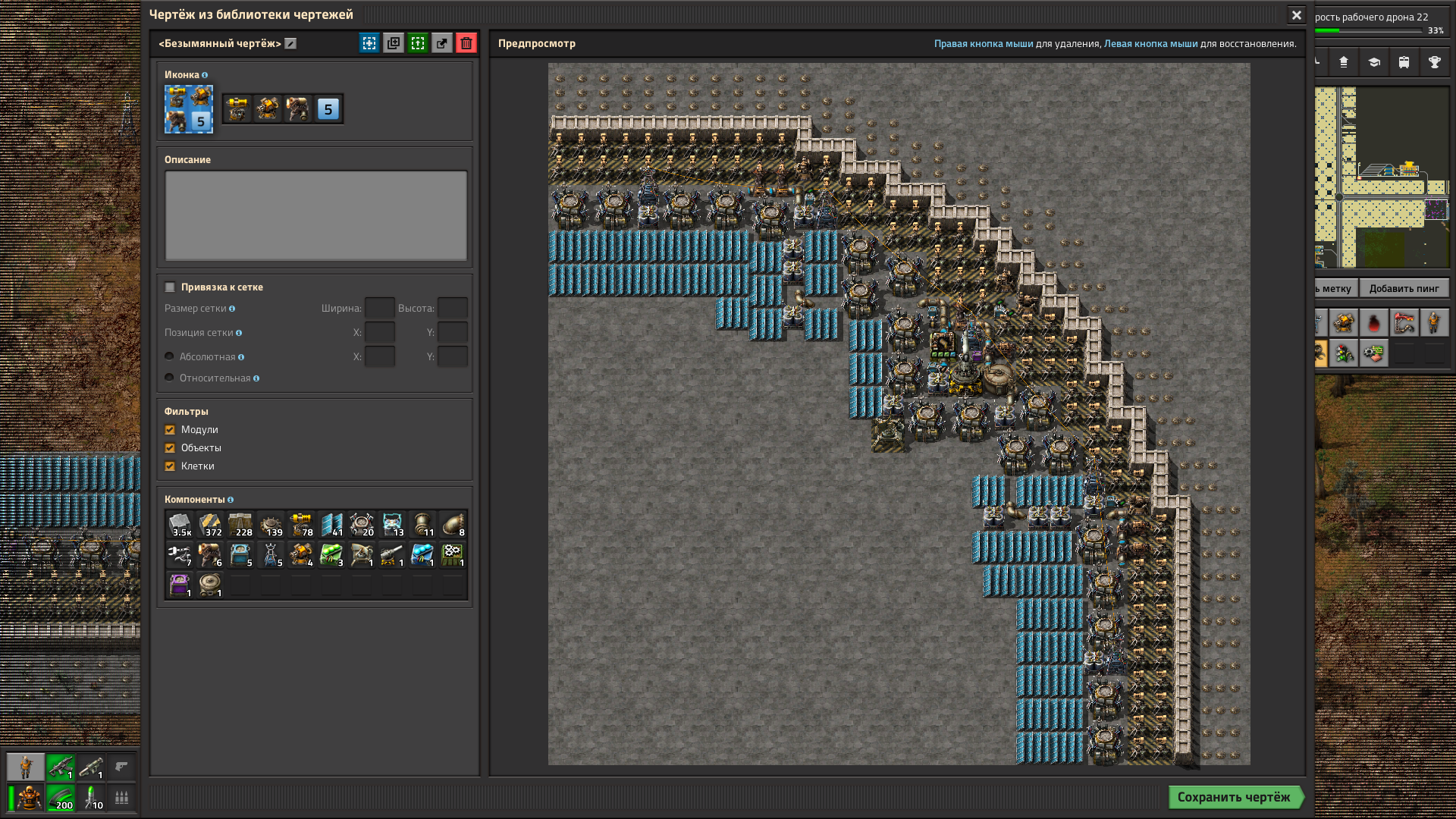

Screenshots of blueprint kernel

Rule: Train color - almost all warehouse trains are pink, trains with weapons are purple, trains with drones are color #ff0060 and the service wagon is white.

table with train colors

Contributor request: if somewhere in the blueprints the color differs from the table, it must be brought to a single standardRule: Manipulators - always and wherever possible, instead of a green manipulator, a white one is used, indicating which resource it moves.

Rule: Fuel - always and everywhere at any station there must be a request chest for nuclear fuel and a manipulator loading fuel into the train.

Rule: Core chests - all chests must be green, some chests that cannot be green due to the consumer must be red.

Rule: In the middle of the core there are two blocks with yellow chests. There should not be a single yellow chest in the factory outside of the core, or perhaps in the future a carefully thought out module specifically designed to handle yellow chests.

Question to developers: I have repeatedly seen that if all the yellow chests are empty and something needs to be delivered to the yellow chests, the drones deliver not to the nearest yellow chests, but across half the map. We need to fix this.

Contributor request: Due to the problem described above, you need to make some kind of station at which there will only be a lot of yellow chests and a lot of drone stations around. And it will be prescribed to install only one in the center of the map. Use only if there is more than one core station and remove all yellow chests at all core stations.

To launch new drones, steel chests, green chests, blue chests and purple chests are used.

Rule: The color of a station must always match the color of the train to that station.

Rule: The train schedule always has a station at which it must stop most of the time, and this station must be the first in the schedule list.

