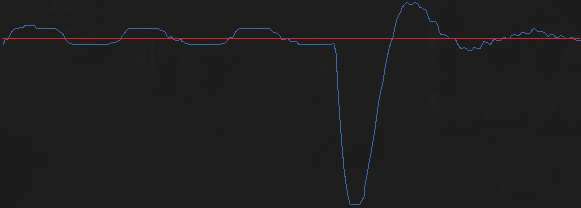

For those who are not familiar with it, this theory describes how to efficiently control different systems in time using regulatory signals (assuming this system has unknown influence from the outer world).

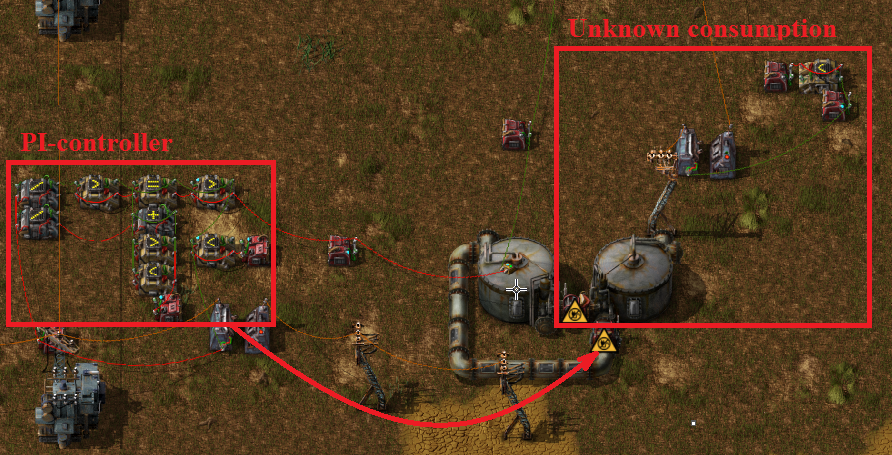

In our case unknown influence is the gas/lube/solid fuel consumption and regulatory signal is enabling cracking/production.

Also, you can try to use PI-controller for this task which can be built with several combinators.

My try