So, I wanted to make a test setup where I can answer questions like: how much copper will a single train be able to move to my circuit plant? How much can I do with 3 trains (with two unloading stops and a waiting bay)? Is it worth it to add more waiting bays, make trains longer, go to rocket fuel, research better braking pads, etc?

Assumptions:

- Working with LCCL double headers with full (24) stack unloaders and unlimited capacity on either side.

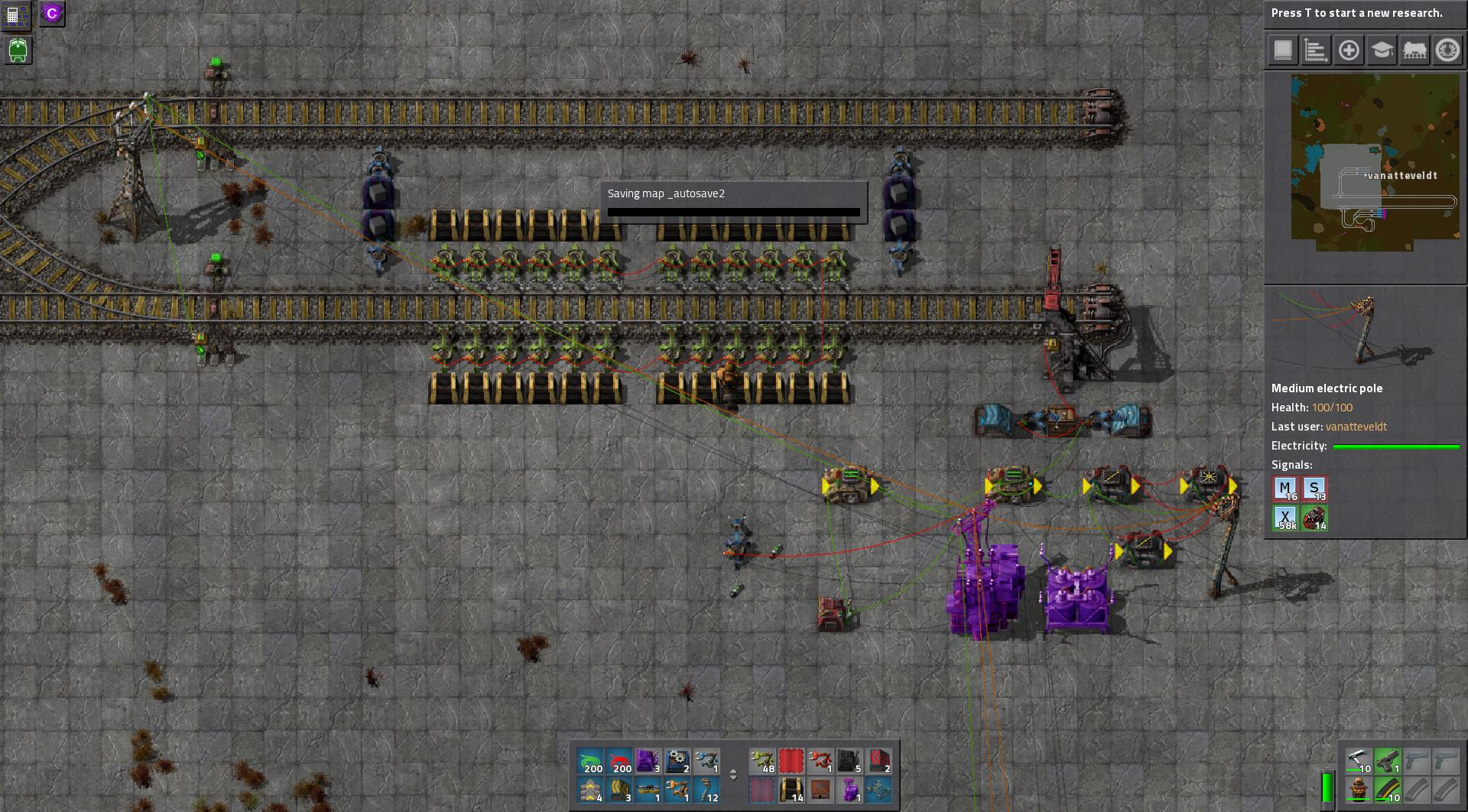

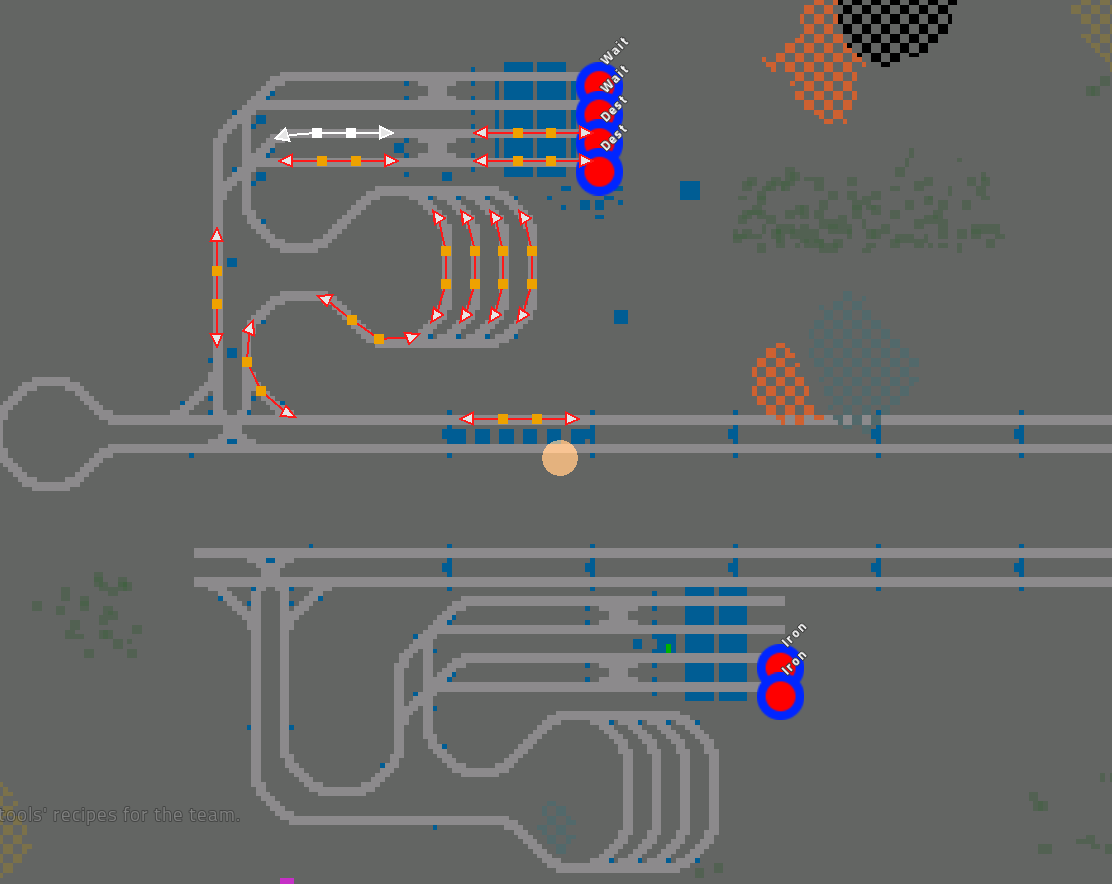

- Medium distance between loading / unloading (see screenshot below; about 600 tiles or so).

test setup

I count the time for 30 trains to arrive. I count from all trains empty in the loading bays (ready to depart) until the counter is at 30, ie train 30 enters the unloading bay. This is divided by the time to get trains per minute (tpm). Outcomes: [in progress]

Single train

coal, stack inserter bonus 2, no brake pads: 64m41 / .46 tpm [trip time about 30 seconds, (un)loading about 40 seconds]

coal, full stack inserter bonus, no brake pads: 40m55 / .73tpm [(un)loading time about 12 seconds]

coal, all techs: 37m50 / 0.79 tpm [trip time about 25 seconds...]

solid fuel, all techs: 36m22 / 0.82 tpm [trips not much faster]

rocket fuel, all techs: 31m34 / .95tpm [trips about 20 seconds]