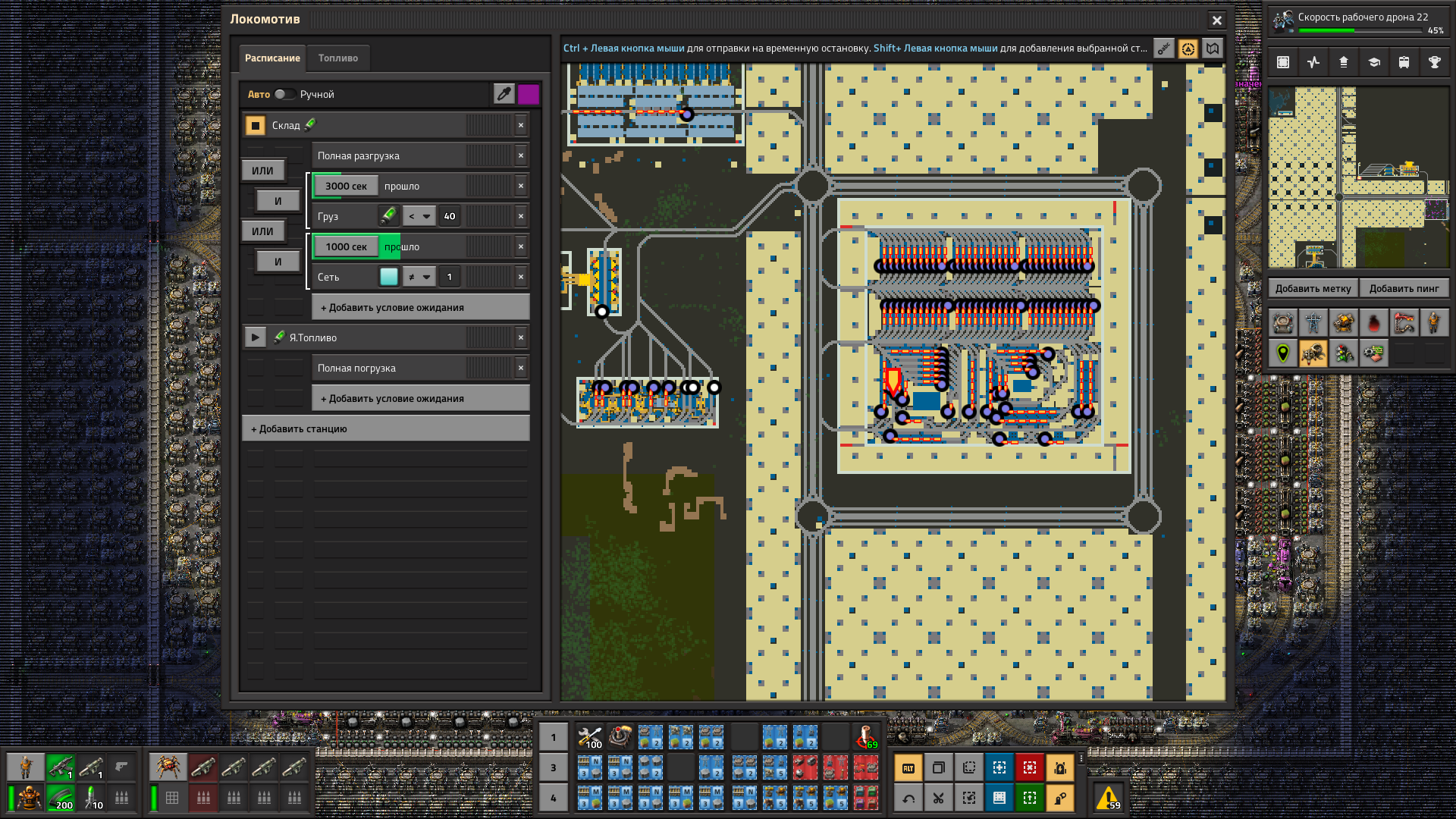

Rule: Warehouse trains wait 1000 seconds for unloading and if the warehouse is not full, the train is sent back for more. And if it waits 3000 seconds for unloading and the train is not full, the train goes back for more.

Rule: Any loading station or storage station can calculate the amount of products in chests

