Single circular belt factory

Posted: Sat Jan 30, 2016 1:11 am

I have been experimenting with easy setups for producing many different items. One obvious solution is the logistic network with requester/provider chests. In my opinion this is too easy and gets boring too fast. Also, you first have to research the logistic network and invest considerable amounts of resources to build up capacity. Instead, I want something belt-based.

Ideally, I'd like a circular belt where I can directly control the number of items. See the idea https://forums.factorio.com/forum/viewtop ... =6&t=18953 for some more details. Since this is not available, we need some other solution to count (or at least estimate) the number of items on a belt.

The best solution I've found so far is by using one smart chest per item type. In the smart chest disable all slots except one to ensure that only one item type gets stored per smart chest. Use a fast inserter to for insertion and a slow inserter for extraction back to the belt.

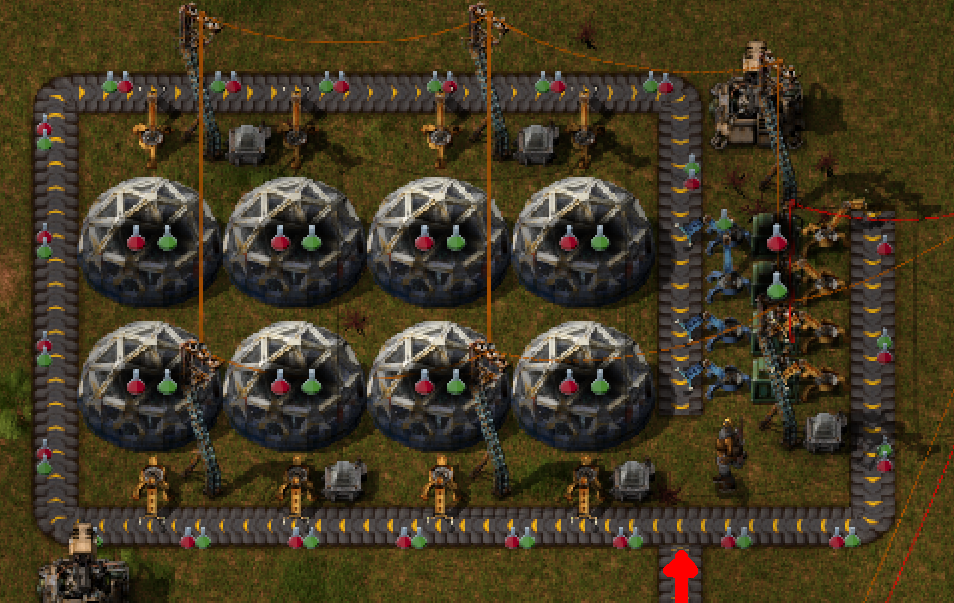

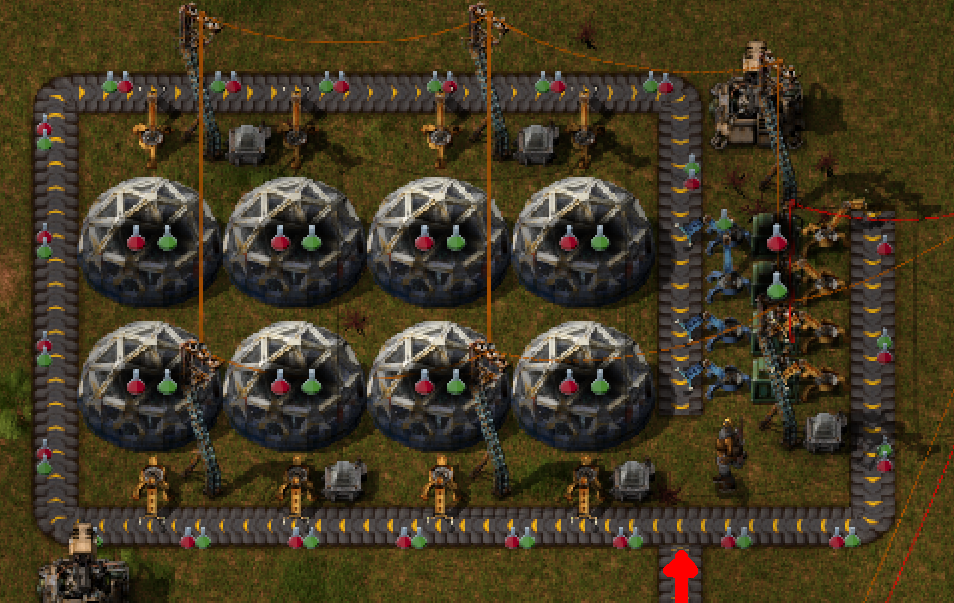

A simple example with just 2 items (red and green science pack):

http://i.imgur.com/VTUKbMI.png

Here you see two smart chests are filled with red/green science packs. The slow inserters put one time on the circular belt every second or so. This puts a dozen or so items on the belt and ten more are in the chests. The science pack generation is controlled via a connected signal and when the number of science packs in the chets falls below a threshold (=0 in this case) extra items are fed into the system.

