Very large input/output plate storage

Posted: Fri Dec 18, 2015 12:42 am

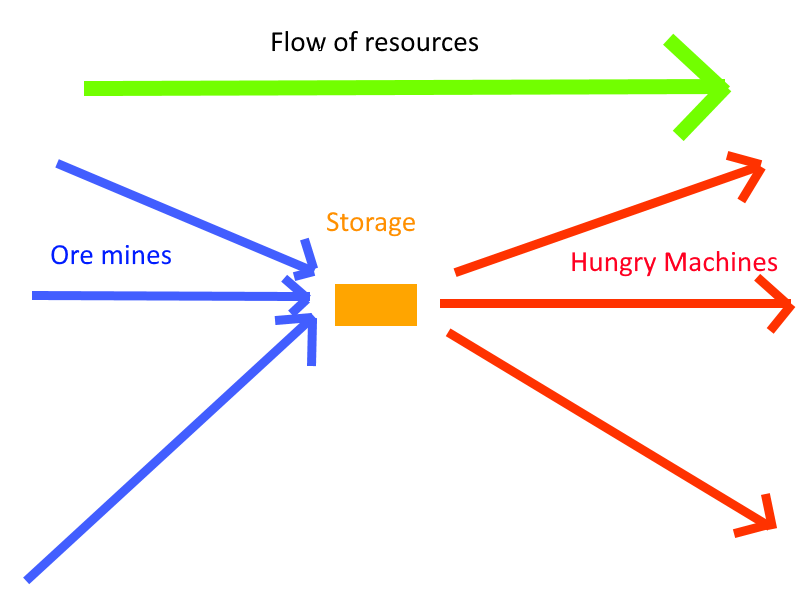

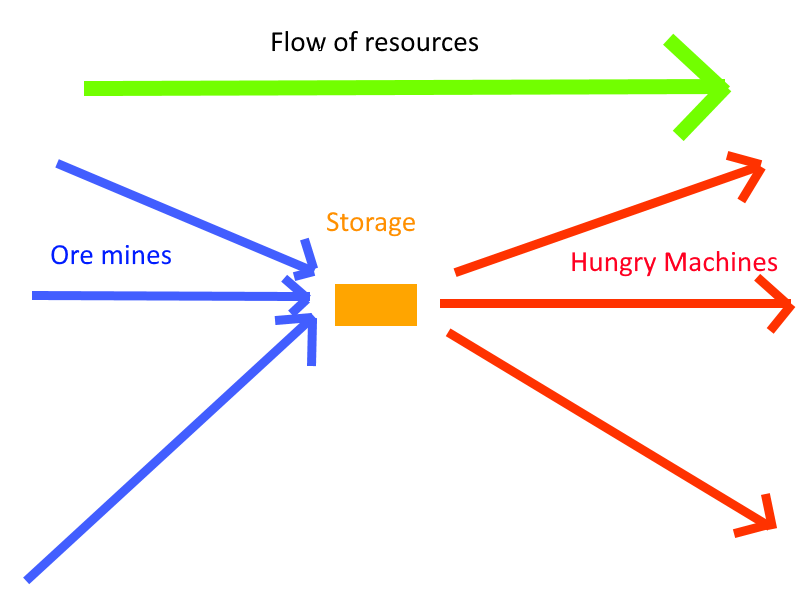

By nature, the the metal plate buffer between furnaces and the rest of a factory makes a bottleneck that can strangle production because every bit of ore ever used needs to all go though one system.

This storage system forms the heart of a factory and needs to do several things well:

-Not mix up copper and iron (possibly a non-issue depending on the setup)

-Very large/expandable storage space

-Have extremely high throughput, enough that no other part of the base is ever waiting on it. (Multiple thousands of units per minute as a base grows)

-Respond to mismatched/changing demand and supply (trains dropping bursts of resources, all iron being used but having excess copper etc.)

-Made of modular pieces to easily expand

So far I haven't come up with a system that does this as efficiently or as simply as I would like. Here is what I have on my current base:

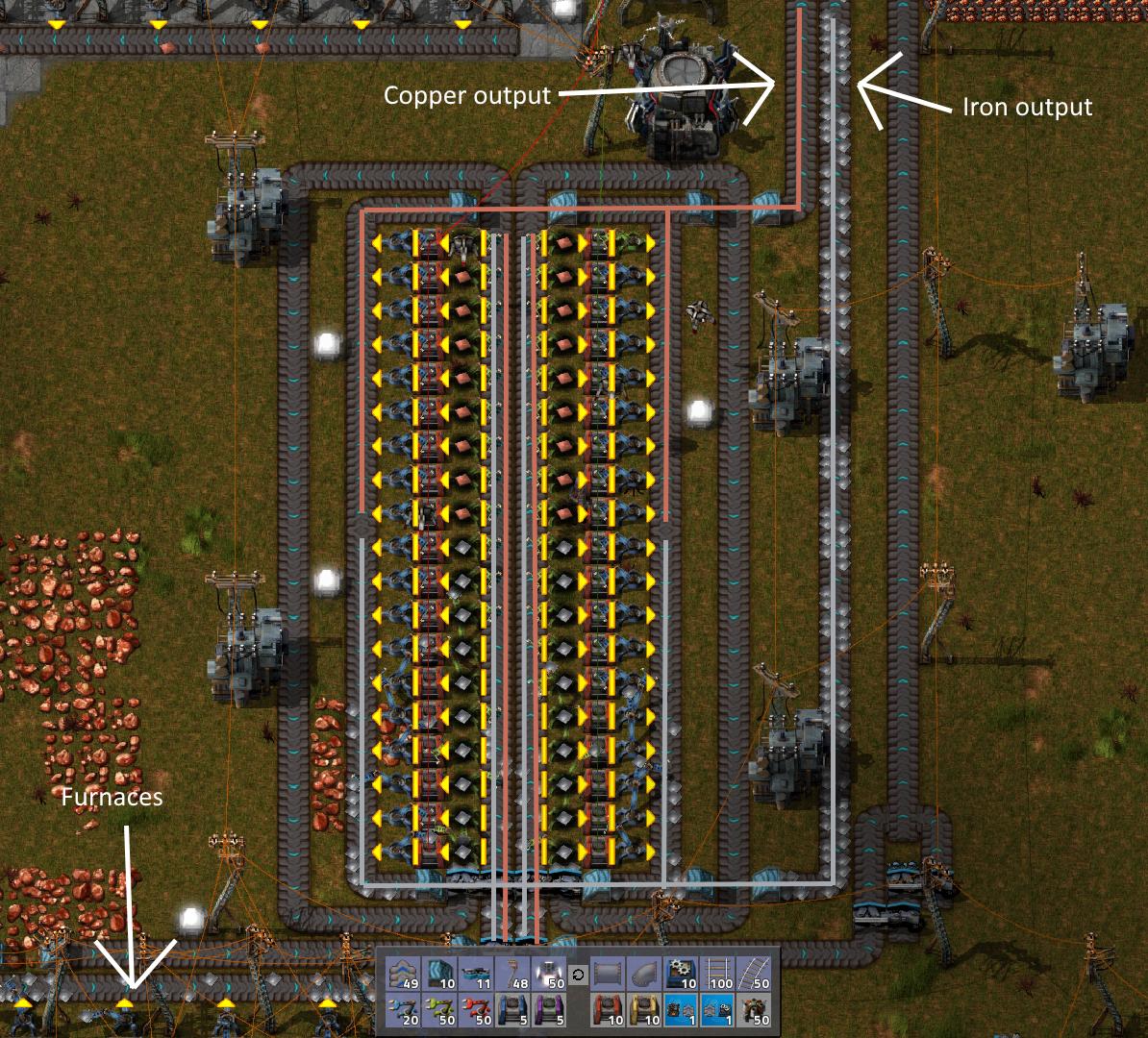

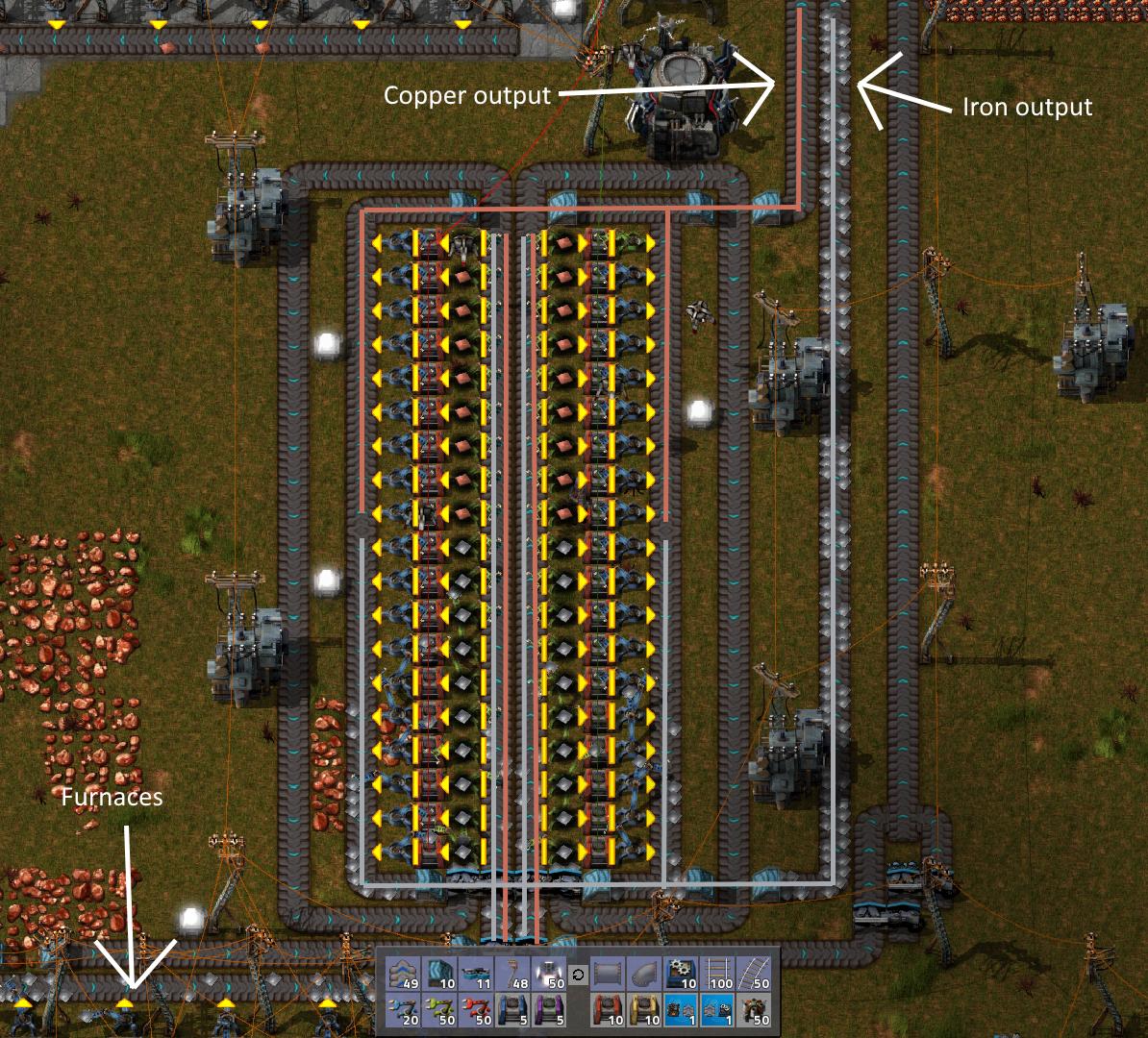

Seperating iron from copper. The passive provider chests also serve as a buffer that logistic robots can pull from if there's any plates that haven't already been sent to the rest of the factory. The outer loop of belts is to circulate back any plates that don't get picked up on the first pass, so iron doesn't sit in front of the copper inserters. Multiple of these can be added to handle more furnaces. This system is prone to clogging if the chests fill up or too many plates come in.

These smart inserters are connected to the chests from the above picture through a circuit network to pull copper off the line if they have are getting full and put it into storage chests. There is a bank of requester chests farther down the line that add the copper back on when the belt is empty (and an identical system for iron). The main drawback of this system is that it pulls off of the same copper belt that is going to feed the machines, so can disrupt their supply.

This system works, but it does not handle strain very well.

The main difference that I can think of if that most other factories I've seen keep iron and copper totally separate, never mixing them. This gets rid of the step of sorting them out, but limits the furnaces to only one material. Personally I prefer to be able to dump all of my ore on the same belts, know that a furnace will be used for a material if it's needed, and forget about it. Each way has pros and cons. I don't think either choice is a limiting factor to how functional the storage system can be.

I also know that you can just dump everything into active provider chests and let logistic bots solve all the problems, but that's not very interesting or fun. Ideally I would like a system without them, and I've tried to keep their involvement to a minimum, but don't know how to make an expandable amount of storage without logistic robots.

I'm very curious what others have done to solve this problem

This storage system forms the heart of a factory and needs to do several things well:

-Not mix up copper and iron (possibly a non-issue depending on the setup)

-Very large/expandable storage space

-Have extremely high throughput, enough that no other part of the base is ever waiting on it. (Multiple thousands of units per minute as a base grows)