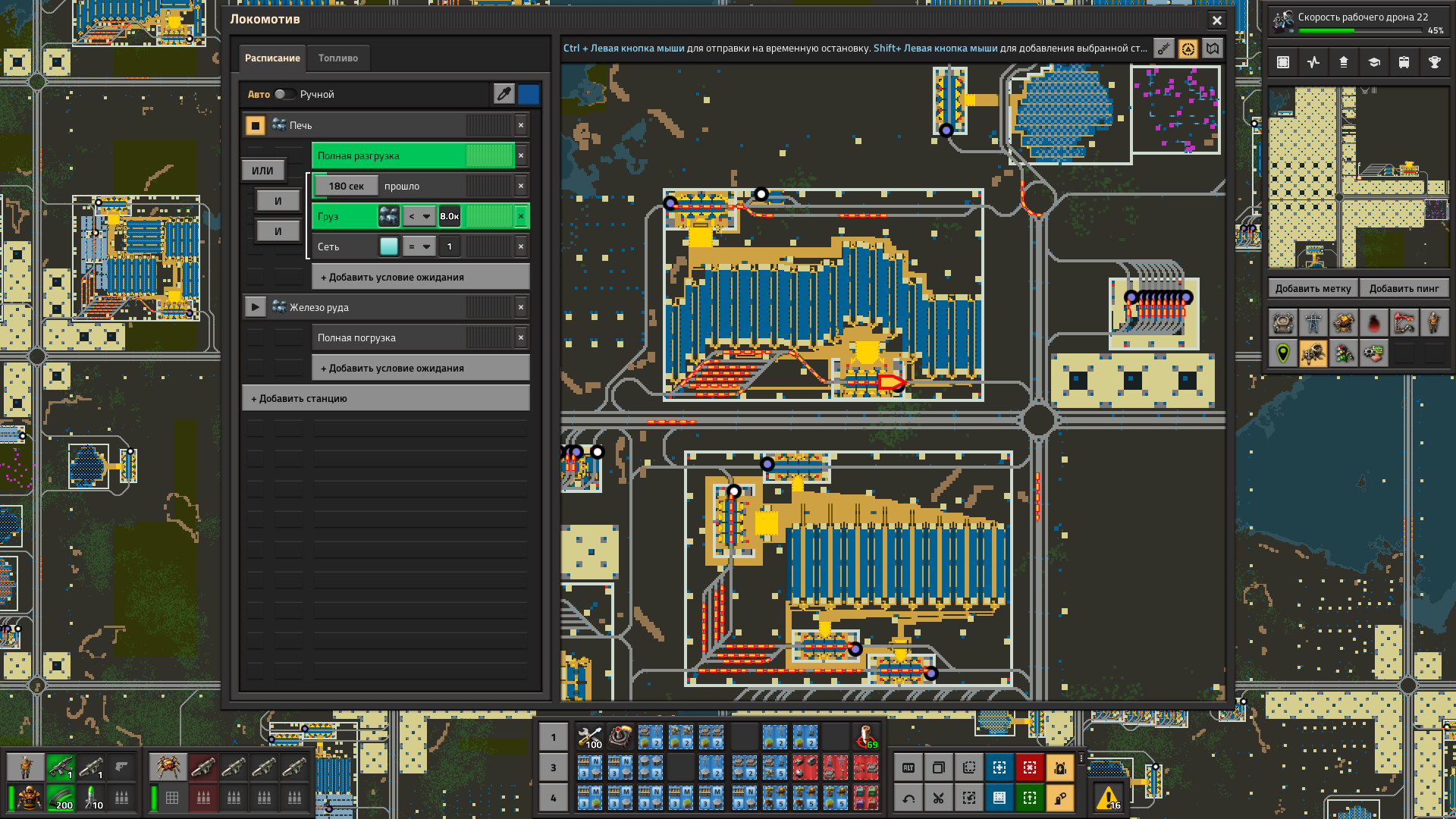

Screenshots of the schedule

Main rule: The entire plant is divided into workshops. Each workshop is occupied with one simple production and this production is brought to perfection.This means that at maximum load all production units are functioning (for example, an assembly machine).

Rule: Each workshop is surrounded by a wall and thus forms a rectangle.

Rule: Each workshop can have the minimum number of train entrances and exits as possible.

Rule: Each workshop sends its own trains for products.

Rule: Almost every workshop has a speaker that turns on when idle for a very long time (for example, if I forgot to start the trains after construction or for some reason the production failed).

Rule: Almost every workshop has one or more loading stations and one or more unloading stations. Either for 1 wagon or for 4.

Rule: Usually each workshop produces one thing, and often has loading stations for both 4 wagons and 1 wagon at the same time.

Rule: Sometimes a workshop has secondary production, this is allowed only if it does not require new loading stations and there is no need to build a loading station for one wagon.

Rule: This rule only applies to: marked reinforced concrete, pipe, fish.

Contributor request: implement marked reinforced concrete, workshop pipes in such a way that this too is produced there.

Rule: Each workshop must have a large power line support along its perimeter. Especially in the corners.

Rule: The entire workshop must be covered with a zone of drone stations. Strictly and necessarily. It is advisable to place drone stations more and more evenly.

Rule: The entire workshop must be an electrical network - avoid unnecessary power lines and have no gaps in the power lines (this is important for the construction of new workshops according to the blueprints).

Rule: A workshop must have 4 request chests around the loading station for 4 wagons with a request for the products of this workshop. The exception is that in warehouses in red chests.

Rule: If the workshop has a branch for loading into one wagon, there should be another request chest with a restriction on passing by this chest as long as there is something in it.

Rule: Also, any workshop that has a branch to a one-wagon station should have a green chest there without any settings (if the player requests, the logistics network should deliver).

Rule: any production in which productivity modules can be applied must have productivity modules (with the exception of ore).

Rule: any production in which productivity modules cannot be used must have one speed module and the rest efficiency modules.

Next I want to talk about the supply concept.

Theoretically, supply can be implemented in two ways - “the workshop produces a lot of products and delivers the products to consumers with its trains” or “the workshop itself sends its trains to pick up raw materials for itself.”

I considered both options and chose the second one for several reasons:

- This option allows you to regulate the quantity of required products.

- When consumption is very fast, it is necessary to supply trains one after another; it is necessary for trains to accumulate in front of the unloading station. And if there are enough tracks to wait there, it would be reasonable to put a train there right away on the blueprint. How else?

- I use the behavior of trains based on the name of the station, more on that later.

- For the convenience of assembling workshops, the train entrance is always in the lower left corner.

- Use a 9-train template using the most widely used material, if possible.

- Indents between paths are 4 cells at the first and last path.

- Traffic lights and semaphores are always at maximum separation.

- There must always be at least one semaphore in front of the station.

----------- Station Book -----------

Blueprints: https://anlide.online/factorio/book.station.txt

Rule: Any station does not have a shutdown condition - in such a huge plant it is simply death at any second in an unpredictable place. Perhaps the developers need to redo the reaction of trains to turning stations on and off.

