'Universal bus' factory setup

Posted: Fri Mar 25, 2016 9:22 am

TL;DR: How to handle one belt with many materials on it.

Hi,

I'm looking to get feedback and have someone try this idea too, and share their solutions.

What I'm playing around with is a setup where one main bus ('spine') transports all the items throughout the factory, then specialized sub-factories take a subset of materials, produce a product and return it onto the bus.

Now I have 1 main problem with that:

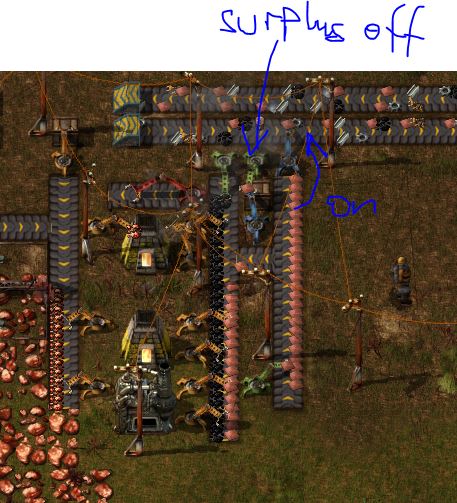

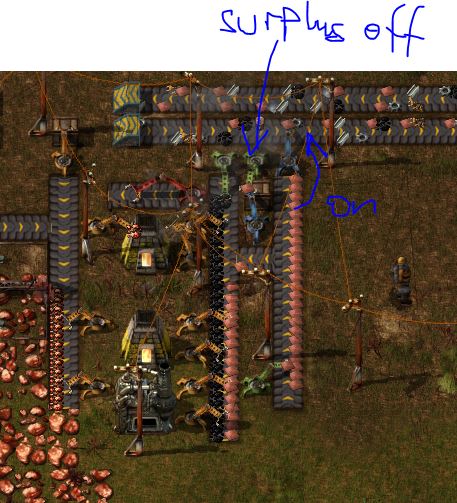

I'm having to use an imperfect system for loading new products onto the belt. As you can see this is designed to take a surplus of product (of copper in this case) of the bus before putting new product onto it - to prevent clog up. Currently it does that on the basis of removing a 'little bit' faster than putting them on there. Ideally it should only send off new product if some receiver, somewhere, has taken it off - so that the balance is exactly 0 (1 used, 1 added). But there is no way to wire things up inserter-to-inserter - to make an one insert ONLY IF another (which can be very remote) has removed the same item type off the belt.

Even if I wired everything up (added chests somewhere, whose contents can be measured), there are only 2 colours of wires and there are plenty of material types here. Can anyone think of a good solution?

I have to say, bar the fact that the bus needs some manual care right now, to have it not clog up, having just one belt connecting the whole base is extremely flexible and convenient.

Hi,

I'm looking to get feedback and have someone try this idea too, and share their solutions.

What I'm playing around with is a setup where one main bus ('spine') transports all the items throughout the factory, then specialized sub-factories take a subset of materials, produce a product and return it onto the bus.

Now I have 1 main problem with that:

I'm having to use an imperfect system for loading new products onto the belt. As you can see this is designed to take a surplus of product (of copper in this case) of the bus before putting new product onto it - to prevent clog up. Currently it does that on the basis of removing a 'little bit' faster than putting them on there. Ideally it should only send off new product if some receiver, somewhere, has taken it off - so that the balance is exactly 0 (1 used, 1 added). But there is no way to wire things up inserter-to-inserter - to make an one insert ONLY IF another (which can be very remote) has removed the same item type off the belt.

Even if I wired everything up (added chests somewhere, whose contents can be measured), there are only 2 colours of wires and there are plenty of material types here. Can anyone think of a good solution?

I have to say, bar the fact that the bus needs some manual care right now, to have it not clog up, having just one belt connecting the whole base is extremely flexible and convenient.