This system is easily extendable to all four science packs without adding a second belt.

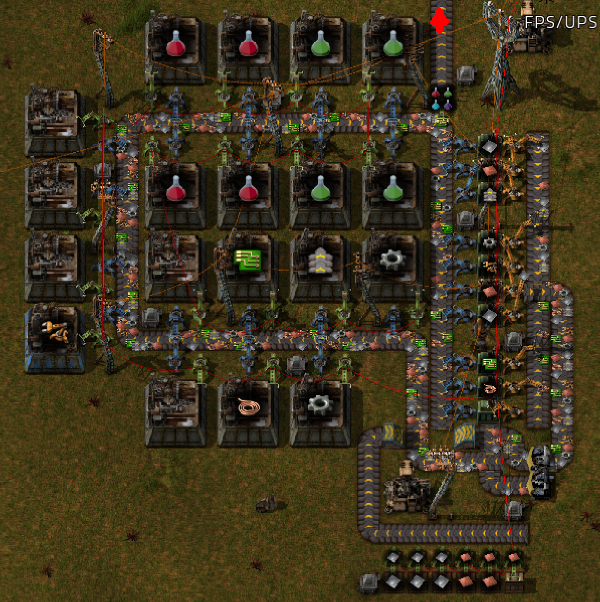

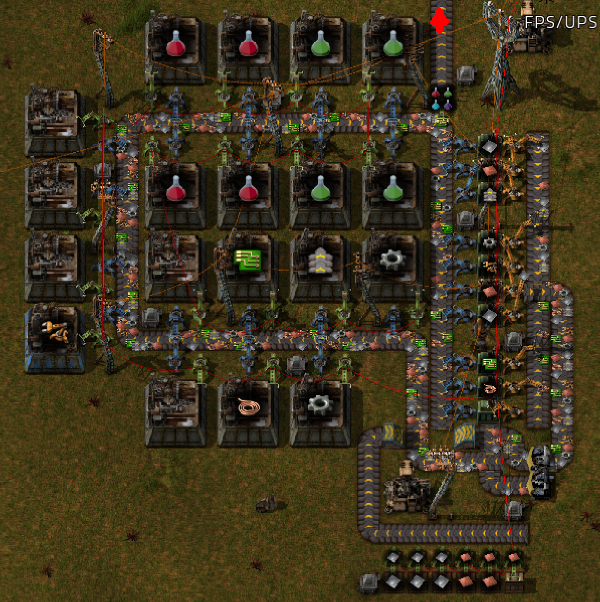

Now to a more complex example, the creation of the red and green science packs:

http://i.imgur.com/tk2sB2P.jpg

Compared to the last example we now have more items, therefore we need more smart chests. You see one chest for every item except copper and iron. They need two chests because the threshold is set to two stacks of items. This increases the rate of copper/iron plates on the circular belt.

The copper and iron plates are fed into the system from the bottom chests. One inserter starts when there are zero items in the chest and the other starts when there is less than a full stack in the chest. Right now there are enough plates in the system, so these inserters stand still.

The circular belt is quite full due to the high number of different items, but there is still enough space left so that everything runs smoothly.

When you follow through the production street you see, that they follow item assemblers are placed in the order the items are processed. First gears, then belts, then inserters, then science packs. First coils, then circuit boards, then green science. Some assemblers are not yet used.

The output of each assembler has a smart inserter. It is activated when the number of produced items in the smart chests is zero.

For example gearwheels. When the science pack production starts, the gearwheels on the belt are consumed. In the chest there are still about 10 gearwheels which are put on the belt via the slow inserter. When the chest is empty, the inserter at the gearwheel assembler is activated ramping up production of gearwheels. Due to the placement of the producing assembler in front of the consumers, they will consume gearwheels until the need is satisified and some reach the smart chest. When storage builds up, the smart inserter stops and production is halted.

This makes for a fine balance with only about 10-20 items of each type being held on the belt and in storage.

The last smart chest has a special role. When the power runs out, the items jam at the end of the belt out of order. The last smart chest has all slots activated and can store all types of items. It is kind of a "catchall" in case something goes wrong or too many different types of items are on the belt. When the power is restored it takes a short while until everything is is in order again and every item has its corresponding chest. In my experience, this setup is robust and does not jam up even at power outages or high demand scenarios when the smart inserters are setup correctly.