Question to developers:

Why if there are two stations at which the number of trains is regulated and switched off and switched off. For example, both stations have a train limit of 1. 2 trains left for them.

Then suddenly one station turns off - then one train will continue moving, and the second will stop in the middle of the movement and will stand waiting for who knows what. Why this logic?

Rule: Therefore, in principle, any conditions for turning on and off stations are not used anywhere. However, stations can be manually turned off for various reasons (for example, when building a new workshop in a busy area or to direct traffic).

Rule: Any unloading station limits the number of trains equal to the number of trains on the blueprint of this workshop. Without exceptions, it is not regulated by combinators anywhere.

Rule: Any loading station always has a limit of 0 trains and the train limit is always set by the logical network.

As can be seen from the list of station templates, they are divided into groups. Unloading stations and loading stations. For liquids and objects. For items on both sides.

Let's consider all the features and rules of the stations. This is a very important detail in this plant.

Loading stations come first because the plant starts there. It is at these stations that ore is loaded. By the way, all forms of ore loading stations are presented below.

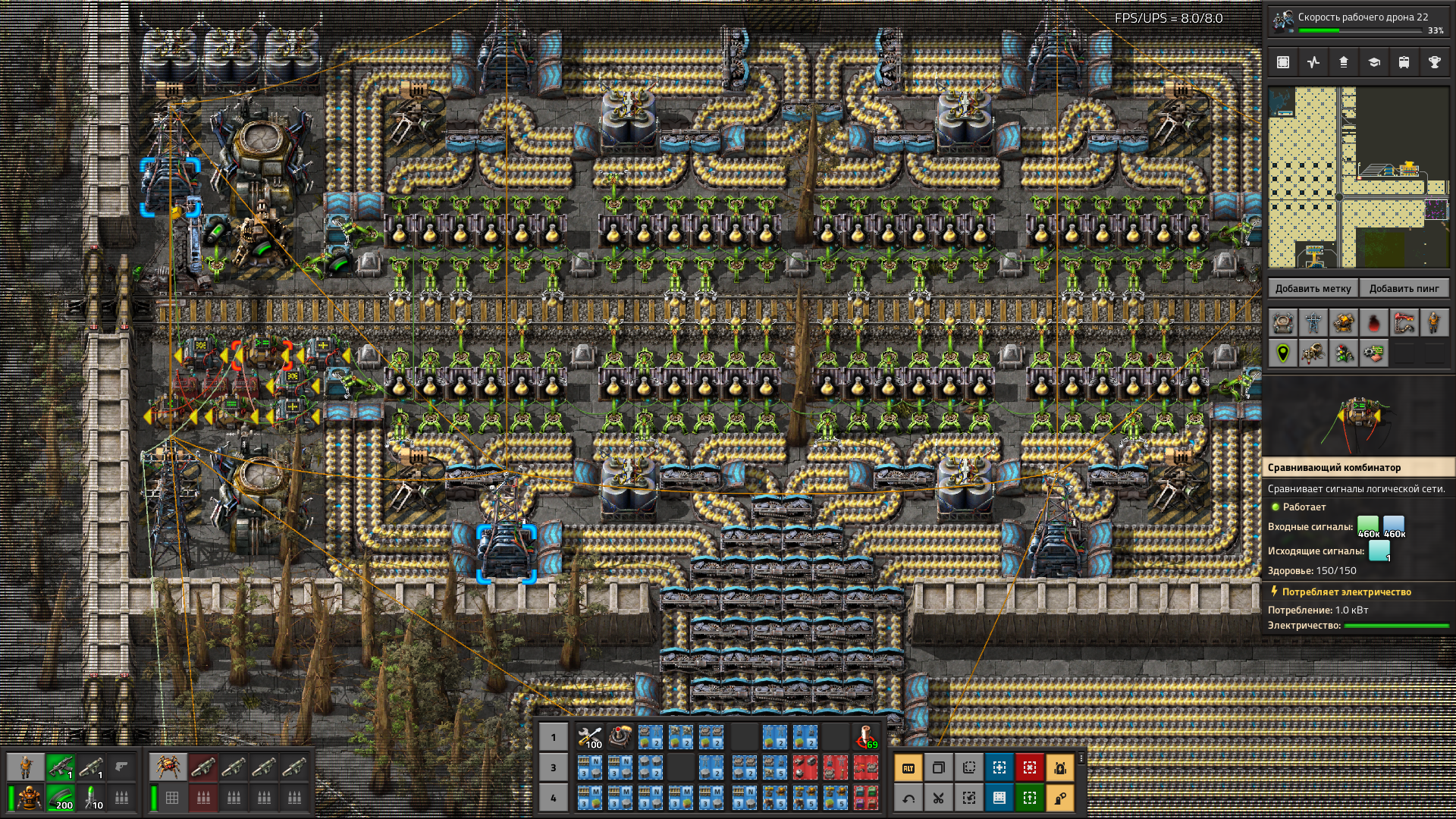

8 conveyors are supplied to the station and it unloads everything as quickly as possible, first into chests, and then into wagons. You can see a huge number of combinators and signal wires, everything is necessary, now I will describe the meaning of each element in order.

The station is grayed out and named "NoName" in case the player forgets to rename the station. Two traffic lights are needed in case the station is carelessly connected to the main railway network.

Lanterns are decorative in nature.

Radar is needed everywhere and putting one in the blueprint here is a good idea.

White manipulators without marking the object are a reminder that you need to mark them.