-Respond to mismatched/changing demand and supply (trains dropping bursts of resources, all iron being used but having excess copper etc.)

-Made of modular pieces to easily expand

So far I haven't come up with a system that does this as efficiently or as simply as I would like. Here is what I have on my current base:

Seperating iron from copper. The passive provider chests also serve as a buffer that logistic robots can pull from if there's any plates that haven't already been sent to the rest of the factory. The outer loop of belts is to circulate back any plates that don't get picked up on the first pass, so iron doesn't sit in front of the copper inserters. Multiple of these can be added to handle more furnaces. This system is prone to clogging if the chests fill up or too many plates come in.

These smart inserters are connected to the chests from the above picture through a circuit network to pull copper off the line if they have are getting full and put it into storage chests. There is a bank of requester chests farther down the line that add the copper back on when the belt is empty (and an identical system for iron). The main drawback of this system is that it pulls off of the same copper belt that is going to feed the machines, so can disrupt their supply.

This system works, but it does not handle strain very well.

The main difference that I can think of if that most other factories I've seen keep iron and copper totally separate, never mixing them. This gets rid of the step of sorting them out, but limits the furnaces to only one material. Personally I prefer to be able to dump all of my ore on the same belts, know that a furnace will be used for a material if it's needed, and forget about it. Each way has pros and cons. I don't think either choice is a limiting factor to how functional the storage system can be.

I also know that you can just dump everything into active provider chests and let logistic bots solve all the problems, but that's not very interesting or fun. Ideally I would like a system without them, and I've tried to keep their involvement to a minimum, but don't know how to make an expandable amount of storage without logistic robots.

I'm very curious what others have done to solve this problem