With red or blue belts, the number of different items doubles or quadruples and many different items can be produced using only a single circular.

Similar to the setup for the science packs, an ammo belt can be built for supplying turrets without actually filling a long, long, belt entirely. Using a smart inserter and a clock circuit, the distance between items can be increased.

Putting high volume items like plates on the same belt as low volume products is a bit inefficient. To increase throughput, these could be supplied to the assemblers via a separate belt.

In my opinion this kind of setup is a good way to escape the belt madness when producing many different items. It already makes sense for red and green science packs and results in a compact production street which can easily be extended. The only gripe i have is that currently you cannot count the number of items placed on the belts, but I have hopes that the Circuit Network Connector http://www.factorio.com/blog/post/fff-123 one day makes this possible. This would eliminate the need for smart chests and decrease the number of items on the belt considerably. Then it would be possible to make an efficient factory for just-in-time production of all items you need without resorting to the logistic network.

I'm happy to respond to questions, critique and ideas for extension.

Ideally, I'd like a circular belt where I can directly control the number of items. See the idea https://forums.factorio.com/forum/viewtop ... =6&t=18953 for some more details. Since this is not available, we need some other solution to count (or at least estimate) the number of items on a belt.

The best solution I've found so far is by using one smart chest per item type. In the smart chest disable all slots except one to ensure that only one item type gets stored per smart chest. Use a fast inserter to for insertion and a slow inserter for extraction back to the belt.

A simple example with just 2 items (red and green science pack):

http://i.imgur.com/VTUKbMI.png

Here you see two smart chests are filled with red/green science packs. The slow inserters put one time on the circular belt every second or so. This puts a dozen or so items on the belt and ten more are in the chests. The science pack generation is controlled via a connected signal and when the number of science packs in the chets falls below a threshold (=0 in this case) extra items are fed into the system.

This system is easily extendable to all four science packs without adding a second belt.

Now to a more complex example, the creation of the red and green science packs:

http://i.imgur.com/tk2sB2P.jpg

Compared to the last example we now have more items, therefore we need more smart chests. You see one chest for every item except copper and iron. They need two chests because the threshold is set to two stacks of items. This increases the rate of copper/iron plates on the circular belt.

The copper and iron plates are fed into the system from the bottom chests. One inserter starts when there are zero items in the chest and the other starts when there is less than a full stack in the chest. Right now there are enough plates in the system, so these inserters stand still.

The circular belt is quite full due to the high number of different items, but there is still enough space left so that everything runs smoothly.

When you follow through the production street you see, that they follow item assemblers are placed in the order the items are processed. First gears, then belts, then inserters, then science packs. First coils, then circuit boards, then green science. Some assemblers are not yet used.

The output of each assembler has a smart inserter. It is activated when the number of produced items in the smart chests is zero.

For example gearwheels. When the science pack production starts, the gearwheels on the belt are consumed. In the chest there are still about 10 gearwheels which are put on the belt via the slow inserter. When the chest is empty, the inserter at the gearwheel assembler is activated ramping up production of gearwheels. Due to the placement of the producing assembler in front of the consumers, they will consume gearwheels until the need is satisified and some reach the smart chest. When storage builds up, the smart inserter stops and production is halted.

This makes for a fine balance with only about 10-20 items of each type being held on the belt and in storage.

The last smart chest has a special role. When the power runs out, the items jam at the end of the belt out of order. The last smart chest has all slots activated and can store all types of items. It is kind of a "catchall" in case something goes wrong or too many different types of items are on the belt. When the power is restored it takes a short while until everything is is in order again and every item has its corresponding chest. In my experience, this setup is robust and does not jam up even at power outages or high demand scenarios when the smart inserters are setup correctly.

With red or blue belts, the number of different items doubles or quadruples and many different items can be produced using only a single circular.

Similar to the setup for the science packs, an ammo belt can be built for supplying turrets without actually filling a long, long, belt entirely. Using a smart inserter and a clock circuit, the distance between items can be increased.

Putting high volume items like plates on the same belt as low volume products is a bit inefficient. To increase throughput, these could be supplied to the assemblers via a separate belt.

In my opinion this kind of setup is a good way to escape the belt madness when producing many different items. It already makes sense for red and green science packs and results in a compact production street which can easily be extended. The only gripe i have is that currently you cannot count the number of items placed on the belts, but I have hopes that the Circuit Network Connector http://www.factorio.com/blog/post/fff-123 one day makes this possible. This would eliminate the need for smart chests and decrease the number of items on the belt considerably. Then it would be possible to make an efficient factory for just-in-time production of all items you need without resorting to the logistic network.

I'm happy to respond to questions, critique and ideas for extension.