Green manipulators are needed to ensure that all possible garbage under the new workshop accumulates in chests (these are then conveniently and easily unloaded from garbage by drones).

Turrets are needed to prevent random single biters or spitters from destroying the entire plant. Having a little bit of turrets in the template, we get a plant that is all studded with a little bit of turrets.

3 permanent combinators: setting the number of items in the stack, setting the maximum number of trains and setting the maximum idle time.

If the loading station chests are not filled to the maximum, the idle timer starts.

If the idle time exceeds the time specified in the corresponding setting, the station sets the train limit to 0 (this means that arriving trains will continue to travel here, but there are no new trains).

If the idle time exceeds the time specified in the corresponding setting by 10 times, the speaker will turn on.

The train limit is calculated based on the cargo available for loading (and for each wagon separately). Thus, you can be sure that if a train goes to this station, then there is enough cargo in it to fill all the wagons of all arriving trains at once. I'm proud of this algorithm.

Screenshots

There is also a modification of loading in the other direction. And there are also two modifications of loading, when at the entrance we have not 8 conveyors, but 16.And immediately predefined modifications for all types of ore, 2 modifications for each ore.

The blueprint book also includes blueprints with settings for permanent combinators - this is convenient for expansion and mass installation of ore stations.

Any loading and unloading stations must be built so that each wagon has a pump attached to it.

Moreover, there are 3 pumps for each wagon. And each pump at the station would be directly connected to the reservoir.

Using a similar scheme, information is collected on the entire storage facility at the station and on the tanks connected to each specific wagon separately.

So we have a natural limit of 3 trains arriving at the station - because 3 tanks can load 3 trains at the same time.

However, inspections cost not 25,000 per wagon, but 22,500 per wagon. To avoid a situation where a full station can only accommodate 2 trains.

There is a separate station for one wagon with acid - it is needed to be installed next to each uranium deposit.

Combinators are convenient for managing the configuration of a station after its installation.

Contributor request:

Implement a loading station for one wagon for all workshops so that the limit of 3 tarins is reached not when the minimum is available for loading, but when a maximum of minus 3 trains is available for loading.

For example, usually 12 full chests can load 14 wagons in a row.

Accordingly, for example, if the chests are full for 12 wagons, give a limit of 1 train, if the chests are full for 13 wagons, give a limit of 2 trains. etc.

The number 3 in this case should be customizable through combinators.

Make the template so that it would be convenient to use in every workshop.

----------- Logistics Book -----------

The scheme is similar to citiblock. But much more flexible.

Blueprints: https://anlide.online/factorio/book.logistic.txt

It has been experimentally established that trains constantly need roundabouts - without them, when changing routes, they can easily enter a plant and block local production.

Why does the train change route? For example, a slot has become available nearby where to go - why now go across half the map when you can arrive at the station nearby.

It has also been experimentally established that such a circular route is often sufficient. Yes, near the missile silo workshop such a patrol is often not enough, but this is rather an exception to the rule.

Contributor request: make a circular drive for 2 circles.

There are 2 forms available - with fill and with reinforced concrete. With backfilling, new territory can be developed by water without any problems.

It's not a matter of saving filling - one can say that an infinite amount of it can be made. The fact is that water is finite, it is not known in advance where and how much it will be needed.

And why the excess filling?

Question to developers:

Why can't the installed fill be removed?

If something is upset there in terms of balance, it may take a very long time and be very expensive in terms of resources, but it is possible.