Conclusion for single-train improvements: stack inserter is hands down the best improvement. Solid fuel is probably not worth the hassle (I generally have coal lying around in a lot of places..). Under normal circumstances you can expect about 1 tpm at medium distances from a single train, or 8k plates/m.

Rocket fuel and braking improvements will be more worthwhile if the trains have to stop more often.

multiple trains [all full tech and rocket fuel]

2 trains, 2 unloading bays: 15m38 / 1.9 tpm

3 trains, 2 unloading bays, 1 waiting bay: 11m15 / 2.67 tpm

Conclusion: the second train+stop doubles throughput (as expected). Adding a third (which is easy in my station design because you get a 'free' waiting bay for each pair of identical stops) gives an extra 40% throughput as the trains start bumping into each other. Maximum throughput in this setup (without a stacker) is about 20k plates/m

6 trains, 2 unloading bays, 1 waiting bay plus stacker: 12m25 for 60 trains -> 4.8 tpm

12 trains, 2 unloading bays, 1 waiting bay plus stacker: 9m27 for 60 trains -> 6.3 tpm

(This is the maximum capacity for 2 unloading bays as trains were continuously waiting)

To test: longer trains (LCCCCL and LLCCCCLL) and single header trains (LCC, LCCCC and LLCCCC). But not tonight