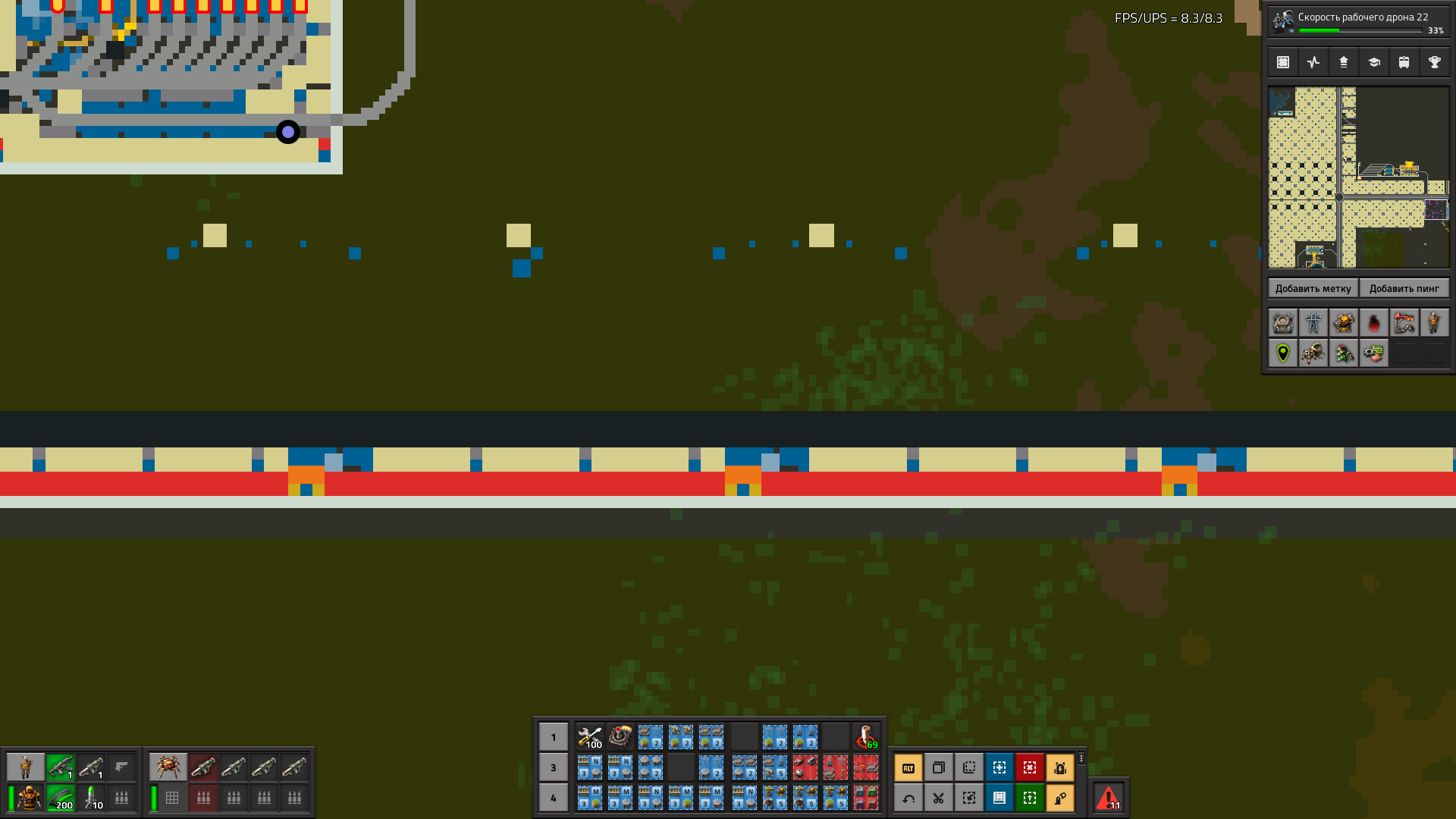

The main track lines are made into 4 lanes for 4 wagons. It is easy and convenient to set up huge long lanes.

Unfortunately, the two circular patterns are slightly larger than one linear path. Therefore, it is very inconvenient to make a replacement if you really need to insert a circular one.

screenshot

blueprints

Contributor request: convert the main tracks into 4 lanes for 4 wagons +1 cell.Contributor request:

A circular fill has excess fill, here is a blueprint of an arc railway with the minimum required fill:

(See in the logistics book line-2 column-1)

You need to apply this in the corresponding blueprints.

Contributor request:

Everywhere it is indicated how balanced the workshop is. If not in terms of loading or unloading speed, then this is already a request to remodel the workshop to suit this balance.

----------- Main book -----------

Here is a list of 62 workshops that produce everything needed to produce all the science-packs and all types of consumables.

Blueprints: https://anlide.online/factorio/book.main.txt

------ General components ------

--- Copper ---

screenshots

Blueprint: https://anlide.online/factorio/main/copper.txtBalanced: according to maximum loading speed

Contributor request:

1. Move the loading one wagon lower.

2. Apply the updated loading to 1 wagon (described above).

3. A lot of free space - make it more compact.

4. It has been experimentally established that 9 waiting trains for loading is a lot, you need to do 7. Reducing to 5 will most likely be a bad idea.

--- Iron ---

screenshots

Blueprint: https://anlide.online/factorio/main/iron.txtSimilar to copper.

--- Stone block ---

screenshots

Blueprint: https://anlide.online/factorio/main/stone-brick.txtBalanced: according to maximum unloading speed

Contributor request:

1. This workshop has most likely been brought to perfection or so, but if you really want to, you can try to reduce the height of the workshop, because there is free space (width will not work).

--- Cable ---

screenshots

Blueprint: https://anlide.online/factorio/main/copper-cable.txtBalanced: according to maximum loading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Instead of many beacons, reduce the size of the workshop.

--- Rod ---

screenshots

Blueprint: https://anlide.online/factorio/main/iron-stick.txtBalanced: according to maximum loading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

--- Gear ---

screenshots

Blueprint: https://anlide.online/factorio/main/iron-gear-wheel.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. There is free space due to which the workshop can be made smaller.

--- Steel ---

screenshots

Blueprint: https://anlide.online/factorio/main/steel.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

--- Microcircuit ---

One of my favorite workshops. Very nicely balanced.

screenshots

Blueprint: https://anlide.online/factorio/main/ele ... ircuit.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Does not follow the path placement rule. + add iron train.

--- Sulfur ---

screenshots

Blueprint: https://anlide.online/factorio/main/sulfur.txtBalanced: according to maximum loading speed

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. There should be 6+ trains with gas

3. There must be buffer tanks around the station (see production of diesel from fuel oil)

4. Loading must be in 16 streams.

5. Maintain a balance of water supply from 4 sources, provide a source capacity of 3000 water/sec.

--- Plastic ---

screenshots

Blueprint: https://anlide.online/factorio/main/plastic-bar.txtBalanced: according to maximum loading speed

Contributor request:

1. Despite the very good balance of the workshop, there were few trains with gas. Looks like we need 7 or 8 trains with gas.

--- U. Microcircuit ---

screenshots

Blueprint: https://anlide.online/factorio/main/adv ... ircuit.txtBalanced: according to the size of drone stations

Contributor request:

1. Redesign the workshop so that the speed of production is limited either by the speed of supply of materials or the speed of loading. Now the balance is very good, but not maximum.

2. Apply the updated loading to 1 wagon (described above).

--- K.M.P. ---

screenshots

Blueprint: https://anlide.online/factorio/main/low ... ucture.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

---Acid ---

screenshots

Blueprint: https://anlide.online/factorio/main/sulfuric-acid.txtBalanced: according to the size of drone stations

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. It was determined experimentally that all produced acid should be poured into one barrel in the middle, then poured into tanks up to the loading station in small blocks.

The problem in the screenshot is that the left side of the plant is constantly working, but the right side is not working.

3. Make the space between paths correct.

--- Processor ---

screenshots

Blueprint: https://anlide.online/factorio/main/processing-unit.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Similar to acid production, the left side of the plant should not go directly to loading, but through the center.

3. Make the space between paths correct.

--- B.U.R. ---

screenshots

Blueprint: https://anlide.online/factorio/main/roc ... l-unit.txtBalanced: according to the size of drone stations x2

Contributor request:

1. Remove loading for 1 wagon (it is only needed for Y.Raketa).

2. Make the workshop larger and balance the speed of loading or unloading

------ Consumables ------

--- Concrete ---

screenshots

Blueprint: https://anlide.online/factorio/main/concrete.txtBalanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. Apply the updated loading to 1 wagon (described above).

3. Loading for 1 wagon must go through the main loading (so that there is no extra exit)

4. Rework the train supply - 9 standard blocks (bottom) and 3-4 iron ore (left)

5. Processing units for one conveyor are already balanced in terms of material supply speed, you can use them

--- Reinforced concrete ---

screenshots

Blueprint: https://anlide.online/factorio/main/ref ... ncrete.txtBalanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 3, it needs to be converted to the 5th generation

2. Put here the production of marked reinforced concrete + its loading station (example in "R.K.S.").

3. Processing units for one conveyor are already balanced in terms of material supply speed, you can use them

4. Rework the train supply according to the standard.

--- Construction drone ---

screenshots

Blueprint: https://anlide.online/factorio/main/con ... -robot.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker)

--- Transport drone ---

screenshots

Blueprint: https://anlide.online/factorio/main/logistic-robot.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker)

--- R.K.S. ---

screenshots

Blueprint: https://anlide.online/factorio/main/exp ... -shell.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

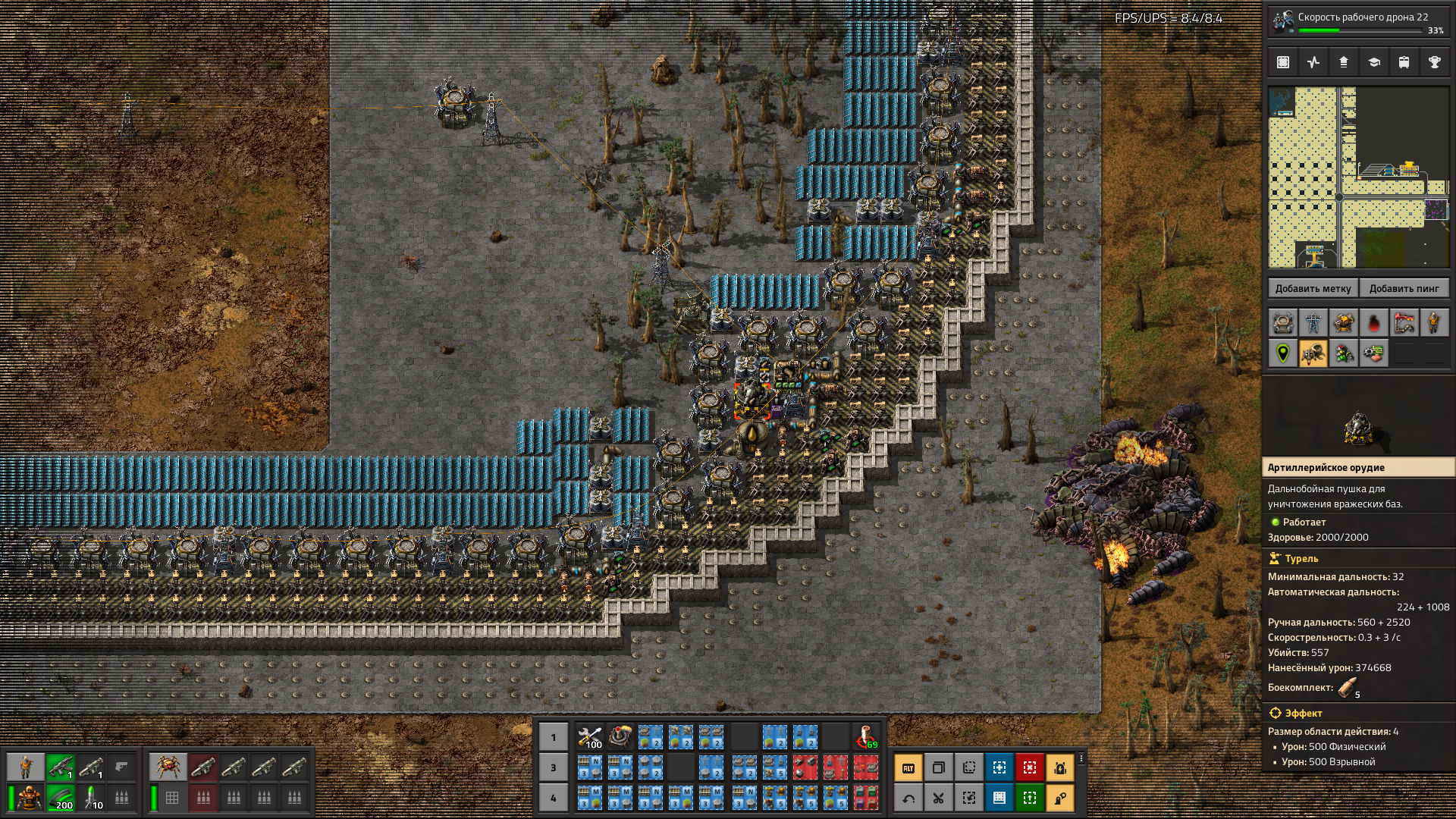

--- A. Projectile ---

screenshots

Blueprint: https://anlide.online/factorio/main/artillery-shell.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. See the descriptions of the core - you need to redo the loading of shells.

--- Backfill ---

screenshots

Blueprint: https://anlide.online/factorio/main/landfill.txtBalanced: according to maximum unloading speed

Contributor request:

1. This is the 4th generation of workshop, it needs to be converted to the 5th generation (no speaker and incorrect manipulators)

--- Explosives ---

screenshots

Blueprint: https://anlide.online/factorio/main/explosives.txtBalanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Apply the updated loading to 1 wagon (described above).

------ For science-pack-2 ------

--- Manipulator#1 ---

screenshots

Blueprint: https://anlide.online/factorio/main/inserter.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. Remove loading station manipulator #1 for one wagon.

3. Add the production of a long-distance manipulator and a loading station for 1 wagon.

4. Add production manipulator #2 and a loading station for 1 wagon.

5. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- Conveyor#1 ---

screenshots

Blueprint: https://anlide.online/factorio/main/transport-belt.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

------ For science-pack-3 ------

--- Wall ---

screenshots

Blueprint: https://anlide.online/factorio/main/stone-wall.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators)

---Grenade ---

screenshots

Blueprint: https://anlide.online/factorio/main/grenade.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. The 5th blue chest is positioned incorrectly.

--- Store#1 ---

screenshots

Blueprint: https://anlide.online/factorio/main/fir ... gazine.txtBalanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- Store#2 ---

screenshots

Blueprint: https://anlide.online/factorio/main/pie ... gazine.txtBalanced: according to the size of drone stations

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. The 5th blue chest is positioned incorrectly.

------ For science-pack-4 ------

--- Pipe ---

screenshots

Blueprint: https://anlide.online/factorio/main/pipe.txtBalanced: according to maximum unloading speed

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Add underground pipe production and a loading station for 1 wagon.

--- Engine ---

screenshots

Blueprint: https://anlide.online/factorio/main/engine-unit.txtBalanced: according to the size of drone stations

Contributor request:

1. Apply the updated loading to 1 wagon (described above).

2. This is the generation of workshop 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Place the 5th blue chest.

4. Add pump production and a loading station for 1 wagon.

5. Add O.Turel production and a loading station for 1 wagon.

5. Make the plant larger and balance production based on the speed of loading or unloading.

------ For science-pack-5 ------

--- Rails ---

screenshots

Blueprint: https://anlide.online/factorio/main/rail.txtBalanced: according to maximum unloading speed

Contributor request:

1. This is workshop generation 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Reduce the number of incoming trains to 5.

---Oven ---

screenshots

Blueprint: https://anlide.online/factorio/main/ele ... urnace.txtBalanced: according to maximum unloading speed

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 3, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Make the plant larger and replace all unloading stations from 8-outlets to 16-outlets.

---Module-p#1 ---

screenshots

Blueprint: https://anlide.online/factorio/main/pro ... module.txtBalanced: according to the size of drone stations

Contributor request:

1. The modification of the module production system will be discussed separately.

------ For science-pack-6 ------

--- Electric motor ---

screenshots

Blueprint: https://anlide.online/factorio/main/ele ... e-unit.txtBalanced: according to the size of drone stations x2

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Make the plant larger and balance the speed of loading or unloading.

--- Frame ---

screenshots

Blueprint: https://anlide.online/factorio/main/fly ... -frame.txtBalanced: according to the size of drone stations x2

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Make the plant larger and balance the speed of loading or unloading.

------ For science-pack-7 ------

--- Battery ---

screenshots

Blueprint: https://anlide.online/factorio/main/battery.txtBalanced: according to the size of drone stations x2

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

3. Add the 5th blue chest.

--- Ac.Block ---

screenshots

Blueprint: https://anlide.online/factorio/main/accumulator.txtBalanced: according to the size of drone stations

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- S.Panel ---

screenshots

Blueprint: https://anlide.online/factorio/main/solar-panel.txtBalanced: according to the size of drone stations

Contributor request:

1. Remove loading for 1 wagon.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

--- Radar ---

screenshots

Blueprint: https://anlide.online/factorio/main/radar.txtBalanced: according to maximum unloading speed

Contributor request:

1. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators and distance between paths)

2. Rework iron unloading - there should be 5-7 trains

--- Satellite ---

screenshots

Blueprint: https://anlide.online/factorio/main/satellite.txtBalanced: according to the size of drone stations x2

Contributor request:

1. Convert loading into 1 wagon. Practice has shown that there is no need to carry satellites in 4 wagons.

2. This is the generation of workshop 4, it needs to be converted to the 5th generation (no speaker and incorrect manipulators)

------ Other ------

---Module-c#1 ---

Blueprint: https://anlide.online/factorio/main/speed-module.txt

Balanced: according to the size of drone stations

Contributor request:

1. The modification of the module production system will be discussed separately.

---Module-e#1 ---

Blueprint: https://anlide.online/factorio/main/eff ... module.txt

Balanced: according to the size of drone stations

Contributor request:

1. The modification of the module production system will be discussed separately.